Feasibility Study of CO2 Flooding under Gross-split Mechanism:

Simulation Approach

Muslim Abdurrahman

1

, Wisup Bae

2

, Adi Novriansyah

1

, Dadan Damayandri

3

and Bop Duana

Afrireksa

4

1

Department of Petroleum Engineering, Universitas Islam Riau,Pekanbaru, Indonesia

2

Sejong University, South Korea

3

LEMIGAS, Indonesia

4

Inha University, South Korea

Keywords:

CO

2

, Simulation Study, WAG, Gross Split, NPV

Abstract:

Importance of Carbon Dioxide (CO

2

) injection into the subsurface reservoir is essential since the concern of

global warming and climate change issues in Indonesia. Selecting the oil reservoir as a candidate for a storage

site is an attractive option due to CO

2

gas utilization is effective for Enhanced Oil Recovery (EOR) purpose.

Continuous and Water-Alternating-Gas (WAG) CO

2

flooding are the most commonly applied scenarios in the

oil and gas industries. Considering the EOR side, choosing an appropriate scenario is mandatory for cost

efficiency reason and influences the oil share amount between the Indonesian Government and operator under

the gross-split mechanism. Therefore, by using a simulation approach, the feasibility of continuous and WAG

CO

2

injection is observed to decide the most financially attractive choice. Simulation results reveal a WAG

scenario recovers slightly more oil compare to continuous injection scheme. Application of gross-split under

base-share makes both injection strategies unattractive for investors. An adjustment of government-contractor

share is required to improve the feasibility of the project.

1 INTRODUCTION

As a part of greenhouse gas (GHG) pollutant, Carbon

Dioxide (CO

2

) emission issue becomes a major

concern of major countries. Through The Kyoto

Protocol and Paris Agreement, most countries agreed

to reduce CO

2

emission level before 2050 due

to avoid the catastrophic effect of global warming

and climate change phenomena. Carbon Capture

and Storage (CCS) is the only effective scheme to

overcome this problem (Agency, 2016). However,

storing CO

2

in the aquifer is not financially satisfied

since CO

2

is injected into the storage site without

gaining any benefit during this activity. This story

may sound interesting if CO

2

storage is performed in

an oil reservoir.

Besides act as a storage site, injecting CO

2

in oil reservoir may bring another benefit in form

oil production enhancement, commonly known as

CO

2

-Enhanced Oil Recovery (CO

2

-EOR). CO

2

-EOR

has successfully implemented in North America for

more than a decade, either using the natural or

anthropogenic source (Whittaker et al., 2011; Jishun

et al., 2015). Mostly CO

2

Flooding Targets crude

oil contains high intermediate component because

the miscible condition of CO

2

and crude oil can

be achieved under reservoir condition (Abedini and

Torabi, 2014). Minimum Miscibility Pressure (MMP)

determination is mandatory in designing the injection

scenario. MMP can be determined through slim-tube,

swelling, vanishing interfacial tension, and rising

bubble experiments. Moreover, PVT and slimtube

simulation methods are capable to estimate MMP

with a reasonable gap with experimental work

(Abdurrahman et al., 2015).

Besides MMP, Deciding the injection scheme is

also important for CO

2

flooding because it relates

to the efficiency of CO

2

utilization in displacing

residual oil. In terms of CO

2

utilization factor.

Statistically, more than one barrel (bbl) Oil can be

produced by injecting 1 million standard cubic feet

of CO

2

(Azzolina et al., 2015). CO

2

utilization

factor implicitly has an effect to the feasibility of

the CO

2

flooding project because it correlates to how

Abdurrahman, M., Bae, W., Novriansyah, A., Damayandri, D. and Afrireksa, B.

Feasibility Study of CO2 Flooding under Gross-split Mechanism: Simulation Approach.

DOI: 10.5220/0009063200150019

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 15-19

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

15

much CO

2

gas should be provided, i.e., how much

fund is required for purchasing CO

2

or constructing

CO

2

anthropogenic capture facilities. Deciding to

use CO

2

from CCS activity potentially reduce the

CCS cost itself (Rubin et al., 2015). Therefore,

CO

2

-EOR, either from natural or anthropogenic,

i.e., from CCS, may bring a financial interest if

properly implemented, including the injection scheme

selection.

Deciding the most suitable scheme of CO

2

flooding is risky and relates to the oil share between

the Indonesian government and operator because

Indonesia adopts production share mechanism.

Indonesia adopted a relatively new oil share

mechanism, known as gross-split. This mechanism

is officially introduced and effectively valid since

2017. This new mechanism still has to be improved

because indicating an undesirable profit for the

operator, feasibility study of CO

2

by considering

injection scheme under gross-split mechanism is

another interesting topic for the researchers (Irham

and Julyus, 2018).

This Paper analyses under simulation method

the feasibility of CO

2

flooding scheme by using

gross-split mechanism. Two injection strategies, CO

2

Continuous injection and CO

2

Water Alternating Gas

(WAG) are compared their capability in recovering

residual oil after primary stage and also feasibility

during CO

2

flooding stage. Mathematical model

represents one of Indonesia oil field condition

was generated by using BUILDER generator and

simulated under GEM simulator. Both of these

modules are licensed under CMG Software. Results

from the GEM simulator will be analyzed its

feasibility for each injection scenario. Injection

scenario is decided by considering the economic

parameter such as NPV and IRR.

2 METHODOLOGY

The reservoir grid model from Indonesia oil field is

used for demonstrating the field-scale CO

2

flooding

in this study. This grid model consists of more

than 7,800 cells with 56, 46, and 3 cells along x,

y, and z directions (represented as i, j, and k in the

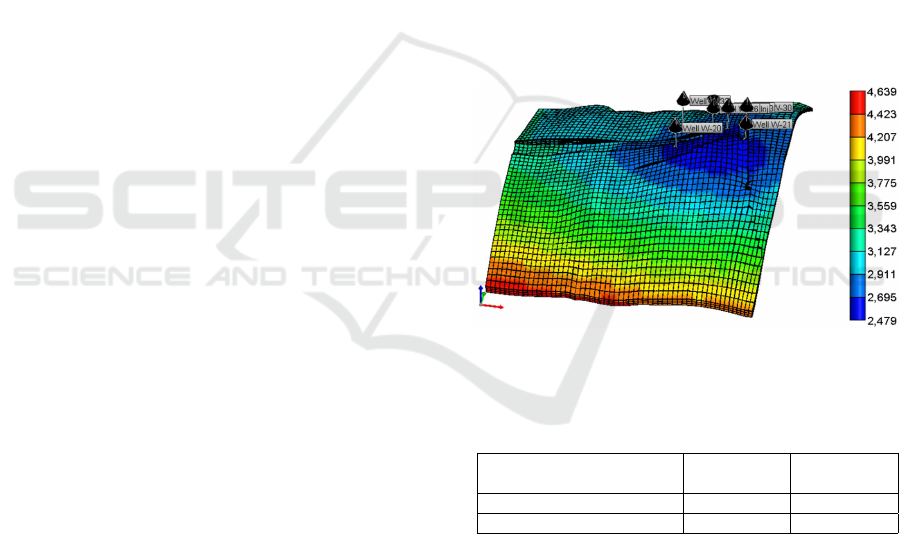

software). Figure 1 shows the grid model with its

grid-top parameter. The average permeability is quite

low, ranged from 30 to 100 millidarcy (md). The

range of porosity of 0.13 to 0.19. The pore-volume of

this model is 0.83 billion reservoir cubic feet (cuft).

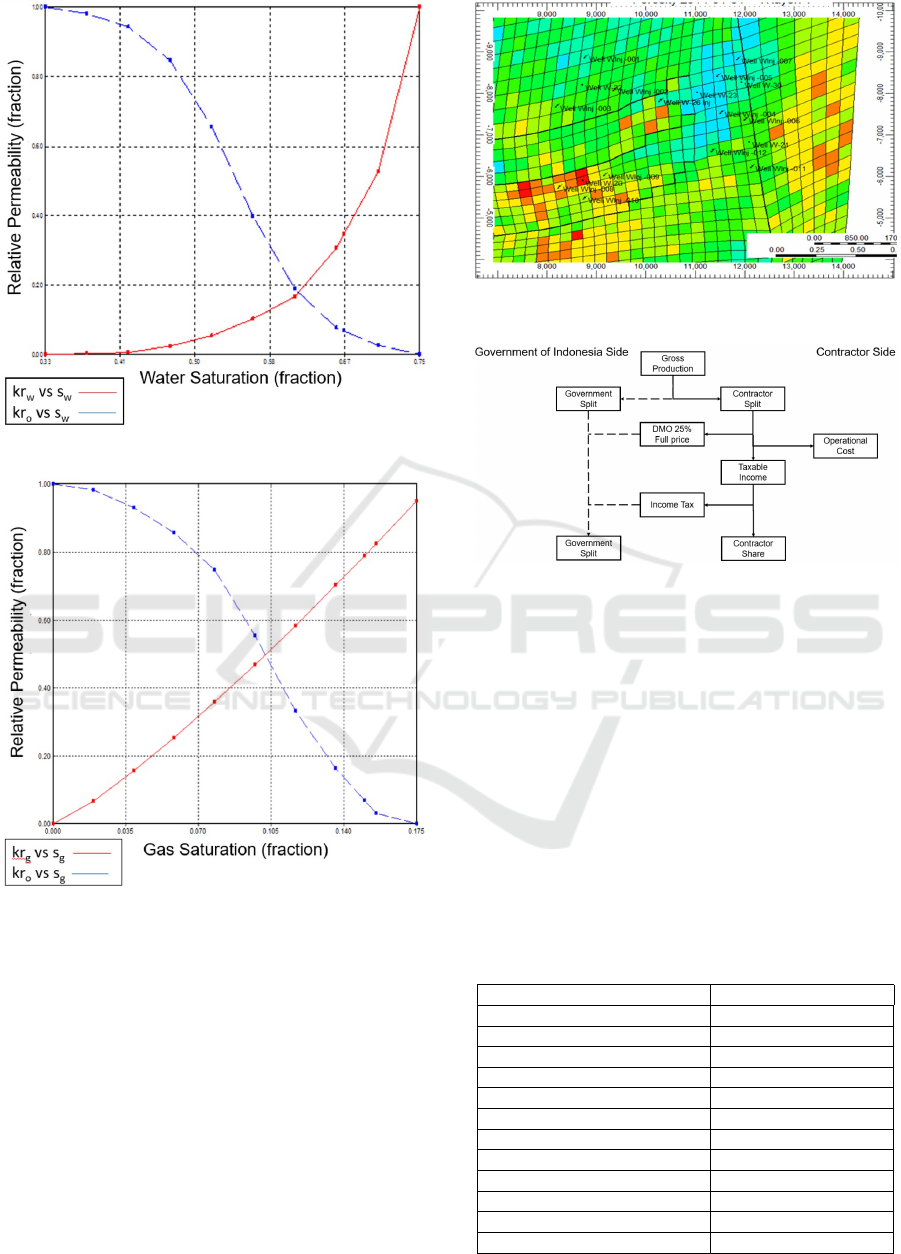

Figure 2 and 3 depict the relative permeability (k

r

)

plot for water-oil and gas-oil systems, respectively.

The relative permeability model in this study is

obtained directly simulation study (Millah, 2014).

In the oil-water system, k

r

is plotted over water

saturation (s

w

) and gas saturation (s

g

) for gas- oil

system. Subscript o, w, and g in figure 2 and 3 are

oil, water, and gas. Twelve injectors are planned to

inject CO2 under continuous and WAG scenarios and

the performance will be analyzed based on production

data on 5 production wells (location of the wells

are shown in Figure. 4). Total injection volume is

limited on 0.6 PV due to economic reason and the 1:1

WAG ratio is selected because this ratio is common in

field-scale operation (Christensen et al., 1998). 2%

Half Cycle Slug Size (HCSS) is designed for this

study. Configuration of CO2 and water injection rate

are tabulated in Table 1.

The model is simulated from 1996 until the end of

2013 for primary recovery stage and continued to 10

years CO

2

flooding under scenario in Table 1 until the

injection period is finished (2024). The oil production

during this CO

2

flooding simulation is recorded for

feasibility calculation.

Figure 1: The grid model that is used in this study, the color

legend represents the grid top of the cell in feet unit.

Table 1: Gas and water injection rate in CO2 flooding

scenarios. “Mscf” means thousand standard cubic feet.

Injection Scenario

Gas Rate Water rate

(Mscf/day) (bbl/day)

Continuous CO

2

injection 1463 -

WAG 1463 1873

Figure 5 draws Schematic share diagram of Gross

Split between government and operator (mentioned

as ”contractor” in this diagram). The difference of

this new mechanism with previously cost-recovery

mechanisms is the contractor must bear every

operating cost, risk, and all taxes. The government

and contractor shares are divided from the gross oil

production while in the cost recovery mechanism, the

oil should be shared to both parties after deducted

from cost recovery post. Three variable influences

the share of government and contractor, e.g., Base

split, variable component, and progressive component

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

16

Figure 2: Relative permeability curve for water-oil system.

Figure 3: Relative permeability curve for gas-oil system.

(Giranza and Bergman, 2018). These variables are

affected by field condition, development status, and

oil price (Roach and Dunstan, 2018).

Several assumption will be made for studying the

feasibility of CO

2

flooding project in this field. The

oil price for this study is assumed 90 US$/bbl and

the share for government and contractor is under base

split (57% - 43%). Moreover, the Indonesian tax is

assumed 45% (Roach and Dunstan, 2018). All cost

and revenue components in this study are tabulated

in Table 2, based on study of Jarrel et al. (2002).

This study also utilized recycled CO

2

and water from

the recycling facilities whereby the annual handling

Figure 4: Distribution of injection and production wells in

the grid model.

Figure 5: Schematic diagram of Indonesia gross-split

mechanism.

capacity of which are 18 MMSCF CO

2

and 730

thousand barrels of water. The Weighing average cost

of capital (WACC) for this study is 12%. Net Present

Value (NPV) of each scenario is will be compared.

3 RESULT AND DISCUSSION

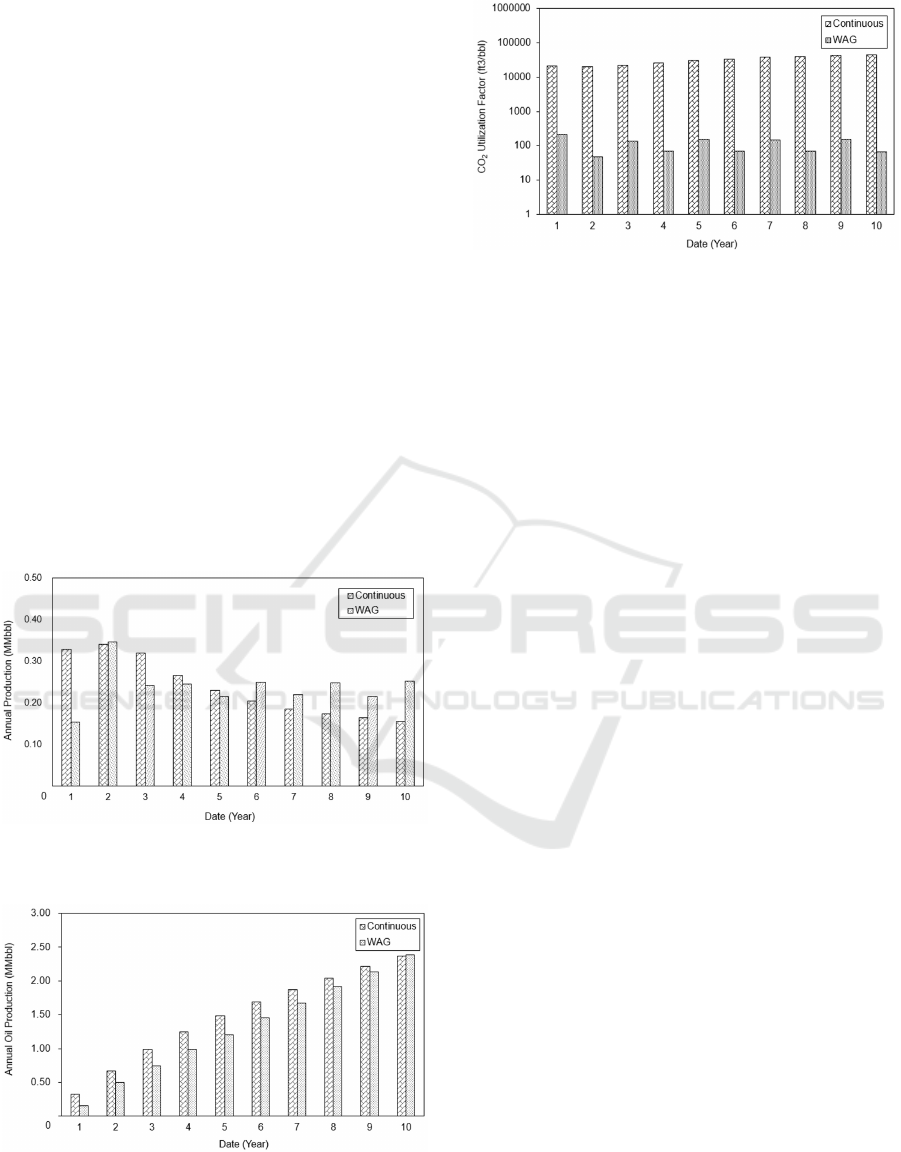

Figure 6 compares the annual production during 10

years continuous CO

2

Flooding and WAG, while the

cumulative production on each scenario are plotted

Table 2: Cost and revenue components assumptions in this

study.

Cost or revenue components Value

Injection well cost 0.600 MMUS$/well

Production well cost 0.450 MMUS$/well

Well completion 0.200 MMUS$

Water injection capital cost 0.011 MMUS$/well

CO2 facility capital cost 0.012 MMUS$/well

Production facility capital cost 0.027 MMUS$/well

Water Injection Cost 1.000 US$/bbl

CO2 Price 2.500 US$/Mscf

Chemical Cost 0.020 MMUS$/well/yr.

CO2 recycle OPEX 0.750 US$/mscf

Water Recycle OPEX 0.300 US$/bbl

Oil Price 90 US$/bbl

Feasibility Study of CO2 Flooding under Gross-split Mechanism: Simulation Approach

17

in Figure 7. Continuous CO

2

injection shows higher

productivity over WAG during two years injection

and gradually decrease for the rest period. It

is contrast with performance under WAG scenario

where the oil recovery is still low in the first year but

significantly increase more than 120% in the second

year. Productivity on WAG tend to show a stable trend

for the next seven years. Results from the figure 7

indicates the WAG application can recover oil slightly

more than continuous flooding scenario with 1%

recovery gap, i.e. the 10-years oil recovery is same. In

terms of CO

2

utilization factor, a ratio of Injected CO

2

to the amount of oil production, simulation results

shows low CO

2

utilization factor is revealed for WAG

scenario, means requires less CO

2

to produce one

barrel of oil. Comparing the data trends on both

scenarios clearly indicates a continuous growth of

CO

2

utilization factor, indicates the requirement to

produce crude oil becomes higher over the time, while

WAG shows a decreasing trend. WAG is effective to

overcome the gravity segregation issue, compare to

continuous CO

2

flooding. Due to lower density. CO

2

tend to move upwards in the reservoir, resulting a poor

displacement efficiency (Jaafar et al., 2014),

Figure 6: Annual oil production during CO

2

flooding phase

for each scenario.

Figure 7: Annual Cumulative oil production during CO2

flooding phase for each scenario.

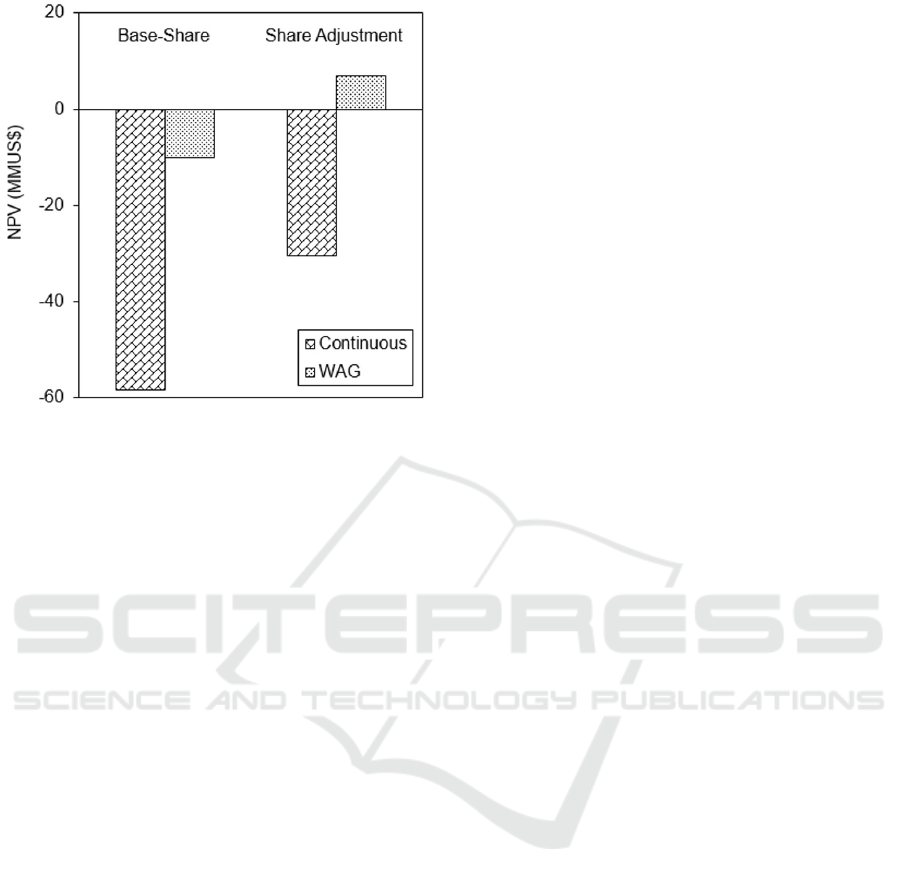

Despite both injection strategies shows same

achievement in term of oil recovery, WAG option

Figure 8: Annual CO2 utilization factor for continuous and

WAG CO2 flooding.

is more attractive because consume less CO

2

inducing low CO

2

Purchase cost. Comparing

these scenarios under gross-split mechanism reveal

unprofitable conclusion, as indicates in negative

value of NPV (Figure 9). Therefore, base-share

between government and contractor is not feasible

from the contractor side, means share adjustment

between these shareholders are required. The

government-contractor share is then adjusted to

35%-65% because these share is suitable for high

operating cost, i.e., both CO

2

flooding scenarios are

categorized into high operating cost projects (Roach

and Dunstan, 2018). Recalculation of NPV under

this new share results negative NPV for continuous

injection project (-30.5 MM$) and 6.9 MM$ for

WAG, means WAG scenario is more profitable.

Moreover, the Internal Rate of Return (IRR) of this

project indicate a significant profit can be made

during this injection period, i.e., the IRR is higher

than Indonesia WACC (32.7% compare to 8%). In

short, CO

2

WAG scenario is effective in displacing

residual oil and also more profitable than another

option. Share adjustment in this study may be an

evidence on the urgency CO

2

issue in Indonesia

gross-split mechanism. Therefore, it is recommended

to include CO

2

issue into the variable and progressive

share components.

The information shared to the all of communities.

A monitor with all the information related to the water

quality installed at the community center or at the

point of common assembly of community for easy to

delivery of information. Furthermore, all the people

and community can have an access to information

shows including the status of river water levels. Based

on monitoring system then all the information is

update for public service and knows the status of the

river.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

18

Figure 9: Effect of share adjustment to NPV for continuous

and WAG CO

2

flooding.

4 CONCLUSIONS

This paper analyze the feasibility of CO

2

project

under Indonesia gross split mechanism by using

reservoir simulation method. One of Indonesia oil

field reservoir is modelled for this study, where the

CO

2

injection schemes is limited to continuous and

WAG scenarios. Simulation results reveals a better

performance of WAG in recovering remaining oil in

the reservoir. Moreover, feasible indication is shown

on WAG scheme after adjusting the base share of

government and contractor. Including the CO

2

issues

into the variable and progressive share, points may

increase the tendency of CO

2

flooding application in

Indonesia

REFERENCES

Abdurrahman, M., Permadi, A., and Bae, W. (2015). An

improved method for estimating minimum miscibility

pressure through condensation–extraction process

under swelling tests. Journal of Petroleum Science

and Engineering, 131:165–171.

Abedini, A. and Torabi, F. (2014). Oil recovery

performance of immiscible and miscible co2

huff-and-puff processes. Energy & Fuels,

28(2):774–784.

Agency, I. E. (2016). 20 Years of Carbon Capture

and Storage: Accelerating Future Deployment.

International Energy Agency.

Azzolina, N. A., Nakles, D. V., Gorecki, C. D., Peck,

W. D., Ayash, S. C., Melzer, L. S., and Chatterjee,

S. (2015). Co2 storage associated with co2 enhanced

oil recovery: A statistical analysis of historical

operations. International Journal of Greenhouse Gas

Control, 37:384–397.

Christensen, J. R., Stenby, E. H., Skauge, A., et al.

(1998). Review of wag field experience. In

International petroleum conference and exhibition of

Mexico. Society of Petroleum Engineers.

Giranza, M. and Bergman, A. (2018). Indonesia’s new

gross split psc: Is it more superior than the previous

standard psc. Journal of Economics, Business and

Management, 6.

Irham, S. and Julyus, P. (2018). The new energy

management policy: Indonesian psc-gross-split

applied on steam flooding project. In IOP Conference

Series: Earth and Environmental Science, volume

106, page 012109. IOP Publishing.

Jaafar, M., Omar, S., Anuar, S., and Suradi, S.

(2014). Reservoir monitoring of eor processes (wag,

foam and polymer) using streaming potential. In

Scientific Cooperations International Workshops on

Engineering Branches, pages 8–9.

Jarrell, P. M., Fox, C. E., Stein, M. H., and Webb, S. L.

(2002). Practical aspects of CO2 flooding, volume 22.

Society of Petroleum Engineers Richardson, TX.

Jishun, Q., Haishui, H., and Xiaolei, L. (2015). Application

and enlightenment of carbon dioxide flooding in the

united states of america. Petroleum Exploration and

Development, 42(2):232–240.

Roach, B. and Dunstan, A. (2018). The indonesian psc: the

end of an era. The Journal of World Energy Law &

Business, 11(2):116–135.

Rubin, E. S., Davison, J. E., and Herzog, H. J. (2015). The

cost of co2 capture and storage. International Journal

of Greenhouse Gas Control, 40:378–400.

Whittaker, S., Rostron, B., Hawkes, C., Gardner, C., White,

D., Johnson, J., Chalaturnyk, R., and Seeburger, D.

(2011). A decade of co2 injection into depleting

oil fields: Monitoring and research activities of the

iea ghg weyburn-midale co2 monitoring and storage

project. Energy Procedia, 4:6069–6076.

Feasibility Study of CO2 Flooding under Gross-split Mechanism: Simulation Approach

19