Modification of Mung Bean Starch by Annealing Treatment and

Acetylation

Azis Boing Sitanggang

1,2

, Patricia Sani

3

and Titri S. Mastuti

3

1

Department of Food Science and Technology, IPB University. Kampus IPB Darmaga Bogor 16680, West Java, Indonesia

2

Southeast Asian Food and Agricultural Science and Technology (SEAFAST) Center, IPB University,

Kampus IPB Darmaga Bogor 16680, West Java, Indonesia

3

Department of Food Technology, Pelita Harapan University, MH Thamrin Boulevard 1100,

Tangerang 15811, Banten, Indonesia

Keywords: Mung Bean, Mung Bean Starch, Dual Modification, Annealing, Acetylation, Modified Starch,

Physicochemical Characteristics of Modified Starch.

Abstract: Mung beans are mainly composed of starch (25-30%). Mung bean starch which found naturally has low

stability during processing and heat sensitive. The purpose of this research was to produce mung bean starch

with higher resistance to heat and higher resistance to enzyme digestion, with combination of annealing and

acetylation modification. Modified starch with 60

o

C of annealing temperature resulted in highest crystallinity.

Additionally, with 20% of acetic acid anhydride concentration and 15 minutes acetylation reaction time

resulted in acetyl percentage and substitution degree that met FDA requirement. Dual modification of

annealing and acetylation with chosen treatments as mentioned, was analysed further to determine starch

content, moisture content, amylose and amylopectin content, swelling power and solubility properties, colour

test, resistant starch content, XRD profile, FTIR profile, pasting properties, and starch granule morphology.

1 INTRODUCTION

Mung bean belongs to Fabaceae family. This bean

can be found easily in Asia, Australia, New Zealand,

and Africa (Yang et al., 2018). Mung bean has

±7.91% water content, ±24.08% protein content,

±1.55% fat content, ±2.87% ash content, ±2.20%

fiber content, and ±25.73% starch content

(Moongngarm, 2013).

Mung bean has bioactive compound like tannin,

phytic acid, flavonoid, phenolic acid, and other

organic acids. These bioactive compounds in mung

bean has positive effects on health, such as free

radical scavenger, detoxification, anti-bacterial,

prevent diabetes, and prevent cancer (Ganesan & Xu,

2018). Mung bean production in Indonesia reach

370,000 tons, this amount was not balanced by its

production which reach 303,000 tons (Kementerian

Pertanian, 2018). Therefore, mung bean was used as

ingredient in starch production to increase its

economic value.

Mung beans mainly composed of starch (25-

30%). However, mung bean starch which found

naturally has low stability and low heat resistance

(Phrukwiwattanakul et al., 2014). Therefore,

modification was needed to alter functional properties

of starch and make it applicable to certain food

industries.

Starch modification can change its polymer,

structure, and functional properties, to increase its

function in food industries or non-food industries

(Lopez et al., 2010). However, study about starch

modification using combination of annealing and

acetylation, and its effect on physicochemical

properties on mung beans starch has not been done.

The purpose of this research was to produce mung

beans starch with higher resistance to heat and higher

resistance to enzyme digestion, with combination of

annealing and acetylation modification. Moreover,

this research was done to determine the effects of

selected treatment to mung beans starch

physicochemical properties, with annealing heating

temperature, acetic acid anhydride concentration, and

acetylation reaction time as factors.

10

Sitanggang, A., Sani, P. and Mastuti, T.

Modification of Mung Bean Starch by Annealing Treatment and Acetylation.

DOI: 10.5220/0009977100002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 10-19

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 MATERIALS AND METHODS

2.1 Materials and Equipment

The materials used in this research were mung beans

obtained from Plaza Baru Ciledug market. Distilled

water (Amidis), acetic acid anhydride, pure glucose,

HCl, NaOH, anthrone reagent, iodine, KI, KOH,

H2SO4 (Merck, EMD Millipore Corp.), pure

amylose, phosphate buffer, α-amylase enzyme,

pepsin enzyme, β-amylase enzyme (Sigma-Aldrich,

EMD Millipore Corp.), ethanol (Smart-Lab, PT

Smart Lab), aquadest, and phenolphthalein indicator

were also used in this research.

The equipment used in this research were beaker

glass, Erlenmeyer flask, volumetric flask, Mohr

pipette, graduated cylinder (Iwaki), blender (HR

2071/20, PT Philips), thermometer (ASTM 12C,

BRAND, Ltd.), oven (UNB 500, Memmert, Ltd.),

cabinet dryer (Rekayasa Wangdi), heater (Cimarec),

analytical balance (Pioneer), refrigerator (Tipe SDC

1000, PT Sanden), vortex (Tipe 37600 Mixer,

Barnstead Thermolyne Corp.), spectrophotometer

UV-Vis (Genesys 10S UV-VIS, Thermo Fisher

Scientific Inc.), pH meter (Tipe 744, Metrohm, Ltd.),

waterbath (WB 14, Memmert, Ltd.), burette

“BRAND”, centrifuge (Z 206 A, Hermle Labor

Technik, Inc.), chromameter (CR-400, Konica

Minolta, Inc.), X-Ray Diffraction (MiniFlex, Rigaku

Corp.), Scanning Electron Microscope (Quanta 650

FEG, Thermo Fisher Sientific, Inc.), Fourier

Transform Infrared Spectroscopy (IRPrestige-21,

Shimadzu Corp.), Rapid Visco Analyzer (RVA-4,

Newport Corp.), spoon, glass rod, spatula, filter cloth,

evaporating dish, test tube, test tube clamp, tray,

desiccator, filter paper, magnetic stirrer, stopwatch,

reflux, quartz cuvette, dropping pipette, bulb pump,

micropipette, metalized plastic, silica gel, aluminium

foil, and centrifuge tube.

2.2 Starch Production

Starch production was done based on Abdel-Rahman

et al. (2008) research. Decorticated mung beans were

rinsed with streaming water to get rid of impurities.

Then, cleaned mung beans was soaked for 2 hours,

and the water was discarded. Afterward, distilled

water was added to mung beans with 1:3 (mung

beans: water) ratio, and crushed with blender within

3 minutes. Next, obtained mushed mung beans was

filtered used 60 mesh filter cloth. Filtration process

produced residue and filtrate. Distilled water was

added to the residue and filtrated again two times,

while the filtrate was settled for 2 hours. Precipitation

process produced precipitate and supernatant. The

supernatant was discarded and the precipitate was

dried at 40

o

C for 15-20 hours using cabinet dryer.

Dried precipitate was crushed using dry blender

within 1 minute, then sieved with 60 mesh sieve. This

powder is mung beans starch that had to be stored in

refrigerator in ± 5

o

C until further analysis.

2.3 Preparation of Annealed Starch

Annealing treatment was done by mixing mung beans

starch with distilled water in 1:2 (mung beans starch:

water) ratio. Then, the slurry transferred to 250 ml

beaker glass and covered with aluminium foil. The

beaker and its content was soaked in water bath at

40°C/ 50°C /60°C for 6 hours. After cooling down,

the slurry was centrifuged at 5,000 rpm for 10

minutes. Centrifugation process produced precipitate

and supernatant. The supernatant was discarded,

while the precipitate was washed with distilled water

and filtered with filter paper. The precipitate was

washed to dissolve impurities and help filtering

process. Next, the precipitate was dried with oven at

40°C for 15-20 hours.

2.4 Preparation of Annealed Starch

Mung beans starch produced from selected annealing

treatment was mixed with distilled water with 4:9

(annealed mung beans starch: water) ratio. Then the

slurry was stirred using magnetic stirrer at 25°C for

60 minutes. pH of the slurry was set to 8 with 3%

NaOH solution. Then, acetic acid anhydride (density

= 1,082g/ml) with 10%, 15%, or 20% concentration

based on sample weight (g) was added slowly to the

slurry, while still keeping pH range between 8-8.4

with 3% NaOH solution. Reaction was settled at 25°C

for 5, 15, or 25 minutes after adding acetic acid

anhydride. After that, pH was set to 4.5 with 1 N HCl.

Then, the slurry was filtered with filter cloth to obtain

precipitate and supernatant. The supernatant was

discarded, while the precipitate was washed two

times with distilled water, to get rid of impurities and

HCl residue. Next, the precipitate washed once with

95% ethanol to get rid of acetic acid anhydride

residue in starch. Washed precipitate then dried at

45°C in oven for 24 hours.

2.5 Experimental Design

Experimental design was applied to annealed and

acetylated starch. Obtained data was tested using

SPSS on acetylated starch. Experimental design used

in annealed starch was completely randomized design

Modification of Mung Bean Starch by Annealing Treatment and Acetylation

11

with one factor, three replication, and three level of

heating temperature which is 40°C, 50°C, and 60°C.

Experimental design used in acetylated starch was

completely randomized design with two factor, two

replication, and three level of acetic acid anhydride

concentration which is 10%, 15%, and 20% along

with three level of acetylation reaction time which is

5, 15, and 25 minutes.

2.6 Analysis Methods

Analysis done in this research were starch yield

(Ratnayake et al., 2007), starch content (Ezeigbo et

al., 2015), moisture content (AOAC, 2005), acetyl

percentage and degree of substitution (Colussi et al.,

2015), amylose and amylopectin content

(Abeysundara et al., 2015), solubility properties and

swelling power (Zaman et al., 2015), colour test

(Nadir et al., 2015), pasting properties, resistant

starch content (AOAC, 2000), starch granule

morphology (SEM), XRD profile, and FTIR profile.

3 RESULTS AND DISCUSSION

3.1 Mung Bean Starch Characteristics

Based on identification test, it was confirmed that

mung bean used as main ingredient to produce starch

is Vigna radiata (L.) R.Wilczek. This mung bean was

processed to produce starch that will be analyzed

further. Results of starch analysis can be found in

Table 1.

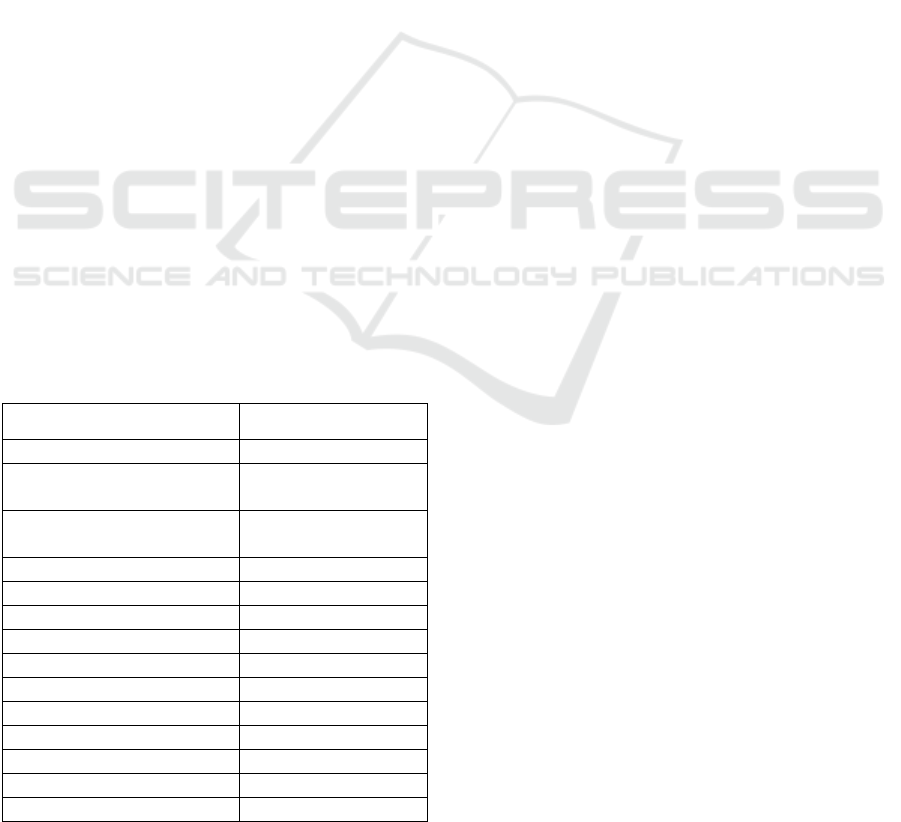

Table 1: Analysis results of native mung bean starch.

Analysis parameters Analysis results

Starch yield 58.44 ± 12.29%

Starch content

(from isolated starch)

88.31 ± 2.68%

Starch content

(from mung bean flour)

29.46 ± 2.30%

Moisture content 6.39% ± 0.29%

Acetyl percentage 0.00%

Degree of substitution 0.00

Amylose 26.79 ± 0.74%

Amylopectin 73.21 ± 0.76%

Solubility 16.48 ± 0.55%

Swelling power 8.83 ± 0.52%

L* value 75.38 ± 0.18

Chroma 7.34 ± 1.18

Resistant starch content 23.96%

Crystallinity 57.94%

Mung bean starch consist of 26,79 ± 0.74%

amylose content and 73.21 ± 0.76% amylopectin

content. According to Kaur et al. (2012), amylose

content of mung bean starch ranged between 29.9 –

33.6%, while amylopectin content reach ±70%. Value

of amylose and amylopectin content can be different,

because of different variety of mung bean plant.

However, same amylose and amylopectin content can

be found even in plants with same variety.

Geographic and environment condition when plants

were planted can affect their amylose and

amylopectin content (Gao et al., 2014).

Amylose and amylopectin content affect

physicochemical properties of starch. High amylose

content (>30%) can increase possibility of starch

retrogradation (Alcazar-Alay & Meireles, 2015).

Moreover, increased amylose content can increase

pasting properties, viscosity, and solubility properties

of starch granules (Colussi et al., 2015). On the other

hand, starch with high amylopectin content (>70%)

has low capacity to absorb water, more resistant to

enzyme digestion and chemical reaction, compared to

starch with high amylose content (Gunaratne &

Corke, 2016).

Starch content obtained from this research is

29.46 ± 2.30%. This result is higher than

Moongngarm et al. (2013) analysis result which is

25.73%. Different sample preparation and isolation

method can affect starch content obtained.

Decorticated mung beans produce more starch yield

and content, compared to whole mung beans (Abdel-

Rahman et al., 2008). Moreover, soaking temperature

(up to 30

o

C) and soaking time (up to 18 hours) of

mung bean in preparation process can increase starch

extraction efficiency. However, soaking in room

temperature for two hours is enough to produce starch

for smaller scale (Usman et al., 2014).

Native starch acetyl percentage and degree of

substitution resulted zero value. Those value was

obtained because there is no acetyl group or glucose

unit bound to acetyl group was found (Colussi et al.,

2105). Resistant starch content obtained was 23.96%.

This value is not much different than analysis result

in Shi et al. (2016) research, which is ranged between

16.1-22.3%. There are some factors affecting starch

digestibility, such as starch structure characteristics

(amylose and amylopectin ratio, gelatinization

degree, retrogradation rate, and formation of amylose

complex), food characteristics, and existence of other

components (Conde-Petit et al., 2001).

2nd SIS 2019 - SEAFAST International Seminar

12

Table 2: Crystallinity percentage of annealed starch.

Annealing

temperature (°C)

Crystallinity percentage

(%)

Native 57.94

40° 63.59

50° 70.73

60° 88.89

3.2 Effect of Annealing Temperature to

Crystallinity Percentage of Mung

Bean Starch

Starch modification with annealing method makes

starch granules structure become more stable,

because of polymer chains re-organization in

crystalline and amorph side that cause increased

crystallinity percentage (Lan et al., 2008). Increasing

temperature between glass transition and starch

gelatinization temperature, can increase hydration

rate and glucan chain mobility (Jayakody & Hoover,

2008). Increased crystallinity percentage of starch can

be detected with XRD in Table 2.

Crystal type of starch can be detected from

diffraction pattern with XRD analysis. XRD analysis

results can be found in Figure 1, and can be concluded

that native starch intensity as well as treated sample

has diffraction angle at 2θ = 15°, 17°, 18°, and 23°

(Colussi et al., 2014). This result showed that mung

bean starch has A-type crystal, in accorandce with

theories that showed peak at 2θ = 23°, but didn’t show

peak at 2θ = 5.6° in A-type crystal graph (Correia et

al., 2012). Phrukwiwattanakul et al. (2014) research

of mung bean starch resulted in similar outcome, with

peak at 2θ = 15°, 17°, 18°, and 23°on the graph. Peak

at same diffraction angle has been found in Colussi et

al. (2014) research too, in rice starch with 20-32%

amylose content. There is no change in starch crystal

type with increased temperature up to 60°C.

Figure 1: XRD analysis results of annealed mung bean

starch.

3.3 Effect of Acetic Acid Anhydride

Concentration and Acetylation

Reaction Time to Mung Bean

Starch

Acetyl percentage is acetyl group amount in every

gram starch sample (wet basis) (Rahim et al., 2017).

Acetyl percentage in annealed and acetylated mung

bean starch can be found in Figure 2. Statistical

results showed that interaction between acetic acid

anhydride concentration and acetylation reaction

time, affect (p<0.05) acetyl percentage of modified

mung bean starch. Difference in acetic acid anhydride

concentration or acetylation reaction time separately,

also affect (p<0.05) acetyl percentage of modified

mung bean starch as well.

According to Figure 2, the highest acetyl

percentage found from acetylated starch with 20%

acetic acid anhydride concentration and 25 minutes

reaction time. Increasing reagent concentration and

reaction time can increase the chance for substitution

group to bind with starch. Increased bonds can

increase acetyl percentage and acetylation reaction

efficiency (Ackar et al., 2015).

Figure 2: Effect of acetylation condition to acetyl

percentage of modified mung bean starch. Different

superscripts indicate significant difference (p<0.05).

Degree of substitution (DS) is average amount of unit

glucose side which bound to substitution group

(acetyl group) (Rahim et al., 2017). DS of annealed

and acetylated mung bean starch can be found on

Figure 3.

Modification of Mung Bean Starch by Annealing Treatment and Acetylation

13

Figure 3: Effect of acetylation condition to degree of

substitution of modified mung bean starch.

Statistical results showed that interaction between

acetic acid anhydride concentration and acetylation

reaction time affect (p<0.05) DS in modified mung

bean starch. Difference in acetic acid anhydride

concentration or acetylation reaction time separately

also affect (p<0.05) DS in modified mung bean

starch. The highest DS found from acetylated starch

with 20% acetic acid anhydride concentration and 25

minutes reaction time. DS is related to acetyl

percentage, more acetyl group found in starch will

also increase the chance of acetyl group to bind with

hydroxyl group in starch (Ackar et al., 2015).

Acetylated starch with 20% acetic acid anhydride

and 15 minutes reaction time, meets FDA

requirement which stated that DS found in starch

can’t exceed 0.2. However, there is no significant

difference (p>0.05) in DS between acetylated starch

with 20% acetic acid anhydride concentration and 15

minutes reaction time, compared to acetylated starch

with 15% acetic acid anhydride and 25 minutes

reaction time. Considering time efficiency and DS

value proximity to FDA requirement, then acetylation

treatment with 20% acetic acid anhydride and 15

minutes reaction time became selected treatment.

Incorporation of acetyl group in starch can be

confirmed with FTIR (Colussi et al., 2014). Result of

FTIR analysis of annealed and acetylated starch with

series of acetic acid anhydride concentration and

acetylation reaction time can be found on Figure 4.

Figure 4: FTIR analysis results of annealed and acetylated

mung bean starch.

Acetylation reaction can subtitute hydroxyl group

in starch molecule to carbonyl contained group. This

occurrence resulted in decreased hydroxyl group

intensity along with increased carbonyl group

intensity. Hydroxyl group intensity in starch can be

found at 3700–3000 cm

-1

. While C=O intensity in

acetyl group can be found at 1700-1500 cm

-1

(Rahim

et al., 2017).

Selected annealing treatment was chosen based on

highest crystallinity percentage. Increased

crystallinity percentage cause decrease in swelling

and solubility, increase in heat stability, and increase

in starch resistance of alpha amylase enzyme (Song et

al., 2011; Siswoyo & Morita, 2010). Therefore 60°C

became selected temperature for annealing, before

acetylation treatment. Additionally, selected

acetylation treatment was based on highest acetyl

percentage and DS that meet FDA requirement. FDA

limit DS of modified starch to maximum 0.2 if the

starch was going to be used as food ingredient (Xu et

al., 2004).

Selected acetylation treatment was combined with

selected annealing treatment, which is 60°C

annealing temperature, 20% acetic acid anhydride

concentration, and 15 minutes acetylation reaction

time. Modified starch with selected treatments was

analyzed with starch content, water content, solubility

properties and swelling power, pasting properties,

XRD profile, resistant starch content, amylose and

amylopectin content, colour test, and starch granule

morphology as parameters.

3.4 Physicohemical Properties of

Selected Starch

Solubility properties and swelling power of mung

bean starch decreased after dual modification.

Swelling power of native starch was decreasing from

18.11% to 11.62%, while solubility properties of

2nd SIS 2019 - SEAFAST International Seminar

14

native starch was decreasing drom 16.48% to 8.83%.

This decreasing value was different significantly

(p<0.05) and can be found in Table 3. Native starch

referred to starch without any treatments, while

selected starch has been annealed and acetylated by

selected treatment. Decreased value of swelling

power and solubility properties can be caused by

annealing treatment, which re-organized starch

crystal to become more compact. Interaction between

amylose and amylopectin from annealing also

decrease hydration of amorph side (Zavareze & Dias,

2011). Moreover, incorporation of acetyl group in

acetylation reaction, makes starch molecule becomes

more hydrophobic (Luo & Shi, 2012).

Basic rheology properties is viscosity, which

affected by temperature, concentration, and shear

stress (Alcazar-Alay & Meireles, 2015). Rheology

properties results can be found in Table 3. Pasting

properties is a term used to explain transformation in

starch after gelatinization. Rapid Visco Analyzer

(RVA) can be used to explain viscosity parameter as

a function to temperature and time.

Starch suspension was given shear forces when

analysis was conducted. Suspension will show peak

viscosity, which started after gelatinization and the

value will increase along with expansion of starch

granule (Alcazar-Alay & Meireles, 2015). Decreased

peak viscosity can be caused by decreased absorption

Table 3: Psycochemical properties of native and selected

starch.

Psycochemical

properties

Native starch

Selected

starch

Solubility (%) 16.48±0.55

a

8.83±0.52

b

Swelling power

(% w/w)

18.11±0.44

a

11.62±0.63

b

Pasting

temperature (°C)

75.8 81.6

Peak viscosity

(cP)

5384 3372

Hot paste

viscosity (cP)

3397 2939

Cold paste

viscosity (cP)

5516 5075

Breakdown (cP) 1987 433

Setback (cP) 132 1703

Resistant starch

(% w/w)

23.96 24.68

Amylose (%) 26.79±0.74

a

24.09±0.72

b

Amylopectin (%) 73.21±0.76

a

75.91±0.68

b

L* value 75.38±0.18

a

75.77±0.10

b

Chroma value 7.34±1.18

a

7.74±0.19

a

capacity of starch (solubility properties) and

decreased starch ability to form a paste (swelling

power) (Marta & Tensiska, 2017).

Breakdown describes a difference value between

peak viscosity and hot paste viscosity. Breakdown

shows starch stability when exposed to heat, while hot

paste viscosity related to heat resistance of starch or

weakness of starch granule chains (Marta & Tensiska,

2017). Decreased value of breakdown will increase

starch stability when heated. This occurrence can be

caused by increased crystallinity and more compact

structure of starch chain when annealing and

acetylation treatment was conducted (Ariyantoro,

A.R. et al., 2018; Mendoza et al., 2016).

Pasting temperature after acetylation treatment

supposed to be lower than native starch, because

incorporation of acetyl group that weakens starch

granule structure, can break the compact structure of

starch granule. However, annealing treatment before

acetylation can increase compactness or crystallinity

of starch structure (Simsek et al., 2012). This

treatment combination can increase pasting

temperature of starch.

Setback is a difference value between cold paste

viscosity and hot paste viscosity. Increasing value of

setback, will increase the chance of retrogradation to

occur (Wang et al., 2015). In cooling period, amylose

leaching will form a three-dimensional gel network.

This gel formation can increase viscosity, which is

cold paste viscosity (Alcazar-Alay & Meireles,

2015). In this research, annealing and acetylation

treatment increase setback value. When annealing

occurred, granule starch texture changed to become

more compact. This occurrence can cause increasing

viscosity when starch cools down and increase

retrogradation rate. Starch with high setback value is

a good gelling agent, which is desirable in certain

food industry (Marta & Tensiska, 2017).

Comparison of XRD analysis results between

native and selected starch can be found in Figure 5.

Mung bean starch crystal type remain unchanged

which is A-type crystal, even after acetylation with

20% acetic acid concentration and 15 minutes

reaction time. Native or treated starch intensity was

found at same diffraction angle which is 2θ = 15°,

17°, 18°, and 23° (Colussi et al., 2014). However,

crystallinity percentage of annealed starch in 60°C

decrease from 88.89% to 87.80% after acetylation.

According to Colussi et al. (2015), decreased

crystallinity percentage after acetylation also

decrease hydrogen bond in starch, resulted in

decreased crystalline structure.

Modification of Mung Bean Starch by Annealing Treatment and Acetylation

15

Figure 5: XRD analysis results of native, annealed (60°C),

and selected starch.

Resistant starch content increased from 23.96% to

24.68% according to Table 3. Heating step in

annealing form more compact structure of starch

granule, because of hydrogen bond between amylose

or amylopectin (Sajilata et al., 2006). Acetylation also

has important role in increasing resistant starch

content. Acetyl group that bind with starch chain, can

hinder active side of α-amylase enzyme that breaks

starch bonds (Sahnoun et al., 2015). α-amylase is an

enzyme that capable of hydrolyze starch randomly at

α-(1→4) D-glucosidic bond, to produce glucose and

oligosaccharide. Starch hydrolysis with α-amylase

can be hindered by acetylation treatment (Chen et al.,

2004).

Colussi et al., (2015) research has used same

acetic acid anhydride concentration, and same

reaction time as selected treatment in this research.

They found no significant difference in resistant

starch between native and acetylated rice starch.

Meanwhile, in Song et al., 2011 research, annealing

before cross-linking treatment can increase resistant

starch content to 31.5%. However, they used 50°C

annealing temperature for 12 hours and cross-linking

reaction time for 4 hours. This founding concluded

that annealing temperature, reagent concentration,

and starch modification reaction timecan affect

hydrolysis rate of starch (Song et al., 2011).

Amylose content of native and modified starch

can be compared in Table 3. Amylose content

decreased from 26.79% to 24.09% after acetylation.

Decreased amylose content resulted in increased

amylopectin content from 73.21% to 75.91%. These

decreasing number was significantly different

(p<0.05).

Acetyl group found in starch granule can hinder

helix structure of amylose to bind with iodine because

of steric hindrance (Gonzales & Perez, 2002).

Another possibility that can cause decreasing

amylose content is depolymerization of amylose

chain. Starch contains polymer chains that can be

broken to monomers by increasing temperature or

degree of substitution (Kapelko-Zeberska et al.,

2017). Decreased amylose content also happened in

acetylated banana starch (Reddy et al., 2014),

acetylated buckwheat starch (Sarkar, 2016), and

acetylated potato starch (Kapelko-Zeberska et al.,

2017).

Figure 6: Physical appearances of mung bean flour, starch

and modified one.

Physical appearance of starch as food ingredient

is important, because it can affect product

acceptability. (Dahiya et al., 2015). Colour difference

between samples can be found in Figure 6.

Decorticated mung bean flour has yellow to brown

colour, while native and annealed mung bean starch

has white colour. However, annealed and acetylated

starch has brighter white colour. L* value and chroma

analysis results can be found in Table 3. Increased L*

value was significantly different (p<0.05), while

increased chroma value was not significantly

different (p>0.05). Acetylation treatment can increase

starch L* value and decrease chroma value. Higher

increase in L* value will make starch appear whiter,

while chroma value describes sample colour purity.

However, chroma value is not really considered to

determine colour characteristic of starch (Bolade &

Oni, 2015). Increasing L* value and decreasing

chroma value is desirable from consumer perspetive

(Ali et al., 2016).

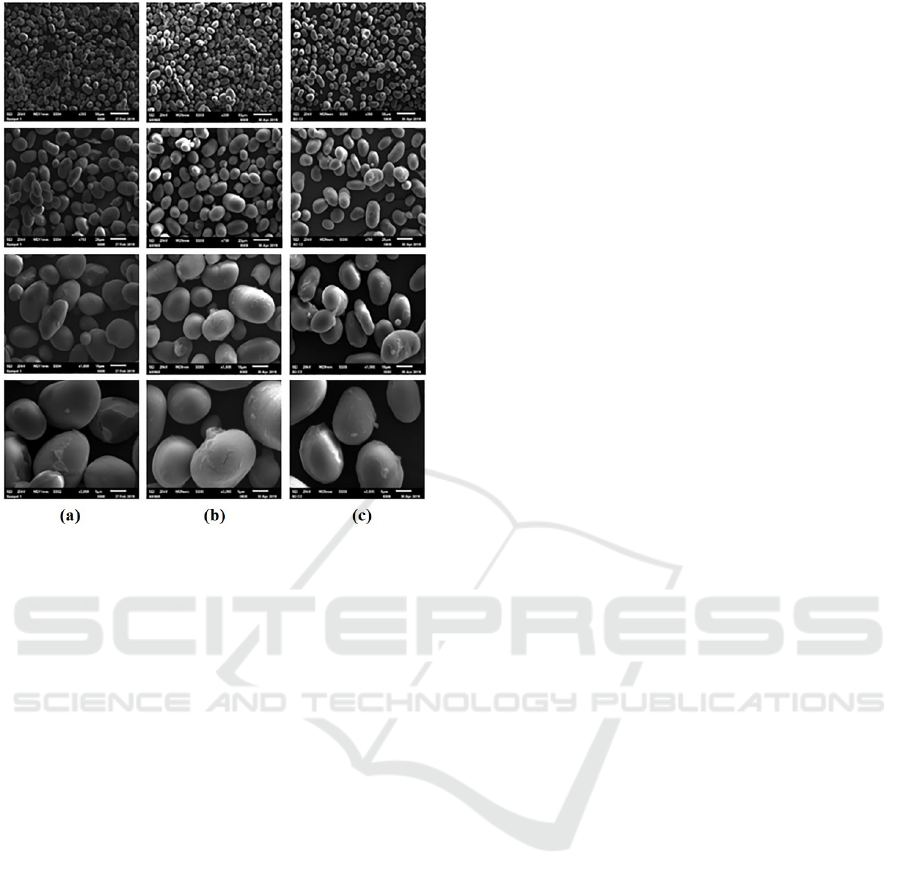

Morphology of starch granule can be observed

using Scanning Electron microscope (SEM). SEM

magnification used in this analysis was 350×, 750×,

1500× and 3000×. Magnification 3000× was used to

observe starch granule surface and shape more

clearly. While magnification 350×, 750×, and 1500×

was used to ensure starch granule condition in 3000×

was found on another magnification too. Mung bean

starch has granule size between 7.65 - 33.15 µm

(Abdel-Rahman et al., 2008). Mung bean granule

starch can be found in Figure 7.

2nd SIS 2019 - SEAFAST International Seminar

16

Figure 7: SEM analysis results of native starch (a), annealed

starch (b), and annealed-acetylated starch (c).

Magnifications used from top to bottom figure were 350×,

750×, 1500×, and 3000×.

Mung bean granule shape remains unchanged

when observed with 3000× magnification. This

occurrence also found in 350×, 750× and 1500×

magnification. Bigger mung bean starch granule has

oval shape, while smaller one has round shape (Liu &

Shen, 2007).

Several native and modified starch granules have

uneven surface, but the particle structure is still intact.

Uneven surface can be observed clearly in 3000×

magnification, but there’s no deformed starch granule

found even in 350×, 750× and 1500× magnification.

Uneven starch granules can be caused by drying

temperature starts from ± 40°C (Lewicka et al., 2015).

Heating process can break hydrogen bonding

between starch polymer chains, resulting weaker

granule structure and rough granule starch surface

(Nadiah et al., 2015). Deformed starch granule has

higher capacity to absorb water, making it more

susceptible to enzyme hydrolysis and high

temperature (Ali et al., 2014). Therefore, intact

granule starch shape is desirable, especially if added

into food product that used high temperature in the

process.

4 CONCLUSIONS

Increasing annealing temperature up to 60°C can

increase crystallinity percentage. Other than that,

increasing acetic acid anhydride concentration and

acetylation reaction time, can cause increased starch

acetyl percentage and degree of substitution. Selected

treatment for starch analysis was annealing with 60°C

temperature, and acetylation with 20% acetic acid

anhydride concentration for 15 minutes reaction time.

Starch produced from combination of annealing and

acetylation with selected treatment, has higher

resistance and stability when heated, along with higher

resistant starch content compared to native starch.

Combination of annealing and acetylation

treatment to mung bean starch, caused decreased

amylose content and increased amylopectin content.

Solubility properties and swelling power value

decreased, correspond with decreased peak viscosity

in pasting properties analysis. Decreased peak

viscosity was followed by decreased breakdown

value, increased pasting temperature, and increased

setback value. Modified starch has brighter colour,

and its granule shape remains unchanged compared to

native starch. Starch with these physicochemical

characteristics were suitable to be used as food

ingredient in cookies or cereal industries.

REFERENCES

Abdel-Rahman E.A., El-Fishawy F.A., El-Geddawy M.A.,

Kurz, T., El-Rify M.N. (2008): Isolation and Physico-

chemical Characterization of Mung Bean Starches.

International Journal of Food Engineering, 4: 1-12.

Abeysundara A., Navaratne S., Wickramasinghe I.,

Ekanayake D. (2015): Determination of Changes of

Amylose and Amylopectin Content of Paddy during

Early Storage. International Journal of Science and

Research, 6: 2094-2097.

Ackar D., Babic J., Jozinovic A., Milicevic B., Jokic S.,

Milicevic R., Rajic M., Subaric D. (2015): Starch

Modification by Organic Acids and Their Derivatives:

A Review. Molecules, 20: 19554-19570.

Alcazar-Alay S.C., Meireles M.A. (2015):

Physicochemical Properties, Modifications and

Applications of Starches from Different Botanical

Sources. Food Science and Technology, 35: 215-236.

Ali A., Wani T.A., Wani I.A., Masoodi F.A. (2016).

Comparative Study of The Physico-Chemical

Properties of Rice and Corn Starches Grown in Indian

Temperate Climate. Journal of the Saudi Society of

Agricultural Sciences, 15: 75-82.

Ali R., Khan M.S., Sayeed S.A., Ahmed R., Saeed S.M.G.

dan Mobin, L. (2014): Relationship of Damaged Starch

with Some Physicochemical Parameters in Assessment

Modification of Mung Bean Starch by Annealing Treatment and Acetylation

17

of Wheat Flour Quality. Pakistan Journal of Botany, 46:

2217-2225.

AOAC. (2005): Official Methods of Analysis of the

Association of Official Analytical Chemists, 18th ed.

USA: AOAC, Inc.

Ariyantoro A.R., Katsuno N., Nishizu T. (2018): Effects of

Dual Modification with Succinylation and Annealing

on Physicochemical, Thermal and Morphological

Properties of Corn Starch. Foods, 7: 133-145.

Bolade M.K., Oni O.J. (2015): Influence of Acetylation on

The Physicochemical Properties of Composited

Starches from Sweet Potato (Ipomoea Batatas L.) And

Water Yam (Dioscorea alata L.). African Journal of

Biotechnology, 14: 3340-3349.

Chen Z., Schols, H.A., Voragen, A.G.J. (2004): Differently

Sized Granules from Acetylated Potato and Sweet

Potato Starches Differ in The Acetyl Substitution

Pattern of Their Amylose Populations. Carbohydrate

Polymers, 56: 219-226.

Colussi R., Halal S.L., Pinto V.Z., Bartz J., Gutkoski L.C.,

Zavareze E.R., Dias A.R. (2015): Acetylation of Rice

Starch in an Aqueous Medium for Use in Food. Food

Science and Technology, 62: 1076-1082.

Colussi R., Pinto V.Z., El-Halal S.L.M., Vanier N.L.,

Villanova F.A., E-Silva R.M., Zavareze E.R., Dias

A.R.G. (2014): Structural, Morphological, and

Physicochemical Properties of Acetylated High-,

Medium-, and Low-Amylose Rice Starches.

Carbohydrate Polymers, 103: 405-413.

Conde-Petit B., Nuessli J., Arrigoni E., Escher F., Amado

R. (2001): Perspectives of Starch in Food Science.

Chimia, 55: 201-205.

Dahiya P.K., Linnemann A.R., Van Boekel M.A.J.S.,

Khetarpaul N., Grewal R.B., Nout, M.J.R. (2015):

Mung Bean: Technological and Nutritional Potential.

Critical Reviewsin Food Science and Nutrition, 55:

670-688.

Ezeigbo O.R., Ukabi C.F., Ike-Amadi C.A., Ekaiko, M.U.

(2015): Determination of Starch and Cyanide Contents

of Different Species of Fresh Cassava Tuber in Abia

State, Nigeria. British Biotechnology Journal, 6: 10-15.

Ganesan K., Xu B. (2018): A Critical Review on

Phytochemical Profile and Health Promoting Effects of

Mung Bean (Vigna radiata). Food Science and Human

Wellness, 7: 11-33.

Gao H., Cai J., Han W., Huai H., Chen Y., Wei C. (2014):

Comparison of Starches Isolated from Three Different

Trapa Species. Food Hydrocolloids, 37: 174-181.

Gonzales Z., Perez E. (2002): Effect of Acetylation on

Some Properties of Rice Starch. Starch/Stärke, 54: 148-

154.

Gunaratne A., Corke H. (2016): Starch Analysis of Quality.

Reference module in Food Science, 3: 202-212.

Jayakody L., Hoover R. (2008): Effect of Annealing on The

Molecular Structure and Physicochemical Properties of

Starches from Different Botanical Origins: A Review.

Carbohydrate Polymers, 74: 691-703.

Kapelko-Zeberska M., Zieba T., Spychaj R., Gryszkin A.

(2017): Selected Rheological Properties of RS3/4 Type

Resistant Starch. Polish Journal of Food and Nutrition

Sciences, 67: 293-299.

Kaur B., Ariffin F., Bhat R., Karim A.A. (2012): Progress

in Starch Modification in The Last Decade. Food

Hydrocolloids, 26: 398-404.

Kementerian Pertanian. (2018): Statistik Konsumsi Pangan

Tahun 2018. Jakarta: Pusat Data and Sistem Informasi

Pertanian.

Lan H., Hoover R., Jayakody L., Liu Q., Donner E., Baga

M., Asare E.K., Hucl P., Chibbar R.N. (2008): Impact

of Annealing on The Molecular Structure and

Physicochemical Properties of Normal, Waxy and High

Amylose Bread Wheat Starches. Food Chemistry, 111:

663-675.

Lewicka K., Siemion P., Kurcok P. (2015): Chemical

Modifications of Starch: Microwave Effect.

International Journal of Polymer Science, 1-10.

Liu W., Shen Q. (2007): Studies on The Physicochemical

Properties of Mung Bean Starch from Sour Liquid

Processing and Centrifugation. Journal of Food

Engineering, 79: 358-363.

Lopez D.V., Zaritzky N.E., García, M.A. (2010):

Physicochemical Characterization of Chemically

Modified Corn Starches Related to Rheological

Behavior, Retrogradation and Film Forming Capacity.

Journal of Food Engineering, 100: 160-168.

Luo Z.G., Shi Y.C. (2012): Preparation of Acetylated

Waxy, Normal, and High-Amylose Maize Starches

with Intermediate Degrees of Substitution in Aqueous

Solution and Their Properties. Journal of Agricultural

and Food Chemistry, 60: 9468-9475.

Marta H., Tensiska. (2017): Functional and Amylographic

Properties of Physically-Modified Sweet Potato Starch.

2nd International Conference on Sustainable

Agriculture and Food Security: A Comprehensive

Approach, 689–700.

Mendoza J.S., RuyDiaz J.H., Quintero A.F. (2016): Effect

of The Acetylation Process on Native Starches of Yam

(Dioscorea spp.). Revista Facultad Nacional de

Agronomia, 69: 7997-8006.

Moongngarm A. (2013): Chemical Compositions and

Resistant Starch Content in Starchy Foods. American

Journal of Agricultural and Biological Sciences, 8: 107-

113.

Nadiah N.I., Uthumporn U., Syahariza Z.A. (2015): Effect

of Microwave Heating on Potato and Tapioca Starches

in Water Suspension. International Journal on

Advanced Science Engineering Information

Technology, 5: 264-271.

Nadir A.S., Helmy I.M.F., Nahed M.A., Wafaa M.M.A.,

Ramadan M.T. (2015): Modification of Potato Starch

by Some Different Physical Methods and Utilization in

Cookies Production. International Journal of Current

Microbiology and Applied Sciences, 4: 556-569.

Phrukwiwattanakul P., Wichienchotand S., Sirivongpaisal

P. (2014): Comparative Studies on Physico-Chemical

Properties of Starches from Jackfruit Seed and Mung

Bean. International Journal of Food Properties, 17:

1965-1976.

2nd SIS 2019 - SEAFAST International Seminar

18

Rahim A., Kadir S., Jusman (2017): The Influence Degree

of Substitution on The Physicochemical Properties of

Acetylated Arenga Starches. International Food

Research Journal, 24: 102-107.

Ratnayake W. S., Wassinger A.B., Jackson D.S. (2007):

Extraction and Characterization of Starch from

Alkaline Cooked Corn Masa. Cereal Chemistry, 84:

415-422.

Reddy C.K., Haripriya S., Suriya M. (2014): Effect of

Acetylation on Morphology, Pasting and Functional

Properties of Starch from Banana (MUSA AAB).

Indian Journal of Scientific Research and Technology,

2: 31-36.

Sahnoun M., Ismail N., Kammoun R. (2016):

Enzymatically Hydrolysed, Acetylated and Dually

Modified Corn Starch: Physico-Chemical, Rheological

and Nutritional Properties and Effects on Cake Quality.

Journal of Food Science and Technology, 53: 481-490.

Sajilata M.G., Singhal R.S., Kulkarni, P.R. (2006):

Resistant Starch: A Review. Comprehensive Reviews

in Food Science and Food Safety, 5: 1-17.

Sarkar S. (2016): Influence of Acetylation and Heat-

Moisture Treatment on Physio-Chemical, Pasting and

Morphological Properties of Buckwheat (Fagopyrum

esculentum) Starch. Asian Journal of Dairy and Food

Research, 35: 298-303.

Simsek S., Ovando-Martinez M., Whitney K., Bello-Perez

L.A. (2012). Effect of Acetylation, Oxidation and

Annealing on Physicochemical Properties of Bean

Starch. Food Chemistry, 134: 1796-1803.

Siswoyo T.A., Morita N. (2010): Influence of Annealing on

Gelatinization Properties, Retrogradation and

Susceptibility of Breadfruit Starch (Artocarpus

Communis). International Journal of Food Properties,

13: 553–561.

Song J.Y., Park J.H., Shin M. (2011): The Effects of

Annealing and Acid Hydrolysis on Resistant Starch

Level and The Properties of Cross-Linked RS4 Rice

Starch. Starch/Stärke, 63: 147-153.

Usman M., Ishfaq M.T., Malik S.R., Ishfaq B., Iqbal M.

(2014). Effects of Temperature, pH and Steeping Time

on the Extraction of Starch from Pakistani Rice

Muhammad. International Journal of Scientific &

Engineering Research, 5: 857-892.

Wang S., Li C., Copeland L., Niu C., Wang S. (2015):

Starch Retrogradation: A Comprehensive Review.

Comprehensive Reviews in Food Science and Food

Safety, 14: 568-585.

Xu Y., Miladinov V., Hanna M.A. (2004): Synthesis and

Characterization of Starch Acetates with High

Substitution. Cereal Chemistry, 81: 735-740.

Zaman A.S., Seruji A.Z., Sarbini S.R. (2015): Effect of

Acetylation on Physicochemical Properties and

Resistant Starch Content of Metroxylon sagu Starch.

International Conference on Food Nutrition, Chemical

and Environmental Engineering. Kuala Lumpur,

Malaysia.

Zavareze E.R., Dias, A.R.G. (2011): Impact of Heat-

Moisture Treatment and Annealing in Starches: A

Review. Carbohydrate Polymers, 83: 317-328.

Modification of Mung Bean Starch by Annealing Treatment and Acetylation

19