Profile of Bioactive Compounds and Antioxidant Capacity of

Indonesian Cocoa Powder: A Case of Food Processing Authentication

Besty R. Ulvia

1

, Nuri Andarwulan

1,2

and Dase Hunaefi

1,2

1

Food Science and Technology Department, Faculty of Agricultural Engineering and Technology,

Bogor Agricultural University, Indonesia

2

Southeast Asean Food and Agricultural Science and Technology (SEAFAST) Center,

Bogor Agricultural University, Indonesia

Keywords: Antioxidant Capacity, Bioactive Compounds, Cocoa Powder, Manufacturing Process.

Abstract: One aim of food authentication for cocoa powder is to prove the manufacturing process. Cocoa powder is one

of the derivative products of cacao resulting from crushing and refining cocoa cake. Cocoa cake is processed

further through alkalization and/or grinded to become cocoa powder. The major bioactive compounds found

in cocoa powder are polyphenols and methylxanthines that potential to be sources of antioxidants. The

objectives of this research are to identify bioactive compounds and antioxidant capacity of Indonesian cocoa

powder from different sources for identifying the manufacturing process of alkalization. Profile of bioactive

compounds was identified by using HPLC-UV. DPPH and FRAP method was used for the quantification of

antioxidant capacity. Folin-Ciocalteau method was used for total phenolic content. The total phenolic content

of Indonesian cocoa powder ranged from 14.80 – 79.93 mg (GAE/g). Antioxidant capacity using DPPH

method ranged from 91.67 – 362.24 (µmol TE/g) and FRAP method ranged from 249.16 – 1000.95 (µmol

Fe

2+

/g). The average content of theobromine in cocoa powder ranged from 1.89 – 3.14 (mg/g) respectively.

For caffeine content, ranged from 0.12 – 0.46 (mg/g). Levels of (+)-catechin in 9 samples ranged from 0.04

– 1.10 (mg/g) respectively. Whereas the average content of (-)-epicatechin ranged from 0.04 – 4.68 (mg/g).

Strong positive correlation with Pearson test was established between total phenolic content and antioxidant

capacity with (R

2

= 0.99) for DPPH and (R

2

= 0.97) for FRAP. Higher total phenolic content indicates higher

antioxidant capacity. Analysis of PCA divides the sample based on similarity of chemical characteristics. The

right quadrant on PCA analysis was a group of natural cocoa powder, illustrates the similarity of color and

higher content of theobromine, (-)-epicatechin, caffeine, and fat content. The left quadrant was a group of

alkalized cocoa powder, illustrates the similarity of higher pH and (+)-catechin content of Indonesian cocoa

powder.

1 INTRODUCTION

One of the largest agricultural commodity in

Indonesia is cocoa. In 2014, Indonesian cocoa

production reached 728,414 tonnes with the largest

production found in Celebes approximately 484,387

tonnes. Cocoa widely used by the food industry as

raw materials in the field of confectionary and non-

confectionary. Cocoa derivative products include

cocoa paste, cocoa butter, cocoa cake, cocoa powder,

and chocolate products such as dark chocolate, milk

chocolate, and white chocolate. One of the cocoa

derivative products are widely used in the food

industry is cocoa powder.

A number of studies have been reported on the

benefits of cocoa powder to human health (Cooper et

al., 2008; Ramljak et al., 2005). Polyphenol

compounds contained in cocoa powder has potential

as an antioxidant that can significantly contribute to

human health (Abbe and Ismail 2010). The

polyphenol content of the cocoa powder has a high

correlation to the antioxidant capacity. Antioxidant

capacity of cocoa per serving is greater than green tea

or black tea (Joli’c et al. 2011). The main polyphenol

compounds in cocoa are flavan-3-ol, anthocyanine

and procyanidins where (+)-catechin and (-)-

epicatechin are the monomers of flavanol component

(Weisburger 2001). In vitro studies have shown that

the polyphenol content in cocoa powder can inhibit

Ulvia, B., Andarwulan, N. and Hunaefi, D.

Profile of Bioactive Compounds and Antioxidant Capacity of Indonesian Cocoa Powder: A Case of Food Processing Authentication.

DOI: 10.5220/0009977300002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 97-105

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

97

reactive species such as 2,2-diphenyl-1-

picrylhydrazyl (DPPH), 2,2'-azino-bis (3-

ethylbenzthiazoline-6-sulphonic acid; ABTS) and

superoxide radicals. The polyphenol content of cocoa

powder also can inhibit the lipid peroxidation and

chelate free pro-oxidant metal ions (Fe

2+

, Cu).

Cocoa products are also rich in methylxanthine

compounds such as caffeine, theobromine, and

theophylline (Rios et al., 2003). Theophylline is

found in very small quantities in cocoa products and

derivatives (Franco et al., 2013). Methylxanthine

compounds contribute to the bitter taste of the cocoa

product. According to Pinilla et al., (2015), the

combination of caffeine and theobromine in cocoa

has benefited as antitumor, anti-inflammatory and

protective action from cardiovascular disease.

Consumption of Indonesian cocoa powder is

expected to increase in the years 2016-2020 with an

average growth of 1.17% per year (Pusdatin, 2016).

The increasing consumption of Indonesian cocoa

powder not supported yet with the information about

the profile of bioactive compounds and antioxidant

capacity contained. Since the level of bioactive

compounds and positive effects of polyphenol,

methylxanthines in cocoa powder are affected by

alkalization process in the manufacturing and limited

information about it, the objectives of this research

are to identify bioactive compounds and antioxidant

capacity of Indonesian cocoa powder from different

sources for identifying the manufacturing process of

alkalization.

2 MATERIAL AND METHODS

2.1 Material

The main materials were cocoa powder samples

produced by PT. Ceres Industrial Company Bandung,

PT. Bumitangerang Mesindotama Tangerang,

household Industry KSU "Guyub Santoso" Blitar,

Aneka Food "Kopkar Sekar" Jember, Big Tree Farm

Bali, Tanjung Subur Farmer Group Padang, West

Sumatra, and bulk cocoa powder from Makassar,

South Sulawesi. Chemicals needed are acetone 80%

(Mallinckrodt, USA), reagent Folin-Ciocalteu 50%

(Merck, Germany), n-hexane, Na

2

CO

3

20%, glacial

acetic acid (Merck, Germany), gallic acid solution,

standard trolox (Sigma, Switzerland), standard

FeSO

4

.6H

2

O, distilled water, a solution of 300 mM

acetate buffer pH 3.6; TPTZ (2,4,6-tripyridyl-s-

triazine) in 40 mM HCL, the solution FeCl

3

· 6H

2

O

20mm, 10

4

mM DPPH reagent, methanol (Merck,

Germany), theobromine standard (Sigma, USA),

caffeine standard (Sigma, USA), (+)-catechin

standard (Fluka 22110), (-)-epicatechin standard

(Sigma E1753), metanol HPLC grade (Merck,

Germany) water HPLC grade (Merck, Germany).

2.2 Extraction Preparation

All samples were prepared for analysis as described

by Brcanovic et al., (2013) with slight modifications.

A mass of 2 g of cocoa powder was defatted with

hexane by using Soxhlet apparatus and the residue

was dried in oven 105

0

C 30 minutes. Defatted cocoa

powder (0.15 g) was then extracted with acetone/

water/ acetic acid (70.29.5.0.5 by volume) using a

sonicator (37 ° C, 10 min) and then centrifuged (1500

rpm, 10 min). The resulting supernatant was decanted

to a 10-mL volumetric flask and diluted with solvent

to the mark. The resulting supernatant here after

referred as extract of cocoa powder.

2.3 Fat, Color, and pH Analysis

Total fat of cocoa powder was determined by Soxhlet

apparatus. The color of cocoa powders was measured

by using Chromameter with Hunter Lab output

notation. the Hunter L scale measures degree of

lightness 0 (black) to 100 (light), the Hunter a scale

measures red to green with true red equal to +100 and

true green equal to -100, and the Hunter b scale

measures yellow to blue with true yellow equal to

+100 and true blue equal to -100. Analysis of pH was

conducted by using pH meter. 1 part of cocoa powder

dissolves with 10 part of water.

2.4 Total Phenolic Content (TPC)

The total phenolic content was determined by using

Folin-Ciocalteu method with gallic acid as standard

according to Miller et al., (2008). 1000 ppm of gallic

acid was prepared and diluted to concentrations

ranging from 50-600 ppm to create a standard curve.

For each analysis, 0.5 ml solution of gallic acid or

extracts of cocoa powder was added to 7.5 ml of

distilled water and 0.5 ml of Folin-Ciocalteu reagent

50% then vortexed. After that, 1 ml of 20% Na

2

CO

3

was added and incubated in the dark at room

temperature for 30 min. Total polyphenols were

measured from the absorbance at 755 nm. Total

phenolic content expressed in milligrams of gallic

acid equivalents per gram defatted cocoa powder.

2nd SIS 2019 - SEAFAST International Seminar

98

2.5 DPPH (1,1-diphenyl-2-

picrylhydrazyl) Assay

Antioxidant capacity with DPPH method was

determined by using a method described by

Brcanovic et al., (2013). DPPH reagent (10

-4

mol/L)

was dissolved using methanol. 0.5 ml of extracts

cocoa powder was added to 4.5 ml of reagent DPPH

then vortexed. The solution then performed

incubation for 30 minutes in a dark room. The color

change of solution was measured using UV-Vis

spectrophotometry at 520 nm. Trolox standard curve

ranging from 50-400 μM was used to calculate the

final result of DPPH. Antioxidant capacity of DPPH

method was expressed in micromoles Trolox

equivalents (TE) per gram defatted cocoa powder.

2.6 FRAP (Ferric Reduction

Antioxidant Power) Assay

FRAP assay was measured by using methods of

Benzie and Strain (1996). FRAP reagent was

prepared from 2.5 ml of 10 mM TPTZ (2,4,6-

tripyridyl-s-triazine) solution in 40mM hydrochloric

acid with 2.5 mL of 20 mM iron (III) chloride and 25

ml of 300 mM acetate buffers at pH 3.6. The FRAP

reagent was prepared fresh daily and warmed to 37

°C in a water bath. 200 µL of cocoa powder extract

was added to 1.3 ml of FRAP reagent and allowed to

react 30 minutes in 37 °C water bath. The absorbance

of the reaction mixture was recorded at 593 nm using

UV-Vis spectrophotometer. The standard curve was

constructed using ferrous sulfate with concentrations

ranging from 50-400 μM and the result was expressed

in micromol ferrous equivalent per gram defatted

cocoa powder.

2.7 Analysis of Individual Bioactive

Compounds using HPLC

Individual bioactive compounds were determined

using an RP-HPLC (Shimadzu SPD-20A).

Determination of individual phenolic compounds

((+)-catechin and (-)-epicatechin)) and

methylxanthines (theobromine and caffeine) was

performed according to the method described by

Ramli et al., (2001). Separation was performed with

C18 (150 mm ID x 4.6 mm, 5 m) column, at flow rate

1 mL/min and an injection volume of 20 µL.

Detection was performed by scanning at 280 nm.

Isocratic elution was used in this method with mobile

phase Methanol: water: acetic acid (20: 79: 1) at

runtime 17 min.

The standard mixture used as a standard for

calibration curve. 50 mg of each standard consisting

of theobromine, (+)-catechin, caffeine and (-)-

epicatechin was weighed then dissolved using mobile

phase in a 25 ml volumetric flask. Mix standard curve

has five points using a dilution series ranging from 10

- 160 ppm. Extracts of cocoa powder prior to use was

filtered by using PTFE 0.45 μm microfilter to prevent

any impurities. Identification was carried out by

comparing the retention times with standards.

Quantitative determination of individual bioactive

compounds in the sample was done using calibration

lines of standard curves.

2.8 Statistical Analysis

All determination was carried out in two replication

and each replication was measured in duplicates. Data

were subjected to one-way analysis of variance

(ANOVA) and the level of significance of (p < 0.05)

using SPSS version programs. The Duncan's Multiple

Range Test (DMRT) was used to separate the means.

A significant difference was considered at level (p <

0.05). Correlations between each analysis were

conducted by Pearson test. Principal component

analysis (PCA) was used to make the results more

easily interpretable.

3 RESULTS AND DISCUSSION

3.1 Characteristics of Total Fat, pH,

and Color of Cocoa Powder

Cocoa powder is divided into two types, natural cocoa

powder and alkalized cocoa powder. Dutch process or

alkalization process performed by washing cocoa

powder with a solution of potassium which aims to

neutralize the acidity of the cocoa beans, relieve

astringent flavor, and initiate the reaction between

pigment cocoa with alkali due to the presence of

oxygen and heat that caused a reddish brown color to

a dark color or often called dark cocoa (Dyer 2003).

The darker the cocoa powder and the higher the pH

contained in cocoa powder indicated a high degree of

alkalization. Characteristics of pH, color and fat

content of Indonesian cocoa powder is presented in

Table 1.

The powders range from pH 4.90 for sample 8, to

pH 8.10 for sample 4. Cocoa powders have been

grouped by pH ranges, described by Miller et al.,

(2008) into lightly alkalized (pH 6.5-7.2), medium

alkalized (pH 7.21-7.60), and heavily alkalized (pH

7.61). Total fat ranged from 11.27 – 37.57 %. Total

Profile of Bioactive Compounds and Antioxidant Capacity of Indonesian Cocoa Powder: A Case of Food Processing Authentication

99

fat contained by alkalized cocoa powder was higher

than natural cocoa powder samples. Color

measurement of cocoa powder by Chromameter with

Hunter Lab notation scale shows L scale value

decrease on alkalized cocoa powder. The results

show that natural cocoa powders a bright color

appearance and alkalized cocoa powder has a darker

color. 1, 2, 3, 4 and 5 has a darker color and higher

pH (> 7) than the other samples. This indicates those

samples had undergone a process of alkalization.

3.2 Total Phenolic Content

Analysis of total phenolic in cocoa powder uses

Folin-Ciocalteau method. The total phenolic content

based on data obtained in Table 2 ranging from 14.80

- 79.93 mg Gallic Acid Equivalent per gram of

defatted cocoa powder dry basis. Results of total

phenolic content were supported by research from

Ramli et al., (2001) that was 20 - 62 (mg GAE / g)

and Miller et al., (2008) that was 7 - 63 (mg GAE/g).

The total phenolic content of samples from the

various regions and brands in Indonesia have

significant differences value (P <0.05). The highest

value of TPC was shown by sample 9 from West

Sumatra (0.37 ± 79.93 mg GAE / g) and the lowest

value was shown by sample 4 from Tangerang (14.80

± 0.23 mg GAE/g). Alkalized cocoa powder samples

(1,2,3,4,5) have a lower value of TPC compared with

natural cocoa powder samples (6,7,8,9). According to

the study of Miller et al., (2008), alkalization process

could damage the flavanol compounds, resulting in

the decrease of TPC on cocoa powder. Beside

alkalization, TPC of cocoa powder can be influenced

by the processing involved in the production of cocoa

powder including fermentation, drying, and roasting.

These treatments affect the content of polyphenols in

cocoa powder (Thomas-Barberan et al., 2012).

Table 1: Characteristics of total fat, pH, and color of Indonesian cocoa powder.

Sample Total fat

1

(%) pH

2

Color identification

Category

L a b

1 16.38 ± 1.22 7.13 ± 0.11 30.47 +8.34 +9.35 Alkalized

2 17.01 ± 2.71 7.16 ± 0.03 30.05 +8.59 +9.38 Alkalized

3 13.43 ± 1.72 7.13 ± 0.05 31.66 +8.40 +8.70 Alkalized

4 11.27 ± 0.35 8.10 ± 0.02 24.65 +5.41 +5.69 Alkalized

5 15.52 ± 0.07 7.44 ± 0.06 21.98 +6.09 +5.59 Alkalized

6 27.84 ± 1.30 6.15 ± 0.05 34.98 +7.79 +8.96 Natural

7 29.22 ± 0.41 5.16 ± 0.07 34.32 +8.28 +8.63 Natural

8 37.57 ± 0.31 4.90 ± 0.03 23.83 +5.52 +5.86 Natural

9 22.84 ± 0.42 5.71 ± 0.10 37.29 +8.39 +9.57 Natural

1

Values listed in the column is the mean ± SE; n = 2

2

Values listed in the column is the mean ± SD; n = 3

Table 2: Total phenolic and antioxidant capacity of Indonesian cocoa powder.

Sample

Production

Origin

Total

Phenolic

Content

(mg GAE/g)

DPPH

(mikromol

TE/g)

FRAP

(mikromol

Fe

2+

/g)

T

*

(mg/g)

Caff

*

(mg/g)

C

*

(mg/g)

EC

*

(mg/g)

1 Bandung 36.90 ± 0.22

d

183.96 ± 2.38

d

540.68 ± 2.78

d

1.99 ± 0.01

a

0.22

± 0.15

b,c

1.10 ± 0.02

e

1.88 ± 0.03

d

2 Bandung 34.19 ± 0.40

c

158.74 ± 1.75

c

473.00 ± 2.85

c

2.51 ± 0.21

b

0.27

± 0.19

c

1.06 ± 0.06

e

1.97 ± 0.02

d,e

3 Tangerang 38.32 ± 0.20

e

185.33 ± 1.26

d

555.55 ± 5.84

d

2.39 ± 0.09

b

0.16

± 0.11

a,b

0.73 ± 0.00

d

0.77 ± 0.01

b

4 Tangerang 14.80 ± 0.23

a

91.67 ± 3.05

a

249.16 ± 2.45

a

1.89 ± 0.16

ac

0.12

± 0.09

a

1.07 ± 0.06

e

0.04 ± 0.01

a

5 Blitar 20.93 ± 0.53

b

119.10 ± 2.20

b

367.02 ± 17.13

b

2.69 ± 0.15

b,c,d

0.26 ± 0.18

c

0.81 ± 0.02

d

0.08 ± 0.01

a

6 Jember 67.76 ± 0.20

g

310.14 ± 5.93

f

826.97 ± 20.89

f

2.89 ± 0.00

c,d

0.46 ± 0.32

d

0.23 ± 0.01

b

4.68 ± 0.01

g

7 Bali 70.47 ± 1.13

h

346.85 ± 4.29

g

1000.95 ± 18.19

h

2.97 ± 0.14

d

0.42 ± 0.29

d

0.38 ± 0.00

c

2.42 ± 0.13

f

8 South Celebes 61.91 ± 0.58

f

296.39 ± 4.15

e

682.27 ± 0.34

e

2.43 ± 0.07

b

0.43 ± 0.31

d

0.04 ± 0.00

a

1.65 ± 0.02

c

9

West

Sumatera

79.93 ± 0.37

i

362.24 ± 3.10

h

934.32 ± 30.49

g

3.08 ± 0.01

d

0.17 ± 0.12

a,b

0.43 ± 0.01

c

2.09 ± 0.00

e

*T = theobromine, C = (+)-catechin, Caff = Caffeine, EC = (-)-epicatechin

Results are the means of two ± standard deviation. Values accompanied by different letters in the same row statistically

different (p<0.05)

2nd SIS 2019 - SEAFAST International Seminar

100

Effect of fermentation of cocoa beans showed

polyphenol content of fermented cocoa beans smaller

than the unfermented cocoa beans (Prayoga et al.,

2013). Fermented cocoa beans decline in the

polyphenol content due to oxidation, polymerization

and proteins binding (Ramli et al., 2006). Generally,

processing of cocoa powder that has a higher

temperature or longer time will reduce the levels of

polyphenols in cocoa powder component as a result

of chemical reactions such as acceleration of

oxidation reactions (Bernaert et al., 2012).

3.3 Antioxidant Capacity

The antioxidant capacity of Indonesian cocoa powder

was evaluated by using DPPH and FRAP (Ferric

Reducing Antioxidant Power) assay. The

identification results of antioxidant capacity using the

two methods are presented in Table 2. The results of

DPPH antioxidant capacity stated by micromoles

Trolox equivalent per gram of defatted cocoa powder

dry basis, whereas for FRAP methods expressed by

Fe

2+

micromoles per gram of defatted cocoa powder

dry basis.

The capacity of antioxidants in Indonesian cocoa

powder depends on the number of hydroxyl groups

which can inhibit the chain reaction of free radicals

associated with hydrogen donors. High levels of

antioxidant in cocoa powder increase the chances of

hydroxyl and hydrogen donors of free radicals

(Tamrin 2012). The antioxidant capacity of DPPH

method ranged from 91.67 - 362.24 (mol TE / g). The

results supported by research of Genovese et al.,

(2009), which has an antioxidant value of 120 mol TE

/ g, but higher than the results reported by Brcanovic

et al., (2013) that was 11.65 - 32.01 (mol TE/g).

Sample 4 had the lowest antioxidant capacity value

(91.77 mol TE/g) and sample 9 had the highest

antioxidant capacity of DPPH method (362.24 mol

TE/g). All samples were significantly different at the

5% significance level except for sample 1 and 3.

The ability for reducing radical compounds is the

latest antioxidant defense mechanisms. This

mechanism is divided into electron transfer and

hydrogen atom transfer (Oboh and Omoregie, 2011).

FRAP method used in this research to calculate the

ability to reduce Fe

3+

to Fe

2+

. FRAP methods have

antioxidant capacity value ranging from 249.16 -

1000.95 (mol Fe

2+

/ g). Results of this study were

lower than the results Oboh and Omoregie (2011) that

was 1466.33 - 2097.12 (mol Fe 2+ / g), but higher

than the Brcanovic et al., (2013), 22:45 - 137.51 (mol

Fe 2+ / g).

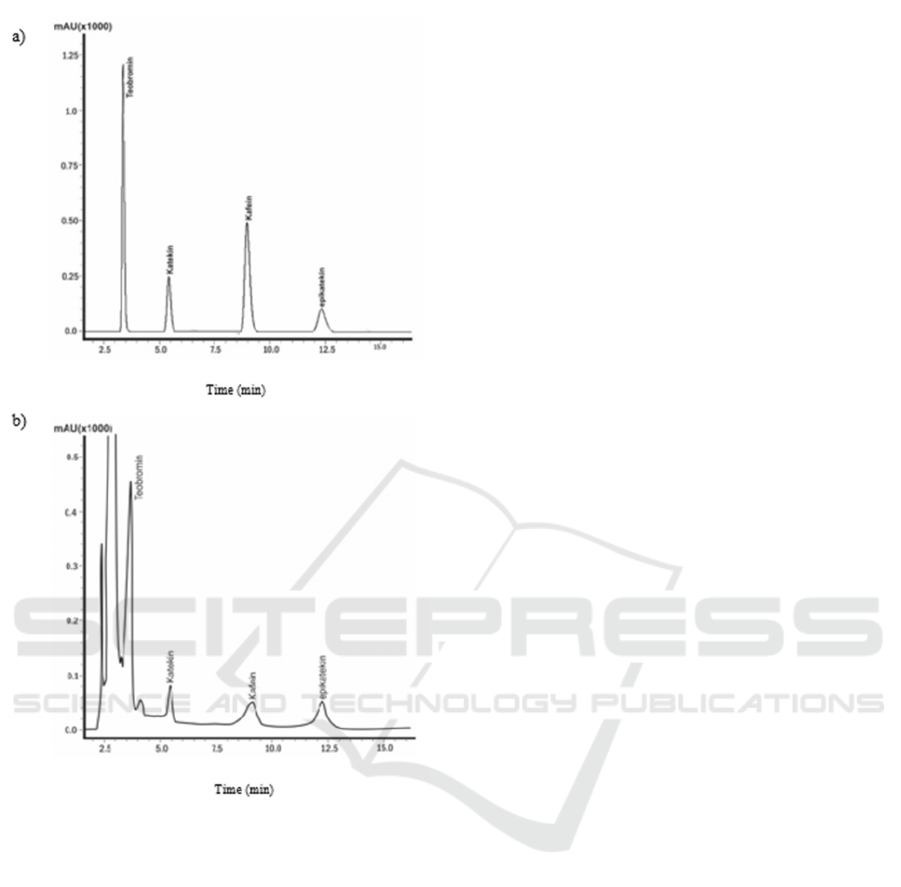

3.4 Profile of Bioactive Compound

Identification of bioactive compounds of Indonesian

cocoa powder using HPLC with UV detector using a

wavelength of 280 nm. Methylxanthines and Phenolic

compounds are identified. The HPLC chromatogram

of bioactive compounds of cocoa powder and

standard can be seen in figure 1. A retention time of

bioactive compounds for theobromine, (+)-catechin,

caffeine, and (-)-epicatechin were 3.3, 5.08, 8.5, and

11.8 minutes, respectively. The results of HPLC

analysis are given in Table 2.

Theobromine content of Indonesian cocoa powder

ranged from 1.89 – 3.14 (mg/g). These results lower

than research from Lo Coco et al., (2007) that was

4,6- 26 (mg/g). The caffeine content ranged from 0,12

– 0.46 (mg / g). The previous studies found the

caffeine content 1.74 - 7:53 (mg/g) from Malaysian

cocoa powder (Ramli et al., 2001) and 0.15 - 1.42

from Croatian chocolate manufacture (Belscak et al.,

2009). Methylxanthine compound decreased during

the fermentation process up to 30% of the initial

methylxanthine content. The decreasing of

methylxanthine is caused by the diffusion of alkaloids

from cotyledon (Nigam and Singh, 2014). The

concentration of methylxanthine decreased with the

increasing of alkalization process, decreasing of the

total theobromine content due to alkalization process

reaches 20% (Li et al., 2012). This is consistent with

the result that shows alkalized cocoa powder was

lower in methylxanthine content than natural cocoa

powder. The HPLC results show that theobromine

compound is the highest bioactive compound of

Indonesian cocoa powder. Consumption of

theobromine from cocoa can significantly increase

plasma HDL cholesterol, lowering LDL

concentrations in plasma, providing cardiovascular

protection and reducing the risk of coronary heart

disease (Khan et al., 2012).

Individual phenolic compounds identified in this

study were (+)-catechin and (-)-epicatechin given in

table 2. (+)-Catechin ranged from 0.04 to 1.10 (mg/g).

This result is supported by the research of Belscak et

al., (2009) that found 0.04 to 0.33 (mg/g) and

Brcanovic et al., (2013) that found 0.03 to 0.18

(mg/g). The (-)-epicatechin content of Indonesian

cocoa powder varied from 0.04 - 4.68 (mg/g). Ramli

et al., (2001) reported (-)-epicatechin content of

Malaysian cocoa and chocolate product ranged from

to 0.48 to 6.32 mg/g), but the result was greater than

the results from Brcanovic et al., (2013) that was 0.04

to 0.14 (mg/g).

Profile of Bioactive Compounds and Antioxidant Capacity of Indonesian Cocoa Powder: A Case of Food Processing Authentication

101

Figure 1: Chromatograms of: a) standard; b) cocoa powder

sample. Analyzed using HPLC with UV detector at a

wavelength of 280 nm.

The (-)-epicatechin content is very influenced by

the level of processing cocoa powder. Meng et al.,

(2009) reported the fermentation process can

significantly reduce the epicatechin content up to 10-

20 %. Sample 1,2,3,4,5 has a lower level of (-) –

epicatechin, it assumed that those samples have

undergone high-temperature of roasting. Roasting

significantly affect the level of polyphenols. Roasting

at higher temperatures induce the epimerization of (-

)- epicatechin into (+) - catechin (Hurst et al., 2011).

This theory supported by the results that show the

concentrations of (+) - catechin were higher in the

alkalized samples (1, 2, 3, 4, 5). Alkalization process

has been reported to reduce the content of (-)-

epicatechin up to 98% and (+)-catechin up to 80%

(Giacometti et al., 2015). This is supported by data

results that showed that the alkalized cocoa powder

samples have a higher value of (+)-catechin and the

lower value of (-) – epicatechin than natural cocoa

powder.

Principal component analysis (PCA) was

performed to classify samples based on the similarity

of their chemical properties. Scatter plots analysis of

PCA are illustrated in Figure 2. The components F1

and F2 represents the total diversity of 87.03% is

considered quite describe the variance of the data

structure. PCA results divided the alkalized and

natural cocoa powder into left and right quadrant.

Samples 6, 7, 8 and 9 (natural) are in the right

quadrant and the alkalized samples are on the

opposite sides. The right quadrant has a lighter color

of cocoa powder and has similarity on high content of

theobromine, (-) - epicatechin, caffeine, and total fat.

These group of samples has high TPC and antioxidant

capacity.

The left side of PCA analysis is identified of

alkalized cocoa powder group. Samples 1, 2, 3, 4, 5

located in the left quadrant has the similar

characteristics of higher pH and (+)-catechin content.

These group of samples has low TPC and antioxidant

capacity level. The pH value contained in the cocoa

powder has a distant quadrant with total phenol and

antioxidant capacity, it can be concluded that a higher

pH value can reduce total phenolic content and

antioxidant capacity.

Correlation between analysis was performed by

Pearson correlation test. The result is shown in Table

3. TPC has a strong correlation with antioxidant

capacity both DPPH and FRAP assay with the

significance level (p <0.01). These results confirm a

relationship between their free radical scavenging and

ferric reducing capacities with the concentration of

phenolic compounds in cocoa powder. Therefore, the

presence of phenolic compounds in the Indonesian

cocoa powder samples contributes significantly to

their antioxidant potential (Brcanovic et al., 2013).

Analysis of color and fat were also correlated

(p<0.05) with TPC and antioxidant capacity. Strong

negative correlation (p< 0.01) was also observed

between pH, TPC, and antioxidant capacity. Higher

pH contained by Indonesian cocoa powder decrease

the level of TPC and antioxidant capacity.

Theobromine and (-)-epicatechin had no

significant correlation at level (p <0.05) to TPC.

Theobromine had a significant correlation at level (p

<0.01) with antioxidant capacity. This is presumably

due to the structure of theobromine that similar to uric

acid which has a mechanism of secondary antioxidant

(Azam et al., 2003). Caffeine compounds do not have

2nd SIS 2019 - SEAFAST International Seminar

102

Figure 2: Scatter plots of the first two principal component vectors (F1 vs. F2) for 9 samples of Indonesian cocoa powder

according to data of pH, total fat, color, TPC, DPPH, FRAP, and Individual bioactive compound.

Table 3: Pearson Correlation coefficient between pH, total fat, color, TPC, DPPH, FRAP, Theobromine, (+)- catechin,

caffeine, and (-)-epicatechin.

Total Phenols DPPH FRAP T C Caf EC pH Color Total fat

TPC

1 0.996** 0.970** 0.745 * -0.799** 0.552 0.727* -0.898** 0.722* 0.774*

DPPH

1 0.977** 0.749 * -0.811** 0.577 0.704* -0.918** 0.693* 0.795*

FRAP

1 0.796** -0.720* 0.555 0.719* -0.863** 0.775* 0.703*

T

1 -0.615 0.524 0.538 -0.656 0.557 0.525

C

1 -0.708* -0.522 -0.871** -0.249 -0.889**

Caf

1 0.680* -0.713* 0.126 0.845**

EC

1 -0.554 0.702* 0.582

pH

1 -0.391 -0.939**

Color

1 0.178

Total

fat

1

** significant at the level of the level of correlation 0:01

* Correlation is significant at the level of 0:05

T = theobromine, C = (+) - catechins, Caf = Caffeine, EC = (-) – epicatechin

a good positive correlation to total phenol and

antioxidant capacity due to their small quantity found

in cocoa powder samples. (+)–Catechin compound

has a negative correlation with total phenol and

antioxidant capacity. That statement can be described

as the effect of epimerization from (-)-epicatechin to

(+)–Catechin structure. According to Cooper et al.,

(2008) epicatechin had a high correlation to total

phenols but not for catechin compounds. There was a

decreasing of polyphenol compounds due to a

processing of cocoa powder, but the decline has

different degrees between each polyphenolic

compounds.

Profile of Bioactive Compounds and Antioxidant Capacity of Indonesian Cocoa Powder: A Case of Food Processing Authentication

103

4 CONCLUSION

Profile of bioactive compounds and antioxidant

capacity of Indonesian cocoa powder have different

values. The total phenolic content ranged from 14.80-

79.93 mg (GAE/g) on a dry basis. DPPH antioxidant

capacity has a range of values 91.67 - 362.24 (mol

TE/g) and FRAP method has a value range 249.16 -

1000.95 (mol Fe

2+

/ g). The content of theobromine,

caffeine, catechin, epicatechin ranged from 1.89 –

3.08 (mg / g); 0.12 - 0:46 (mg / g); 0.04 – 1.10 (mg/g);

0.04 - 4.68 (mg/g), respectively. The high positive

correlation was found between TPC and antioxidant

capacity both DPPH and FRAP. Total fat and color

had a positive correlation with total phenol, however,

pH had a strong negative correlation to total phenol.

PCA analysis divides the samples based on similarity

of chemical characteristics. Left quadrant was a group

of alkalized cocoa powder and right quadrant was a

group of natural cocoa powder.

ACKNOWLEDGMENT

This research work was financially supported by the

Southeast Asean Food and Agricultural Science and

Technology (SEAFAST) center, Bogor Agricultural

University, Indonesia.

REFERENCES

Abbe, M., Ismail A. 2010. Antioxidant properties of cocoa

powder. J Food Biochem. 34: 111–128.

And´ujar, I., Recio, M.C., Giner, R.M., Rios, J.L. 2012.

Cocoa polyphenols and their potential benefits for

human health. Oxid Med Cell. Article ID 906252, 23

pages. Available from: http://dx.doi.org/10.1155/2012/

906252.

Azam, S., Hadi, N., Khan, N.U., Hadi, S.M. 2003.

Antioxidant and prooxidant properties of caffeine,

theobromine and xanthine. Med Sci Monit. 9 (9) : 325-

330

Belscak, A., Komes, D., Horzic, D., Ganic, K.K., Karlovic,

D. 2009. Comparative study of commercially available

cocoa products in terms of their bioactive composition.

Food Research Inter. 42:707-716

Benzie, I.F.F., Strain J.J. 1996. The Ferric reducing ability

of plasma as a measure of “antioxidant power”: the

FRAP assay. Analyt Biochem. 239(1): 70-76.

Bernaert, H., Blondeel, L., Allegaert, L., & Lohmueller, T.

(2012). Industrial treatment of cocoa in chocolate

production: health implication. In: Paoletti et al. (eds).

Chocolate and Health. 17-31.

Brcanovic, J.M., Aleksandra, N., Miti S.S., Stojanovi G.S.,

Manojlovi, D.D., Kali, B.M., and Jovana, N.V. 2013.

Cyclic voltammetric determination of antioxidant

capacity of cocoa powder, dark chocolate and milk

chocolate samples: correlation with spectrophotometric

assays and individual phenolic compounds. Food

Technol. Biotechnol. 51 (4): 460–470

Cooper, K.A., Donovan, J.L., Waterhouse A.L, Wiliamson

G. 2008. Cocoa and health: a decade of research. British

J. of Nutrition. 99: 1-11

Data and Information Center for Agriculture [Pusdatin].

Cocoa Commodity Outlook 2014. Jakarta (ID): Center

for Agricultural Data and Information Secretariat

General of the Ministry of Agriculture.

Directorate General of Plantation (Ditjetbun). 2015.

Statistics Commodities Cocoa Plantation Indonesia

2014 - 2016 Jakarta (ID): Directorate General of

Plantation.

Dyer, B. 2003. Alkalized cocoa powder. Retrieved on

August 15, 2010 from Website:

www.blommer.com/_documents/alkalized-cocoa-

powders-article.pdf

Franco, R., Astibia, A.O., Pinilla, E.M. 2013. Health

benefits of methylxanthines in cacao and chocolate.

Nutrients. 5(10) : 4159 – 4173.

Genovese, M.I. and Lannes. 2009. Comparison of total

phenolic content and antiradical capacity of powders

and “chocolates” from cocoa and cupuassu. Sci. Tech.

Align. 29(4).

Giacometti, J., Joli´c, S.M., Josi ´ c, D. 2015. Cocoa

processing and impact on composition. In: Preedy VR

editor. Processing and impact on active components in

food. London/Waltham/San Diego: Academic Press. p

605–12.

Joli´c, S.M, Radojˇci´c, Redovnikovi´c, I., Markovi´c,

K.,ˇSipuˇsi´c, D.I., Delonga, K.. 2011. Changes of

phenolic compounds and antioxidant capacity in cocoa

bean processing. Int J Food Tech. 46:1793–1800

Khan, N., Monagas, M., Andres-Lacueva, C., Casas, R.,

Urpí-Sardà, M., Lamuela-Raventós, R.M., Estruch, R.

2012. Regular consumption of cocoa powder with milk

increases HDL cholesterol and reduces oxidized LDL

levels in subjects at high-risk of cardiovascular disease.

Nutr Metab Cardiovasc Dis. 22:1046–1053.

Li, Y., Feng, Y., Zhu, S., Luo, C., Ma, J., Zhong, F. 2012.

The effect of alkalization on the bioactive and flavor-

related components in commercial cocoa powder. J

Food Compos Anal. 25: 17–23.

Meng, C.C., Jalil, A.M., Ismail, M. 2009. Phenolic and

theobromine contents of commercial dark, milk and

white chocolates on the malaysian market. Molecules.

14: 200-209.

Miller, K.B., Hurst, W.J., Payne, M.J., Stuart, D.A., Apgar,

J., Sweigart, D.S., Boxin, O. 2008. Impact of

Alkalization on the Antioxidant and Flavanol Content

of Commercial Cocoa Powders. J Agric Food Chem.

56: 8527–8533.

Nigam, P.S., Singh, A. 2014. Cocoa and coffee

fermentations. In: Batt CA, Tortorello ML, editors.

Encyclopedia of food microbiology. 2nd ed.

2nd SIS 2019 - SEAFAST International Seminar

104

London/Burlington/San Diego: Academic Press. p

485–92.

Oboh, H.A., dan Omoregie, I.P. 2011. Total phenolics and

antioxidant capacity of some nigerian beverages.

Nigerian J. of Basic and App. Sci. 19(1): 68-75

Pinilla, E.M., Astibia, A.O., Franco, R. 2015. The

relevance of theobromine for the beneficial effects of

cocoa consumption. Front Pharmacol. 6: 30

Prayoga, R.D., Murwani, R., Anwar S. 2013. Polyphenol

extracts from low-quality cocoa beans: antioxidant,

antibacterial and food coloring properties. Internat.

Food Res. J. 20(6), 3275-3281.

Ramli, N., Seng, R., Hassan, L.K., Said, M. 2006. Effect

of pulp preconditioning on the content of polyphenols

in cocoa beans (Theobroma cacao L.) during

fermentation. Indust. Crops Prod. 24: 87-94.

Ramli, N., Yatim, A.M., Said, M., Hok, H.C. 2001. HPLC

determination of methylxanthines and polyphenols

levels in cocoa and chocolate products. Malaysian

Journal of Analytical Sciences. 7 (2): 377-386

Ramljak, D., Romanczyk, L.J., Metheny-Barlow, L.J.,

Thompson, N., Knezevic, V., Galperin, M., Ramesh,

A., Dickson, R.B. 2005. Pentameric procyanidin from

Theobroma cacao selectively inhibits growth of human

breast cancer cells. Mol Cancer Ther. 4(4):537–546.

Rios, L.Y., Gonthier, M., Remesy, C., Mila, I., Lapierre, C.,

Lazarus, S.A., Williamson, G., Scalbert, A. 2003.

Chocolate intake increases urinary excretion of

polyphenol-derived phenolic acids in healthy human

subjects. J Clin Nutr 77: 912–918.

Sci. Tech. Align. 29(4).

Tamrin. 2012. Perubahan aktivitas antioksidan bubuk

kakao pada penyangraian vakum. Proceeding of

Departement Food Science and Technology, Faculty of

Agriculture, Haluoleo University, Kendari: Indonesia

Thomas-Barberan, F.A., Cienfuegos-Jovellanos, E., Marın,

A., Muguerza, B., Gil-izquierdo, A., Cerda, B.,

Zafrilla, P., Morillas, J., Mulero, J., Ibarra, A.,

Pasamar, M.A.A., Ramoän, D., Espın, J.C. 2007. A

new process to develop a cocoa powder with higher

flavonoid monomer content and enhanced

bioavailability in healthy humans. J. Agric. Food Chem.

55: 3926-3935

Weisburger, J.H. 2001. Chemopreventive Effects of Cocoa

Polyphenols on Chronic Diseases. New York (US):

American Health Foundation.

Profile of Bioactive Compounds and Antioxidant Capacity of Indonesian Cocoa Powder: A Case of Food Processing Authentication

105