Preparation and Characterization of Tungsten Trioxide (WO

3

)

Particles and Their Photocatalytic Performances for Methylene Blue

Degradation

Lusi Ernawati

1

, Ruri Agung Wahyuono

2

, Inggit Kresna Maharsih

1

, Ade Wahyu Yusariarta

1

1Institut Teknologi Kalimantan

2

Institut Teknologi Sepuluh Nopember

Keywords: Photodegradation, organic dye, methylene blue, photocatalytic, UV irradiation, WO

3

Abstract: Tungsten trioxide (WO

3

) nanoparticles were successfully synthesized using sodium tungstate dihydrate

(Na

2

WO

4

.2H

2

O, as WO

3

source) via facile sol-gel method. This study aims to synthesize WO

3

and to

investigate the effects of Na

2

WO

4

precursor concentration on the particle morphology, crystallinity, and

photocatalytic performance. The prepared particle can be activated under UV irradiation and showed good

photocatalytic efficiency for methylene blue (MB) degradation. The results showed WO

3

dose-dependent

photocatalytic performance toward 10 mg/L MB degradation. The adsorption kinetics of MB to the WO

3

catalyst surface can be evaluated and fit by using the pseudo-first-order kinetic adsorption model. The

photodegradation test showed that the concentration (C

t

/C

o

) of 180 ml of MB decreases rapidly up to 88%

with 110 mg of WO

3

for 2h irradiation.

1 INTRODUCTION

There are more than 700,000 tons of different dyes

substances annually produced, among which 15%

are discharged as effluent into the environment by

industries such as textiles, rubber, leather, plastics,

and food (Him et al., 2019). It is well known that

wastewater treatment, particularly in the textile and

dye industry, mainly involves the treatment of

highly colored wastewater containing a variety of

dyes in different concentrations. This dye-

contaminated wastewater can cause harmful damage

to the ecosystem and health, for example, increasing

the DO (Dissolved Oxygen) level in the polluted

ecosystem, which will result in an increase in COD

(Chemical Oxygen Demand) (Chong et al., 2010;

Coleman et al., 2007; Dai et al., 1999; Ernest et al.,

2010).

There are a variety of adsorbents developed for

dye removals that have been studied, among which

activated carbons are most widely used. However,

their current applications are limited due to their

relatively high cost (Fujishima et al., 2001). Other

alternative technologies are also developed for the

decoloring process, for example, by coagulation

techniques, flocculation, adsorption with activated

carbon (Halliday et al., 2011). Nonetheless, it has

been found that the color removal using these

technologies only transforms the dyes from the

liquid into the solid phase while they do not degrade

the dye into less harmful compounds (Indonesia’s

Garment and Textile Sector, 2018).

Considering the limitation of the

abovementioned treatment process, studies of

photocatalytic degradation of organic

dyes/pollutants are growing. Amongst various

photocatalyst, titanium oxide (TiO

2

) is considered

the suitable materials for photodegradation of

organic compounds as it is inexpensive, largely

available, thermally stable, and harmless [9].

However, this material has a relatively wide energy

bandgap (Eg) of 3.2 eV, which limits further

applications of the material in the visible-light

region (λ + 390 nm) (Ke et al., 2018). In this regard,

tungsten trioxide (WO

3

) has been proposed as an

attractive candidate due to its high stability in

aqueous solution under acidic conditions.

Furthermore, its low energy bandgap (Eg) of 2.4-2.8

eV (Kang et al., 2001) allows for a photocatalytic

process triggered under visible solar spectrum (Kim

et al., 2006) and the conduction band level of WO

3

is suitable to allow favorable charge transfer to

Ernawati, L., Wahyuono, R., Maharsih, I. and Yusariarta, A.

Preparation and Characterization of Tungsten Trioxide (WO3) Particles and Their Photocatalytic Performances for Methylene Blue Degradation.

DOI: 10.5220/0009193000050011

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 5-11

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

5

generate intermediates OH• responsible for pollutant

degradation (Michalow et al., 2009).

While the preparation of WO

3

nanoparticles is

often reported using complicated synthetic routes

that require high-temperature process, pressure, and

expensive apparatus (Kang et al., 2001; Kim et al.,

2006; Michalow et al., 2009), the work at hand

presents a facile way and low-cost approach to

synthesize WO

3

nanoparticle via sol-gel method at

mild temperature. The crystallite morphology and

structure are discussed upon varying the ratio

between precursor and surfactant. The dose-

dependent of WO

3,

as well as the dye concentration-

dependent to photocatalytic activities for the

Methylene Blue (MB) degradation, are studied in

detail.

2 EXPERIMENTAL METHODS

2.1 Synthesis of WO

3

Particles

The synthesis was conducted through acidic

precipitation method using Na

2

WO

4

.2H

2

O under

mild condition. An amount of Na

2

WO

4

.2H

2

O was

dissolved in 50 ml of aqua dest and stirred for 30

min. Subsequently, 2 M of HCl was added into the

solution to reach pH < 6 and heated up to 90

o

C.

Afterward, the CTABr solution was poured into the

mixture (with 1 :1, 2 :1, and 4 :1 ratio to

Na

2

WO

4

.2H

2

O), and white precipitation was formed.

The mixture solution was kept at 90

o

C and stirred

for another 30 min. Finally, the precipitates were

filtered, dried in an oven (100

o

C, 1 h), and annealed

in the furnace at 500

o

C for 4 h.

2.2 Photocatalytic Performance of

WO

3

Particle for Methylene Blue

Degradation

Photocatalytic activity of WO

3

against organic

pollutants, i.e., methylene blue (MB), was assessed.

MB photodegradation tests were carried out

employing a different dose of WO

3

catalysts and

different concentrations of MB. The photocatalyst

was soaked in the aqueous MB solution and then

transferred into a custom-built photoreactor and

irradiated under UV light (T5-UV7-W, 254 nm in

wavelength) for several times, i.e., every 15 min for

2 h. The solution was stirred to increase contact

between photocatalyst and MB molecules. In

addition, the reactor was isolated from the ambient

light irradiation. Photodegradation of MB was

detected through absorption change at 665 nm

measured using a UV/vis spectrometer (Rayleigh

UV-9200). The decrease of MB optical density was

used to determine the decreasing MB concentration

due to the catalytic activity of the WO

3

catalyst.

2.3 Characterization

X-Ray Diffraction (XRD) patterns were obtained

using a PAN analytical type X’Pert Pro

diffractometer with Cu-Kα as the radiation source

operated at 40 kV and 40 mA. Samples were

scanned between 10 and 100° diffraction angle (2θ)

with a resolution of 0.05°. Crystallite size was

estimated using the Debye-Scherrer equation. SEM

image of WO3 powder was measured by scanning

electron microscopy (SEM, FEI type Inspect 21) at

100 kV accelerating voltage. Fourier-transform

infrared (FTIR) spectroscopy was carried out using

PerkinElmer Spectrum version 10.5.1.

3 RESULTS AND DISCUSSIONS

3.1 Physical and Microstructural

Properties of WO3 Particle

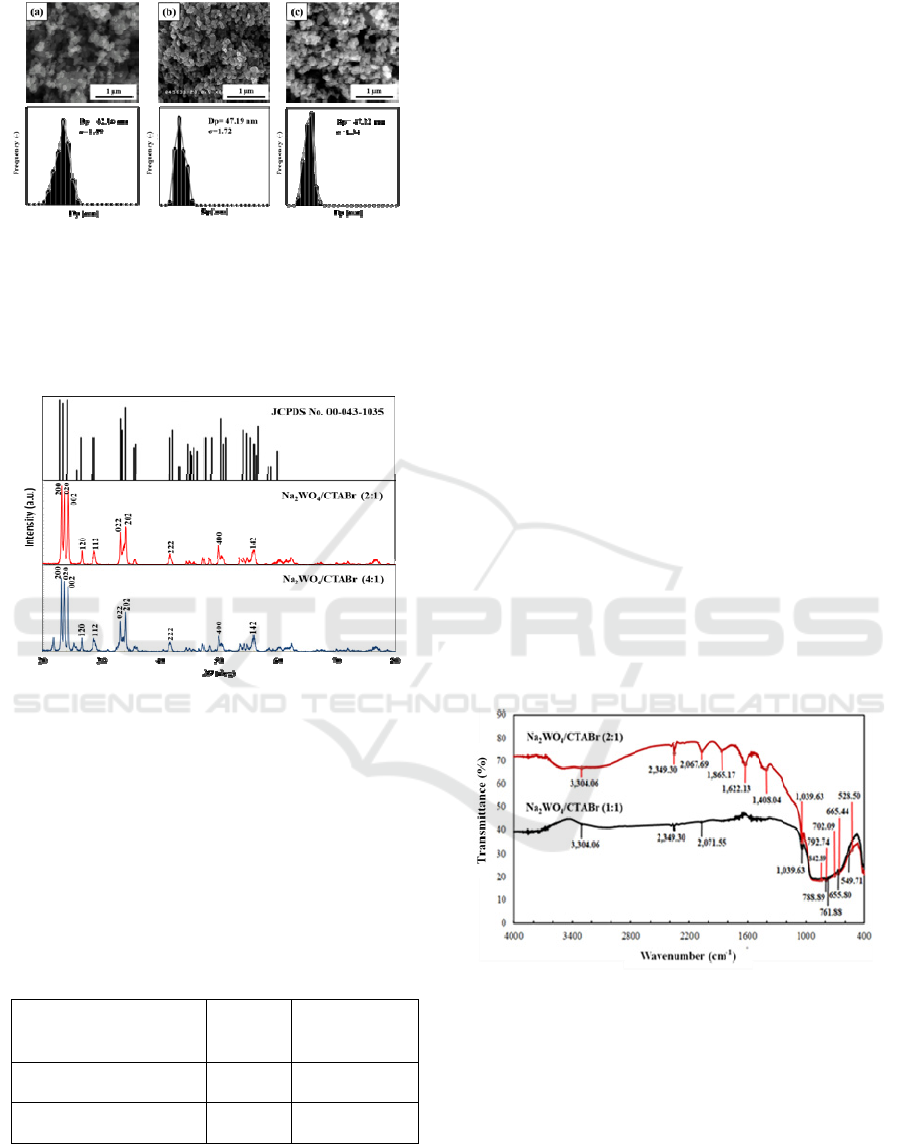

SEM micrographs (Figure 1) showed the

morphology of the resultant WO

3

particles by the

different concentration of sodium tungstate,

including 0.1; 0.2 and 0.3 M after annealing at

500

o

C for 4 h. The morphology of synthesized WO

3

particles exhibits a small spherical shape.

Nonetheless, WO

3

particles show particle size

distribution with a high polydispersity for all molar

ratio used in this work, Na

2

WO

4

(0.1 M, Dp=

42.16) ; Na

2

WO

4

(0.2 M, Dp= 55.27) ; and Na

2

WO

4

(0.3 M, Dp= 47.72). Hence, the results indicate that

the concentrations of Na2WO4 play an insignificant

rôle to tune the particle size. In addition, aggregation

is observed as a small WO

3

particle tends to be

unstable and easier to form aggregates than larger

particles (Szekely et al., 2016). The aggregation is

also plausibly formed due to interactions and

collisions between particles (Morales, 2008).

ICONIT 2019 - International Conference on Industrial Technology

6

Figure 1. Morphology of synthesized WO3 particle with

variation of Na2WO4 concentration (a) 0.1 M, (b) 0.2 M

and (c) 0.3 M.

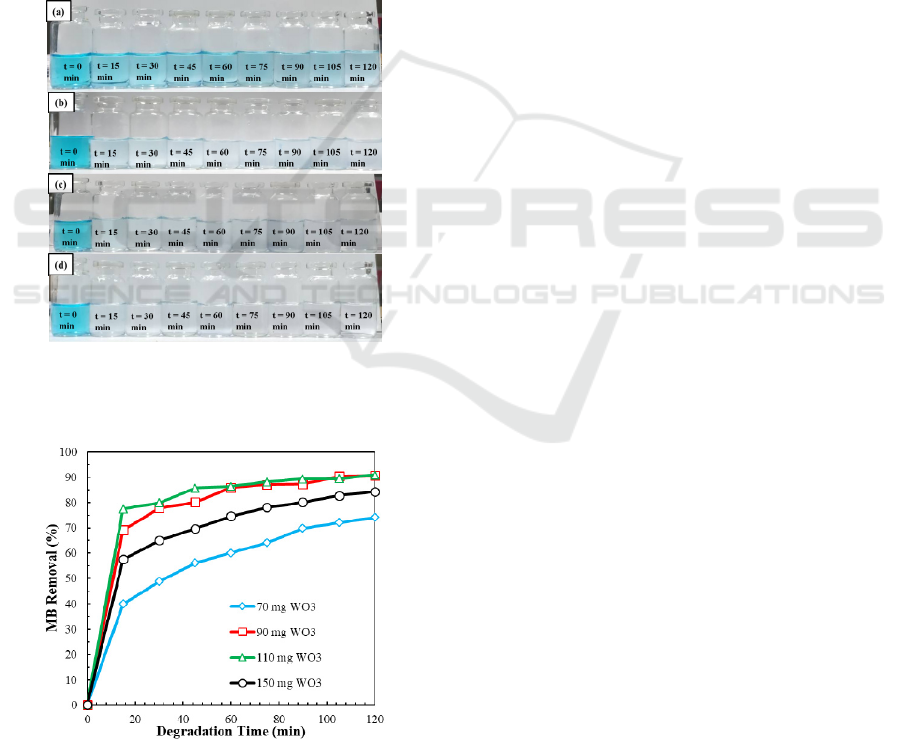

The microstructures of prepared WO

3

particles

were characterized by XRD analysis. The results are

shown in Figure 2.

Figure 2. XRD powder diffractogram of WO

3

with

variations composition of Na

2

WO

4

/ CTABr.

According to JCPDS (No. 00-043-1035), the

prepared WO3 shows characteristic of a monoclinic

WO3 crystal structure indicated by diffraction angle

2ϴ at 23.15°, 23.66°, 24.37°, 26.63°, 28.76°, 33.30°,

34.16°, 41.71°, 49.96°, and 55.93°. The crystallite

size is then estimated using the Scherrer equation

(Table 1).

Table 1. The crystallinity of WO

3

particles with different

composition of Na2WO4/CTABr

WO

3

Sample

Crystal

Size

(nm)

Crystallinity

(%)

Na

2

WO

4

/CTABr (2:1)

40,39 89,33

Na

2

WO

4

/CTABr (4:1)

45.68 90,01

The crystallinity of synthesized WO

3

particle, as

shown in Table 1 also does not show a significant

difference, i.e., the crystallinity is found as high as

90%. It should be noted that the crystallinity is

influenced by the calcination temperature. The

higher the calcination temperature of WO

3

, the

higher the crystallinity (Palupi, 2006). The

crystallite size of WO

3

using Na

2

WO

4

/CTABr (4:1)

is larger than WO

3

Na

2

WO

4

/CTABr (2:1). It is

indicating that CTABr, as a surfactant, is able to

prevent collisions among WO

3

particles during

nucleation leading to a slower formation of WO

3

particles as well as the nucleation rate. Therefore,

the size of the WO

3

particles is getting smaller with

respect to the higher concentration of CTABr (Papp,

1994).

3.2 FTIR Spectra of WO3 Particle

The functional groups of WO

3

particles were

characterized by FTIR, as shown in Figure 3. The IR

spectra exhibit distinct peaks between 400 and 4000

cm

-1

. Both WO3 particles show a peak at 3304.06

cm

-1

, which assigned to the vibration of O-H bonds

of water content in WO

3

(Patel and Vashi, 2015).

Notably, WO

3

particle with the composition of

Na2WO4/CTABr (2:1) shows the OH group

vibration at 1622.13 cm-1 and 1408.04 cm-1

(Petsom et al., 2018). In addition, both WO3

particles exhibit IR peaks at 1039.63 cm-1 that can

be ascribed to W-OH bond vibration (Sanchez-

Martinez et al., 2014). Further IR fingerprint of W-O

bonds is characterized by peaks within the range of

500-1000 cm

-1

.

Figure 3. FTIR spectra of WO

3

Compounds with the

varied composition of Na

2

WO

4

/ CTABr.

Comparing these two particles, WO

3

prepared

using Na

2

WO

4

/ CTABr (2:1) shows a strong vibration

at 842.89, 792.74, 702.09, 665.44, and 528.50 cm

-1

.

Meanwhile, WO

3

prepared using Na

2

WO

4

/ CTABr

(1:1) exhibit slightly different strong vibration bands

at 788.89, 761.88, 655.80, and 549.71. All of these

bands can be indicative of a W-O-W bond (Szekely

et al., 2016). Thus, it can be deduced that pristine

WO

3

particles (without impurities) are obtained.

Preparation and Characterization of Tungsten Trioxide (WO3) Particles and Their Photocatalytic Performances for Methylene Blue

Degradation

7

3.3 Effect of WO

3

amount on MB

Degradation

The initial investigation of photocatalytic activity is

carried out to understand the effect of the WO

3

dose

on the photocatalytic degradation of MB as organic

pollutants. The photoreactor containing 10 ppm of

MB solution and the amount of WO

3

particles tested

is varied by 70 mg, 90 mg, 110 mg, and 150 mg.

The photographs of MB degradation with variations

amount of WO

3

is depicted in Figure 4. Upon the

pictorial view, 70 mg of WO

3

cannot fully degrade

the MB after 120 minutes’ irradiation. However, the

colorless solution is observed upon using at least 90

mg WO

3

catalyst after 120 minutes irradiation. In

addition, maximum degradation is obtained using

150 mg of WO

3

.

Figure 4. Photographes of MB degradation at 120 minutes

using variation amount of WO

3

particle (a) 70, (b) 90, (c)

110, and (d) 150 mg.

Figure 5 The time-dependent MB concentration using

different amounts of WO

3

particle. The amount of MB (10

ppm) was kept constant.

The quantitative results of MB degradation by

WO

3

particle are shown in Figure 5. It is shown that

at least 70% of MB is degraded using 70 mg of the

catalyst after irradiation. The photocatalytic activity

tends to be low at a minimum dose of 70 mg

(39.89% degradation) at 15 minutes, while the high

and rapid photocatalytic activity is obtained using

150 mg, i.e., 95.8% MB is degraded within 15

minutes. Overall, the results show that the rate of

MB degradation depends on the dose of the WO

3

catalyst. The higher concentration of catalyst used

will increase MB percentage removal because the

surface area of the catalyst increases. The increased

surface area influences the number of existing active

sites and the magnitude of the reaction rate of the

photo-generated electron-hole pairs on the surface to

react with water creating more oxidant agents, which

increases the efficiency of photocatalytic activity

(Wang et al., 2019).

It is interesting to note that 110 mg and 150 mg

dose of catalyst do not show significant difference

since the available active sites provided using 110

mg are already sufficient (reach a saturated value) to

adsorb the amount of MB in solution. The stagnant

and even decreasing degradation upon increasing the

dose of catalyst can also be caused by increasing

turbidity. Increasing the turbidity of the solution

decreases the absorption of light, which related by

the number of particles capable of capturing photons

and producing reactive oxidants to degrade organic

compounds (Werth et al., 2003).

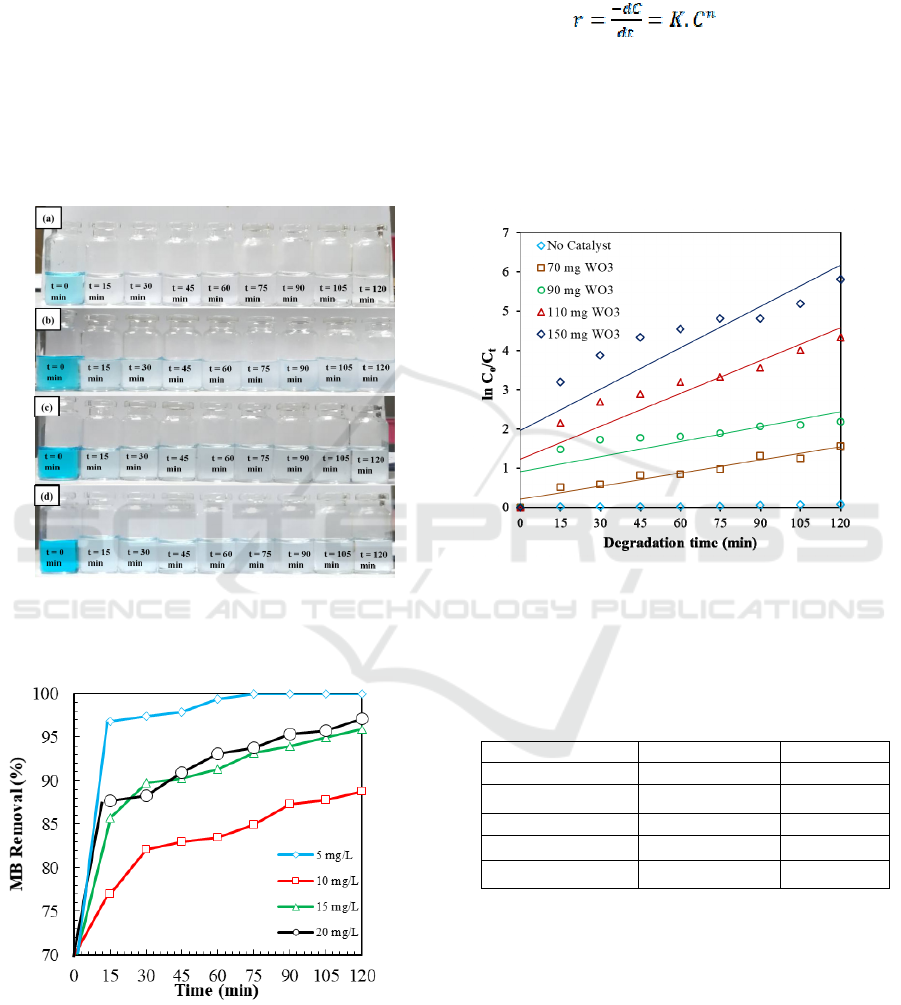

3.4 Effect of MB Concentration

Further investigation is carried out to understand the

effect of MB concentration on the photocatalytic

degradation process. In this regard, the photoreactor

containing 10 mg mL-1 of WO

3

particles was used,

and the concentration of MB solution tested was

varied by 5, 10, 15, and 20 mg L-1. The qualitative

results are indicated in Figure 6, while the

quantitative results are shown in Figure 7.

It is apparent that the concentration of MB as a

coloring agent affects the photocatalytic activity

(Figure 7). The concentration of MB at 5 mg L

-1

has

the largest MB removal, which reaches 100% while

at 10 mg L

-1

MB is the smallest MB removal

(88.7%). For 20 mg L

-1

concentration is MB

removal marked by 90%, while 94% MB removal is

obtained for 15 mg L

-1

concentration. The results

obtained above can be explained as follow: The less

concentrated MB solution (5 mg L

-1

) can increase

the degradation rate because the oxidants OH•

produced by the reaction between catalysts and

ICONIT 2019 - International Conference on Industrial Technology

8

specific H

2

O and H

2

O

2

are able to degrade all MB in

75 minutes. However, in this study, the smallest %

MB removal is owned by the MB concentration of

10 mg L

-1

, which can be due to randomly limited

MB adsorption on the surface of the catalyst and

diffusion at the active site of the catalyst (Wicaksana

et al., 2014). When the MB concentration is

sufficiently high, more MB can be adsorbed and

diffused at the active site of the catalyst. As a result,

more OH• are generated and able to efficiently

degrade MB on the surface catalyst (Zheng et al.,

2011).

Figure 6. Photographes of MB degradation after 120

minutes’ irradiation using variation concentration of MB

(a)5 mg/L, (b) 10 mg/L, (c) 15 mg/L, (d) 20 mg/L.

Figure 7 The corresponding percentage of MB degradation

under various MB concentration. The amount of

WO

3

(110 mg) and stirred at 300 rpm.

In this study, the reaction rate constant (K) is

approached and determined using the homogeneous

system following first-order reaction (n =1). Kinetics

of photodegradation using different amount of WO

3

catalyst is therefore evaluated following pseudo-

first-order kinetic expression:

(3)

Where K is the reaction rate constant, and n is

the order of the reaction. The order of reaction and

reaction rate constants are determined from the

integration of the reaction rate equation resulting in

a linear equation, in which K is the slope of the

linear curve.

Figure 8. Time-dependent ln (Co/Ct) for photodegradation

of MB (10 mg L

-1

) under different amount of WO

3

particles (70, 90, 100, and 150 mg).

Table 2. Reaction rate constants (K) and the coefficient of

determination (R

2

) obtained for photodegradation of MB

using different amount of WO

3

WO

3

amount k ( min

-1

) R

2

No Catalyst k1 = 0.0006 0.9073

70 mg k2 = 0.0111 0.9383

90 mg k3 = 0.0127 0.6198

110 mg k4 = 0.0279 0.8097

150 mg k5 = 0.0351 0.7227

The kinetic study reveals that pseudo-first-order

reaction is sufficient to fit the kinetic data. Hence, it

can be understood that the MB molecules are

physisorbed on the catalyst surface prior to exposing

the photocatalytic process. The kinetic study also

indicates that the increasing amount of WO

3

induces

the rate of reaction to increase as indicated by the

increasing slope at a higher amount of WO

3

. It is

apparent that the amount of WO

3

influences the rate

of the reaction (Table 2). The catalyst amount of 150

mg has the highest reaction rate (0.0351 min

-1

),

Preparation and Characterization of Tungsten Trioxide (WO3) Particles and Their Photocatalytic Performances for Methylene Blue

Degradation

9

while the catalyst amount of 90 mg has the lowest

reaction rate (0.0111 min

-1

). The results obtained

here show promising performance as compared to

the reaction rate obtained for other WO

3

nanostructures reported in the literature (Zheng et

al., 2011; Ernawati et al., 2019).

4 CONCLUSIONS

WO

3

nanoparticles were successfully synthesized by

acidic precipitation-assisted sol-gel method using

Na

2

WO

4

.2H

2

O as a precursor and CTABr as a

reactive agent. It is found that the composition of

CTABr and Na

2

WO

4

.2H

2

O during the synthesis

affects the aggregation formation of WO

3

nanoparticles. However, varying composition does

not yield a significant difference in the crystallinity

of nanoparticles. The photocatalytic degradation test

of MB in aqueous medium indicates a WO

3

dose-

dependent performance as well as MB

concentration-dependent performance. The kinetic

study unravels that the initial mechanism of MB

degradation using WO

3

is physisorbtion of the dye

molecules on catalyst surface as indicated by the

pseudo first-order kinetic fit. The highest reaction

rate constants were obtained by using 150 mg of

WO

3

catalyst (k5 = 0.0351 min

-1

).

ACKNOWLEDGMENT

The author would like to thank Laboratorium Pusat

Sentral Material Maju dan Terbarukan (Universitas

Negeri Malang) for technical assistant of material

characterizations. This research is supported by

Lembaga Penelitian dan Pengabdian Masyarakat

(LPPM) Institut Teknologi Kalimantan, Indonesia.

REFERENCES

Chi Him, A. T., Kai, L., Yuxuan, Z., Wei, Z., Tao, Z.,

Yujie, Z., Ruijie, X., Dennis, Y. C. L., Haibao, H.

2019. Titanium oxide Based photocatalytric materials

development and their role for the air pollutant

degradation: overview and forecast. 125, 200-228.

Chong, M. N., Jin, B, Chow, C. W, Saint, C., 2010. Recent

developments in photocatalytic water treatment

technology: A review. Water Res 44:2997–3027.

Coleman, H. M., Vimonses, V., Leslie, G., Amal, R.,

2007. Degradation of 1,4-dioxane in water using TiO

2

based photocatalytic and H

2

O

2

/UV processes. J.

Hazard Material, 146, 496-501.

Dai, Q., Zhang, Z. He, N., Li, P. Yuan, C., 1999.

Preparation and Characterization of Mesostructured

Titanium Dioxide and Its Application as a

Photocatalyst for the Wastewater Treatment. J.

Materials Science and Enginering. 8-9, 417-423.

Ernest M.H., Tanapon P., Gregory V. L., 2010.

Nanoparticle Aggregation: Challenges to

Understanding Transport and Reactivity in the

Environment. J. Quality, 39, 1909-1924, Carnegie

Mellon University, Qatar.

Fujishima, A., Rao, T. N., Tryk, D. A., 2001. Titanium

dioxide Photocatalysis. J. Photocem and Photobio, 1,

1- 21.

Halliday, D., Resnick, R., Walker, J., 2011. Fundamentals

of Physics. Hoboken, N. J. Wiley.

Indonesia’s Garment and Textile Sector, 2018. Remain

Optimistic Amid Mounting Pressure. Global Business

Guide Indonesia.

J. J. Moses., L. Ammayappan., 2015. Growth of textile

industry and their issues on environment with

reference to wool industry.

Ke, D., Liu, H., Peng, T., Liu, X., 2008. Preparation and

photocatalytic activityof WO

3

/TiO

2

nanocomposite

particles. J. Materials Letters, 62, 447-450.

Kang, Y. S., Myun, K. P., Young, T. K., Hyun, W. L.,

Won, J. C., Wan, I. L., 2001. Preparation of

Transparent Particulate MoO

3

/TiO

2

and WO

3

/TiO

2

Films and Their Photocatalytic Properties. J. Catalyst.

191, 192-199.

Kim, J. O., Traore, M. K., Warfield, C., 2006. The textile

and apparel Industry in Developing Countries. Textile

Progress, 38(3), 1-64.

Michalow, K. A., Heel, A., Vital, A., Amberg, M.,

Fortunato, G., Kowalski, K., Graule, T.J., Rekas, M.,

2009. Effect of Thermal Treatment on the

Photocatalytic activity in Visible Light of TiO

2

-W

flame Spray Synthesized Nanopowders., Top. Catal.

52, 1051-1059.

Morales, W., 2008. Combustion Synthesis and

Characterization of Nanocrystalline WO

3

. The

University of Texas at Arlington, Arlington.

Palupi, E., 2006. Degradasi Methylene Blue dengan

Metode Fotokatalisis dan fotoelektrokalasis

menggunakan film TiO

2

. Skripsi. Institut Teknologi

Bandung.

Papp, J., Soled, S., Dwight, K., Wold, A., 1994. Surface

Acidity and Photocatalytic Activity of TiO

2

,

WO

3

/TiO

2

and MoO

3

/TiO

2

Photocatalysts. Chem.

Mater. 6, 496-500.

Patel, H., Vashi, R. T., 2015. Characterization and

treatment of textile wastewater. Elsevier: 3 -5.

Petsom, K., Kopwitthaya, A., Horphathum, M.,

Ruangtaweep, Y., Sangwarantee, N., Kaewkhao, J.,

2018. Shape-controlled synthesis of tungsten oxide

nanostructures and characterization. J. Metals,

Materials and Minerals, 28, 69-75.

Sanchez-Martinez, D., Hernandez-Uresti, D. B., Cruz, A.

M. L., Guzman-Sepulveda, S., Torrez-Martinez, L.

M., 2014. Characterization and Photocatalytic

properties of hexagonal and monoclinic WO

3

prepared

ICONIT 2019 - International Conference on Industrial Technology

10

via microwave-assisted hydrothermal synthesis. J.

Ceramics, 40:4767-4775.

Szekely, I., Kovacs, G., Baja, L., Danciu, V., Pap. Z.,

2016. Synthesis of shape-tailored WO

3

micro/nanocrystals and the photocatalytic activity of

WO

3/

TiO

2

composites. J. Materials, 9(258), 1-14.

Wang, W. W., Fu, H. T., Yang, X. H., An, X. Z., 2019.

Preparation and visible-light-driven photocatalytic

activity of WO

3

/TiO

2

core-shell nanorods,

International Workshop on Materials Science and

Mechanical Engineering, 504.

Werth J.H., M. Linsenbuhler, S.M. Dammer, Z. Farkas, H.

Hinrichsen, K.-E Wirth, dan D.E. Wolf., 2003.

Agglomeration of Charged in Nanopowder

Suspensions, Germany.

Wicaksana, Y., Liu, S., Scott, J., Amal, R., 2014. Tungsten

Trioxide as a Visible Light Photocatalyst for Volatice

Organic Carbon Removal. J. Molecules, 19, 17747-

17762.

Zheng, H., Ou, J.Z., Strano, M.S., Kaner, R.B., Mitchell,

A., Kalanta-zadeh, K., 2011. Nanostructured Tungsten

Oxide-Properties, Synthesis, and Applications.

Adv.Funct. Mater. 21(12), 2175–2196.

Ernawati, L., Wahyuono, R. A., Muhammad, A. A.,

Nurislam Sutanto, A. R., Maharsih, I. K., Widiastuti,

N., Widiyandari, H., 2019. Mesoporous WO

3

/TiO

2

Nanocomposites Photocatalyst for Rapid Degradation

of Methylene Blue in Aqueous Medium. International

Journal of Engineering TRANSACTION A: Basics, 32,

1345-1352.

Preparation and Characterization of Tungsten Trioxide (WO3) Particles and Their Photocatalytic Performances for Methylene Blue

Degradation

11