Surface Structure and Morphology of Gallium Nitride Thin Film

Grown on Molybdenum Disulfide Layer

by Molecular Beam Epitaxy

Iwan Susanto

1,2

, Ing-Song Yu

1

, Dianta Mustofa Kamal

2

, Belyamin

2

, Fuad Zainuri

2

,

Sulaksana Permana

2,3

, Chi-Yu Tsai

1

, Yen-Ten Ho

4

, Ping-Yu Tsai

5

1

Department of Materials Science and Engineering, National Dong Hwa University, Hualien 97401, Taiwan ROC

2

Department of Mechanical Engineering, State Polytechnic of Jakarta, Depok 16424, Indonesia

3

Center of Mineral Processing and Corrosion Research, Department of Metallurgy and Materials Engineering,

University of Indonesia, 16424 Depok, Indonesia

4

International College of Semiconductor Technology, National Chiao Tung University, Hsinchu 300, Taiwan ROC

5

Department of Electronic Systems Research Division, Chung-Shan Institute of Science & Technology,

Tao-Yan 325, Taiwan ROC

belyamin@mesin.pnj.ac.id, fuad.zainuri@mesin.pnj.ac.id, sulaksana@yahoo.com

Keywords: Gallium Nitride, Thin Films, Molybdenum Disulfide, Surface Character

Abstract: The layer of gallium nitride thin film was grown near to the surface of the molybdenum disulfide substrate

by plasma-assisted molecule beam epitaxy (PA-MBE) system. In-situ RHEED and ex-situ characterization

of AFM and SEM were used to exploit subsequently the surface character of GaN films. The results show

that the RHEED pattern demonstrated the mix structure of polycrystalline and amorphous with 2-

dimensional (2D) growth mode. The crystalline structure was influenced by the defect constructed in the

GaN films. Meanwhile, the 3D AFM image served in detail the smooth surface with root mean square

(RMS) of 3.87 nm. Further, the SEM image with an EDS pattern performed the fixture of morphology and

surface composition. However, Ga cluster like particles presented on the surface of the GaN layer. The

sufficient of the thermal energy with the crystalline structure provided by the substrate would be a

promising approach for creating GaN film with greater structures and smoother surface.

1 INTRODUCTION

GaN semiconductor is an interesting material

because it has several excellent properties like high

electrons mobility, high conductivity and chemically

stable (Kawashima et al., 1997; Hanada, 2009).

According to this feature, GaN was utilized for some

applications of optoelectronic devices and electronic

components (Würtele et al., 2011; Su, Chen and

Rajan, 2013; Joshin et al., 2014; Chen et al., 2017).

Unfortunately, GaN layers are generally grown on

other materials substrate, since the GaN bulk has

been a high-cost material as subtract (Liu and Edgar,

2002). Several attempts have been done for growing

GaN layers on other materials (Kukushkin et al.,

2008). However, the lattice-mismatched with

different thermal expansion coefficient rises the

residual stress which could create defects in GaN

film during the cooling process (Trampert, 2002;

Poust et al., 2003). In general, the defects will be

started from the surface boundary in the interface of

two materials and afterward they propagate to the

inside of the film up to the surface of GaN film

(Trampert, 2002).

Several efforts have been strived for reducing the

residual strain by growing the GaN layer on the

close-lattice matched (Mánuel et al., 2010; Gupta et

al., 2016) (Susanto, C.-Y. Tsai, et al., 2019).

Recently, MoS

2

as an interesting semiconductor

material applied for optoelectronic which is grown

on GaN material (Wan et al., 2018; Zhang et al.,

2018). Since the MoS

2

has been a lattice-matched

with closed to GaN, it becomes a promising chance

for growing high-quality GaN film layers.

Moreover, GaN films are usually grown with a thick

layer until 1.8 µm (Kimura et al., 2005), So that the

Susanto, I., Yu, I., Kamal, D., Belyamin, ., Zainuri, F., Permana, S., Tsai, C., Ho, Y. and Tsai, P.

Surface Structure and Morphology of Gallium Nitride Thin Film Grown on Molybdenum Disulfide Layer by Molecular Beam Epitaxy.

DOI: 10.5220/0009871000002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 27-30

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

27

defects were not seen on the surface of the film. On

the other hand, observations of the GaN film surface

near the substrate surface have also not been

reported more clearly. It will be an interesting

section to investigate the thin layer near to the

surface substrate which has a potential area to

generate serious defects at the surface boundary.

So, in this study, we investigated the surface

structure and morphology of GaN grown near to the

surface of the MoS

2

layer by molecular beam

epitaxy technique. The surface of the substrate and

GaN film was observed using in-situ and ex-situ

characterization techniques. Observation of two

surfaces is carried out using RHEED, AFM, and

SEM. The results of the characterization will be

presented in 2-dimensional (2D) and 3-dimensional

(D) images. Structure and character of the surface

will be analyzed using the results of RHEED

monitoring. Whereas surface roughness will be

monitored using AFM. Meanwhile, the morphology

and composition of surface elements will be

investigated by SEM.

2 EXPERIMENTAL METHOD

The GaN layer was grown on the MoS

2

substrate

using the PA-MBE system. While, the substrate used

to deposit the MoS

2

layer is a single crystal of c-

plane sapphire by the PLD method (Ho et al., 2015).

The deposited temperature was given at 800 C with

a background pressure at 8 x 10-6 Torr. For GaN

film, the growth temperature is determined at 600 C

for 20 minutes with a substrate rotation speed of 10

rpm. All of the growth parameters have been done in

our previous study (Susanto, C. Tsai, et al., 2019).

Before the growth process of the GaN layer, the

substrate is heated up to 600 for 40 minutes to clean

contaminants on the surface. The growth of the GaN

layer carried out using K-cell as a producer of Ga

atoms at 800 C and facilitated by a nitrogen gun as a

source of N atoms with a flow rate of 0.8 sccm at Rf

power 500 Watt. The ratio flux of nitrogen and

gallium (N/Ga) is 161 or N-rich conditions (Susanto

et al., 2017). During the cleaning substrate and

growth GaN film, the surface condition is monitored

using RHEED. Finally, the GaN film products were

then examined by AFM and SEM to investigate in

detail the characteristics of surface condition.

3 RESULT AND DISCUSSION

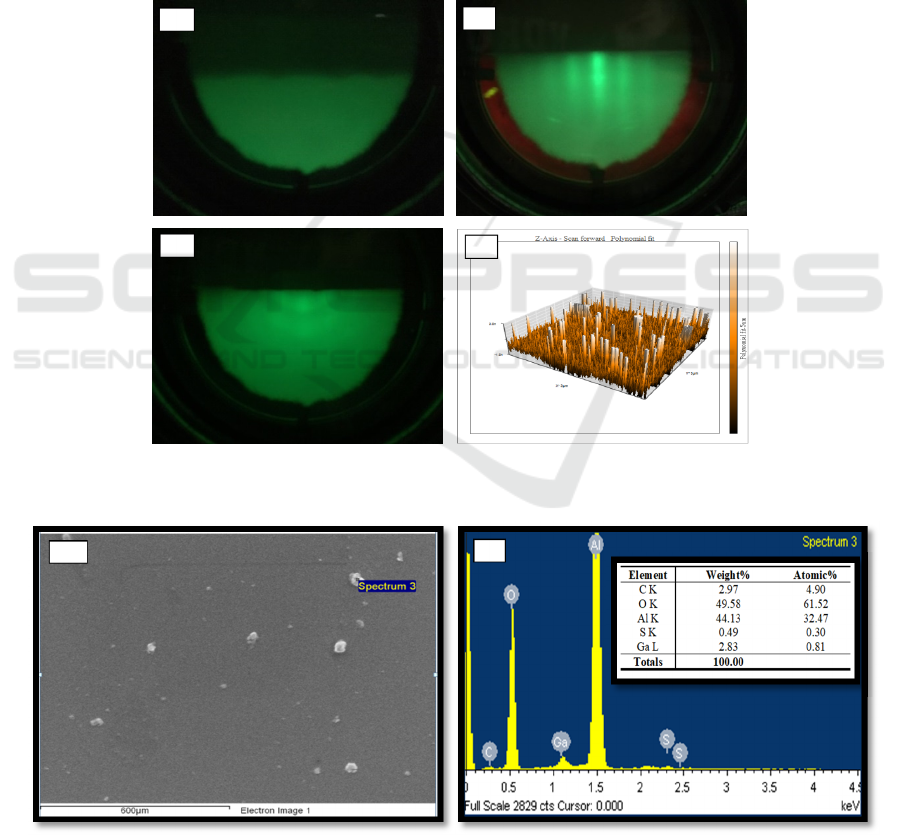

Figure 1 shows the RHEED pattern on the surface of

MoS

2

during the hot cleaning process. The foggy

pattern is shown by RHEED in Figure 1(a) before

hot cleaning. This pattern explains that the structure

formed of the MoS

2

layer is amorphous. After the

hot cleaning, a bright streak pattern is displayed by

RHEED in Figure 1 (b). This pattern explains that

the surface structure constructed on the MoS

2

layer

is a crystalline structure. So, based on the cleaning

results by the heating process, the surface structure

is changed from amorphous to crystalline. This

process was found to be effective in removing

contaminants that covered the surface of the MoS

2

layer and improving the surface structure of the

substrate. Besides, the striped pattern explains that

the surface layer is 2-dimensional. Meanwhile, the

bright intensity of the streak pattern shown explains

the crystal structure formed in the MoS

2

layer. The

stronger intensity of the pattern indicates the

crystallinity structure formed. Further, the RHEED

pattern in Figure 1 (c) displays the surface of the

GaN film growing on the MoS

2

layer. The dots

connected with a ring in the RHEED pattern show

the surface structure of the layer which is a

polycrystalline structure. This structure leads to be

constructed low mobilization of atoms caused by the

lack of heat energy provided by the substrate results

in the creation of Ga droplets or clusters due to low

desorption and diffusion of atoms (Susanto et al.,

2017). Moreover, the substrate's surface character

related to the different orientation was also

responsible for creating the structure. While the

weak intensity pattern correlates with the

polycrystalline mixed with an amorphous structure.

In addition, the single crystal of GaN films was not

constructed on the epitaxial structure. It indicates

that the defect was formed on the layer and

influencing the crystalline structure. The result is

consistent with the surface morphology on the GaN

film shown in the AFM image in Figure 1(d). The

peaks and valleys pattern on the surface illustrates

the surface character of the GaN film formed. The

RMS total of surface roughness constructed on GaN

film is 3.87 nm, in which the height peak is 118.93

nm and the depth valley is 15.99 nm. The presence

of peaks could be due to the accumulation of Ga

atoms which generate Ga clusters during the growth

process. The formation of valleys is created due to

the low mobilization of Ga and N atoms during

growth as well. The minimum of atoms mobilization

corresponds to less desorption influenced by the

ASAIS 2019 - Annual Southeast Asian International Seminar

28

insufficiency of thermal energy (Susanto, Kan and

Yu, 2017).

Furthermore, the morphology and composition

element of the surface film was presented more

clearly in Figure 2. The GaN film with some light

particles has completely covered the substrate. The

smooth surface corresponded to 2D layers has

deposited on the MoS

2

layer. However, there are

also Ga clusters like a particle with a brighter color

attend on the surface of the GaN film. The clusters

pattern is believed to be the peaks demonstrated in

the AFM image in figure 1 (d). To ensure these

particles are Ga clusters, the observations are

targeted more focus at particles in spectrum 3 using

the EDS test shown in Figure 2(a). The result of the

spectrum 3 observations is shown in Figure 2 (b).

The peaks on the image are the elements constructed

from such as the films and substrate. The high peak

corresponds to the quality of the elements, while the

area of peaks relates to the number of elements.

Moreover, the number of elements namely Al, O, S,

C, and Ga is tabulated inset in Figure 2(b). The

presenting of Al, O and S elements could become

from the substrate material, while the Ga element

attends from Ga films. Based on the surface

morphology and composition element results, it

clears that the GaN film has grown well on the MoS

2

layer without the pits defect on the surface.

Figure 1: RHEED patterns (a) MoS

2

/Sapphire, (b) MoS

2

/Sapphire after nitridation, (c) GaN films, and (d) 3-dimensional

(3D) AFM GaN film surfaces with a volume of 3 µm x 3 µm x 5nm.

Figure 2. SEM and EDS images of GaN film surface

(a)

(b)

(c)

(d)

(b

(a)

Surface Structure and Morphology of Gallium Nitride Thin Film Grown on Molybdenum Disulfide Layer by Molecular Beam Epitaxy

29

4 CONCLUSIONS

The GaN layer has been successfully grown near the

surface of the MoS

2

layer with the PA-MBE

technique. The surface substrate of the MoS

2

layer

was covered throughout with GaN films. The

structure formed on the GaN film was either

polycrystalline closed-amorphous or a mixture

structures of polycrystalline and amorphous. The

defect influenced the crystalline structure of GaN

films. While the surface contour formed was in 2D

mode with a roughness of RMS 3.87. The smooth

layer of GaN film with presenting the Ga cluster also

constructed on the MoS

2

layer. The low heat energy

provided by the substrate was responsible to

construct the Ga cluster on the surface of GaN films.

In addition, the mixture of structures formed is also

believed to be formed due to low mobilization and

desorption of atoms during the growth epitaxy.

ACKNOWLEDGMENTS

All authors would like to thank Ministry of Science

and Technology, Taiwan for financially supporting

this study (MOST 107-2221-E-259- 001-MY2 and

107-3017-F-009-002), and Dr. Iwan Susanto would

like to give thanks for the support provided by Pusat

Penelitian dan Pengabdian Masyarakat, Politeknik

Negeri Jakarta (PPPM PNJ nomor

SP.DIPA.042.01.2.400994/2019).

REFERENCES

Chen, K. J. et al. (2017) ‘GaN-on-Si power technology:

Devices and applications’, IEEE Transactions on

Electron Devices. doi: 10.1109/TED.2017.2657579.

Gupta, P. et al. (2016) ‘Layered transition metal

dichalcogenides: promising near-lattice-matched

substrates for GaN growth’, Scientific Reports. doi:

10.1038/srep23708.

Hanada, T. (2009) ‘Basic Properties of ZnO, GaN, and

Related Materials’, in. doi: 10.1007/978-3-540-88847-

5_1.

Ho, Y. T. et al. (2015) ‘Layered MoS

2

grown on c -

sapphire by pulsed laser deposition’, Physica Status

Solidi - Rapid Research Letters, 9(3), pp. 187–191.

doi: 10.1002/pssr.201409561.

Joshin, K. et al. (2014) ‘Outlook for GaN HEMT

technology’, Fujitsu Scientific and Technical Journal.

Kawashima, T. et al. (1997) ‘Optical properties of

hexagonal GaN’, Journal of Applied Physics. doi:

10.1063/1.365671.

Kimura, R. et al. (2005) ‘Thick cubic GaN film growth

using ultra-thin low-temperature buffer layer by RF-

MBE’, Journal of Crystal Growth, 278(1–4), pp. 411–

414. doi: 10.1016/j.jcrysgro.2005.01.058.

Kukushkin, S. A. et al. (2008) ‘Substrates for epitaxy of

gallium nitride: New materials and techniques’,

Reviews on Advanced Materials Science.

Liu, L. and Edgar, J. H. (2002) ‘Substrates for gallium

nitride epitaxy’, 37, pp. 61–127.

Mánuel, J. M. et al. (2010) ‘Structural and compositional

homogeneity of InAlN epitaxial layers nearly lattice-

matched to GaN’, Acta Materialia. doi:

10.1016/j.actamat.2010.04.001.

Poust, B. D. et al. (2003) ‘SiC substrate defects and III-N

heteroepitaxy’, Journal of Physics D: Applied Physics.

doi: 10.1088/0022-3727/36/10A/321.

Su, M., Chen, C. and Rajan, S. (2013) ‘Prospects for the

application of GaN power devices in hybrid electric

vehicle drive systems’, Semiconductor Science and

Technology. doi: 10.1088/0268-1242/28/7/074012.

Susanto, I. et al. (2017) ‘Effects of N/Ga flux ratio on GaN

films grown on 4H-SiC substrate with 4° miscutting

orientation by plasma-assisted molecular beam

epitaxy’, Journal of Alloys and Compounds. Elsevier

B.V, 710, pp. 800–808. doi:

10.1016/j.jallcom.2017.03.320.

Susanto, I., Tsai, C., et al. (2019) ‘Morphology and

surface stability of GaN thin film grown on the short

growth time by Plasma Assisted Molecular Beam

Epitaxy’, J. Phs : Conference Seriese, 1364(012067).

doi: 10.1088/1742-6596/1364/1/012067.

Susanto, I., Tsai, C.-Y., et al. (2019) ‘The influence of 2D

MoS

2

layers on the growth of GaN films by plasma-

assisted molecular beam epitaxy’, Applied Surface

Science, 496(July), p. 143616. doi:

10.1016/j.apsusc.2019.143616.

Susanto, I., Kan, K. and Yu, I. (2017) ‘Temperature

effects for GaN fi lms grown on 4H-SiC substrate with

4 miscutting orientation by plasma-assisted molecular

beam epitaxy’, Journal of Alloys and Compounds.

Elsevier B.V, 723, pp. 21–29. doi:

10.1016/j.jallcom.2017.06.224.

Trampert, A. (2002) ‘Heteroepitaxy of dissimilar

materials: Effect of interface structure on strain and

defect formation’, in Physica E: Low-Dimensional

Systems and Nanostructures. doi: 10.1016/S1386-

9477(02)00317-X.

Wan, Y. et al. (2018) ‘Epitaxial Single-Layer MoS

2

on

GaN with Enhanced Valley Helicity’, Advanced

Materials. doi: 10.1002/adma.201703888.

Würtele, M. A. et al. (2011) ‘Application of GaN-based

ultraviolet-C light emitting diodes - UV LEDs - for

water disinfection’, Water Research. doi:

10.1016/j.watres.2010.11.015.

Zhang, Z. et al. (2018) ‘Interface Engineering of

Monolayer MoS

2

/GaN Hybrid Heterostructure:

Modified Band Alignment for Photocatalytic Water

Splitting Application by Nitridation Treatment’, ACS

Applied Materials and Interfaces. doi:

10.1021/acsami.8b01286.

ASAIS 2019 - Annual Southeast Asian International Seminar

30