Risk Identification in Management System Process Integration Which

Have Impact on the Goal of Management System Components

Nastasia Ester Siahaan, Leni Sagita and Yusuf Latief

Department of Civil Engineering, Universitas Indonesia, Depok, Indonesia

Keywords:

Risk Identification, Process Integration, Integrated Management System.

Abstract:

Integrated Management System is a combination of two or more management system that facilitate a

company to achieve its goals. In this case, the integrated systems are Quality Management System (QMS),

Environmental Management System, and Safety Management System. In integrating one management system

with another, the approach used is process integration. In the process integration, there are several risks

that have impact on component goals in the management system process integration. The purpose of this

study is to identify risks that have an impact on the goals of the component and make the dominant risks

management strategy in the process integration. This study uses respondents’ survey strategy to identify

risks in the management system process integration and case study strategy to find out the dominant risks

management strategies. The result of this study are risks in the process integration of management system and

dominant risk management strategies.

1 INTRODUCTION

Implementation of Integrated Management System

for better quality management is a preference

for many organizations (Muzaimi et al., 2017).

Previously, organizations in the world were not

exempt from construction companies too focused on

individual management systems (Mourougan, 2015).

The American Society of Quality (2015) divides

the integration of management systems in three

approaches which are process integration, risk

integration, and audit integration (Paraschivescu,

2016). Process integration is a simulated device that

aims to achieve optimization, feasibility, and integral

solutions in a sustainable design (Klemes et al., 2013)

Process integration is a method of combining part

or all of the process to reduce resource consumption

(Bugdol and Jedynak, 2015). This research uses

a process integration approach that consists of 8

components, namely the scope (1), leadership (2),

integration of management policy (3), planning (4),

support (5), operational (6), performance evaluation

(7), and improvement (8) (Masuin et al., 2018).

The integration of system management has

advantages for the organization. On the other hand,

there are factors that inhibit and cause the purpose

of the management system components to be not

achieved. In the research of Rajkovic, Aleksic,

Milicevic, and Cudic (2008), the risk comes from

internal and external.

Process integration has a fairly high risk and

can have an impact on objectives. Therefore, it is

necessary to mature planning and identify the risks

that may occur either during management system

process integration. Once the risk is identified, the

risk should be assessed based on possible occurrence

and impact it may cause. This is done to prevent any

accidents that occur and can have an impact on project

work in particular and on the safety of the surrounding

environment in general.

From the explanation above, the study was

conducted with the aim of identifying the risks that

can occur in the integration process. When the risk is

identified, the appropriate strategy can be applied to

manage risk (in this research is the dominant risk) and

the purpose of the component on process management

system integration can be achieved.

2 LITERATURE REVIEW

Integrated Management System (IMS) is a

management system that combines all components

into a comprehensive system to facilitate the

achievement of objectives and goals (Muzaimi, Chew,

& Hamid, 2017). An IMS occurs when two or more

Siahaan, N., Sagita, L. and Latief, Y.

Risk Identification in Management System Process Integration Which Have Impact on the Goal of Management System Components.

DOI: 10.5220/0009091400410048

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 41-48

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

41

systems unite by eliminating the independence of one

or both, but without losing their identities (Poltronieri

et al., 2017). The integration consists of three main

management systems: Quality Management System

(QMS), Environmental Management System (EMS),

and Safety Management System (SMS). The goal of

implementing a management system by integrating

several standards and documents is to achieve

synergistic action in the organization (Zgodavova and

Bober, 2012).

IMS can be done by using 3 approaches,

namely process integration, risk integration, and audit

integration (Paraschivescu, 2016). Process integration

is a method of combining part or all of the process to

reduce resource consumption and harmful emissions

to the environment (Klemes, Varbanov, & Kravanja,

2013). Bugdol et al (2015) explained that only 0-70%

of all processes are integrated with the integration

matrix (Bugdol & Jedynak, 2015). Bugdol (2015)

said that not all processes need to be integrated.

This research uses a process integration approach

that consists of 8 components, namely the scope

(1), leadership (2), integration of management policy

(3), planning (4), support (5), operational (6),

performance evaluation (7), and improvement (8)

(Rofi’udin, Masuin, & Latief, 2018).

The three standards of QMS, EMS, and

SMS are generally based on the principle of

continuous improvement by the Deming cycle

(Plan-Do-Check-ACT) (Zeng et al., 2010). The

PDCA cycle is a concept of sustainable business

enhancement and additional troubleshooting (Singh,

2013). The process integration of the third process

management system is also based on the PDCA

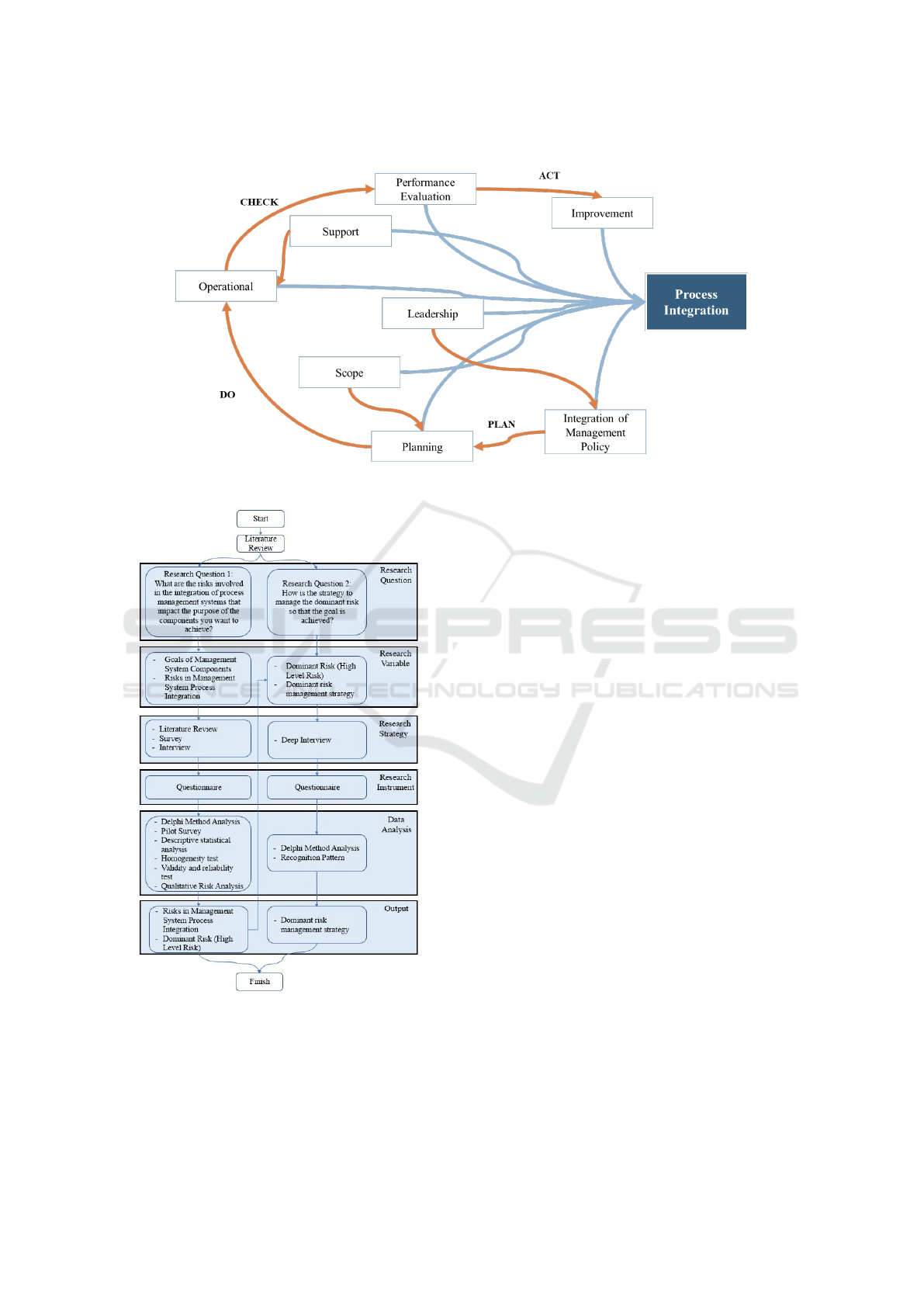

approach described in Figure 1.

Blue lines demonstrate leadership, integration of

management policy, scope, planning, supporter,

operational, performance evaluation, and

improvisation supporting the system to perform

process integration.

The red lines demonstrate PDCA cycle in process

integration and its correlation with management

system components. PDCA is an ongoing approach

of management system in the flow of planning,

implementation, checking and corrective action

(Ribeiro et al., 2017). The planning stages consist

of scope, leadership, and integration of management

policies. Leadership is needed to create the unity

of goals and direction and involvement of people

activating an organization to align strategies, policies,

processes and resources to achieve its objectives.

The Input of planning in the integration process

management system is the needs and expectations of

stakeholders as well as internal and external issues of

the organization that are reflected in the scope of the

system regarding organizational objectives and goals

(Mourougan, 2015).

The implementation stage requires operational

and supporting components. The operation of the

system must be done in accordance with the planned.

In operation, it takes resources that build, implement,

and maintain an integrated management system. The

required resources are on supporting components.

Performance evaluation should be done to the

results and services produced in the operational

phase. The result of performance evaluation was

made the foundation for a system improvement.

Organizations must find and filter opportunities for

improvement and take important actions to respond

to system sustainability objectives.

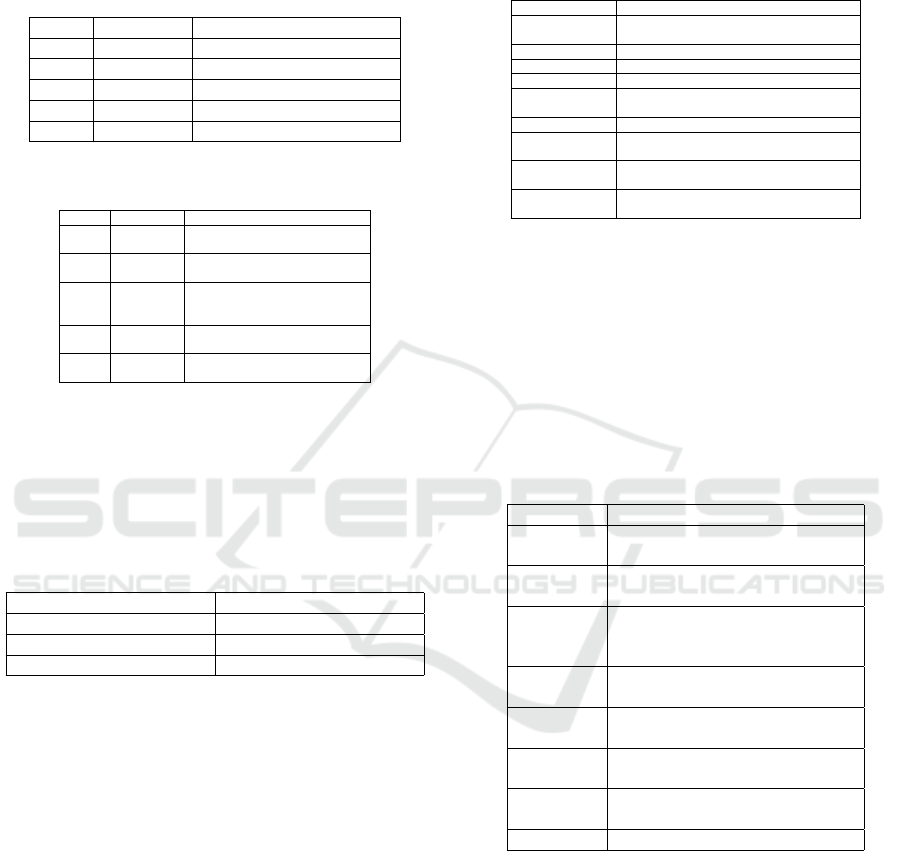

3 RESEARCH METHOD

This study uses two methods, respondents survey

and case studies. Respondents survey is suitable

to answer what and how large the correlation of

each survey variable. Analysis of surveys is useful

for identifying a thing (Yin, 2013). Therefore, this

strategy is used to identify risks in the integration

of process management systems that impact the

objectives of IMS components on construction

company organizations. The samples taken in this

research survey strategy are purposive samples. In

accordance with the research restrictions that have

been included in the research constraints in the first

chapter, selected respondents are the stakeholders of

the construction management (government or private

owned) implementing QMS, EMS, and SMS.

Case studies are used to investigate a small

number of cases in depth, such as the study of why a

project failed (Tan, 2011). The case study strategy is

suitable for answering the question ”How and why”

(Yin, 2013). Yin (2013) argues that this strategy

is conducted without controlling the characteristic

errors of the events studied and the research focuses

on contemporary events. The case studies research

strategy is due to questions relating to operational

relationships that need to be tracked over time, rather

than sheer frequency or incidence. This strategy is

suitable for use in this research as it can answer

strategies for managing the dominant risk, so that

the objectives of the integrated management system

components can be achieved.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

42

Figure 1: Process integration model. Source: (Rofi’udin, Masuin, & Latief, 2018)

Figure 2: Research Operational Model

3.1 The Goals of Management System

Components

This study defines the purpose of the clauses or

components of the integration process management

system. The purpose of clauses is obtained by literary

studies and validated by experienced experts in the

Integrated Management System.

3.1.1 Scope

Scope assignment is required:

• to identify external and internal issues of the

organization

• to know the organization and its context and

identify the needs and expectations of the

company

3.1.2 Leadership

Good leadership is one aspect that guarantees the

continuity of the system achieved (Gianni and

Gotzamani, 2014). The goals of this component or

clause are:

• to determine who is responsible for the QMS

EMS, and SMS;

• to create a unity of purpose and direction of

organizational policy;

• to establish norms or standards that become a

reference to integrating management systems.

3.1.3 Integration of Management Policy

Integration of management policies integrates

several elements, which are values, regulations,

objectives, objectives, vision, and organizational

mission (Rofi’udin et al., 2018). The integration

of management policies is a process by which an

Risk Identification in Management System Process Integration Which Have Impact on the Goal of Management System Components

43

institution performs a change from a irregularity and

multi-dimensional institution to a new governance

system (Candel and Biesbroek, 2016). The goals of

this component are:

• to provide instructions regarding the outcome of

an organization

• to define the most important and common

terminology in the design process approach,

implementation, operation of integrated

management systems

3.1.4 Planning

Planning aims to set project scope, correct the

objectives, and determine the required actions for the

project’s purpose to be achieved. In planning, the

inputs needed in the management integration process

are the needs and expectations of stakeholders as well

as internal and external issues of the Organization

in relation to the objectives and objectives of

an organization (Mourougan, Auditing Integrated

Management System for Continuing Suitability,

Sustainability, and Improvement, 2015).

3.1.5 Support

The goals of this component or clause are:

• to determine and provide the resources

required for the establishment, implementation,

maintenance and continuous improvement

• to determine competence. Competence criteria

need to be set for each function and role relevant

to the management system

• to raise the awareness of the people involved in

the management system of policies, significant

aspects, and the impact of relevance on their

activities.

• to ensure that the mechanisms that facilitate the

communication in the management system run

effectively

3.1.6 Operational

The goals of operational are:

• to ensure that processes are ready to meet the

requirements of the management system and to

implement the actions identified in the planning;

• to establish, implement and maintain the

necessary processes to address potential

emergency situations identified.

3.1.7 Performance Evaluation

Therefore, evaluation is an important part of

the integration of process management systems.

Performance evaluation includes inspection,

measurement, analysis, assessment, internal audit,

and management review. The goals of this component

are:

• to determine the range of monitoring and

measurement necessary to assess the fulfilment of

obligations on the management system.

• to ensure that all processes are audited at the

required frequency and ensure that internal audits

are consistent and thorough, clear objectives and

scope must be set for each audit

• to ensure the continued suitability, adequacy and

effectiveness of quality management system.

3.1.8 Improvement

This component has several purposes as follows:

• to determine the opportunity for improvement and

apply the necessary actions to achieve the desired

results.

• to eliminate the cause of the actual problem so as

to avoid recurrence of the problem.

• to continuously improve the suitability, adequacy

and effectiveness of management systems

(quality, environment, safety) to improve

performance.

3.2 Risks in Management System

Process Integration

After defining the purpose in the clause in the

integration process, the findings gained are the

identification of risks that occur in the integration

process that may affect the purpose of the clause or

component. These risks are obtained by conducting

related literary studies and conducting 2-round expert

validation. The identified risks that are validated by

experts are as many as 95 risk factors.

3.2.1 Risk Assessment

Risk quality analysis is performed to determine the

level of risk, whether low, moderate, or high. The

Level of risk can be obtained by multiplying the

average probability value and the average impact

value. The average probability value is obtained by

summing the risk frequency and then divided by the

total data obtained, which is 30 respondents. The

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

44

average impact value is obtained by summing the

impact value then divided by the amount of data,

which is 30 data. The following are indicators of the

scale:

Table 1: Scale Assessment of Risk Frequency.

Scale Category Indicator

0,1 Very Low Very small possibilities

0,3 Low Less likely to occur

0,5 Moderate Quite possibly happening

0,7 High It may happen

0,9 Very High Very likely to happen

Table 2: Risk Impact Assessment Scale.

Scale Category Indicator

0,05 Very Low

No impact on the purpose of

components/clauses

0,1 Low

Slight impact on the purpose of

components/clauses

0,2 Moderate

Insufficient impact on the

purpose of

components/clauses

0,4 High

Impact on the purpose of

components/clauses

0,8 Very High

Greatly affects the purpose of the

component/clause

After obtaining the average probability value and

the average impact value, the multiplication is done

between the two values to get the risk value. From

the risk value, it is rated from 1 to 95 from the highest

risk rating to the lowest risk rating. Then, determined

the level of risk by looking to match the table below.

Table 3: Risk Category.

Risk Score Risk Category

0,01-0,05 Low Risk

0,06-0,17 Moderate Risk

0,17-0,72 High Risk

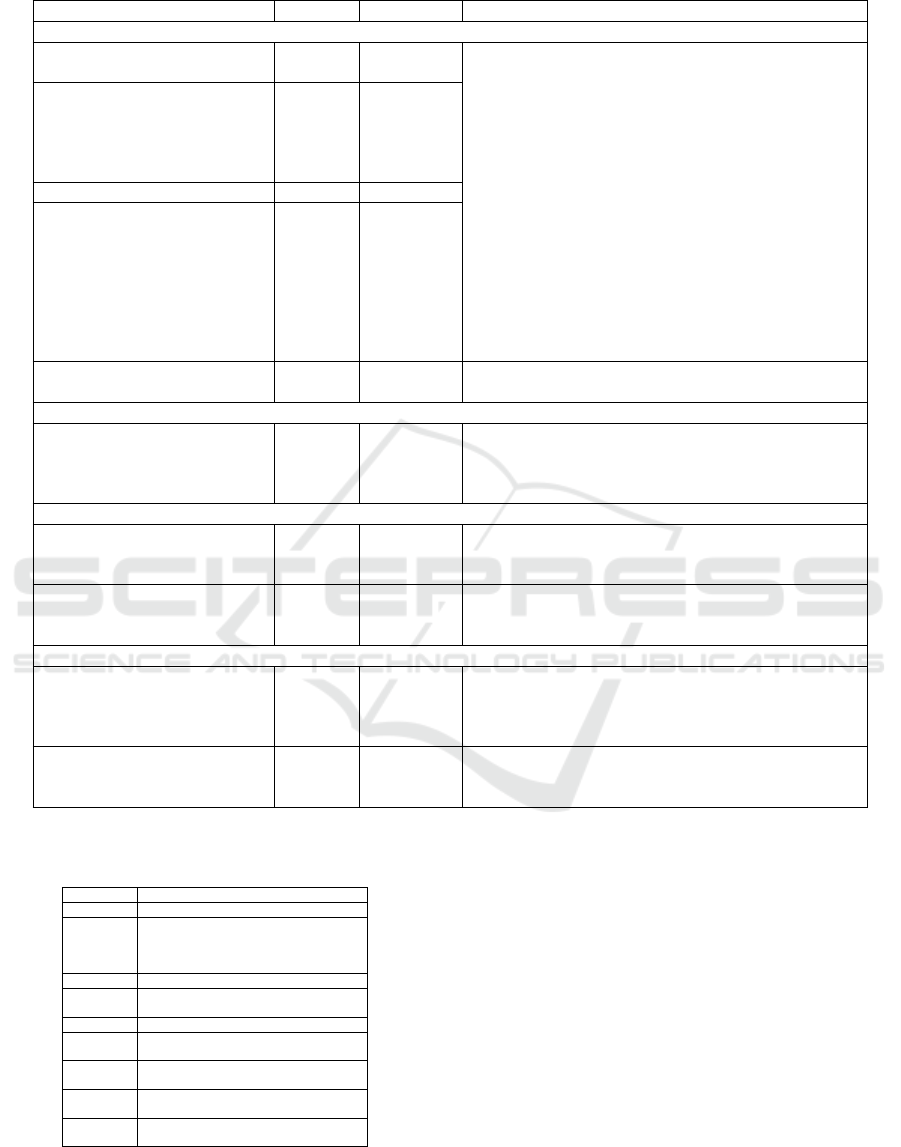

After the calculation is done, 10 of the highest

risks are obtained as follows in Table 4.

3.3 Strategies for Managing the

Dominant Risks

At the previous stage, the dominant risk has been

identified through a qualitative assessment of risk.

Dominant risk is interpreted as a high level of risk.

This stage aims to collect data in the form of strategy

proposals by outlining causes, preventive measures,

impacts and corrective actions.

3.3.1 Causes and Impact of Risk

Causes that have been identified and validated as

much as 9 causes. One cause could be the cause

for some risk. The most common cause of risk is

P2, which is lack of human resources competenceIn

Table 5 are compiled causes previously validated by

experts.

Table 5: Causes of Risk in Process Integration Management

System.

Code Cause

P1

Lack of awareness to consider inflation in the

identification of issues

P2 Lack of human resource competence

P3 Limited partner availability

P4 Understanding the different scopes

P5

Lack of socialization on the importance of

unity

P6 Preparation of an immature program

P7

Management system problems are rarely used

as a subject in the company’s activities

P8

Lack of training and certification obtained by

human resources

P9

Analysis of the root cost is not specific or not

on target

The impact has been identified and validated by

experts as much as 35 impact. Any impact can occur

due to more than one risk factor. The most impact

occurs because the risk occurs is D2 and D6. D2

is an implementation of an integrated management

system that is not optimal. D6 is an organizational

performance goal not achieved. Table 6 are compiled

impacts previously validated by experts.

Table 6: Impacts of Risk in Process Integration

Management System.

Code Impact

D1

Identify external and internal

organization issues inaccurate

D2

Implementation of integrated

management system not optimal

D3

Organizational risk does not

comply with the third process of

management systems

D4

Company identification need

and expectation inaccurate

D5

Workers ’ views are not equal or

unequal

D6

Organizational performance

goals not achieved

D7

The audit process is not running

properly

D8 Ineffective management system

3.3.2 Risk Response

After identification of the cause of the risk, a

preventative action can be sought to prevent the cause

from occurring. The proposed preventive action is

9 actions and has received approval from the expert.

Preventive measures may be enforced to prevent more

than one cause. The most proposed preventive action

to prevent the cause is TP5, which is conducting

related socialization activities. Table 7 are compiled

preventive actions previously validated by experts.

Risk Identification in Management System Process Integration Which Have Impact on the Goal of Management System Components

45

Table 4: Highest Risks that Have Impact on the Goal of Management System Components

Risk Ranking Risk Score Goal of the Component

Component/Clause Scope

X1. Lack of inflation

considerations

2 0.307

To identify external and internal issues of the

X2. The organization in the

construction company does

not set the Job Description

& Standard/Requirements

integrated to the 3 systems

3 0.291

X3. Weak partner selection 1 0.481 organization

X4. The organization in the

construction company has

not been able to identify

and analyse important

issues related to Risk and

Opportunity in relation

to quality, safety, and

environment

9 0.218

X5. Inaccurate Corporate

priority orientation

8 0.231 To know the organization and its context and identify

the needs and expectations of the company

Component/Clause Leadership

X6. Lack of unity of view of

all employees who are already

working under the previous

standard

6 0.24 To create a unity of purpose and direction of

organizational policy.

Component/Clause Support

X7. Lack of financial

resources

7 0.235 To determine and provide the resources required for

the establishment, implementation, maintenance and

continuous improvement

X8. Lack of employee

motivation

4 0.264 To raise the awareness of the people involved in the

management system of policies, significant aspects,

and the impact of relevance on their activities

Component/Clause Performance Evaluation

X9. Lack of competence

auditors

10 0.215 To ensure that all processes are audited at the

required frequency and ensure that internal audits are

consistent and thorough, clear objectives and scope

must be set for each audit

X10. Evaluation of follow-up

results of audit results still less

precise

5 0.258 To ensure the continued suitability, adequacy and

effectiveness of quality management system.

Table 7: Preventive Actions of Risk in Process Integration

Management System.

Code Preventive Action

TP1 Consider economic factors

TP2

Using competent human resources to set

JOB Description & Standard/requirements

integrated to all three management

systems,

TP3 Conduct a partner prequalification

TP4

Improving socialization and related

training

TP5 Conducting socialization regarding

TP6

Prepare programs for financial resource

needs in detail

TP7

Integrate management systems with

business processes

TP8

Increase training and certification programs

related to

TP9

Ensuring evaluation of follow-up results of

audit results researched

The risks that occur will cause impact. Therefore,

it is necessary to identify the impact that will occur,

so that it can be determined the corrective action.

From table 8, it is possible to know that a proposed

corrective action was proposed to take as many as 8

actions. The corrective action can be proposed for

more than one variable. The most corrective action

to be proposed for risk factors is TK1, which is to

perform the related review.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

46

Table 8: Corrective Actions of Risk in Process Integration

Management System.

Code Corrective Action

TK1 Perform related rereviews

TK2

Set Job Description According to

scope management system used

TK3

Choose a new partner that’s

considered stronger

TK4 Re-identify

TK5 Re-socialize

TK6

To make planning the financial

resources

TK7

Monitor motivation by integrating

motivation towards understanding

the management system in the

company

TK8

Audit by combining senior auditors

and junior auditors

Lack of HR competence is the cause of the many

risks that occur. There are 5 risk factors that can

occur due to lack of HR competence. It is in the

background of lack of perfect knowledge of human

resources in the field of integrated management

system considering the integration of management

system has not been implemented in many companies,

especially construction companies(Asif et al., 2008).

Lack of HR competence can be prevented by

preventive measures such as conducting socialization,

training, and certification related to integrated

management system. It is considered relevant because

the most corrective action proposed in the study is

to socialize the details of the integrated management

system. From the findings,it can be seen that the

organizational performance is not achieved is the

most widely encountered impact when a risk occurs.

As for the most proposed corrective action is to do

a re-review of issues or problems that occur in the

integration of process management systems.

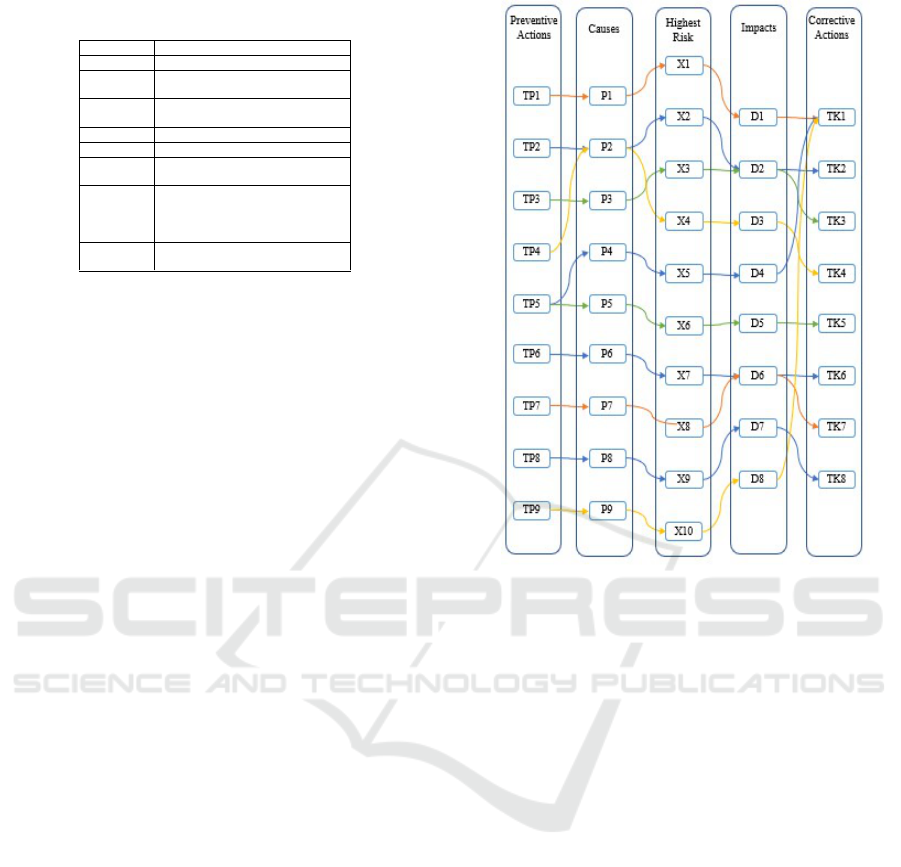

3.3.3 Pattern Recognition

After defining the cause and impact of the risks that

occur, as well as propose preventive actions and

corrective actions, can be made recognition pattern

as in Figure 3. The recognition pattern is a flow

from left to right, starting from preventive action,

cause, risk, impact, corrective action. From the

recognition pattern, it can be clearly seen the pattern

of interrelated strategies between one’s risk and the

other risk. For example, TP5 can be done to prevent

the causes of P5 and P6.

4 CONCLUSIONS

Process integration has a fairly high risk and can have

an impact on objectives. Therefore, it is necessary

to mature planning and identify the risks that may

occur either during management system process

Figure 3: Recognition Pattern for Top 10 Risks

integration.The identified risks must be managed by

defining their causes and impacts. Once known cause

and impact, it can be proposed preventive measures to

prevent occurrence and corrective action in response

if the impact occurs.

Based on this study, there are 10 highest risks in

management system process integration and 5 risks

occuring in scope component/clause.

ACKNOWLEDGMENTS

The authors would like to thank the financial support

provided by University of Indonesia University

through the PITTA 2019 funding scheme managed

by Directorate for Research and Public Services

(DRPM) University of Indonesia.

REFERENCES

Asif, M., Bruijn, E. J., and Fisscher, O. A. (2008).

Process Embedded Design of Integrated Management

Systems. POMS 19th Annual Conference. California.

Bugdol, M. and Jedynak, P. (2015). Integrated Management

System. New York: Springer International Publisher.

Risk Identification in Management System Process Integration Which Have Impact on the Goal of Management System Components

47

Candel, J. and Biesbroek, R. (2016). Towards a processual

understanding of policy integration. Policy Sci,

49:211–231.

Gianni, M. and Gotzamani, K. (2014). Management

system integration: Lesson from an abandonment

case. Journal of Cleaner Production, 86:265–276.

Klemes, J., Varbanov, P. S., and Kravanja, Z. (2013).

Recent development in process integration. Chemical

Engineering Research and Design, 91(10).

Masuin, R., Latief, Y., Zagloel, T. Y., and Sagita, L.

(2018). Integrated Management System to Achieve

Sustainable Construction - A Conceptual Framework.

AIP Conference Proceeding.

Mourougan, S. (2015). Auditing integrated management

system for continuing suitability. Sustainability,

and Improvement. IOSR Journal of Bussiness and

Management, 17(10):1–14.

Muzaimi, H., Chew, B. C., and Hamid, S. R. (2017).

Integrated Management System: The Integration of

ISO 9001, ISO 14001, OHSAS 18001, and ISO 31000.

AIP Conference Proceeding, Melaka.

Paraschivescu, O. (2016). The advantages of the process

of integrating quality management system. Economy

Transdisciplinarity Cognition, 19(2):45–55.

Poltronieri, C. F., Gerolamo, M. C., and Carpinetti,

L. R. (2017). An instrument for the assessment

of management system integration. Sao Carlos,

24(2):638–652.

Ribeiro, F., Santos, G., Rebelo, M. F., and Silva, R. (2017).

Integrated Management Systems: Trends for Portugal

in the 2025 horizon. 13.

Rofi’udin, M., Masuin, R., and Latief, Y. (2018). Important

Clauses Construct the Integration Process of Quality.

Safety, Occupational Health, and Environment

Management Systems. International Conference on

Information Management and Technology.

Singh, V. (2013). Pdca cycle: A quality approach.

Utthan-Journal of Management Sciences, 1(1):89–96.

Tan, W. (2011). Practical Research Method (4th ed.).

Jurong: Pearson Education South Asia.

Yin, R. K. (2013). Case Study Reasearch. London: Sage

Publication.

Zeng, S. X., Tam, V. W., and Le, K. N. (2010). Towards

effectiveness of integrated management systems for

enterprises. Engineering Economics, 21(2):171–179.

Zgodavova, K. and Bober, P. (2012). An innovative

approach to the integrated management system

development: Simpro-ims web based environment.

Quality Innovation Prosperity, 16(2):59–70.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

48