Software Design of Automatic Vacuum Forming Machine for a Small Food

Industry

Hasvienda M. Ridlwan

1

, Pribadi Mumpuni Adhi

1

, Sonki Prasetya

1

, Sugeng Mulyono

1

and Muslimin

1

1

Politeknik Negeri Jakarta, Kampus Baru UI Depok, 16425. Indonesia

Mechanical Engineering Department Politeknik Negeri Jakarta

Keywords: PVC, Food Industry, Packaging, Vacuum Forming Machine

Abstract: This paper explains the design and testing of software for control vacuum forming machine. The design and

testing is carried out using LabView software which is intended to test the feasibility of the control system

before it is implemented on the actual device or vacuum forming machine. The testing arrangement also used

an Arduino controller via serial communication protocol to USB in realtime. Moreover, Labview software is

integrated with Arduino is capable of rendering remote automation from experiments and using an easy

interface. The objective of this study is to make the automation system of thermal vacuum forming machine

for small food industrial applications. Therefore, it is suited with the machine design to provide efficient

operation automatically. In testing the control for vacuum forming machine software has been running and

integrated with Arduino. The result shows that the temperature control can stabilize the heat after 3 minutes

of heating. Meanwhile the software of Human Machine Interface monitors and helps an operator to use the

machine easily. After this testing phase will be evaluated and implemented on a real machine.

1 INTRODUCTION

The development of the food industry in

Indonesia also affects packaging needs (Grün, 2016).

Packaging that is incompatible with food products in

both form and type will result in product defects,

unhygienic food, easy to expire and unattractive in

terms of aesthetics. Meanwhile, to order packaging in

the form that is tailored to the product to the plastic

packaging factory, a high cost is required or must

order in large quantities. This causes the UKM in the

food sector will find it difficult to be creative in a

variety of forms and types of food. Therefore, an

automatic UKM scale Vacuum Forming machine

with an economical cost is very important.

The Vacuum Thermoforming process is one

method for processing sheet plastics into plastic

packaging that can later be used to wrap food

(Hussain & Safiulla, 2016). This plastic processing

utilizes temperature and pressure for its processing.

The working principle of the machine is that the

stretched plastic sheet is placed under the heating

element above the vacuum chamber, the heated

plastic sheet is placed on the molding and the pressure

will be reduced to help form a better material.

The vacuum thermoforming study has become

the focus of several researchers. Film thermoforming

for molding Polycarbonate decoration molding is

done by (Chen, Huang, Lin, & Chien, 2008).

Meanwhile, the product for the microfluidic system is

formed using a polymer to reduce the wrinkle due to

the thickness of the polymer. In order to optimize the

result, Erchiqui adds infra-red during the

thermoforming process(Erchiqui, 2017).

Furthermore, the vehicle spare part is also used

thermoforming method (Balakrishnan & Seidlitz,

2018). As an additional, the thermoforming process

for the composite material is presented in the

Intelligent Computation in Manufacturing

Engineering conference in Naples Italia (Bruns,

Bohne, Micke-Camuz, Behrens, & Raatz, 2018).

However, for a small type of vacuum forming

normally activated manually by an operator. The

earlier design of the Vacuum Forming machine for

the small food industry has been carried out where the

focus of previous research was temperature control on

the vacuum forming machine.

This paper focuses on developing software that

was previously designed to be simpler than the

previous tools. Moreover, it has been equipped with

an automatic control system to produce a machine

Ridlwan, H., Adhi, P., Prasetya, S., Mulyono, S. and Muslimin, .

Software Design of Automatic Vacuum Forming Machine for a Small Food Industry.

DOI: 10.5220/0009871900002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 49-52

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

49

that is more economical, efficient. It is expected that

after the software implementation, the product can be

used to make plastics with various shapes for UKM

industry.

2 METHODOLOGY

This paper describes three steps to develop the

study namely theoretical base for the plastic forming,

components required and the software designed for

automatic control.

2.1 Theoretical Thermoforming

The heat transfer during the thermoforming

process is considered as the type of radiation. The

number of emitted radiation of a black body follows

the formula (Ashter, 2014; Selke & Culter, 2015).

(1)

where

, dan are the energy, Boltzman

constant= 0.5674 × 10

–10

kW/m

2

°C

4

and temperature.

In order to provide the heat, the radiation process

uses a specific wavelength. The energy required for

generating those wavelengths obey the rule as

formulated in (Ashter, 2014; Selke & Culter, 2015).

(2)

where C

1

= 3.734 × 105 kW mm

4

/m

2

, C

2

= 1.439 × 104

Kµm and λ is the wavelength (µm).

The heating of the plastic sheet is molded under

the specific temperature (between its glass transition

and melting temperature). The temperature to form

the plastic depends on the material as listed on the

table.

Table 2.1. Plastic transition table (Jr., 2007)

Material

Glass

Tansition

Temperatur

e [

o

C(

o

F)]

Melting

Temperat

ure

[

o

C(

o

F)]

Polyethylene (low

density)

-110 (-165) 115 (240)

Polytetrafluoroethylen

e

-97 (-140) 327 (620)

Polyethylene (high

density)

-90 (-130) 137 (279)

Polypropylene -18 (0) 175 (347)

Material

Glass

Tansition

Temperatur

e [

o

C(

o

F)]

Melting

Temperat

ure

[

o

C(

o

F)]

Nylon 6,6 57 (135) 265 (510)

Poly(ethylene

terephthalate) (PET)

69 (155) 265 (510)

Poly(vinyl chloride) 87 (190) 212 (415)

Polystyrene 100 (212) 240 (465)

Polycarbonate 150 (300) 265 (510)

2.2 Components

The components used is considered in order to

develop the control system. Inputs of the systems.

1. Temperature uses K Type Thermocouple for

the feedback system (Figure 2.3).

Figure 2.1 Thermocouple Sensor

2. Limiter switch for marking the position of

the tray either maximum or minimum

position. (Figure 2.2).

Figure 2.2. Limiter Switch

Futhermore the outputs of the machine are:

3. Heater has a function to create the

temperature required for the sheet to be

molded. The chosen heater is the tubular type

(Figure 2.3)

Figure 2.3 Tubular Heater

ASAIS 2019 - Annual Southeast Asian International Seminar

50

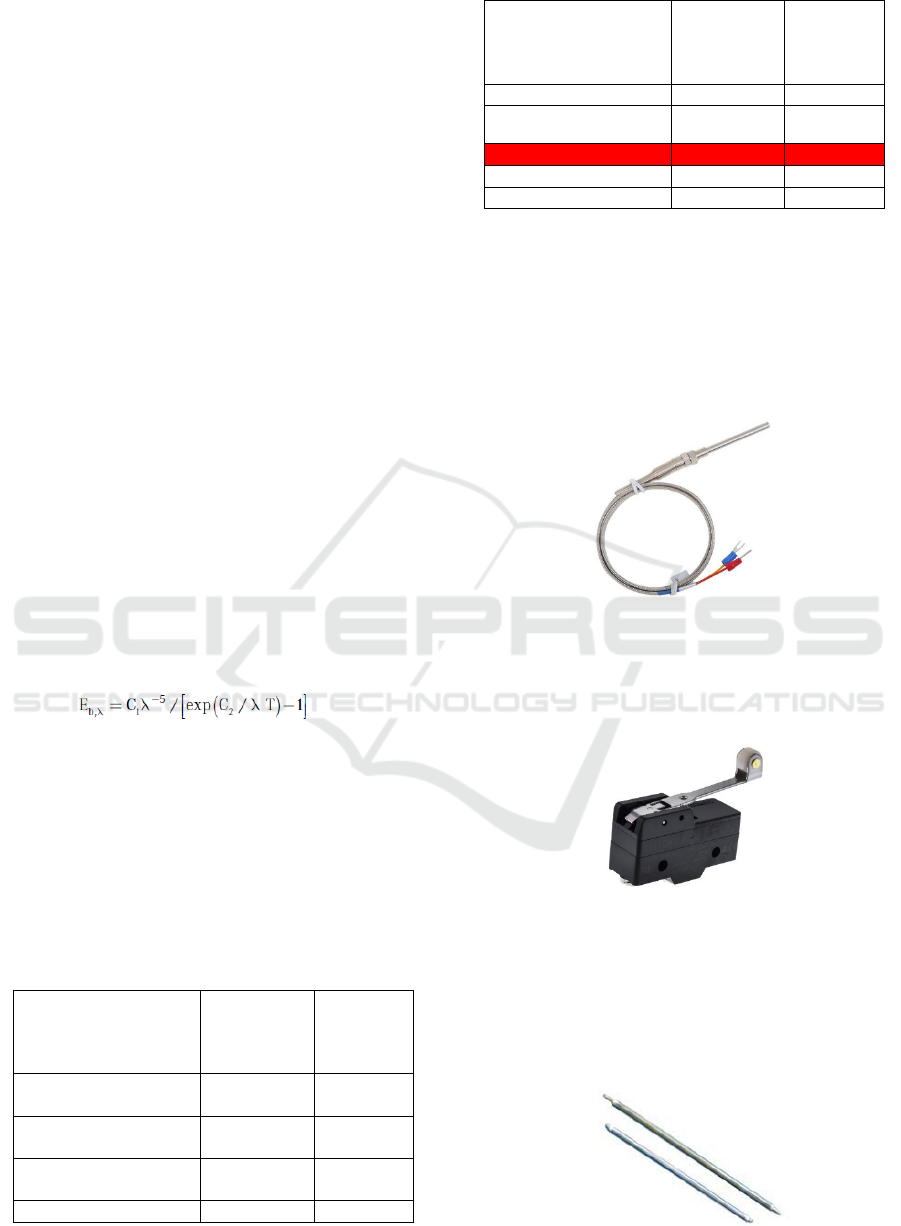

4. It uses the dc motor DC (Planetary Geared

Motor) to move the tray up and down. The

selected type is PG-45ZY45 (Figure 2.4).

The electrical specifications are 7.4 (V) with

1 (A) of current.

Figure 2.4 dc motor

5. MD10C is dc motor driver (Figure 2.5)

which is designed to drive high current

brushed DC motor up to 13Amps

continuously. It offers several enhancements

over the MD10B such as support for both

locked-antiphase and sign-magnitude PWM

signal as well as using full solid state

components that result in faster response

time and eliminate the wear and tear of the

mechanical relay.

Figure 2.5 MD10C dc motor driver

3 RESULT AND DISCUSSIONS

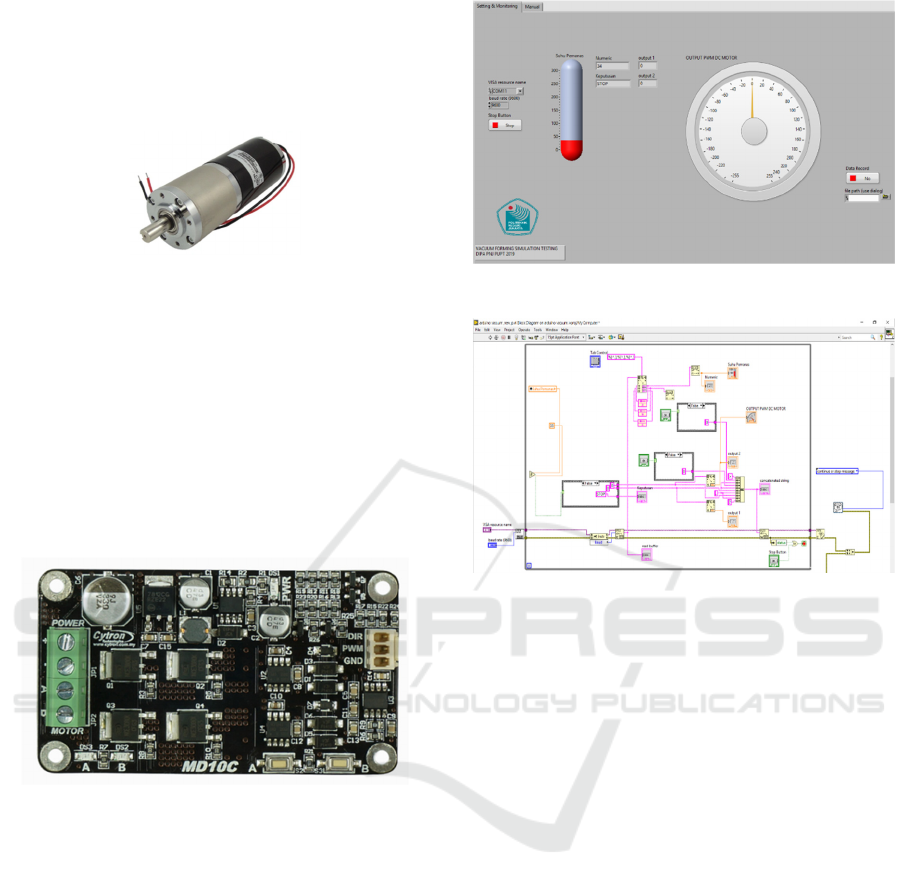

The development of the software uses interfacing

between the micro-controller with the computer

(laptop). Using the laptop, an operator can select the

the type of plastic sheet material. Furthermore, the

selected material will result in the set point of

temperature to be maintained.

Figure 3.1. Layout of the display monitor

Figure 3.2. The block diagram

4 CONCLUSIONS

The conclusion of this paper is organized as follows:

The control of temperature achieved with

the temperature fluctuates steadily after

steady state condition at 100

o

C for PVC

sheet material

The first movement of the tray to be heated

requires around 3 seconds. Later on, heating

process needs around 3 minutes before it

moves back to the ground to be vacuumed.

ACKNOWLEDGEMENTS

This work was funded by Jakarta State Polytechnic

through the PUPT 2019 Program.

REFERENCES

Allen, Maggie., Clifford, John., & Atkinson, David. (2019).

Exploring Consumers Reliance On Plastic In Fresh

Food Packaging: Adding To The Waste?

Software Design of Automatic Vacuum Forming Machine for a Small Food Industry

51

Ashter, S. A. (2014). Modelling of Thermoforming

Thermoforming of Single and Multilayer Laminates:

William Andrew Elsevier.

Ayadi, A., Lacrampe, M. F., & Krawczak, P. (2019).

Bubble assisted vacuum thermoforming: considerations

to extend the use of in-situ stereo-DIC measurements to

stretching of sagged thermoplastic sheets.

Balakrishnan, V. S., & Seidlitz, H. (2018). Potential repair

techniques for automotive composites: a review.

Composites

Balzarotti, S., Maviglia, B., Biassoni, F., & Ciceri, M. R.

(2015). Glass vs. Plastic: Affective Judgments of Food

Packages After Visual and Haptic Exploration.

Bruns, C., Bohne, F., Micke-Camuz, M., Behrens, B.-A., &

Raatz, A. (2018). Heated gripper concept to optimize

heat transfer of fiber-reinforced thermoplastics in

aautomated thermoforming process. Paper presented at

the CIRP Conference on Intelligent Computation in

Manufacturing Engineering Naples Italy.

Chen, S.-C., Huang, S.-T., Lin, M.-C., & Chien, R.-D.

(2008). Study on the thermoforming on PC films used

for in-mold decoration. International Communications

in Heat and Mass Transfer Elsevier, 35, 967-973.

Cruz, Rui M.S., Alves, Vera., Khmelinskii, Igor., & Vieira,

Margarida C. (2018). New Food Packaging Systems.

Erchiqui, F. (2017). Application of genetic and simulated

annealing algorithms for optimization of infrared stage

in thermoforming process. Applied Thermal

Engineering Science Direct.

Grün, G.-C. (2016). Six data visualisation that explain

plastic problem

Hall, Jon G., & Rapanotti, Lucia (2017). A design theory

for software engineering.

Hahladakis, John N., Purnell, Phil., Iacovidou, Eleni.,

Velis, Costas A., & Atseyinku, Maryan. (2018). Post-

consumer plastic packaging waste in England:

Assessing the yield of multiple collection-recycling

schemes.

Hawkins, G. (2018). The skin of commerce: governing

through plastic food packaging.

Hussain, B., & Safiulla, M. (2016). Comparative study of

cooling systems for vacuum forming tool. Paper

presented at the PMME 2016.

Jr., W. D. C. (2007). Materials Science and Engineering.

Iowa.

Selke, S. E. M., & Culter, J. D. (2015). Thermoforming

Plastics Packaging: Carl Hanser Verlag.

Takahashi, Mutsumi., Araie, Yoshiaki., Satoh, Yoshihide.,

& Iwasaki, Shin Ichi. (2017). Influence of continuous

use of a vacuum-forming machine for mouthguard

thickness after thermoforming.

Yamaoka, Junichi., & Kakehi, Yasuaki. (2017). ProtoMold:

An interactive vacuum forming system for rapid

prototyping.

ASAIS 2019 - Annual Southeast Asian International Seminar

52