Optimizing Production Time in Book Printing using PERT/CPM

Endang Yuniarti

1

and Emmidia Djonaedi

1

1

Teknik Grafika, Politeknik Negeri Jakarta, DR. G.A. Siwabessy street, Depok, Indonesia

Keywords: production time, network diagrams, printing products

Abstract: Advanced planning will generate best production process in accordance to its production implementation

schedules. Any delay in production process affect to other following activities such as the packing process,

shipping and so on. This can lead to consumer dissatisfaction. Time in producing is important in accordance

with the agreement to consumer. Printing production process includes pre-press, press and post-press

(finishing). Beside production process time, the instruction and the order of the production process are

significant. The aim of this research is to produce an optimal production time with a case study of a

production of a printed book entitled Brilliant. This book was printed in Jakarta printing areas for about

20,000 units. The methods used in this study include: Project Evaluation and Review Technique (PERT)

and Critical Path Method (CPM) methods. The methods used are Project Evaluation method and Review

Technique (PERT) and Critical Path Method (CPM). This research reveals that a total production process

time of the book is 2700 minutes or 41.5 hours. After applying the PERT / CPM method, the sequence of

production processes that result by the critical path is the B (pre-press web activity) – D (press web activity

– E (post press activity) path.

1 INTRODUCTION

Advance planning is essential in any production

system. Any deferral or postpone might affect to the

production schedule. According to Fadli (2010), a

project activity is limited by time and allocation of

resources to complete the specific tasks. This applies

especially in printing process where customers’

order or Make to Order (MTO) become the main

part of the production process. Each customer order

has an agreement including product specifications

and product completion time.

The printing production process includes pre-

press, press and post-press (finishing). Each

activity can be both parallel and not parallel process,

depends on the machine. Seeing the importance of

time and sequence of the production process is

necessary to conduct research to solve the problems

that have been described above. There are many

methods that can be applied to measure the

production process time based on ordering

process. The character of this case study is the MTO

product, considering the time, the sequence of the

production process and the suitable method. Project

Evaluation and Review Technique (PERT)

and Critical Path Method (CPM) methods are

examined and proven. Determination of the optimal

production time required good scheduling method,

and this can be applied using the PERT / CPM

approach (Mas'ud, 2017). This method is often and

suitable to be used in scheduling projects in the civil

field for example housing construction (Raharja,

2014), shop houses (Caesaron, 2015) and

construction of sewage treatment (Mas'ud, 2017).

This CPM method is applied to obtain the

critical path that occurs in the order of the

production process. From the sequence of processes,

evaluation of the actual production process time are

carried out using PERT to obtain the optimal

time. Based on the optimal time and planning the

cost calculation can be done to see the comparison.

The object taken in this research is a printed book

entitled Brilliant which were produced for 20,000

units. This case study was conducted at a printing

company in Jakarta. Based on the description above,

the main purpose of this research is to obtain an

Optimization Production Time in Book

Printing using PERT / CPM approaches.

102

Yuniarti, E. and Djonaedi, E.

Optimizing Production Time in Book Printing using PERT/CPM.

DOI: 10.5220/0009896300002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 102-107

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 PRODUCTION SYSTEM

A book entitled “Brilliant” is an object of this

research. The material used for this book is art paper

for the book’s cover and LWC paper for the book’s

content pages.

The production process of a printed product

involves 3 stages i.e. pre-press, press and post-press

(finishing). Each stage has sub-stages for each

production process activity. The pre-press process

includes the preparation of the Final Art Work (FA)

to plate. The press process is converting blank

paper to printed paper. Then, the last process is

finishing (post- press) which includes folded and

stacked the books. All processes are observed and

the time of each process is calculated using a stop

watch. This research primary data was taken directly

from book printing company. Secondary data is

used as a reference to the sequence of processes in

production activities.

The sampling method has been done randomly

where each activity took five measurements

data. The data taken during the process, starting

from the process of pre-press, press to post press of

making a book with the circulation above. All

processes (pre-press, press, post- press) provide one

measure of time to facilitate observation. A road

whiteboard and calculator also needed to calculate

the real time in each process.

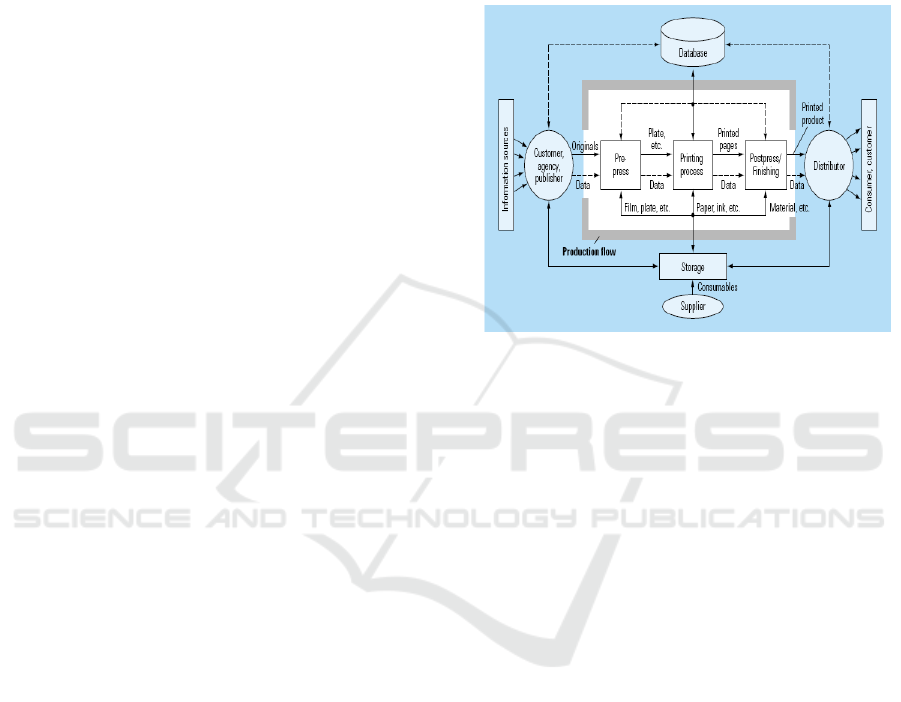

2.1 Printing Production Process

Printing or commonly called graphic is a technique

of conveying messages, ideas, information, thoughts,

feelings through duplication by

printing and presenting to the public (Kipphan,

2001). Prepress is the steps needed to prepare a

printed product such as writing and editing , graphic

design, proofing, and plate making. Prepress

procedure includes the manufacture of plates printed

references, image or form which ready for mounting

on a printing press. The adjustment of image and

text or the creation of file need to be in high

quality. The source of prepress is soft file because

the output of prepress is a plate to print reference.

Press process is production of printing product.

Techniques used in the press process are flat

printing, high printing, deep printing, digital printing

and filter printing.

The printing technique used in this study is

offset printing. The input of the press process is the

blank paper and the output is the printout. The final

process in printing is finishing / post press. In this

process, printed products were added some features

and functions based on customer order

specifications. These steps are including cutting,

folding, joining, binding, lamination, etc. Source of

post press is the printed paper and the output is in

the form of a finished product (for example: a

book). General description of the printing industry

production process is as follows:

Figure 1. Production Printing flow

(Source: Kipphan, 2001)

2.2 Concepts of PERT / CPM Methods

Network analysis is a conventional way to find the

optimal way to link a number of activities directly or

indirectly which meet the supply and demand

requirements at different project activities and

scheduling locations. Over the years, two approaches

that have proven useful in project planning,

scheduling and control are PERT and CPM (Agyei,

2015).

2.2.1 CPM

According Levin and Kirkpatrick (1972), the Critical

Path Method (CPM) is a method for planning and

monitoring projects. This system is most widely

used among all other systems. CPM method is

widely used by industry or construction

projects. This method can be applied if the duration

of the work is known and not fluctuate too

much. CPM as a project management model that

prioritizes costs as the object being analysed. CPM

is a network analysis which seeks to optimize the

total project cost through reducing the total project

completion time. Using the CPM method can save

time in completing various stages of a project.

Optimizing Production Time in Book Printing using PERT/CPM

103

2.2.2 PERT

Project Evaluation and Review Technique is

a management science model for planning and

controlling a project. According to Levin and

Krikpatrick (1972), the PERT method is a method to

reduce production delays, disruptions and conflicts,

coordinate and synchronize as part of an overall

work and accelerate the completion of projects. The

application of PERT method can be known where

CPM the amount of time required, the level of

confidence desired in determining the time of each

activity. There are surveillance activities especially

in the critical path that can be more concentrated

(Prog, 2014).

The PERT method accommodates the existence

of uncertain elements, then analyzes the possibilities

of the extent to which the project deviates or meets

(Caesaron, 2017). PERT and CPM can be used as

references in setting up the schedule, so as to

facilitate the course of the project to determine

delays in each process, so as to overcome these

problems (Sari, 2018).

According to Grace (2016), the steps in making

PERT are:

1. Identification of activities and events

2. Establish the order of activities

3. Make a network diagram

4. Estimated time for each activity

5. Specifies the critical path

6. Update the diagram according to project

progress.

The planning step for PERT approach is intended to

find out the probability value of project activities,

especially on the critical path, either is completed on

time according to the expected schedule or not

(Chuong, 2007).

2.3 Optimizing Production Activity

The product specifications are as follows: The size

of the book will be 17.6 x 2 5 cm; Cover is Art Paper

210 GSM ; Content page is HVS 70 gsm, Color

processes using 4 /0 color to cover and 1 /1 color to

book; Number of pages are 115 pages; Finishing is

with glue.

Figure 2. Book product

(Source: CV Arya Duta, 2018)

2.3.1 Production Activity

Pre-press activity is using a soft file of book design

in and output is printed plate. The activities

are file checking/ color reproduction, paper

deposition, proofing, printing plate, and buckling

and plate holes. The pre-press activity is divided into

two parts, cover plates for sheet machines and

fill plates for web machine. The production of this

book needs seven plates which are ready to be

printed. This consists of six content plates (using a

web offset machine) and one cover plate (using an

offset sheet machine).

Figure 3. Pre-press activity

(Source: CV. Arya Duta, 2018)

Second stage is press activity, content of the

book printed with web offset machine and cover

printed with sheet offset machine. In the press stage,

activity include: preparation of paper, ink and

equipment and supporting materials, machine

settings, plate mounting, print try, mass printing,

cleaning of machines and work areas. The process of

sheet printing uses the Hiedelberg machine and web

printing uses the Komori machine.

The final stage in book making is post-

press (finishing). The activity includes cutting,

folding, collation and binding. Binding method is

perfect binding.

ASAIS 2019 - Annual Southeast Asian International Seminar

104

Figure 4. Post Press Activity

(Source: CV Arya Duta, 2018)

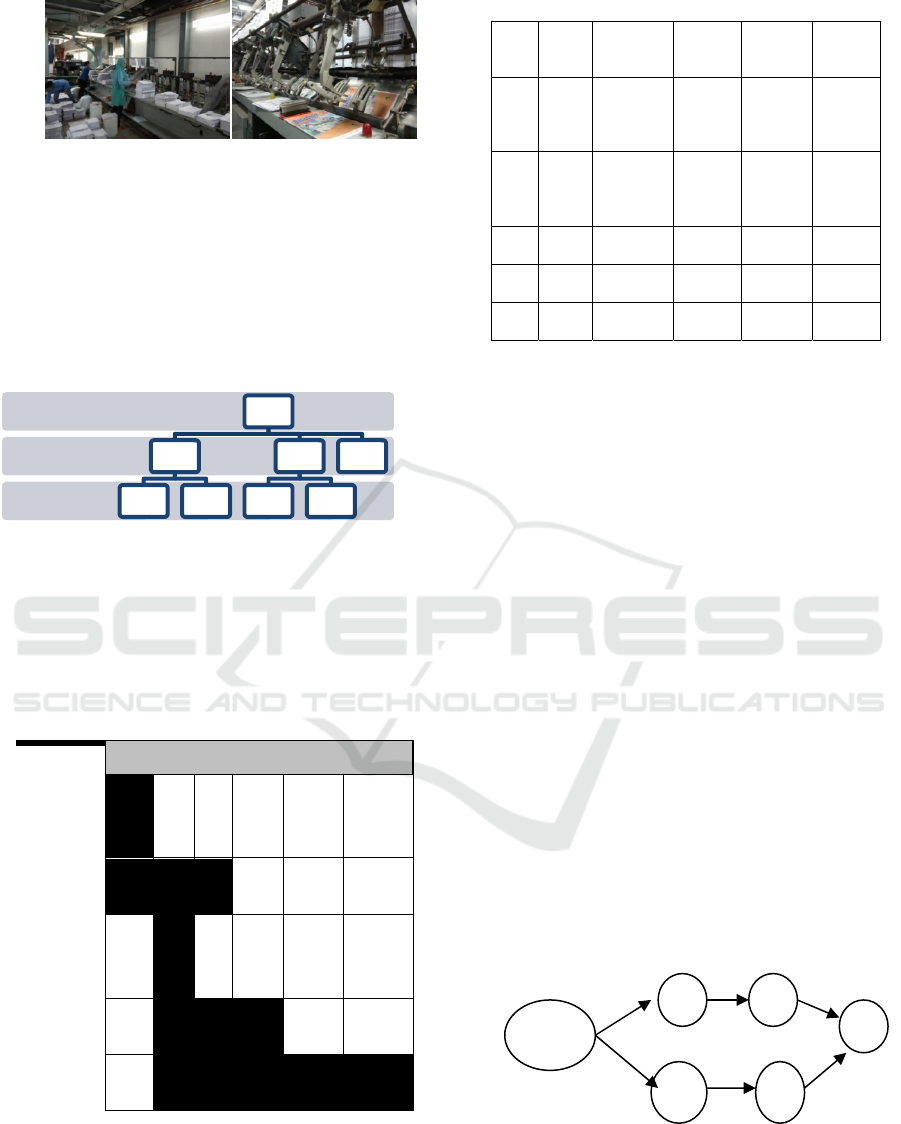

2.3.2 Work Breakdown Strukture (WBS)

Before using PERT/CPM method, first, the sequence

of the production process of this book can be done

by creating a Work Breakdown Structure (WBS)

with the following scheme:

Figure 5. WBS level

The production of the book can be done WBS

development to emphasize the activity of the actual

activities that occur, so it can be accordance to the

project schedule.

Table 1. Activity using WBS

Activity Time (Hours)

S

ta

r

t 5 10 15 20 25

PrePress

Sheet

(Cover)

Pre press

Web (Isi)

Press

Sheet

(Cover)

Press

Web (Isi)

Post press

(finishing)

To create network diagrams, this study uses the

AOA diagram approach. Activity using PERT shows

like below:

Table 2. Activity using PERT

No Acti

vity

Activity

descripti

on

Begin

Activit

y

Time

(menit)

Time

(hours)

1 A Pre-

press

Sheet

(Cover)

- 35 0.6

2 B Pre-

press

Web

(Isi)

- 394 6.6

3 C Press

sheet

A 187 3.1

4 D Press

Web

B 757 12.6

5 E Post

press

C, D 1335 22.3

Using PERT have 5 activity: Pre-press sheet (A),

pre-press web (B), press sheet (C), press web (D)

and post press or finishing (E).

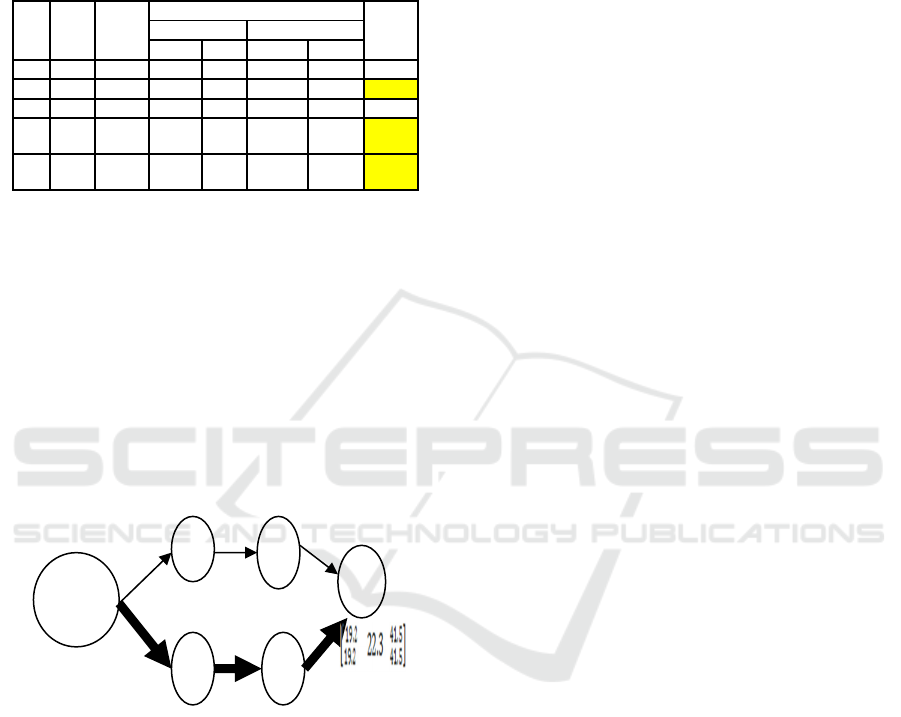

3 RESULTS AND DISCUSSION

Overall, the process of graphics production includes

three stages: pre-press, press and post

press. However, before the actual production process

time, it is necessary to know the actual process

flow. First after observing in a book printing,

process there are several activities that can be done

simultaneously, but there are also activities that to be

done sequentially. The activity in printing

production of this book needed is 45.2 hour or 2708

minutes.

The printing process of the content pages and

cover page of the book used two different machines.

The content page use web offset machine and the

cover page use sheet offset machine. Therefore, both

press activities can be done in parallel. However,

post-print activities must wait until the completion

of these two press activities, the network diagram is

formed as shown below:

Figure 6. Path using PERT method

Level3

Level2

Level1

Produk

siBuku

Brilian

Pra

cetak

Sheet

(cover)

Web

(isi)

Cetak

Sheet

(cover)

Web

(isi)

Paska

Cetak

(finishi

ng)

Start

A

B

C

D

E

Optimizing Production Time in Book Printing using PERT/CPM

105

A PERT chart allows managers to evaluate the

time and resources necessary to manage project. It

needs information about Earliest Start Time (ES),

Earliest Finish Time(EF), Latest Start Time(LS) and

Latest Finish Time (LF) as set like this:

Table 3. Optimizing time using PERT method

There are three activities which contain of slack

activity (with nominal slack is zero). The three

activities are B, D and E. Those activities cannot be

delayed in production system.

The PERT analysis can be performed further

using CPM. By doing so, itcan find out which

activities are going through the critical path. Based

on the PERT table, this shows that the activity is a

critical activity so it can be concluded that the

critical path in the book production activities is on

the B-D-E.

t

0.6

.

.

.

.

3.1

.

.

.

.

6.6

.

.

.

.

12.6

.

.

.

.

Figure 7. Optimizing Using PERT/CPM

4 CONCLUSIONS

This research reveals that the actual total production

time needed is 45.2 hour or 2708 minutes,

meanwhile after applying PERT/CPM method need

2700 minutes or 41.5 hours. Applying the PERT

method shows there are five activities sequences i.e.

sheet prepress (A), web prepress (B), sheet press

(C), web press (D) and finishing (E). slack time

showed in B, D and E activity. Meanwhile, applying

CPM method obtained the sequence of production

processes path is the B (pre press web activity) – D

(press web activity – E (post press activity) path.

ACKNOWLEDGEMENTS

We would like to thank the following institutions for

helping us complete this research. To Politeknik

Negeri Jakarta (PNJ) specially Pusat Penelitian dan

Pengabdian Kepada Masyarakat (P3M) who fund

this research under the Dosen Pemula research

scheme and to Jurusan Teknik Grafika Penerbitan

for providing technical and support staff. We also

wish to show our appreciation to CV Arya Duta

Jakarta for providing the comprehensive data.

REFERENCES

Agyei, W., 2015. Project Planning and Scheduling Using

PERT and CPM Techniques with Linear

Programming: Case Study, International Journal of

Scientific & Technology Research, 4(8), hal. 222–

227.

Burge, Stuart, 2006. The Systems Thingking Tool Box.

Miline: A.A

Bishnoi, Nisha, 2018. Critical Path Method (CPM): A

Coordinating Tool. International Research Journal of

Management Science & Technology: Vol 9 Issue 1,

ISSN 2348-9367

Caesaron, Dina dan Andrey Thio, 2015. Analisa

Penjadwalan Waktu Dengan Metode Jalur Kritis dan

PERT Pada Proyek Pembangunan Ruko (Jl. Pasar

Lama No.20, Glodok). Journal of Industrial

Engineering & Management Systems: Vol 8 No. 2

Ekanugraha, Arif Rakhmat, 2016. Evaluasi Pelaksanan

Proyek dengan Metode CPM dan PERT (Studi Kasus

Pembangunan Terminal Binuang Baru Kec.

Binuang). Artkel Ilmiah Mahasiswa: Universitas

Islam Indonesia Yogyakarta.

Fadli, M., Syarif SS., 2010. Model Teori Manajemen

Proyek. Politeknik Caltex Riau.

Haque, Farhana, Raisa Tabassum dan Md Mohibul Islam.,

2017. Project Scheduling Problem, Quality Loss and

Time-Cost Trade off. World Review of Business

Research: Vol 7 No. 2 Issue. Pp. 68-87

Jain, Susmit, 2013. Application of PERT Technique in

Health Programme Monitoring and Control.

International Journal of Research in Commerce,

IT&Management.Vol. 3 No.04, ISSN 2231-5756

Kim, J, Kang, CW & Hwang, IK., 2012. A practical

approach to project scheduling: considering the

potential quality loss cost in the time–cost tradeoff

problem, International Journal of Project

Management, Vol. 30, pp. 264–272

N

o

Eve

nt

Time

(hour

s)

Schedule Slack

(LS-

ES)

Early Late

ES EF LS LF

1 A 0.6 0.0 0.6 15.5 16.1 15.5

2 B 6.6 0.0 6.6 0.0 6.6 0.0

3 C 3.1 0.6 3.7 16.1 19.2 15.5

4 D 12.6 6.6 19.

2

6.6 19.2 0.0

5 E 22.3 19.2 41.

5

19.2 41.5 0.0

Start

A

B

C

D

E

ASAIS 2019 - Annual Southeast Asian International Seminar

106

Kipphan, Helmut, 2001. Handbook of Print Media.

Springer-Verlag Berlin Heidelberg New York: ISBN

3-540-67326-1

Levin, R. I. dan Kirkpatrick, C. A., 1972. Perencanaan dan

Pengawasan dengan PERT dan CPM. Jakarta:

Bhratara.

Mas’ud, M. Imron & Erik Wijayanti, 2017. Analisis

Evaluasi Biaya dan Penjadwalan Waktu Proyek

Pengolahan Limbah PT KI dengan Pendekatan

PERT. Jurnal J-Ensitec: Vol 03 No. 02

Raharja, Irvan, 2014. Analisa Penjadwalan Proyek dengan

Metode PERT di PT. Hasana Damai Putra

Yogyakarta pada Proyek Perumahan Tirta Sani.

Jurnal Bentang: Vol. 2 No. 1

Ridho, Muhammad Rizki, Syahrizal, 2015. Evaluasi

Penjadwalan Waktu dan Biaya Proyek Dengan

Metode PERT dan CPM. Jurnal Ilmiah. Universitas

Sumatera Utara.

Sari, Rianita Puspa, Okky Jayadi dan Langgam Tandya

Nugraha, 2018. Optimalisasi Proses Manufakturing

dalam Pembuatan Pipa Union dengan Menggunakan

Metode Hungarian dan PERT/CPM. Journal of

Industrial and Management Systems. Vol 11 No. 1, 1-

6

Sailaja, A, Basak, PC &Viswanadhan, KG, 2015. Hidden

Costs of Quality: Measurement & Analysis,

International Journal of Managing Value and Supply

Chains (IJMVSC), Vol. 6, No. 2, DOI: 10.5121.

Optimizing Production Time in Book Printing using PERT/CPM

107