A Novel Correlation on MMP Prediction in CO2-LPG Injection System:

A Case Study of Field X in Indonesia

Prasandi Abdul Aziz, Hendra Dwimax, Tutuka Ariadji, Steven Chandra, Wijoyo Niti Daton, Ressi

Bonti

Petroleum Engineering Program, Institut Teknologi Bandung, Bandung, Indonesia

Keywords:

Minimum Miscibility Pressure, Slimtube Experiment.

Abstract:

In order to increase Indonesia’s petroleum production, which mostly comes from the marginal field, an En-

hanced Oil Recovery (EOR) method is needed. One EOR method that is proven to be able to increase large oil

yield is mixed CO2 injection. In implementing EOR CO2 injection mixed, the Minimum Reliability Pressure

(MMP) value is the key to success. One of the problems faced by oil fields in Indonesia in carrying out EOR of

mixed CO2 injection is that the reservoir pressure has dropped due to old age making it difficult to inject with

MMP pressure above the reservoir pressure. The solution that can be done to overcome this is by reducing the

MMP value using Liquified Petroleum Gas (LPG).This study will determine the optimal method of LPG use

to reduce CO2 injection MMP values from Field X fluid in South Sumatra. Then, the MMP value in various

conditions will be determined using a slimtube simulation which will be used to make a correlation to deter-

mine the MMP value. From the results of the study, in principle mixing LPG with CO2 will reduce the MMP

value optimally. In addition, the average MMP value dropped by 29.5% with an increase in the composition

of LPG in the gas mixture of CO2 - LPG injection by 30%, the MMP value increased by 23% with a change

in hexane plus molecular weight of 27.5% higher than before, and the MMP value increased by an average of

13.4% with an increase in temperature of 20%.The resulting correlation is formed using parameters that have

a significant influence on the determination of the MMP value. The resulting correlation has R-Squared of

98.65%. The correlation is then tested with MMP values previously determined through a slimtube simulation

and produces an Average Absolute Relative Error (AARE) value of 4.52%. Correlation was then re-tested

against the correlations of other MMP determinations using 9 fluid MMP data from other literature. The result

is the proposed correlation produces an AARE value of 10.82%.

1 INTRODUCTION

Production of crude oil and condensate in Indonesia

is 803,000 barrels per day in 2017 (Statistics of the

Ministry of Energy and Mineral Resources). Mean-

while, Indonesia’s national oil consumption currently

reaches 1.6 million barrels per day and continues to

increase (Statistical Review of World Energy 2017

BP). This means that crude oil production in Indone-

sia is smaller than consumption of petroleum as an en-

ergy source. In addition, Indonesia’s petroleum pro-

duction has experienced a downward trend of 1.35%

every year since 2012 (Statistics of the Ministry of

Energy and Mineral Resources). Indonesia needs to

make breakthroughs in order to increase its petroleum

production.

One such breakthrough is Enhanced Oil Recov-

ery (EOR). The breakthrough is a step to increase oil

acquisition if a field has gone through the primary re-

covery stage, which is the stage where the reservoir

fluid can flow by itself; and the secondary recovery

stage, which is the stage where the field is injected

with gas or water to maintain pressure in the reservoir

so that it does not drop dramatically (Lake, 1989).

EOR is the third step or tertiary recovery.

One type of EOR method that is quite well known

is CO2 injection. CO2 injection is still rarely used in

fields in Indonesia. There are 2 mechanisms for CO2

injection, namely: miscible injection (mixed injec-

tion) and immiscible injection (injection not mixed).

From the literature study conducted, it is known that

miscible injection produces oil that is greater than im-

miscible injection. This also underlies the research

focus on the miscible CO2 injection mechanism.

In performing miscible CO2 injection, the Mini-

mum Miscibility Pressure (MMP) value is very im-

Aziz, P., Dwimax, H., Ariadji, T., Chandra, S., Daton, W. and Bonti, R.

A Novel Correlation on MMP Prediction in CO2-LPG Injection System: A Case Study of Field X in Indonesia.

DOI: 10.5220/0009359802850290

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 285-290

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

285

portant to know. MMP is the minimum pressure so

that the reservoir fluid and injection fluid can mix.

Unfortunately, the value for miscible CO2 injection is

quite high considering the reservoir pressure has dras-

tically reduced because of the primary and secondary

production stages. As a result, the injected CO2 can-

not mix with the oil in the reservoir and the miscible

CO2 injection mechanism can be considered a failure.

There are two methods for this problem, namely:

• Injecting another gas into the reservoir so that the

intermediate component (C2-C6) of hydrocarbons

in the reservoir increases before injecting CO2, or

• Mixing the other gases with CO2 gas on the sur-

face then inject the mixed gas into the reservoir.

Both of these methods are carried out so that the

MMP value of the reservoir fluid against CO2 can

decrease and the fluid can mix at the current reser-

voir pressure.

The mixed gas is generally a hydrocarbon intermedi-

ate component such as propane and butane. It was

also known that the biggest decrease in MMP was in

mixing between CO2 and butane with a ratio of 40:60

(Muslim dan Permadi, 2016; Permadi, 2014; Rom-

merskirchen and Nijssen, 2016). In this study, the gas

used as a mixture of CO2 to be injected is LPG, as-

suming the main constituent is propane.

Field X in South Sumatra is one field that has been

operating since 1987. The field includes the old field

category (brownfield). The Feasibility Study (FS)

conducted by the Bandung Institute of Technology

(ITB) team on Field X showed that the EOR method

that was right for the field was CO2-EC miscible so

that the value of MMP was needed. Fluid data from

Field X was obtained from reservoir and fluid descrip-

tion data in the Final Report of Feasibility of Field X

in 2009. This study will try to determine CO2 in-

jection MMP from Field X fluid in various conditions

using a mixture of LPG on gas injection. The ultimate

goal of this study is to form a correlation that can be

used to determine the value of MMP injection of pure

CO2 or CO2 - LPG on Field X and compare it with

other correlations that have been formed.

2 ANALYSIS ON MINIMUM

MISCIBILITY PRESSURE

Minimum Miscibility Pressure (MMP) is the low-

est pressure for a gas to be mixed through a multi-

contact process with reservoir oil at reservoir tem-

perature (Elsharkawy, ). MMP can actually be di-

vided into two, namely multiple contact miscibility

pressure (MCMP) and first-contact miscibility pres-

sure (FCMP). The MCMP value must be below the

FCMP value (Holm, 1987; Martin and Taber, 1992).

However, as explained earlier, MMP in this study uses

MCMP as the definition of MMP. This is because mis-

cibility for EOR can be achieved at pressures below

FCMP and above MCMP (Zhang et al., 2004). There

are several definitions of MMP CO2 injection mathe-

matically, namely:

• Pressure when oil is equal to or very close to the

maximum final gain when 1.2 pore volume (PV)

is injected (Yellig et al., 1980).

• Pressure which causes oil acquisition as much as

80% in CO2 breakthrough and oil yield of 94%

at gas to oil ratio of 40000 SCF / stb (Holm and

Josendal, 1974).

• Pressure that causes oil recovery of 90% or more

at CO2 injection of 1.2 PV (Glaso, 1985).

In this study, Glaso’s definition was used to determine

MMP using a slimtube simulation. Some parameters

that affect the MMP value are as follows.

• Reservoir temperature. An increase in reservoir

temperature will increase the MMP value.

• Oil composition. The higher the composition of

the intermediate component C2 - C6 and the lower

the composition of the heavy component of oil,

the lower the MMP value.

• Gas injection composition. The higher the com-

position of the intermediate component C2 - C6

gas injection, the lower the MMP value. (Zhang

et al., 2015).

These parameters will be used as the main param-

eter to perform sensitivity and correlation formation.

MMP Correlation and LPG Injection. There are

several determinants of the MMP value of injection

of pure CO2 that has been previously formed. The

correlation used as a comparison in this study is the

correlation of Cronquist, Lee, Yelling-Metcalfe, Orr-

Jensen, Alston, Emera-Sarma, Yuan, Shokir, Chen,

Ju, and Hao Zhang (Ju et al., 2012; Al-Hinai et al.,

2014; Bayagub, 2017; Bon and Sarma, 2005).

Gas injection of Liquified Petroleum Gas (LPG)

has a lower MMP value than the MMP value for CO2.

The use of LPG in EOR is relatively more benefi-

cial than the use of other light hydrocarbons (Ortega,

2017). According to a study conducted by Holm,

CO2 injection can have oil yield of up to 75% while

by using LPG, oil yield can reach 95%.

LPG injection will help develop oil volume, re-

duce oil density, and reduce oil viscosity. In addition,

LPG moves residual oil that is spread in the reservoir

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

286

(Bayat, 2015). Even so, LPG costs have an expen-

sive price. With these conditions, it is necessary to

mix CO2 with LPG so that the obtained oil is higher

and the price is economical (Kumar and Von Gonten,

1973). The LPG used in this study was propane

(C3H8).

Slim Tube Injection Process. Slimtube simulation

in IPM - PVTP vers software. 9.5 is used to determine

the MMP value in various field conditions of X. The

simulation of the slimtube is used because the use of

the slimtube in the laboratory will take a very long

time and the costs are not cheap. Slimtube modeled

in this simulation has 10 cells, where each cell has a

size of 2.3727 ft in the x-direction, 0.0113686 ft in the

y-direction, and 0.0113686 ft in the z-direction. The

porosity used for the slimtube model is taken from the

average porosity of Field X, which is 0.16275. The

permeability of the slimtube model is also taken from

the average permeability of Field X, which is equal

to 63.5 mD. The Field X reservoir depth becomes the

slimtube depth input data, which is 6490 ft. To de-

termine the MMP value, the Slimtube simulation re-

quires a definition for the MMP value. As mentioned

in the previous chapter, the MMP value is the pressure

at which 90% or more oil has been obtained when in-

jecting a gas of 1.2 pore volume into the slimtube.

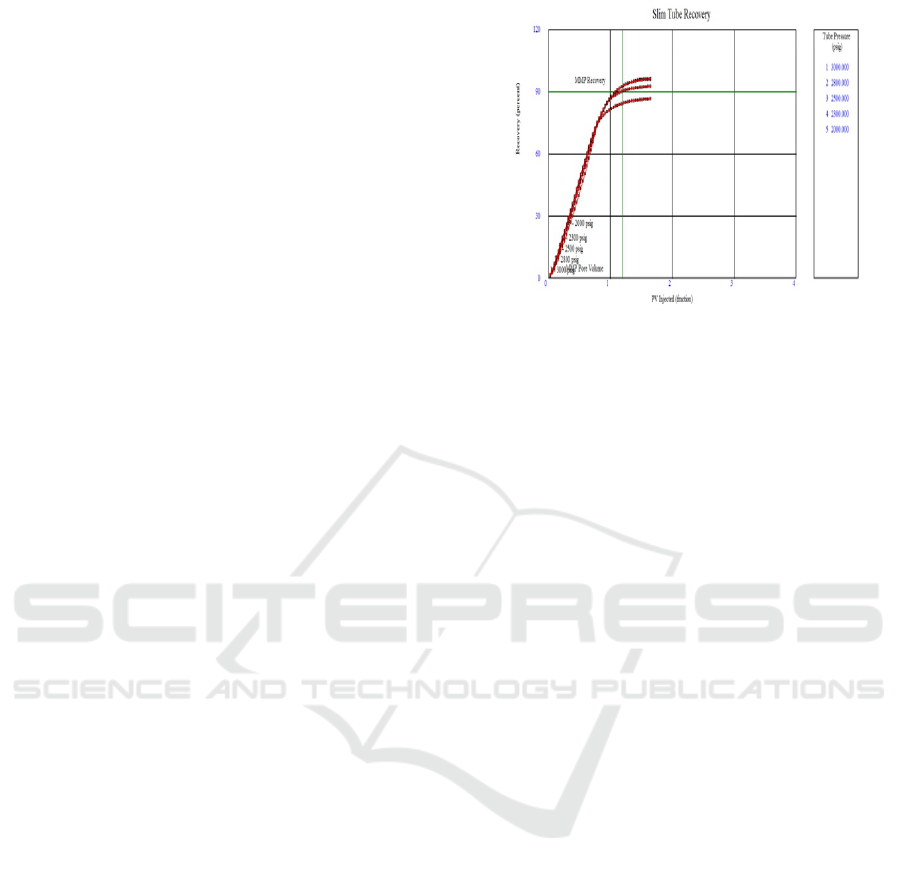

The results of the slimtube simulation to determine

MMP under certain conditions will be displayed in

the graph of recovery vs pore volume. An example

of the MMP determination can be seen in Figure 1.

Before determining the MMP value in various con-

ditions, it is necessary to validate whether the fluid

model to be simulated on the Slimtube in the PVTP

software has the same MMP value as the fluid MMP

when tested with a slimtube in the laboratory. The

field X MMP oil value on the slimtube test from the

laboratory test was 2820 psi. In the slimtube simula-

tion for this validation, the CO2 injection MMP value

was 2870 psi. An error of 50 psi or 1.77% is con-

sidered to be tolerable and the determination of MMP

using a slimtube simulation and the fluid model in this

PVTP can be started.

To do a slimtube simulation, gas injection is

needed. In this study, there are 2 methods to be tested,

namely injection of LPG first into the reservoir fluid

and then injecting CO2 and injection of a mixture of

CO2 and LPG into the reservoir fluid.

For the first method, the reservoir fluid will be in-

jected with LPG by comparison as follows.

• 95% reservoir fluid and 5% LPG

• 90% reservoir fluid and 10% LPG

• 80% reservoir fluid and 20% LPG

Figure 1: Example of Slimtube Simulation.

• 70% reservoir fluid and 30% LPG

Next, the value of MMP is determined by the second

method. The injection gas used is as follows.

• 100% CO2

• 70% CO2 and 30% LPG

• 60% CO2 and 40% LPG

• 50% CO2 and 50% LPG

Both methods were tested with the same weight

temperature and molecular weight components,

namely 263,525 oF and 196,073 gr / mol. Further-

more, one method will be selected for further study

by conducting sensitivity to temperature, weight of

molecular weight components, and LPG composi-

tion. These parameters are selected based on literature

studies that have been done before. The sensitivity for

each parameter is as follows.

• Temperature (250, 263,525 and 300 oF)

• MW C6 + (196,073, 225 and 250 gr / mol)

• LPG composition (0%, 30%, 40%, and 50%)

3 RESULTS AND DISCUSSION

The next step is to form a correlation that can deter-

mine the MMP value for Field X with the constituent

variables in the form of parameters that are significant

to the MMP value. The formation of this correlation

uses the Design of Experiment (DOE) method as de-

scribed previously. The DOE feature in MINITAB 17

software with the Two-Level Factorial Design model

requires 8 input data in the form of MMP values be-

cause there are 3 parameters to be tested. Each param-

eter requires input data in the form of maximum and

minimum sensitivity values. Then, the MMP value

A Novel Correlation on MMP Prediction in CO2-LPG Injection System: A Case Study of Field X in Indonesia

287

for each pair of sensitivity values between parameters

was included in MINITAB 17. The input data for this

DOE can be seen in Table 7.

Table 1: DOE Input Data.

MW

C6+

Co2 Temperature

(

◦

f)

MMP(psi)

196.073 100 250 2795.00

196.073 50 250 1336.33

196.073 100 300 3025.00

196.073 50 300 1788.75

250 100 250 3455.00

250 50 250 1920.00

250 100 300 3900.00

250 50 300 2122.82

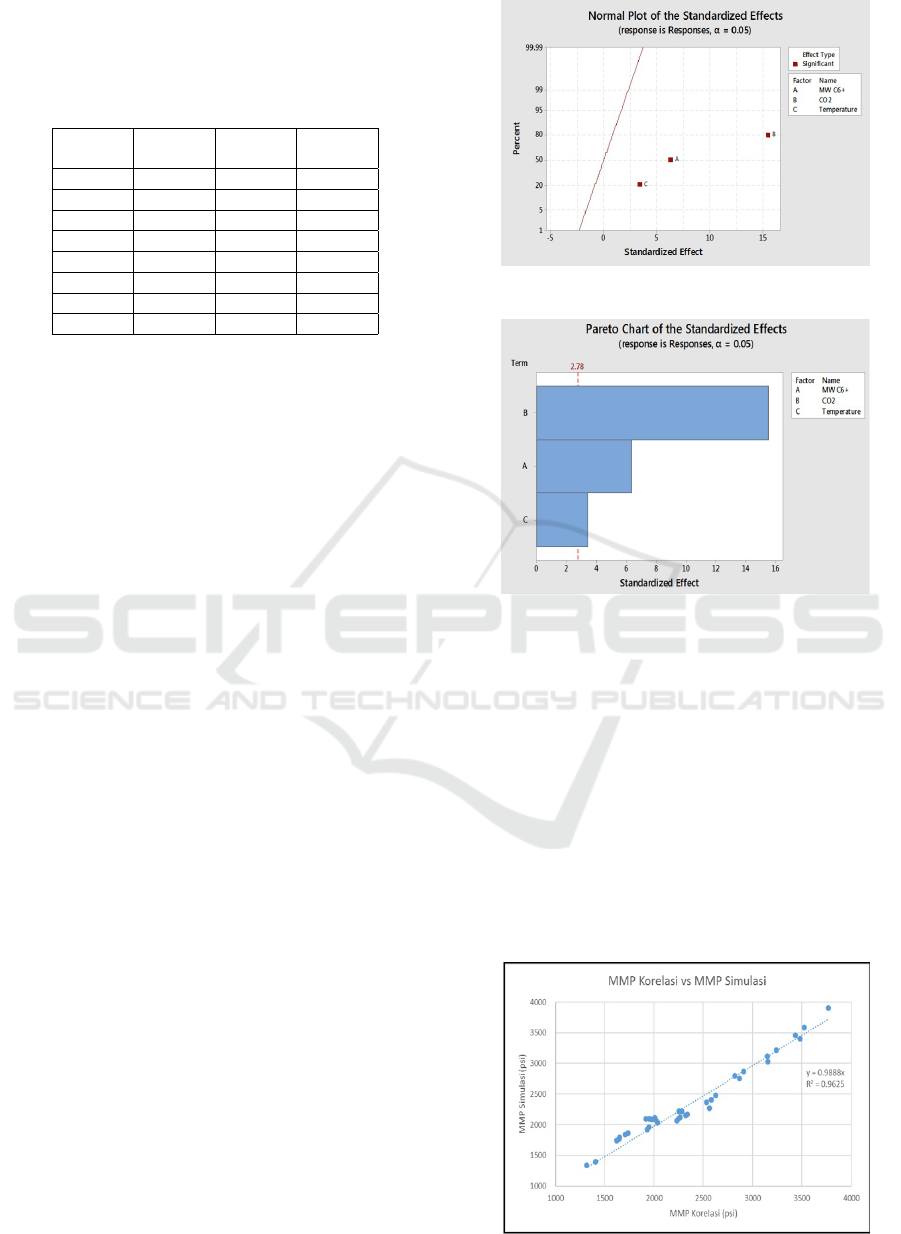

The results obtained for the DOE in this study can

be seen in the Pareto Chart and Normal Plots shown

in Figure 2 and Figure 3. In the Pareto Chart, it can

be seen that the three parameters have a significant ef-

fect on the determination of the MMP Field X value.

This can be seen from 3 the parameter bar has crossed

the minimum line which indicates the boundary of a

parameter has a significant effect or not. From the

Pareto Chart, it can be seen that the parameter with

the most significant effect is the composition of CO2 -

LPG, then followed by the molecular weight of C6 +,

and finally the temperature. This shows that the effect

of the composition of CO2 - LPG is the most impor-

tant parameter in reducing MMP on case of Field X.

In addition, Normal Plot also shows that all three pa-

rameters have a significant effect on MMP values and

CO2 - LPG composition parameters having the far-

thest point from the normal line. This again confirms

how the composition of CO2 - LPG has the most sig-

nificant effect. The three parameters are to the right

of the normal line which indicates that the higher the

value of the parameter, the MMP value will also in-

crease (positive effect). This is because in this DOE

test the composition parameters of CO2 - LPG only

use CO2 input as a parameter so that the increase

in CO2 composition will certainly increase the MMP

value.

Furthermore, MINITAB 17 software forms a cor-

relation consisting of these parameters. The correla-

tion formed is a linear correlation. The correlation is

as follows.

MMP = - 4075 + 11.37 x (MW C6) + 30.04 x (CO2)

+ 6.65 x (T)

From the correlation, the R-Squared value is

98.65%, with the Standard Error of Regression (S) of

136,754. The correlation summary model is shown in

Table 2. This shows that the resulting correlation is

very good and has a high match with the input data.

Furthermore, a feasibility test for the correlation

Figure 2: Normal Plot of Parameter Effects.

Figure 3: Pareto Chart of The Correlation.

that has been formed is carried out by calculating the

previous MMP value. From the results, it can be seen

that the Average Absolute Relative Error (AARE)

value is 4.52% with Maximum Absolute Relative Er-

ror (MARE) of 13.22%. In addition, a graph plot was

carried out between the slimtube MMP value and the

MMP value calculated using correlation. The results

can be seen in Figure 4. The R-Squared generated

in this graph is 96.47% which means that this corre-

lation is considered to determine the MMP value for

Field X.

Figure 4: Accuracy of the New MMP Correlation.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

288

Table 2: Correlation Summary.

S R-sq R-sq(adj) R-sq(pred)

136.754 98.65% 97.64% 94.62%

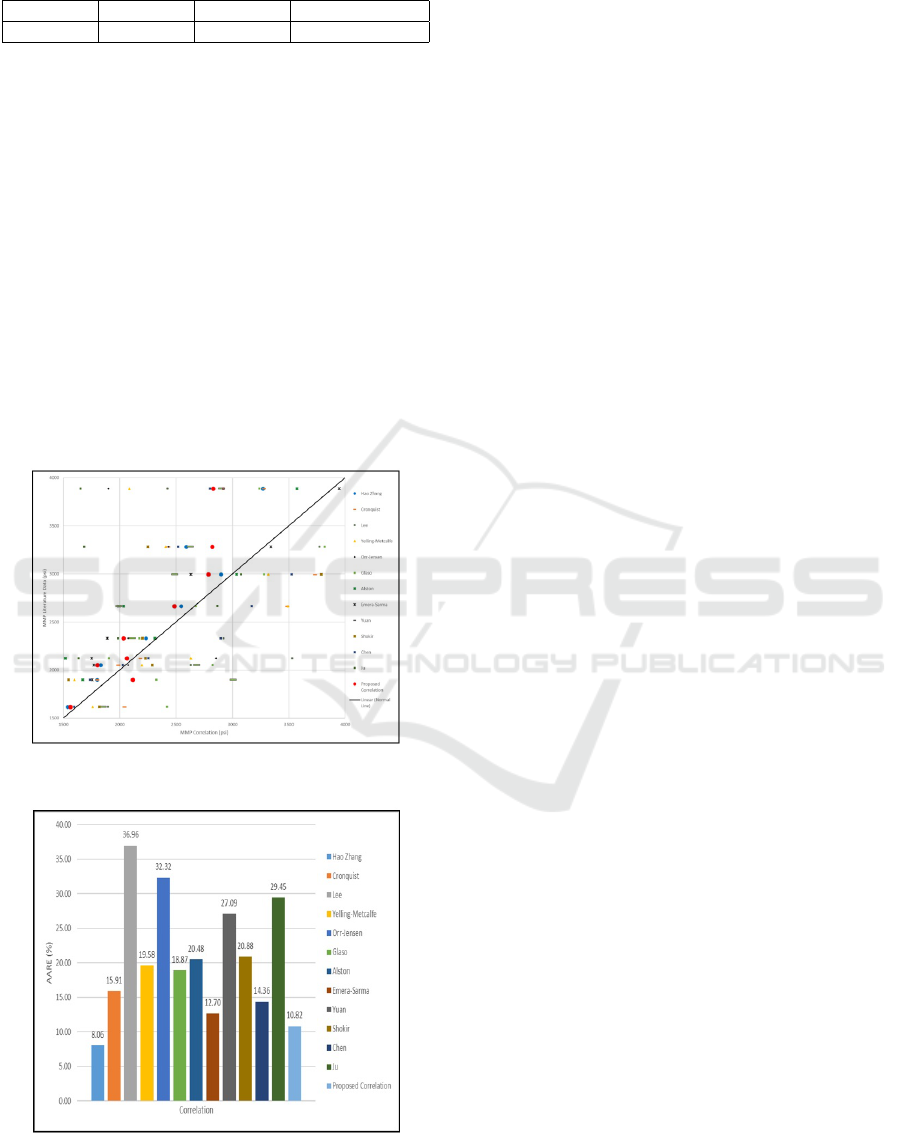

Correlations that have been formed will then be

compared with various other correlations. There are

12 correlations that will be used to test the feasibil-

ity of the correlations that have been formed. The 12

correlations were the correlations of Cronquist, Lee,

Yelling-Metcalfe, Orr-Jensen, Alston, Emera-Sarma,

Yuan, Shokir, Chen, Ju, and Hao Zhang. This correla-

tion will be used to calculate MMP values in various

oil conditions. There are 9 oil data with various com-

positions and temperatures obtained from various lit-

erature. The oil data will be used as input data for cal-

culating MMP values with the correlations mentioned

above. Comparison between MMP correlation values

and literature MMP is shown in Figure 5. In addi-

tion, the AARE value of each correlation is shown in

Figure 6.

Figure 5: Comparison of MMP Calculation Correlation.

Figure 6: AARE Comparison of MMP Correlations.

From the results of calculations that have been

made, it can be seen that the correlation proposed in

this study has AARE and MARE values of 10.82%

and 27.18%. Meanwhile, the correlations of Cron-

quist, Lee, Yelling-Metcalfe, Orr-Jensen, Alston,

Emera-Sarma, Yuan, Shokir, Chen, Ju, and Hao

Zhang produced an AARE score of 15.91%, 36.96%,

19.58%, 32.32% respectively. , 18.87%, 20.48%,

12.70%, 27.09%, 20.88%, 14.36%, 29.45%, and

8.06%. This means that the correlation formed has

quite good results because other correlations have a

greater AARE value, except for the correlation of Hao

Zhang who has AARE of 8.06%. This can occur be-

cause the correlation formed in this study uses C6 +

heavy components while the input data is C7 +. In ad-

dition, the parameters for the formation of correlation

in this study have not been checked with a broader

value. Even so, the results of calculating the MMP

value using the correlation formed from this study can

be said to be better than some of the existing correla-

tions.

4 CONCLUSIONS

Based on the studies that have been done, the obtained

conclusion as follows.

• The method of reducing CO2 injection MMP by

mixing LPG and CO2 first successfully reduces

MMP significantly more than the CO2 injection

MMP reduction method by mixing LPG into Field

X oil. Thus, the mixing method of LPG and CO2

is the most optimal method to reduce CO2 injec-

tion MMP in Field X.

• In Field X, the composition of CO2 - LPG, C6

+ molecular weight, and temperature are parame-

ters that significantly influence the CO2 injection

MMP value. The average MMP value decreased

by 29.5% with an increase in the composition of

LPG in the gas mixture of CO2 - LPG injection by

30%, the MMP value increased by an average of

23% with a change in molecular weight of hexane

plus of 27.5% higher than before, and the MMP

value increased by an average of 13.4% with an

increase in temperature of 20%.

• The resulting correlation to determine the value

of MMP of CO2 injection in Field X is as fol-

lows. MMP = - 4075 + 11.37 x (MW C6) +

30.04 x (CO2) + 6.65 x (T). The correlation has R-

Squared of 98.65% and AARE between the MMT

results of the slimtube simulation and the correla-

tion is 4.52%.

• The resulting correlation has AARE of 10.82%

and MARE of 27.18% when tested using data

A Novel Correlation on MMP Prediction in CO2-LPG Injection System: A Case Study of Field X in Indonesia

289

from other literature. Correlations of Cron-

quist, Lee, Yelling-Metcalfe, Orr-Jensen, Alston,

Emera-Sarma, Yuan, Shokir, Chen, Ju, and Hao

Zhang produced AARE values in a sequence

of 15.91%, 36.96%, 19.58%, 32.32%, 18.87%

, 20.48%, 12.70%, 27.09%, 20.88%, 14.36%,

29.45%, and 8.06%. Compared to other corre-

lations, the correlation formed in this study re-

sulted in a fairly good MMP value because it has

a smaller AARE value, except the Hao Zhang cor-

relation which has an AARE value of 8.06%.

REFERENCES

Al-Hinai, K., Al-Bemani, A., and Vakili-Nezhaad, G.

(2014). Experimental and theoretical investigation of

the co2 minimum miscibility pressure for the omani

oils for co2 injection eor method. International Jour-

nal of Environmental Science and Development.

Bayagub, F. (2017). Study of Miscible Flooding Design Us-

ing LPG Mixture to Increase Oil Recovery. Institut

Teknologi Bandung, Bandung.

Bayat, A. (2015). Application of co2-based vapor extrac-

tion process for high pressure and temperature heavy

oil reservoirs. Journal of Petroleum Science and En-

gineering.

Bon, J. and Sarma, H. (2005). An investigation of mini-

mum miscibility pressure for co2 - rich injection gases

with pentane-plus fraction. Kuala Lumpur: Society of

Petroleum Engineers.

Elsharkawy, A. Measuring co2 mmp: Slimtube or rising

bubble method? Energy and Fuel, 10:2.

Glaso (1985). ”generalized minimum miscibility pressure

correlation”. paper spe 12893 pa. In SPE Annual Tech-

nical Conference and Exhibition. San Antonio, Texas.

Holm, L. (1987). Miscible displacement. Petroleum Engi-

neering Hand Book, Society of Petroleum Engineers,

page 1–45.

Holm, L. and Josendal, V. (1974). Mechanisms of oil dis-

placement by carbon dioxide. Society of Petroleum

Engineers, 4736.

Ju, B., Qin, J., Li, Z., and Chen, X. (2012). A pre-

diction model for the minimum miscibility pressure

of the co2-crude oil system,. Acta Petrolei Sinica,

33(2):274–277.

Kumar, N. and Von Gonten, W. (1973). An investigation of

oil recovery by injecting co2 and lpg mixtures. 48th

annual fall meeting. of the Society of Petoleum Engi-

neers of AIME. Las Vegas: American Institute of Min-

ing, Metallurgical, and Petroleum.

Lake, L. (1989). Enhanced Oil Recovery. Prentice-Hall,

Inc, USA.

Martin, D. and Taber, J. (1992). Carbon dioxide flooding.

Society of Petroleum Engineers.

Muslim dan Permadi, A. (2016). Pencampuran gas co2 un-

tuk menurunkan tekanan tercampur minimum: Studi

kasus pada lapisan ab-4 dan ab-5 formasi air benakat,

cekungan sumatera selatan jurnal teknologi minyak

dan gas. Bumi, 10(1).

Ortega, A. (2017). Effect of liquified petroleum gas (lpg) on

heavy oil recovery process. The Italian Association of

Chemical Engineering.

Permadi, A. (2014). Introduction To Petroleum Reservoir

Engineering. ITB, Bandung.

Rommerskirchen, R. and Nijssen, P. (2016). Reducing the

miscibility pressure in gas injection oil recovery pro-

cesses. abu dhabi. In International Petroleum Exhibi-

tion & Conference in Abu Dhabi, UAE, page 7–16.

Yellig, W., , and Metcalfe, R. (1980). Determination and

prediction of co2 minimum miscibility pressure. Jour-

nal of Petroleum Technology, 32:1.

Zhang, H., Hou, D., and Li, K. (2015). An improved co2-

crude oil minimum miscibility pressure correlation.

Technical report, School of Energy, Chengdu Univer-

sity of Technology, Chengdu, Sichuan.

Zhang, P., Sayegh, S., , and Zhou, X. (2004). Effect

of co2 impurities on gas-injection eor processes. In

SPE/DOE Fourteenth Symposium on Improved Oil

Recovery held in Tulsa. Oklahoma, U.S.A.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

290