Performance of Unbending Embedded for Precast Concrete

A. Rudi Hermawan

1

, Eka Sasmita Mulya

2

1

Teknik Sipil,Teknik Konstruksi Gedung,Politeknik Negeri Jakarta

2

Teknik Sipil, Konstruksi Gedung,Politeknik Negeri Jakarta

Keywords: embedded, precast,concrete

Abstract: Usually we used embedded for joint of precast concrete with bending embedded system (PCI Standard).

Bending embedded system used reinforced with bending in the end of plate but for unbending embedded

system used reinforced with unbending in the end of plate. This research aims to determine perform of

embedded with unbending system. The materials used in this research was reinforced with Diameter 12,59

mm, Plate 4,58 mm thick and electrodes used in this welding method was E6013.This experiment was testing

of the ultimate tensile strength of unbending embedded joint of precast concrete and testing of ultimate tensile

strength of the reinforced bar. The results of this research was the average value of ultimate tensile strength

of unbending embedded 597,16 Mpa broken at the reinforced bars. Average value of ultimate tensile strength

of reinforced bar was 605,23 Mpa. Conclusion of this research is embedded with unbending system for precast

concrete can be used for construction of joints.Usually we used embedded for joint of precast concrete with

bending embedded system (PCI Standard). Bending embedded system used reinforced with bending in the

end of plate but for unbending embedded system used reinforced with unbending in the end of plate. This

research aims to determine perform of embedded with unbending system. The materials used in this research

was reinforced with Diameter 12,59 mm, Plate 4,58 mm thick and electrodes used in this welding method

was E6013..This experiment was testing of the ultimate tensile strength of unbending embedded joint of

precast concrete and testing of ultimate tensile strength of the reinforced bar. The results of this research was

the average value of ultimate tensile strength of unbending embedded 597,16 Mpa broken at the reinforced

bars. Average value of ultimate tensile strength of reinforced bar was 605,23 Mpa. Conclusion of this research

is embedded with unbending system for precast concrete can be used for construction of joints.

1 INTRODUCTION

1.1 Previous Reserach

Unbending Embedded are elements joint of precast

concrete which use materials consist of plate and

reinforce bar. Research of embedded for precast

concrete has been widely done since 1993 and widely

used by society of Consultants or Contractors sector.

In 1993 Ugur Ersoy and Tugrul Tankut on research

Precast Concrete Members With Welded Plate

Connections Under Reversed Cyclic Loading

2

. This

research was used unbending embedded element to

joint between beam and column for sustain moment

and shear occur.

Research of Seismic behavior of a type of welded

precast concrete beam-column connection by Mario

E. Rodríguez, Miguel Torres-Matos concern bending

embedded at negative moment in 2013.

5

Andrea

Belleri, Paolo Riva in 2012 research concern Seismic

performance and retrofit of precast concrete grouted

sleeve connections.

4

All research above concern to

bending embedded joint system. This research was

used unbending embedded joint system which used

materials same as with bending embedded. The

different is at bend and unbend to reinforce bar.

Goal of this research is making joint with result

perform not different to each other system. Result of

research unbending embedded system has performed

so good to sustain of tension.

1.2 Design of Joint

Many types of joint for precast concrete in

construction and embedded system has been many

using in construction sector. Type of Embedded

system using materials plate and reinforce bars. To

connecting material plate and reinforce bar using

144

Hermawan, A. and Mulya, E.

Performance of Unbending Embedded for Precast Concrete.

DOI: 10.5220/0009968400002905

In Proceedings of the 8th Annual Southeast Asian International Seminar (ASAIS 2019), pages 144-148

ISBN: 978-989-758-468-8

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

electrode to weld between plate and reinforce bar.

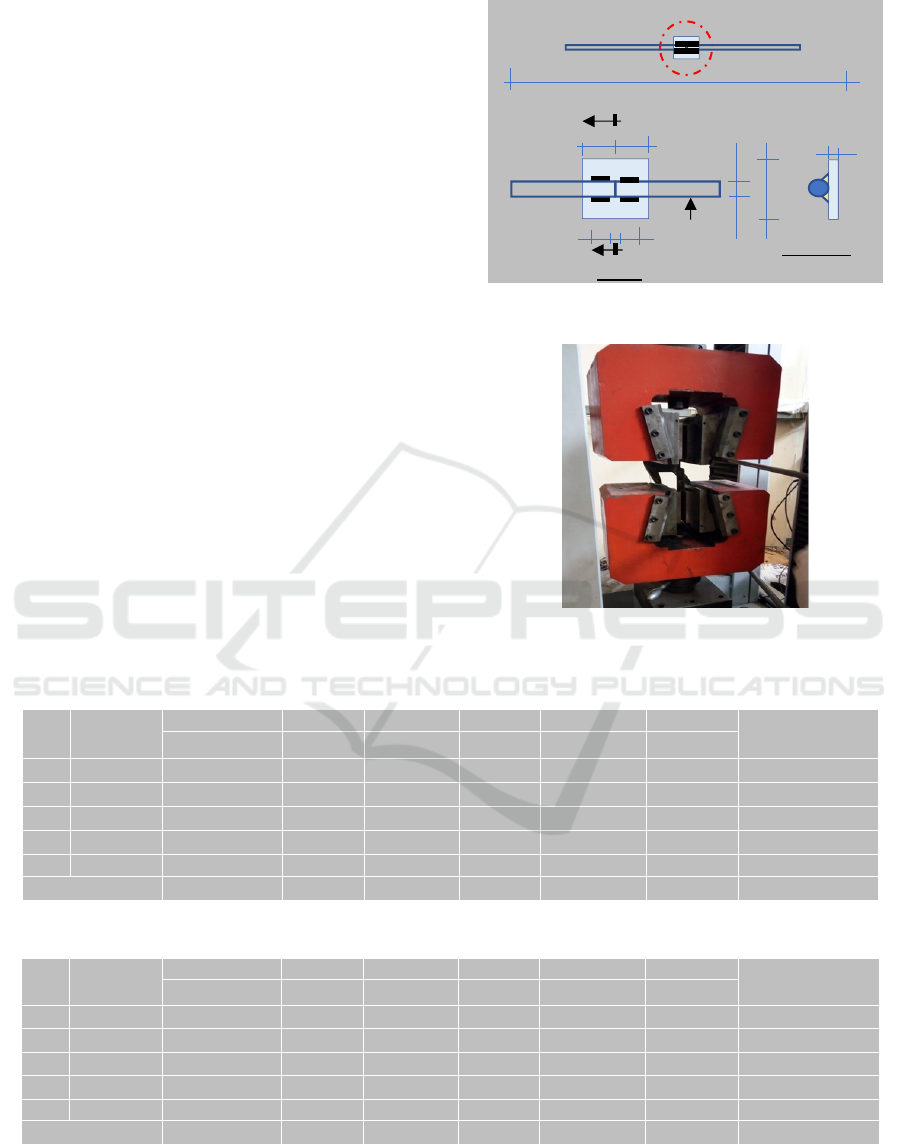

Figure 1 show element unbending embedded system.

And can be simple Formulated

10,11

:

Ld =

mm

fc

dbfy

300

'.25

.....18

Figure 1. Element unbending embedded system

Figure 2. Photo of Unbending Embedded

2 RESEARCH METHOD

Testing elements used location at Lembaga Uji

Konstruksi (LUK) BPPT Serpong South of

Tangerang. This research has 5 samples for tested

unbending embedded tensile strength dan 5 samples

for tested tensile strength reinforced bars. Reinforced

bars used D12,59 and plate which have 4,58 mm thick

with electrode type

E6013.

. to joint between plate and

rebars with 5 mm thick. figure 2 was show prototype

of sample test unbending embedded tensile strength

and figure 3 was show prototype of reinforced bar

tensile strength.Figure 4 describe of dimension

sample test for unbending embedded tensile strength

which have measurement of total length of welded 66

mm, length of reinforced bar 400 mm and dimension

of plate 80/70 mm as base of welding. Figure 5 show

of method of research which was used UTM machine

at Puspitek BPPT Serpong and appropriate ASTM

standard for test tension of elements.

Figure 3. Photo of Reinforced bars

3 RESULTS AND DISCUSSION

The Research of unbending embedded for all

specimens were capable to resisting tensile load until

broken, cause all specimens were its broken at the

reinforce bars. Specimen 2A indicated ultimate

tensile strength value 608,12 Mpa as ultimate load

75,67 KN, specimen 2B indicated ultimate tensile

strength value 609,84 Mpa as ultimate load 75,88 KN,

specimen 2C indicated ultimate tensile strength value

589,38 Mpa as ultimate load 73,21 KN, specimen 2D

indicated ultimate tensile strength value 594,29 Mpa

as ultimate load 73,95 KN and specimen 2E indicated

ultimate tensile strength value 585,18 Mpa as

ultimate load 72,81 KN. The

results of this research

was the average value of ultimate tensile strength of

unbending embedded 597,16 Mpa as ultimate load

74,31 KN broken at the reinforced bars.Table 1 gives

T

T

T

Embedded

Plat

FWelde

Ld

T

Ld

T

where :

fy= Yield Stress ( Mpa )

= Reinforcement location factor

Coating factor

Ligthweigth aggregate concrete factor

db= Nominal Diameter

fc’= Compression Concrete ( MPa )

and another formulated

1,3

Tu = As.fy. ( N )

Fw = L.fsw.t

Where :

Tu = Tensile Strength Rebar ( N )

As= Area of Rebar ( mm2 )

Fw= Shear Strength of Welded ( N )

L= Length of Welded ( mm )

fsw= Shear Stress of Welded ( Mpa )

t= Thick of Welded ( mm )

Performance of Unbending Embedded for Precast Concrete

145

the result of ultimate tensile strength of all specimens

unbending embedded system.Figure 6 show of photo

specimens of unbending embedded have tested.The

Research of reinforce bars for all specimens were

tested until broken. Specimen 4A indicated ultimate

tensile strength value 646,47 Mpa as ultimate load

80,44 KN, specimen 4B indicated ultimate tensile

strength value 596,73 Mpa as ultimate load 74,25 KN,

specimen 4C indicated ultimate tensile strength value

592,63 Mpa as ultimate load 73,74 KN, specimen 4D

indicated ultimate tensile strength value 593,19 Mpa

as ultimate load 73,81 KN and specimen 4E indicated

ultimate tensile strength value 597,13 Mpa as

ultimate load 74,30 KN. The results of this research

was the average value of ultimate tensile strength of

reinforce bars 605,23 Mpa as ultimate load 75,31 KN.

Table 2 gives the result of ultimate tensile strength of

all specimens reinforce bars.Figure 7 show of photo

specimens of reinforce bars until tested.The value of

average ultimate tensile strength both of specimens

unbending embedded or specimens reinforce bars

have resulted almost not different only about 1,01 KN

for ultimate load and 8.07 Mpa for ultimate tensile

strength and all of specimens broken at the reinforced

bar. This result test can be category fulfill of tensile

strength and can be used for construction as specially

joint of

precast concrete. Figure 8 show chart of load

versus stress.

Figure 4: Sketch of Unbending Embedded

Figure 5: UTM Machine

Table 1: Result Test of Unbending Embedded

Table 2: Result Test Of Reinforce Bar D 12.59 mm

No Sample Dia Area Fy Fu fy fu Result

mm mm2 kN kN MPa MPa

1 4A

12.59 124.43 58.82 80.44 472.72 646.47 Reinf.broken

2 4B

12.59 124.43 51.83 74.25 416.54 596.73 Reinf.broken

3 4C

12.59 124.43 51.28 73.74 412.12 592.63 Reinf.broken

4 4D

12.59 124.43 50.86 73.81 408.75 593.19 Reinf.broken

5 4E

12.59 124.43 52.16 74.30 419.20 597.13 Reinf.Broken

Average

52.99 75.31 425.87 605.23

No Sample Max.Load t.Plate L.Rigth L.Left fu.Rigth fu.Left Result

kN mm mm mm MPa MPa

1 2A

75.67 4.56 66.50 64.50 608.14 608.14 Reinf.broken

2 2B

75.88 4.65 67.00 65.50 609.83 609.83 Reinf.broken

3 2C

73.21 4.54 64.00 65.50 588.37 588.37 Reinf.broken

4 2D

73.95 4.57 64.00 67.00 594.32 594.32 Reinf.broken

5 2E

72.81 4.56 65.00 64.00 585.15 585.15 Reinf.Broken

Average

74.31

4.58 65.30 65.30 597.16 597.16

Sect-B-B

40 mm40 mm

12,59

33 mm

33 mm

70 mm

B

B

D 12,59 mm

4,58 mm

Det.A

A

400 mm

ASAIS 2019 - Annual Southeast Asian International Seminar

146

Figure 6: Samples Have Tested

Figure 7: Photo of Reinforced bar

Figure 8. Ultimate load vs ultimate tensile strength.

4 CONCLUSION

The results of this research was the average value of

ultimate tensile strength of reinforce bars 605,23 Mpa

as ultimate load 75,31 KN and the average value of

ultimate tensile strength of unbending embedded

597,16 Mpa as ultimate load 74,31 KN broken at the

reinforced bars and difference both of specimens

almost not different, only about 1,01 KN for ultimate

load and 8.07 Mpa for ultimate tensile strength and

all of specimens broken at the reinforced bars,

indicate that research about connection use

unbending embedded system can be applicated. SNI

and ACI requiring 1,25fy strength of rebars if joint

element used welded for connect each other

s

Advantage of this system, for making element joint

will be faster than system bending embedded joint

with the result that, cost of all element joint will be

cheaper.

REFERENCES

Rodríguez. dan Torres M, Summer 2013 , “Seismic

Behavior of type of welded precast concrete beam-

colum connection, PCI Journal Paper,Vol.58, Issue: 3,

Page number: 81-94

Ugur Ersoy and Tankut Tugrul, July-August 1993,”

Precast Concrete Members with Welded Plate

Connections Under Reversed Cyclic Loading “ PCI

Jurnal Paper, Volume 38, Issue: 4, Page number: 94-

100

Nadim,M and Manaser,A, 2008, Structural Concrete :

Theory and Design , John Wiley and Sons, USAAndrea

Belleri, Paolo Riva,2012, “Seismic performance and

retrofit of precast concrete grouted sleeve

connections”, Volume: 57, Issue: 1, Page number: 97-

109

Mario E. Rodríguez, Miguel Torres-Matos,2013, “Seismic

behavior of a type of welded precast concrete beam-

column connection”, Volume: 58, Issue: 3, Page

number: 81-94

Ameli,J dan Park,Joel E, March - April 2015,” Seismic

evaluation of grouted splice sleeve connections for

reinforced precast concrete column–to–cap beam joints

in accelerated bridge construction”, PCI Journal Paper,

Volume: 60 Issue: 2 Page number: 80 – 103

Nabi Goudarzi, Yasser Korany, March-April 2016,”

Characterization of the shear behavior of Z-shaped steel

plate connectors used in insulated concrete panels”, PCI

Journal Paper, Volume: 61,Issue: 2, Page Number: 23-

37

Elide Pantoli dan Tara C. Hutchinson, July-August 2016,”

Seismic-drift-compatible design of architectural precast

0

200

400

600

800

45 50 55 60 65 70 75 80 85

f , Mpa

F , kN

LOAD VS STRESS

Fu,fu Embedded

Fy,fy ReBars

Fu,fu ReBars

Performance of Unbending Embedded for Precast Concrete

147

concrete cladding: Tieback connections and corner

joints”, PCI Journal Paper, Volume: 61, Issue: 4, Page

Numbers: 38-52

Hatem M. Seliem dan Lining Ding, September-October

2016,” Use of a carbon-fiber-reinforced polymer grid

for precast concrete piles”, PCI Journal Paper,Volume:

61, Issue: 5, Page Number: 37-48

ACI Committee 318, 2011, Building Code Requirments for

Structure and Commentary,American Concrete

Institute, Detroit

SNI 03-2847-2012,Standar Nasional Indonesia ,Tata Cara

Perhitungan Struktur Beton Untuk Bangunan Gedung,

Bandung, 2012

Clay Naito, Robin Hendricks, and Andrew Osborn, March

- April 2019, Flange-to-flange double-tee connections

subjected to vehicular loading, part 2: Fatigue life

assessment, Volume: 64, Issue: 2, Page Numbers: 23 –

38

Antoine N. Gergess, May - June 2019, Analysis of bonded

link slabs in precast, prestressed concrete girder

bridges, Volume: 64, Issue: 3, Page Numbers: 47 – 65

Chad Van Kampen and Alex Mihaylov, September -

October 2019, Panelization and connections for rapid

erection of high-rise elevator and stair cores,

Volume: 64, Issue: 5, Page Numbers: 23 – 29

Robin Hendricks, Clay Naito, and Andrew Osborn, July -

August 2018, Flange-to-flange double-tee connections

subjected to vehicular loading, part 1: Numerical

assessment approach, Volume: 63, Volume: 63,

Issue: 4, Page Numbers: 41-53

P. Selvachandran, S. Anandakumar, and K. L. Muthuramu,

January-February 2017, Influence of deformability

behavior in prestressed concrete beams using carbon-

fiber-reinforced polymer tendon, Volume: 62, Issue: 1,

Page Numbers: 66-77

ASAIS 2019 - Annual Southeast Asian International Seminar

148