Magnesium Impregnated Silica Mesoporous Prepared using Ester

Ricinoleic as Template for the Esterification

Andriayani

1,2*

, Marpongahtun

1

, Yugia Muis

1

1

Department of Chemistry, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Medan, Indonesia,

20155

2

Pusat Kajian IPTEKS Minyak Atsiri Eucaplytus Universitas Sumatera Utara, Medan, 20155, Indonesia

Keywords: mesoporous silica, ester ricinoleic, template, magnesium.

Abstract: Synthesis of mesoporous silica material was carried out using ricinoleate ester as a template. Mesoporous

silica products were characterized using FT-IR, XRD, SEM and nitrogen adsorption. Mesoporous silica

material was impregnated with magnesium nitrate, impregnation products were characterized using FT-IR,

XRD, SEM and BET analysis. MgO impregnated silica mesoporous is applied as a catalyst in the reaction

of esterification of castor oil to ricinoleate ester.

1 INTRODUCTION

Porosity greatly influences the physical properties of

a material such as density, heat conductivity,

strength and others (Schubert, Ulrich S. and Husing,

2005). The synthesis technique of mesopore material

(2-50 nm pore diameter) is currently developing

rapidly because mesopore material has unique

properties, such as a more regular pore structure,

large surface area and uniform pore size distribution.

So much applied as catalysts (Li et al., 2011),

adsorbents (Yan et al., 2006), drug delivery

(Slowing et al., 2008), biosensors (Hasanzadeh et

al., 2012), optics (Kumari and Sahare, 2013) and

others.

The synthesis technique of mesoporous material

is carried out by combining inorganic components as

material and organic components such as surfactants

functioning as pore printers (templates). The pore

will be obtained after the organic component has

been removed by calcination.

In this paper, tetraethylortosilicate (TEOS) is

used as a source of silica, risinolet methyl ester as a

template is made by extracting Ricinus communis

seeds that grow in wild forests in the North

Sumatera Karo region. Also used are 3-

aminopropyltrimethoxysilane (APMS) as a co-

structure directing agent (CSDA). The alkoxylane

group from CSDA will condense with inorganic

precursors and the ammonium group will interact

electrostatically with anionic surfactants. The

interaction that occurs between surfactant and

silicate is S-N

+

I

-

where N

+

is CSDA.

In the previous study (Andriayani et al., 2013)

have been done synthesized of material silica using

sodium risinoleate as a template by varying the

addition of HCl 0,1N. In this paper we impregnate

MgO on silica mesoporous which is made using

methyl ester ricinoleate as a template and analyzed

using FT-IR, XRD, SEM and BET. The mesoporous

silica impregnation product was applied as a catalyst

in the reaction of castor oil eseterification to

ricinoleate ester. Given the increasingly limited

fossil fuels, ricinoleic esters can be an alternative to

fuels sourced from plants.

2 MATERIALS AND METHODS

2.1 Materials

Tetraethylorthosilicate (TEOS, 98%) and 3-

aminopropyltrimethoxysilane (APMS) were

purchased from Sigma Aldrich, methanol, and

hexane purcase from Emerc, methyl esther ricinoleic

acid (C

19

H

36

O

3

) obtained from Ricinus Communis

seed and deionized water obtained from PT Sumber

Aneka Karya Abadi. Jatropha seed oil is obtained

from Bratachem, Mg(NO

3

)

2

(Merck), n-hexene.

274

Andriayani, ., Marpongahtun, . and Muis, Y.

Magnesium Impregnated Silica Mesoporous Prepared using Ester Ricinoleic as Template for the Esterification.

DOI: 10.5220/0008921702740279

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 274-279

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2.2 Characterizations

The obtained products were then subjected to

characterization by using X-ray diffraction (Philip

PW 1710), Fourier transform infrared (Shimadzu IR-

Prestige-21), scanning electron microscope (JEOL

JSM-7000F), transmission electron microscope

(JEOL JEM-1400) and adsorption desorption

isotherm (Quantachrome Auto¬sorb), Atomic

absorption spectroscopy (Shimadzu AA7000).

2.3 Synthesis of Silica Mesoporous

Material using Risinoleic Methyl

Ester as a Template

Methyl esters of ricinoleate (C

19

H

36

O

3

) of 4.52 g

(0.015 mol), 100 ml deionized water and 1.2 grams

of methanol were put into two neck flasks and

sterilized at room temperature for 30 minutes (mix

A). Then a mixture of 1.2 g (0.007 mol) APMS

(C

6

H

17

SiO

3

N) and 6.04 g (0.029 mol) TEOS (C

8

H

20

SiO

4

) was stirred for 10 minutes (mixture B).

The mixture (B) was added to the mixture (A)

and then stirred for 2 hours. Then let it sit in the

oven at 80

o

C for 3 days (36 hours) until a porous

solid is formed. The mixture is centrifuged and the

solids are separated and washed with deionized

water. The solid is dried at 50

C and then calcined

at 550

C for 6 hours. Silica mesoporous products

were then characterized using FT-IR, XRD, SEM

analysis and N

2

isotherm adsorption / desorption.

2.4 Impregnation of Mesoporous Silica

Material with Magnesium

Silica mesoporous material (0.75 gram) mixed with

Mg(NO

3

)

2

.6H

2

O (g) and added 25 mL of dry

methanol, then stirred at room temperature for 2

hours. The mixture is vacuumed to dry solids and

then solids are calcined for 12 hours at 550

o

C.

Mesoporous silica impregnation products were

characterization using FT-IR, XRD, AAS, BET and

SEM.

2.5 Application of Mesoporous Silica

Impregnation Products as

Esterification Catalyst

Mesoporous silica impregnation products (0.2 g),

methanol (p.a) (6.14 g) and castor oil (15 grams)

were put into a two neck flask. The mixture is stirred

with a magnetic stirrer for 4 hours at 80° C by reflux

method. The solid is separated from the reaction

mixture by filtering. The filtrate is extracted using n-

hexane and distilled water. Then the n-hexane phase

was vacuum and a pale yellow methyl ester product

of 10.59 grams or 70.6% yield was obtained. The

ricinoleate methyl ester product was characterized

using FT-IR and GC-MS.

3 RESULTS AND DISCUSSION

The silica mesoporous used to be applied as a

catalyst was obtained from one of the silica

mesoporous under the conditions of the preparation

of methanol addition variations without the addition

of 0.1M HCl. The reaction conditions for

mesoporous silica preparation using

tetraethylortosilicate (TEOS) as a source of silica,

methyl ester risinoleate obtained from esterification

of castor oil from castor beans (Ricinus communis)

as a template, using 3-aminopropiltrimethoxysilane

(APMS) as a co-structure directing agent and adding

methanol 1 2 grams without the addition of 0.1M

HCl. After maturing for 72 hours, the solid is

separated, washed, dried and to remove the template

calcined at 550

o

C for 6 hours a white solid is

obtained. Furthermore, it is characterized by FT-IR,

XRD, SEM and porosity analysis using BET.

Mesoporous silica is impregnated using

Mg(NO

3

)

2

in a dry methanol solvent, the solid is

separated, vacuum and calcined at 550

o

C for 12

hours. White solids were obtained as much as

0.6415 grams. Mesoporous silica impregnation with

Mg (NO

3

)

2

produced silica-MgO mesoporous (MS-

MgO). Magnesium oxide is attached to the surface

of the mesoporous silica material. AAS analysis

results showed that the Mg content contained in

mesoporous silica material was 1.3549 ppm.

Subsequently the solids were characterized using

FT-IR, XRD, SEM and porosity analysis using BET.

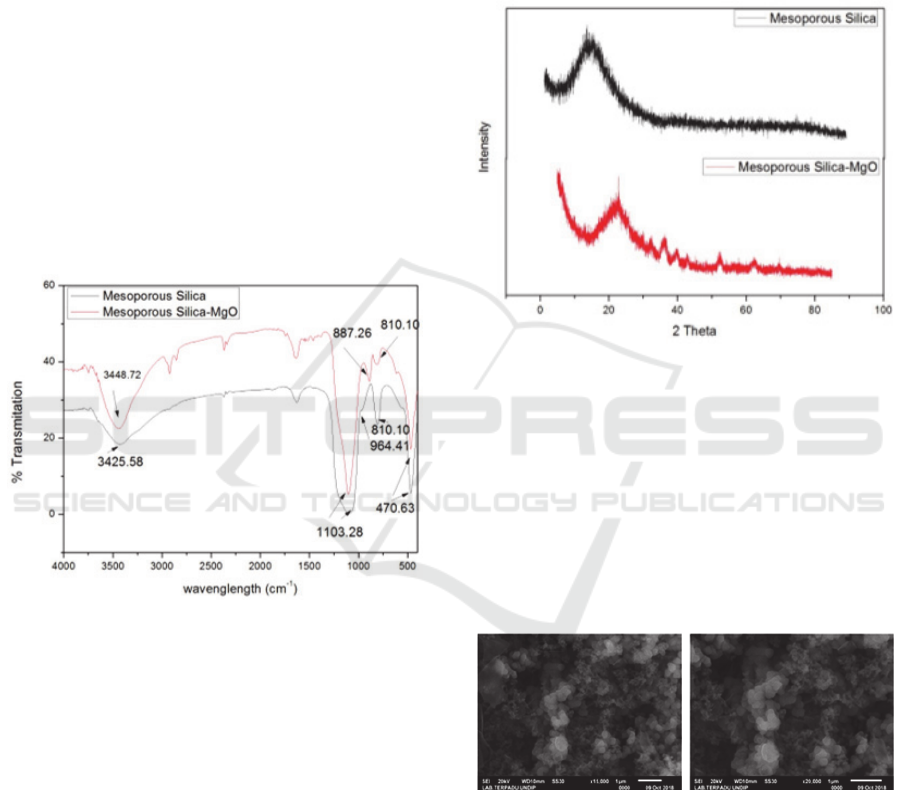

Functional group analysis using the FT-IR

spectrum of mesoporous silica that has not been

impregnated with silica mesoporous that has been

impregnated with MgO (Figure 1) shows the change

in functional groups in both materials. The

mesoporous silica spectrum before impregnation

(Figure 7 in black) showed an absorption peak at

3428.58 cm

-1

which was widening due to OH (strain

Si-OH) strain and supported the absorption peak at

964.41 cm

-1

due to streching (–SiO-H). The

absorption peak at 1103.28 cm

-1

is strong due to the

asymmetric streching of Si-O-Si and the wave

number at 810.10 cm

-1

is caused by the presence of

symmetrical Si-O-Si. The spectrum data is adjusted

to the literature: (Khalil, 2007; AlOthman and

Apblett, 2010; Liu et al., 2010; Zhao et al., 2011).

While the mesoporous silica spectrum that has been

impregnated by MgO shows the absorption peak at

3448.72 cm

-1

which was widened due to OH group

Magnesium Impregnated Silica Mesoporous Prepared using Ester Ricinoleic as Template for the Esterification

275

strain (Si-OH) and supported the absorption peak at

887.26 cm

-1

due to streching (–SiO-H). The

absorption peak at 1103.28 cm

-1

is strong due to the

asymmetric streching of Si-O-Si and the wave

number at 810.10 cm

-1

is caused by the presence of

symmetrical Si-O-Si groups.

The peak absorption of Si-OH groups is different

compared to mesoporous silica before being

impregnated where the peak shape is not too wide

and there is a shift in the wave number. This is due

to the surface of the silanol group which has been

impregnated with MgO. Likewise with the peak

caused by the Si-O-Si group there is a difference

compared to the mesoporous before digrafting such

as a sharp peak shape but not widening (slimmer)

with an intensity of 5.19 while for the mesoporous

silica the sharp peak shape widens and the intensity

is low 0.04. This is due to the mesoporous that has

been impregnated by the formation of Si-O-M bonds

(M = metal Mg) which is in the wave number 1000-

900 with a strong band (Smith, 1960).

Figure 1: Mesoporous Silica FT-IR Spectrum Before

Impregnation and After MgO Impregnation

Analysis of the mesoporous silica structure

before impregnation and after impregnation (Figure

2) shows the differences in the diffractogram of the

two materials. The mesoporous XRD diffractogram

of silica before impregnation (Figure 2 in black) has

only one diffractogram peak at an angle of 2 at

20.9865 the broad peak (broad) with a peak height

of 14.20. This shows that the material is

nanoparticles and amorphous structures that have

pores. This is consistent with data reported by

previous researchers (Park et al., 2006; Khalil, 2007;

Shah, Li and Ali Abdalla, 2009; Liu et al., 2010;

‘No Title’, 2011; Li et al., 2011; Zhao et al., 2011).

Whereas the mesoporous silica diffractogram that

has been impregnated with MgO (Figure 2 in red)

has several diffractogram peaks. Diffractogram at an

angle of 2 at 22.8454 with a peak that widened to

a height of 31.63 indicates that the material is

nanoparticles with a porous amorphous structure.

Whereas the diffractogram at 2 at 32, 35, 36,

39, 42 and 45 is the peak of the Mg metal

diffractogram which is impregnated on the silica

mesoporous surface. This proves the process of

mesoporous silica impregnation has taken place.

Figure 2: XRD Diffractogram of Mesoporous Silica

Mesopori Before Impregnation and After MgO

Impregnation

Mesoporous morphological analysis of the silica

before impregnation (Figure 3) using a scanning

electron microscope (SEM) magnification 15000

times and 20000 times showed that the material has

a mixed particle form, dominated by dispersed

spherical particles and some that form smaller

aggregates. Other particles in the form of sheets with

a small amount.

Figure 3: SEM Image of Mesoporous Silica Before MgO

Impregnation (left 15000 times and right 20000

times magnification)

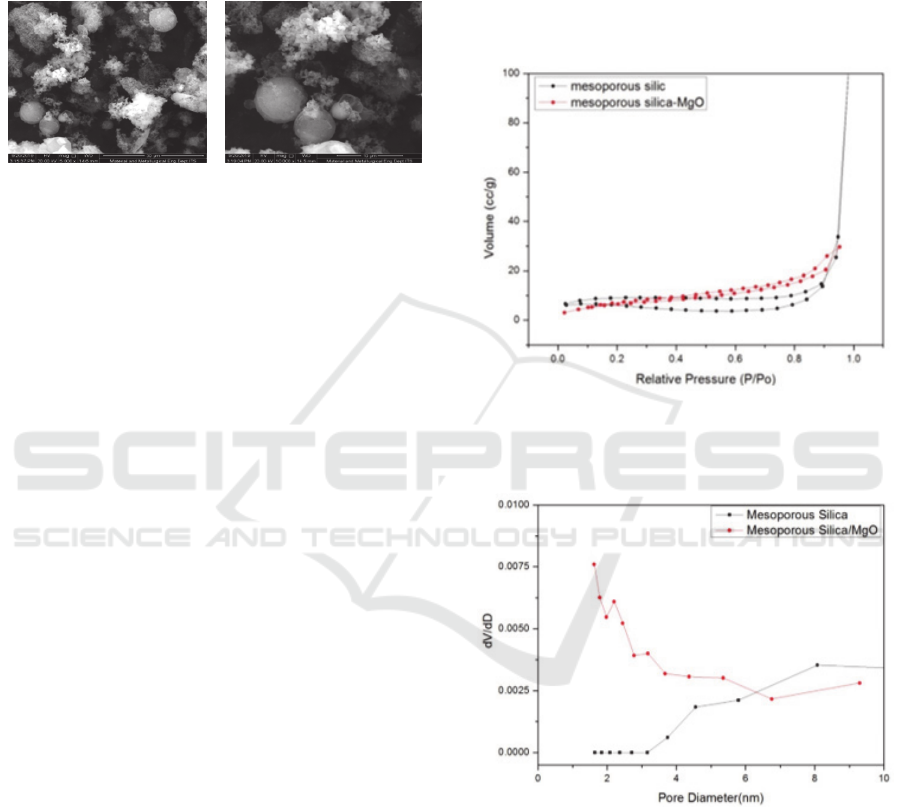

Analysis of porosity of silica material before

impregnation and after impregnation of MgO

(Figure 5) shows the differences in adsorption

desorption isotherm graphs. Based on its hysterical

form, silica material approaches Type IV for silica

mesoporous according to the specific IUPAC

classification for silica mesoporous material. Graph

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

276

of silica meopore desorption adsorption before

impregnation (Figure 5 in black) lop hysteresis form

is Type H4, where the lop's hysteresis form is a bit

more complex because of the reversible micropore

filling area followed by multilayer physisorption and

capillary condensation. So lop H4 is the same as lop

H3 for non-micropore materials.

Figure 4: SEM Image of Mesoporous Silica After MgO

Impregnation (left 15000 times and right 20000

times magnification)

While the graph of adsorption desorption

isotherm of silica mesoporous material after MgO

impregnation (Figure 5 in red) the form of hysteresis

is Type H3 (Sing and Williams, 2004). This is due to

the shape of aggregate and plate particles,

characteristic desorption grooves and lower

approaching end points (closure points). Lop H3

does not have a plateau at high P/P0 values

(mesoporous volume is not well formulated), so

interpretation of high P/P0 values is more difficult.

Branch adsorption graphs on type H3 show that gas

adsorption only occurs on surfaces or manolayers so

that this shows that the obtained silica material can

be grouped also on Type II isotherm charts for non-

porous solids (Gregg S. J., and Sing, 1982). This is

due to the silica impregnated surface of MgO in the

pores that are already covered by MgO so that the

shape of the hysteresis loop resembles non-pore

solids.

Graph of mesoporous silica pore size distribution

before impregnation and silica mesoporous after

pregreated MgO (Figure 6) were calculated using the

Barret-Joyner-Halenda (BJH) method. The pore size

distribution of the two materials shows a difference.

The mesopore pore size distribution before

impregnation (Figure 5 in black) shows the pore size

distribution in the range of 1.64 nm - 8.105 nm.

While the pore size distribution of silica mesoporous

material that has been impregnated by MgO shows

that the pore size distribution is in the range of 1.61

nm - 9.31 nm.

The pore size distribution graph of the two

materials has a difference in the dV / dD value,

which is because there is a re-calcination treatment

for silica mesoporous MgO impregnated causing the

number of pores formed in the range of pore size

distribution of 1 nm - 6 nm to increase. Whereas the

dV/dD value of mesoporous material before

impregnation with the same (smaller) pore size

distribution range. But the dV/dD value in the pore

size distribution from 6-10 nm for mesoporous

materials impregnated with MgO is getting smaller

because the pores are covered with MgO, whereas

the silica mesoporous material before the

impregnation of dV/dD values in the same pore size

distribution range is smaller big because it's not

covered in metal.

Figure 5: Adsorption Graph Desorption of Silica

Mesoporous Isotherm Before Impregnation and

After MgO Impregnation

Figure 6: Graphs of Silica Mesoporous Pore Size

Distribution Before Imprgenation and After

MgO Impregnation

The silica mesoporous material impregnated by

MgO was tested for its catalytic activity in the

esterification reaction of castor oil. The catalytic

system of esterification reaction takes place under

heterogeneous conditions where mesoporous silica-

MgO is insoluble (remains solid). Such reaction

conditions are advantageous because they are easily

separated between the product and the catalyst. The

Magnesium Impregnated Silica Mesoporous Prepared using Ester Ricinoleic as Template for the Esterification

277

reaction was carried out at 80

o

C for 4 hours. After

the reaction is stopped, the catalyst solids are

separated and the filtrate is extracted with n-hexane

and washed with distilled water, after vacuum the

product has obtained a pale yellow methyl ester

product of 10.59 grams or a yield of 70.6%. The

ricinoleate methyl ester product was characterized

using FT-IR and GC-MS.

The formation of ricinoleate methyl ester product

was characterized using FT-IR and GC-MS. FT-IR

spectrum of methyl ester ricinoleate castor oil

esterification product (castor oil) using silica-MgO

mesoporous catalyst (Figure 7) shows the

appearance of widening at 3417.86 cm

-1

due to OH

groups in the carbon chain of methyl ester ester

risinoleate. While the sharp peak at 2854.65 cm

-1

is

caused by the vibration frequency of the -CH-

hydrocarbon chain group of methyl ester ricinoleate.

Another sharp peak at 1743.65 cm

-1

was caused by

the carbonyl methyl ester ricinoleate group.

Figure 7: FT-IR Spectra of Risinoleate FT-IR Spectrum

Transeterification of castor oil using mesoporous

silica-MgO-catalyzed methanol produces a mixture

of fatty acid methyl esters. This is due to the

distance that there are other fatty acids such as

ricinoleic acid, palmitic acid, stearic acid, linoleic

acid, oleic acid and others. So if esterified other fatty

acids might also be esterified. To find out the

composition of methyl esters formed from castor oil,

GC-MS analysis was performed. Through GC-MS

method, it can be known the percentage of methyl

esters of ricinoleate formed through the application

of silica-MgO mesoporous catalyst. The results of

GC-MS chromatogram of castor oil esterification

products with a heterogeneous reaction system

(Figure 8) can be seen that the risinoleate methyl

ester formed has a remaining 84.48% purity of

15.52% is a methyl ester from other fatty acids.

Figure 8: Chromatogram GC-MS of Risinoleate Esther

4 CONCLUSIONS

The mesoporous silica impregnation which was

made using methyl ester ricinoleate as a template

was successfully carried out. This can be proven by

the differences in analysis of mesoporous silica

products before being impregnated and after being

impregnated, it can be proven from FT-IR, XRD and

BET analysis. Its application as a catalyst in castor

oil esterification reaction results in ricinoleate ester

of 10.96 g (73.06%).

ACKNOWLEDGEMENTS

This research was funded by the DRPM

Republic of Indonesia Ministry of Research and

Technology Republic of Indonesia Fiscal Year 2019.

REFERENCES

AlOthman, Z. A. and Apblett, A. W. (2010)

‘Synthesis and characterization of a hexagonal

mesoporous silica with enhanced thermal and

hydrothermal stabilities’, Applied Surface

Science, 256(11), pp. 3573–3580. doi:

10.1016/j.apsusc.2009.12.157.

Andriayani, A. et al. (2013) ‘Synthesis of

Mesoporous Silica from Tetraethylorthosilicate

by Using Sodium Ricinoleic as a Template and

3-Aminopropyltrimethoxysilane as Co-Structure

Directing Agent with Volume Variation of

Hydrochloric Acid 0.1 M’, Advanced Materials

Research, 789, pp. 124–131. doi:

10.4028/www.scientific.net/AMR.789.124.

Gregg S. J., and Sing, K. S. W. (1982) Adsorpsi,

Surface Area and Porosity. Second Edi. London:

Academic Press.

Hasanzadeh, M. et al. (2012) ‘Mesoporous silica-

based materials for use in biosensors’, TrAC -

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

278

Trends in Analytical Chemistry, 33, pp. 117–129.

doi: 10.1016/j.trac.2011.10.011.

Khalil, K. M. S. (2007) ‘Cerium modified MCM-41

nanocomposite materials via a nonhydrothermal

direct method at room temperature’, Journal of

Colloid and Interface Science, 315(2), pp. 562–

568. doi: 10.1016/j.jcis.2007.07.030.

Kumari, S. and Sahare, P. D. (2013) ‘Optical studies

of fluorescent mesoporous silica nanoparticles’,

Journal of Materials Science and Technology.

Elsevier Ltd, 29(8), pp. 742–746. doi:

10.1016/j.jmst.2013.05.013.

Li, B. et al. (2011) ‘Preparation of MCM-41

incorporated with transition metal substituted

polyoxometalate and its catalytic performance in

esterification’, Microporous and Mesoporous

Materials. Elsevier Inc., 156(1), pp. 73–79. doi:

10.1016/j.micromeso.2012.02.017.

Liu, H. et al. (2010) ‘Synthesis of spherical-like Pt-

MCM-41 meso-materials with high catalytic

performance for hydrogenation of nitrobenzene’,

Journal of Colloid and Interface Science.

Elsevier Inc., 346(2), pp. 486–493. doi:

10.1016/j.jcis.2010.03.018.

‘No Title’ (2011), 08(03), pp. 71–79.

Park, Y. et al. (2006) ‘Encapsulation method for the

dispersion of NiO onto ordered mesoporous

silica, SBA-15, using polyethylene oxide (PEO)’,

Journal of Colloid and Interface Science, 295(2),

pp. 464–471. doi: 10.1016/j.jcis.2005.09.006.

Schubert, Ulrich S. and Husing, N. (2005) Synthesis

of Inorganic Materials. 2nd, Revis edn. German:

Wiley-VCH.

Shah, A. T., Li, B. and Ali Abdalla, Z. E. (2009)

‘Direct synthesis of Ti-containing SBA-16-type

mesoporous material by the evaporation-induced

self-assembly method and its catalytic

performance for oxidative desulfurization’,

Journal of Colloid and Interface Science.

Elsevier Inc., 336(2), pp. 707–711. doi:

10.1016/j.jcis.2009.04.026.

Slowing, I. I. et al. (2008) ‘Mesoporous silica

nanoparticles as controlled release drug delivery

and gene transfection carriers’, Advanced Drug

Delivery Reviews, 60(11), pp. 1278–1288. doi:

10.1016/j.addr.2008.03.012.

Smith, A. L. (1960) ‘Infrared spectra-structure

correlations for organosilicon compounds’,

Spectrochimica Acta, 16(1–2), pp. 87–105. doi:

10.1016/0371-1951(60)80074-4.

Yan, Z. et al. (2006) ‘Pyridine-functionalized

mesoporous silica as an efficient adsorbent for

the removal of acid dyestuffs’, Journal of

Materials Chemistry, 16(18), pp. 1717–1725.

doi: 10.1039/b517017f.

Zhao, Q. et al. (2011) ‘Stability and textural

properties of cobalt incorporated MCM-48

mesoporous molecular sieve’, Applied Surface

Science. Elsevier B.V., 257(7), pp. 2436–2442.

doi: 10.1016/j.apsusc.2010.09.114.

Magnesium Impregnated Silica Mesoporous Prepared using Ester Ricinoleic as Template for the Esterification

279