Effect of the Fractional Distillation on an Increment Patchouli

Alcohol Content in Patchouli Oil

Yuliani Aisyah

1,2

, Sri Haryani Anwar

1

and Yulia Annisa

1

1

Agricultural Product Technology, Agriculture Faculty, Universitas Syiah Kuala, Banda Aceh, Indonesia, 23111

2

PUI - Atsiri Research Center, Universitas Syiah Kuala, Banda Aceh, Indonesia, 23111

Keywords: Patchouli oil, fractional distillation, patchouli alcohol, boiling point.

Abstract: Indonesia is one of the patchouli oil producers in the world, however, the problem is the quality of patchouli

oil, especially patchouli alcohol content that are still below the required standard. One of the methods that can

be used to increase the content of patchouli alcohol is fractional distillation method. This research aims to

know the influence of the initial concentration of patchouli alcohol and height of column against increment

of patchouli alcohol content in patchouli oil. The experimental design which used was Complete Randomized

Design (CRD) consist of two factors, first factor namely the initial concentration of patchouli alcohol (C1 =

31,11%, C2 = 32,83%, and C3 = 33,61%) and second factor is height of column (H1 = 25 cm and H2 = 45

cm). Analysis of variance shows that the height of vigreux column has a real influence against the increased

levels of patchouli alcohol. The highest levels of patchouli alcohol (83,86%) obtained from the residue

fraction of distillation with 31.11 % initial concentration of patchouli alcohol and 45 cm height of column.

The higher levels of patchouli alcohol in patchouli oil residue fraction, the higher specific gravity and the

refractive index, and solubility in ethanol will be easier. The result shows that this sample have 1.013 specific

gravity, clear in ethanol at 1:5 and have 1.5166 refractive index.

1 INTRODUCTION

Patchouli (Pogostemon cablin Benth) is one of the

plants that produce an essential oil known as the

Patchouli oil. Patchouli comes from a family of

Lamiaceae, the order of Lamiales and Class of

Angiospermae. There are several types of Patchouli

in Indonesia, such as Pogostemon cablin Benth, or

widely known as Aceh Patchouli (Nilam Aceh),

which has the oil content of 2.5-5%. Furthermore,

the Pogostemon heyneanus which is known as Java

Patchouli (Nilam Jawa) with the oil content of 0.5-

1.5%, and Pogostemon hortensis also known as Soap

Patchouli with the oil content of 0.5-1.5% (Rukmana,

2003).

According to Aisyah et al. (2008), there are 15

identified chemical constituents of Patchouli oil. The

constituents with the highest percentage are patchouli

alcohol (32.60%), δ-guaiene (23.07%), α-guaiene

(15.91%), seychellene (6.95%) dan α-

patchoulene (5.47%). These five components are also

similar to the result of Corine and Sellier (2004).

The patchouli alcohol (PA) is one of the quality

parameters of patchouli oil. Patchouli alcohol is an

oxygenated sesquiterpene that has a boiling point of

140 ºC at 8 mmHg pressure, the molecular weight of

224 and a molecular formula of C

15

H

26

O (Bulan et al.,

2000). According to the international standard, the

best quality of patchouli oil is the one with patchouli

alcohol content at least 38% (Essential Oil

Association of USA, 1975), and 31% (SNI 06-2385-

2006). The patchouli oil produced in Indonesia

relatively has a low content of patchouli alcohol

which is < 30%. This is because the postharvest

handling before distillation is not conducted very

well, the distillation process is not optimal (simple

method and equipment, and short distillation time),

and because of the material source. Therefore, the

parameter of patchouli alcohol content needs to be

improved to expand the market.

All this time the farmers only capable to produce

the oil with patchouli content of 26-28%, while the

distillation industry that uses the stainless-steel

distillation equipment can produce the oil with

patchouli alcohol content up to 31-35% (Sarwono,

1998).

Several types of research have been conducted to

improve the patchouli alcohol content in patchouli oil

80

Aisyah, Y., Anwar, S. and Annisa, Y.

Effect of the Fractional Distillation on an Increment Patchouli Alcohol Content in Patchouli Oil.

DOI: 10.5220/0009957100800085

In Proceedings of the 2nd International Conference of Essential Oils (ICEO 2019), pages 80-85

ISBN: 978-989-758-456-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

by using different method, for instance the fractional

distillation (Bulan et al., 2000; Harfizal, 2003;

Yanyan et al., 2004), rotary evaporator with

fractionation temperature control (Suryatmi, 2008),

cellulose acetate membrane (Aisyah et al., 2010),

vacuum fractionation distillation (Aisyah et al., 2013;

Isaroiny and Mitarlis, 2005), a combination of

fermentation, delignification and distillation methods

(Muharam et al., 2017). The result showed that the

increase of patchouli alcohol content varies depends

on the method used.

Based on the boiling point, constituents of

patchouli oil have boiling point as follows: patchouli

alcohol (140°C at 8 mmHg), eugenol (252.66 °C at

760 mmHg), benzaldehyde (178.07 °C at 760

mmHg), cinnamic aldehydes (251.00 °C at 760

mmHg) and cadinene (274 °C at 760 mmHg)

(Guenther, 1949). The difference in the boiling point

leads the components to be separated by the

fractionation distillation process. To provide a

thorough result and prevent component damage due

to the impact of temperature on ordinary fractionation

distillation, the process will be accompanied by

vacuum fractionation distillation.

This research aims to optimize the vacuum

fractional distillation by considering the factor of

initial patchouli alcohol of patchouli oil and factor

of fractionational distillation column used in this

process. It is assumed that these two factors can

produce a higher percentage of final patchouli alcohol

than initial patchouli alcohol from patchouli oil.

2 MATERIAL AND METHOD

2.1 Material

The material used in this research is patchouli oil

from Meukek, Pasie Raja, and Panjupian Sub-district

of Aceh Selatan Regency. The equipment used is a

series of vacuum fractionation distillation equipment

consisting of 500 ml round neck flasks, vigreux

columns, thermometers, condensers, 3 heart-shaped

flasks, vacuum pumps, pans, and hot plates. Quality

analysis is using Gas chromatography-mass

spectrometry Shimadzu GCMS-QP 2010S, GC-QP

2010S, pycnometer, analytical scale, test tubes, drop

pipettes and Abbe refractometers.

2.2 Method

Vacuum Fractional Distillation Process (Modified by

Aisyah, 2008). The fractional distillation process of

patchouli oil is using a series of vacuum fractionation

distillation equipment which is accompanied by a

vacuum pump. The patchouli oil used is 300 ml. The

distillation was done at ±2 KPa (± 15.001 mmHg)

pressure and temperature of 30-190 °C. The

distillation was conducted until there are no more

distillate drops on the heart-shaped flask. The sample

of patchouli oil is analyzed by using GC-MS before

fractionation. The residue from the fractional

distillation then was analyzed to determine the final

patchouli alcohol content. Furthermore, the residue

with the highest content of patchouli alcohol was

analyzed for refractive index and solubility in water.

3 RESULT AND DISCUSSION

3.1 Chemical Constituent of Patchouli

Alcohol

The Chromatogram (Figure 1) represents the analysis

result of chemical constituent using GC-MS on three

patchouli oil before fractionation, and the chemical

constituent components in patchouli oil that is above

1% can be seen in Table 1.

Table 1: Chemical constituent of Patchouli Oil

Chemical constituent Meukek

Pasie

Raja

Panju

pian

β-Patchoulene 1,62 1,76 1,73

2,4-Diisopropenyl-1-

methyl-1-vinyl-

cyclohexane

1,00 1.02 1,20

β-Caryophyllene 2,87 2,77 3,06

ߙ-Guaiene

17,39 16,61 18,10

Seychellene 4,68 4,27 4,67

α-Patchoulene 6,89 6,46 6,65

Alloaromadendrene 2,82 2,81 3,32

Δ -Guaiene 21,45 20,23 20,08

1H-

Cycloprop[e]azulen-

4-ol, decahydro-

1,1,4,7-tetramethyl

4,03 5,35

Patchouli alcohol 31,11 32,83 33,61

2H-Pyran-2,4(3H)-

dione, 3-acetyl-6-

methyl

1,12

Effect of the Fractional Distillation on an Increment Patchouli Alcohol Content in Patchouli Oil

81

Figure 1: Chromatogram of GC-MS result of Patchouli Oil:

(a) Meukek Patchouli Oil, (b) Pasie Raja Patchouli Oil, (c)

Panjupian Patchouli Oil

Based on Figure 1, it shows that each oil has the

same chromatogram pattern but has different peak

heights, which means that each patchouli oil has

different percentage of each of the different chemical

constituent components. The five highest constituents

are patchouli alcohol, Δ-guaiene, α-guaiene, α-

patchoulene, seychellene, and β-

carryophyllene, with a different percentage in each

patchouli oil (Table 1).

The difference in the percentage of each oil

caused by some factors, namely genetic (type),

cultivation, environment, postharvest and postharvest

handling (Irawan, 2010). It is assumed that the most

influencing factor from all of the mentioned factors is

the factor of the distillation process that leads to the

difference in the chemical constituent of patchouli oil

before the fractionation. It has been mentioned before

that the oils come from three different distillation

location. Thus, the distillation was conducted

differently.

The result from GC-MS analysis on Table 1 is

slightly different from the research by Corine and

Sellier (2004), who identified 4 new constituents

which are γ-gurjunene, germacrene D, aciphyllene

and 7-epi-α-selinene. Whereas in this research, the

result from analysis on oil before fractionation found

the component of γ-gurjunene and germacrene A.

Besides the factors mentioned above, it is assumed

that this difference is due to the method used in

analyzing using GC-MC is also different.

3.2 Patchouli Alcohol Content

Vacuum fractional distillation which was conducted

at ±2 KPa pressure can produce an average of 3

fractions, which are 2 distillates and 1 residue. Each

fraction was produced from a different temperature.

Based on the research of Aisyah (2008) we know that

the residue fraction from fractional distillation as a

higher content of patchouli alcohol than the other

fraction. Therefore, this research is analyzing the

patchouli alcohol using GC on residue fraction.

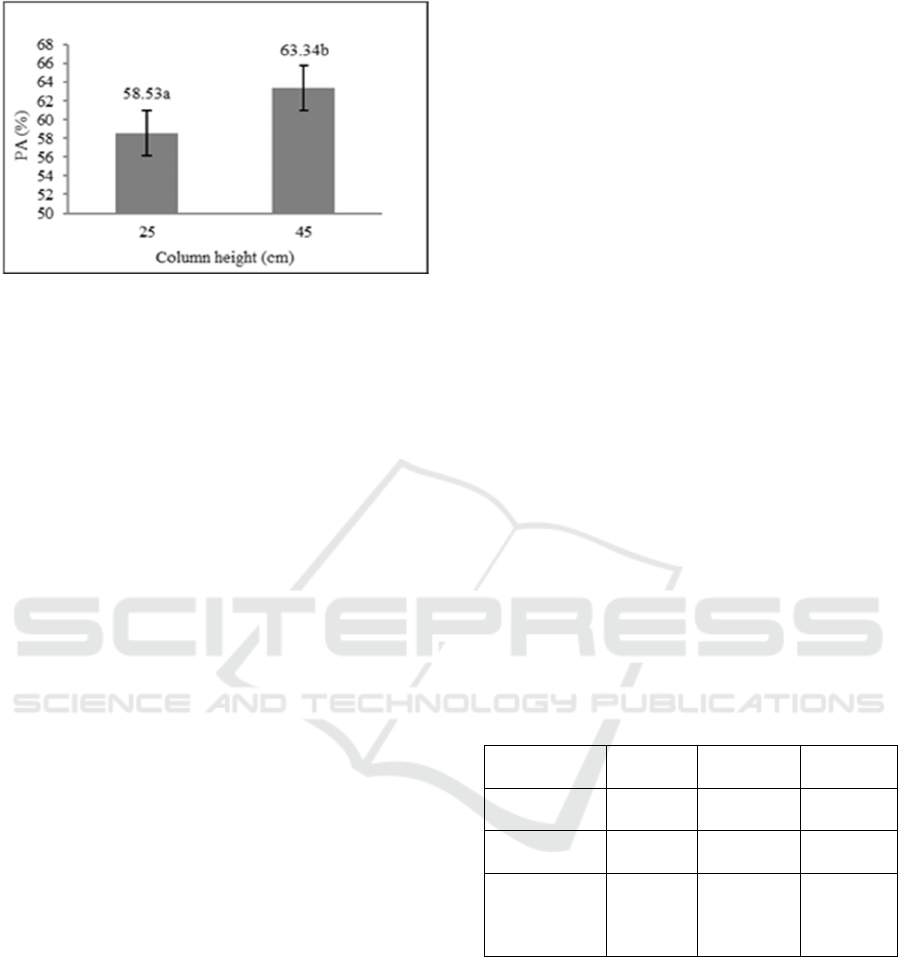

The result from GC analysis shows that the

patchouli alcohol ranged from 31.98% to 83.86%

with the average of 55.17%. The result from analysis

of variance shows that the height of Vigreux column

has a significant effect (P ≤ 0,01) on the increase of

patchouli alcohol content in patchouli oil.

Meanwhile, the initial content of patchouli alcohol

and interaction between two factors has no significant

effect (P>0,05) on the increase of patchouli alcohol

content in patchouli oil. The influence of Vigreux

column height on the increase of patchouli alcohol

content can be seen in Figure 2.

LSD

0.05

test result shows that the 45 cm column

can increase the patchouli alcohol content in

patchouli oil and higher than the use of a 25 cm

column. Based on Figure 2, the increase of patchouli

alcohol content on the 45 cm column is different

significantly with the 25 cm column.

The column is used to separate the vapor from

liquid compound which has a similar boiling point

(<20°C). The barrier (tray/plate) in the fractionation

column causes vapors with the same boiling point

will both evaporate or compounds with low boiling

points that will continue to rise until finally condenses

and descends as a distillate. Meanwhile, if the

compounds with higher boiling points have not

reached the boiling point value, they will drip back

into the distillation flask, which eventually will reach

the boiling point value if the heating continues. The

compound will evaporate, condense and drop/drip as

a distillate.

A

B

C

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

82

Figure 2: The effect of vigreux column height on the

increase of patchouli alcohol (PA) content in residue

fraction (LSD

0.05

= 4,06, CV = 20,18%, values that followed

by the same letter show no significant difference).

The components of a substance undergoing the

fractionation distillation process will experience

direct contact in the column. The fractionation

column (vigreux column) contains a tray that serves

as a component selection media. During the

distillation process, the components in the oil will

evaporate according to the boiling point of each

component and pass through the trays in the column.

The farther the tray is from the heat source, the lower

the temperature of the tray.

It is assumed that the components that can rise to

the top of the 45 cm column and becomes distillate

are only those who have boiling point lower than

patchouli alcohol. This is due to the low temperature

of the tray at the top of the column. Hence, only the

components with a low boiling point that can

maintain the form of gas after hitting the tray.

Whereas the temperature difference between base and

top of 25 cm column is not too far away that makes

the components with a similar boiling point with

patchouli alcohol also evaporate and becomes

distillate.

According to Geankoplis (1983), condensation or

the process of gas turn into liquid occurs when

saturated gas touches the solid that has a temperature

below gas temperature. This conversion makes the

components that have a low boiling point fall back

down to the base of the column.

Geankoplis (1983) also stated that if the

component is in liquid form when passing through the

tray, then the components will fall to the previous

tray. Meanwhile, the components in the gas form will

keep drove off to the next tray where the components

will be having more contact with the liquid that

coming down from the tray above it. Under these

conditions, the concentration of the component with

a low boiling point will increase in the vapor and

decrease in the liquid which descends towards the

bottom of the fractionation column. This statement

implies that the fractionation column, especially the

tray in the column, can affect the chemical

composition of the distillate fraction and the residue

from the fractionation distillation.

According to Ma’mun and Maryadhi (2008),

patchouli alcohol has a relatively higher boiling point

than other components in patchouli oil. The content

that was obtained in this research is lower than the

content of patchouli alcohol from the research of

Ma’mun and Maryadhi (2008) which is about 91.5%.

This is due to the difference of pressure used by those

researchers with the pressure used in this research.

This research is using the pressure of ± 2 KPa because

it was the minimal pressure that can be reached by the

vacuum pump. Meanwhile, Ma’mun and Maryadhi

(2008) used the pressure of 0 cmHg (similar with 0

KPa) that caused the boiling point of those

components can be reduced further and the separation

occurs more easily without having to experience

overheating which allows decomposition.

The result of the research is also contrary to the

research from Aisyah et al. (2008). It is assumed that

the difference was due to the same cause which is the

difference in the condition of the vacuum fractional

distillation process. The comparison of results from

several types of research about vacuum fractional

distillation of patchouli alcohol can be found in Table

2.

Table 2: The comparison of research result of vacuum

fractional distillation of patchouli oil

Condition

Aisyah

(2008)

Ma’mun

(2008)

This

research

Pressure 4 mmHg 0 mmHg 2 KPa (15

mmHg)

Temperature 90-135

ºC

150-180 ºC 140-190

ºC

Highest

patchouli

alcohol

content

87.36 % 91.5 % 83.86 %

3.3 Physical Properties of Residue

Fraction of Patchouli Oil

Analysis of physical properties was performed on

specific gravity, solubility in ethanol and refractive

index. The sample is residue fraction from treatment

which has initial content of 31.11% with 3 different

columns. The chosen sample is the sample from the

treatment that produced a residue fraction with a

patchouli alcohol content higher than other samples.

Effect of the Fractional Distillation on an Increment Patchouli Alcohol Content in Patchouli Oil

83

3.4 Specific Gravity

Specific gravity is the result of the ratio comparison

between oil weight and water weight at the same

volume and temperature (SNI, 2006). According to

Gunther (1949), this parameter is essential in finding

the foreign matter in a liquid or the shifts that may be

affecting the quality of the oil. The result from the

analysis of specific gravity (Table 3) shows that the

specific gravity of the sample goes beyond the

standard that has been determined by the Indonesian

National Standard (SNI) which is about 0.950-0.975.

This suggests that the residue fraction of patchouli oil

from the treatment of 25 cm and 45 cm column cannot

be sell as crude oil. However, the residue fraction can

be applied as a material in derivative products from

patchouli oil.

Table 3: Specific gravity and refractive index of residue

fraction of patchouli oil

Sample

Specific

Gravity

Refractive

Index

Without fractionation 0.953 1.5070

25 cm column height 1.005 1.5156

45 cm column height 1.013 1.5166

Table 3 shows the increase of the specific gravity

of patchouli oil before and after fractionation

(control). This increase influenced by the components

in the oil. According to Rizal (2010), specific gravity

represents the comparison between heavy fractions

and light fractions contained in the oil. The heavier

fractions contained a higher specific gravity. The

heavy fractions are influenced by the length of the

molecular chain of a compound contained in the oil.

Patchouli oil is a compound with a molecular

formula of C

15

H

26

O. Hence, this compound has a

relatively long molecular chain which caused the oil

to dominated by high specific gravity patchouli

alcohol components. The result is shown in Table 3.

The patchouli oil before fractional distillate only

contains 31.11% of patchouli alcohol and a specific

gravity of 0.953, while the residue fraction of

patchouli oil which has been fractionated by 25 cm

column has 75.14% of patchouli alcohol and a

specific gravity of 1.005. Furthermore, the residue

fraction of patchouli oil which has been fractionated

by 45 cm column has 83.86% of patchouli alcohol

and a specific gravity of 1.013.

3.5 Refractive Index

The refractive index is the ratio of the velocity of

light in air to its velocity in the examined substance at

a certain temperature (Armando, 2009). According to

Guenther (1949), the index of refraction value of

patchouli oil or other essential oil can be determined

by using Abbe refractometer. The result from the

analysis of the refractive index (Table 3) shows the

treatment of a 45 cm column with the initial content

of 31.11% resulting in the highest refractive index of

1.5166. Guenther (1949) explained that the value of

the specific gravity of essential oil will affect the

refractive index value. As can be seen at Table 3,

Patchouli oil which has not been fractionated and

with a patchouli alcohol content of 31.11% with a

specific gravity value of 0.953, has a refractive index

value of 1.5070, where this value is much lower than

after fractionation with a 45 cm column height of

1.5166. This is in accordance with the statement from

Armando (2009) who stated that the more

components with a long chain-like sesquiterpene or

sesquiterpene or oxygen clusters components

contained, the density of essential oil medium will

increase. Hence, the light will be harder to refract and

the refractive index value will be higher.

3.6 Solubility in Ethanol 90%

The solubility of patchouli oil in ethanol is one of the

examinations of patchouli oil quality based on

physical properties. This test is conducted to

determine the purity of essential oil.

Table 4: Residue fraction of patchouli oil solubility in

Ethanol 90%

Without

fractionation

25 cm column

height

45 cm column

height

1 : 5 Turbid 1 : 4 Turbid 1:3 Turbid

1 : 6 Turbid 1 : 5 Turbid 1:4 Turbid

1 : 7 Turbid 1 : 6 Turbid 1:5 Soluble

1 : 8 Soluble 1 : 7 Soluble 1:6 Soluble

Based on Table 4, it can be seen that the patchouli

oil residue fraction resulting from the K

1

T

2

treatment

is soluble at a ratio of 1: 5 (1 ml of oil and 5 ml of

ethanol). The treatment shows a clear solution at the

lowest ratio compared to other treatments, even

clearer than the raw material (control) which is

soluble at a ratio of 1:8. According to Guenther

(1949), the solubility of oil in alcohol is determined

by the type of chemical components contained in

essential oil. In general, essential oils which contain

oxygenated terpene compounds will be more soluble

in alcohol compared to essential oils containing non-

oxygenated terpene components. This is because of

the non-oxygenated terpene compounds which are

ICEO 2019 - 2nd International Conference of Essential Oil Indonesia

84

nonpolar compounds that do not have functional

groups. Thus, it is difficult to react with alcohol.

Patchouli alcohol is a component in patchouli oil

which is included in an oxygenated terpene

compound and has a functional group. Therefore,

patchouli oil which has a higher level of patchouli

alcohol such as the residual fraction resulting from

the K

1

T

2

treatment will be more soluble in alcohol

compared to other treatment.

4 CONCLUSION

The height of vigreux column used in vacuum

fractionation distillation has a significant effect on the

increase of patchouli alcohol levels in patchouli oil

residue fraction, while the initial patchouli alcohol

levels did not affect the increase in patchouli alcohol

levels in patchouli oil residue fraction. The value of

specific gravity and refractive index from the fraction

of residual fractionation result of patchouli oil is

higher than patchouli oil before fractionation so that

the solubility in ethanol will be easier. The highest

alcohol content of patchouli was obtained from

fractionation distillation using a column height of 45

cm which was 83.86%.

REFERENCES

Aisyah, Y., Hastuti, P., Sastrohamidjojo, H., and Hidayat,

C. 2008. Komposisi Kimia dan Sifat Antibakteri

Minyak nilam (Pogostemon cablin). Majalah Farmasi

Indonesia, 19 (3), 151-156.

Aisyah, Y., Hastuti, P., Hidayat, C., and Sastrohamidjojo,

H. 2010. Peningkatan Kadar Patchouli Alkohol Minyak

Nilam (Pogostemon cablin Benth) dengan

Menggunakan Membran Selulosa Asetat. Jurnal

Agritech, 30(3), 184-191.

Aisyah, Y., S.H. Anwar., and Y, Annisa. 2013. Increment

of patchouli alcohol in patchouli oil by vacuum

distillation fraction method. Proceedings of The 3rd

Annual International Conference Syiah Kuala

University (AIC Unsyiah) In conjunction with The 2nd

International Conference on Multidisciplinary

Research (ICMR).

Armando, R. 2009. Memproduksi 15 Jenis Minyak Atsiri

Berkualitas. Penebar Swadaya, Jakarta.

BSN (Badan Standardisasi Nasional). 2006. SNI No. 06-

2385-2006. http://sisni.bsn.go.id (10 Mei 2012).

Bulan, R. 2004. Esterifikasi Patchouli Alkohol Hasil Isolasi

dari Minyak Daun Nilam (Patchouli Oil). Jurusan

Kimia Fakultas Matematika dan Ilmu Pengetahuan

Alam Universitas Sumatera Utara.

Corine, M.B., Sellier, N.M., 2004. Analysis of The

Essential Oil of Indonesian Patchouli (Pogostemon

cablin Benth.) Using GC/MS (EI/CI). J. Essent. Oil

Res., 16, 17-19.

Essential Oil Association of USA. 1975. EOA

Spesifications and Standard. EOA USA. New York.

Geankoplis, G.J. 1983. Transport Process and Unit

Operation. Second Edition, Allyn and Bacon, Inc,

Boston, London, Sydney, Toronto.

Guenther, E. 1949. Essential Oils : Volume II. Van

Nostrand Reinhold Company, New York.

Harfizal. 2003. Penerapan teknologi distilasi vakum untuk

meningkatkan mutu minyak nilam. Prosiding Seminar

Teknologi untuk Negeri.

Irawan, B. 2010. Peningkatan Mutu Minyak Nilam dengan

Ekstraksi dan Destilasi Pada Berbagai Komposisi

Pelarut. Tesis. Magister Teknik Kimia Universitas

Diponegoro, Semarang.

Isaroiny, R., Mitarlis. 2005. Peningkatan Kadar Patchouli

Alkohol pada Minyak Nilam (Pogostemon cablin

Benth) dengan Metode Distilasi Fraksinasi Vakum.

Berk. Penel. Hayati, 10, 123–127.

Ma’mun., Adhi Maryadhi. Isolasi Patchouli Alkohol dari

Minyak Nilam untuk Bahan Referensi Pengujian dalam

Analisis Mutu. Bul. Littro, 19(1), 95 – 99.

Muharam, S., Lela, M. Y., and Iim, S. R. 2017. Peningkatan

Kualitas Minyak Nilam (Pogostemon Cablin Benth)

menggunakan Kombinasi Metode Fermentasi,

Delignifikasi dan Destilasi. Jurnal Kimia Valensi, 3 (2),

116-121.

Rizal, S. 2010. Kajian Proses Penyulingan Minyak Nilam

Menggunakan Sistem Distilasi Air. Fakultas Teknologi

Pertanian IPB, Bogor.

Rukmana, R. 2003. Nilam: Prospek Agribisnis dan Teknik

Budidaya. Kanisius. Yogyakarta.

Sarwono, B. 1998. Budidaya Nilam di Purbalingga. Trubus

343-Th XXIX-Juni 1998. 77-78.

Suryatmi, R.D. 2008. Fraksinasi minyak nilam. Prosiding

Konferensi Nasional Minyak Atsiri.

Yanyan, F.N., Zainuddin, A., Sumiarsa, D. 2004.

Peningkatan kadar patchouli alkohol dalam minyak

nilam (patchouli oil) dan usaha derivatisasi komponen

minornya. Jurnal Perkembangan Teknologi TRO, 16,

72-78.

Effect of the Fractional Distillation on an Increment Patchouli Alcohol Content in Patchouli Oil

85