Laboratory-scale Synthesis of Mono-diacylglycrol from Palm Oil

Stearin using Glycerolysis

Didah Nur Faridah

1,2

, Nurhadi Rahmat Sumitra

1

, Purwiyatno Hariyadi

1,2

, Ria Noviar Triana

2

,

Andri J. Laksana

2

and Nuri Andarwulan

1,2

1

Department of Food Science and Technology, IPB University, Indonesia

2

Southeast Asian Food Science and Agricultural Science and Technology (SEAFAST) Center, IPB University, Indonesia

phariyadi@apps.ipb.ac.id, andarwulan@apps.ipb.ac.id,

Keywords: Glycerolysis, MDAG, Reaction Order, Stearin.

Abstract: CPO refining process generally consisted of degumming, bleaching, filtration, deodorizing and fractionation.

At the end of the process, the yield is divided into two products, namely olein (liquid fraction) and stearin

(solid fraction). The aims of this research was to study the difference of stirring speeds on synthesis of MDAG

using glycerolysis method at laboratory scale. The stirring speed was performed at scale 3 and 4, while MDAG

was synthesized at substrate ratio of stearin:glycerol (1:2.3), temperature reaction of 180°C, time reaction of

90 min, and addition of 0.5% NaOH. Formation of MAG and DAG, as well as decomposition of TAG, was

found to follow reaction order 0, with R

2

of 0.4053, 0.5833, dan 0.3588, respectively. In the use of scale 3,

formation of MAG and DAG followed reaction order 0, whereas decomposition of TAG followed reaction

order 1, resulting in R

2

of 0.6551, 0.6114, and 0.7708, respectively. At verification stage, the results

demonstrated high accuracy, with Coefficient of Variance (CV) of < 5%, resulting in MAG 0.56% and DAG

2.52%. Acylglycerol fractions of verified MDAG product showed a noticeable variety, i.e. MAG

46.68±0.26%, DAG 32.57 ± 0.82%, and TAG 6.78 ± 0.47%. Furthermore, physichochemical characteristics

of MDAG showed the greatest proportion of fatty acid as follows: palmitic acid (C16: 0) 55.71±0.41% and

oleic acid (C18: 1 cis) 29.48±0.15%, with moisture content 0.57±0.02%, FFA 1.91±0.07%, iod number

6.08±0.04 mg/g, and slip melting point at 48.5-50 °C.

1 INTRODUCTION

As a precious commodity in Indonesia, oil palm has

received economic importance to the country.

Economically, palm oil industrial sector significantly

contributed to the country's foreign exchange

(Ministry of Agriculture 2015). For this reason, total

area for oil palm farm has continuously increased and

currently reached 9.26 millions Ha in 2017, with the

production of 35.36 million tons at productivity rate

of 3.82 tons per Ha; this leads Indonesia as the world's

largest palm oil producer (Ministry of Agriculture

2017).

Palm fruit consists of two parts, namely CPO

(Crude Palm Oil) which is produced from palm fruit

flesh and PKO (Palm kernel oil) from its fruit core

(Larasati et al. 2016). CPO is rich in palmitic acid

(C16: 0), while PKO is rich in lauric acid (C12: 0) and

myristic acid (C14: 0) (Ketaren 2008). Conversion of

CPO into food products needs refining process,

including degumming, bleaching, filtration, and

deodorizing. The final result of refining was obtained

without refined palm oil (RBDPO) (Silalahi et al.

2017). Now, palm oil is used more for cooking oil,

oleochemical and biodiesel industries.

The fractionation stage is an advanced process to

separate the RBDPO into two fractions, namely the

solid fraction (stearin) by 25% and the liquid fraction

(olein) by 75% (Malik 2015). Stearin has melting

points in the range 33.4-46.2 °C, while olein is 13-23

°C; thus, stearin is at solid state room temperature, but

olein is liquid. Olein is widely appleid as cooking oil

due to its properties during frying, including low

oxidation and degradation rate. Meanwhile, stearin is

generally used as main ingredient for hard fat in

various products, such as shortening, pastry,

margarine. Stearin is often considered a by-product of

palm olein, which make it cheaper compared to olein

(GAPKI 2014). Therefore, there is a need to convert

112

Faridah, D., Sumitra, N., Hariyadi, P., Triana, R., Laksana, A. and Andarwulan, N.

Laboratory-scale Synthesis of Mono-diacylglycrol from Palm Oil Stearin using Glycerolysis.

DOI: 10.5220/0009977700002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 112-117

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

RBDPStearin into high quality products, such as

mono-diacylglycerol (MDAG) as emulsifier.

MDAG is commonly known as emulsifying agent

in a variety of industries such as food, cosmetics and

pharmaceutical, estimated to reach 70% total

emulsifier use. In food industries, it is applied in

bakery products, margarine, and frozen dessert.

Generally, MDAG is used as part of fatty products

and is often combined with other types of emulsifiers.

To produce MDAG, chemical glycerolysis from oils

or fats was carried out at high temperature, with the

help of inorganic alkaline catalysts (Cheirsilp et al.

2009). These emulsifiers are available in various

forms, such as liquid, solid, semi-liquid, flakes,

grains, and powders. The emulsifier relates to some

advantageous features, including water-in-oil (w / o)

with HLB of 4-6, no smell and taste, not water-

soluble at room temperature (O'Brien 2009). In the

food industry, MDAG is widely used in bakery,

margarine and chocolate products. Based on CFR

Regulation (2002), MDAG with code 21 CFR

182.4505 has no ADI value (acceptable daily intake)

or not limited; therefore, it can be categorized as

GRAS (Generally Recognized as Safe).

As a result of synthesize a laboratory-based

MDAG using palm oil stearin, the MDAG was

properly made from ratio substrate (stearin: glycerol)

of 1: 2.3, 0.5%N NaOH catalyst, reaction temperature

180 °C for 90 min, and stirring speed on scale 3,

yielding product with a percentage of acylglycerol

MAG fraction, DAG, and TAG as follows: 50.33 ±

0.95%, 28.13 ± 0.63%, and 4.49 ± 2.08%,

respectively. The MDAG product posseseed ALB

value of 1.64 ± 0.00%, moisture content of 0.55 ±

0.02%, iodine number of 34.56 ± 0.01 mg / g, and a

slip melting point of 49.5-50 °C. In this reagard,

stirring speed became a crucial factor that affects

formation of MDAG. According to Baeza-Jiménez

(2013), higher rate of stirring leads to increase in

decomposition time of TAG into MAG and DAG.

Therefore, this current work investigated the effect of

stirring speeds on MDAG synthesis from palm oil

stearin.

2 MATERIAL AND METHODS

2.1 Materials

This research was conducted at Chemistry Laboratory

Center, SEAFAST, IPB University. Chemicals used

in this experiment included stearin, olein, and PKO,

glycerol, sodium hydroxide (NaOH), citric acid,

nitrogen gas, standard Fatty Acid Methyl Esters

(FAME) Mix C4-C24, N-Methyl-N-trymethylsilyl

trifluoroacetamide, 0.1 M Na

2

S

2

O

3

solution, 95%

neutral alcohol solution, 50% citric acid, glacial

acetic acid, chloroform, heptane, acetone, distillate

water, Wijs solution, KI solution, phenolphthalein

indicator, starch indicator, and other analytical

materials.

The main equipments included 250 mL-three

neck flask equipped with a condenser, oil bath,

stirring hotplate, magnetic stirrer. For chemical

analysis, equipment needed was parafilm, aluminum

foil, analytical balance, Erlenmeyer flask, biuret,

pipette mohr, oven, desiccator, Gas

Chromatoghraphy FID Hewlett Packard 6890 series

DB5 HT column, GC FID series DB 23 column

Shimadzu Co. and HPew RID Hewlett Packard Series

1100.

2.2 Characterization of Palm Oil Raw

Materials

The physicochemical conditions of raw materials can

affect the effectiveness of the glycerolysis; thus, raw

material needs to be ensured for meeting all

requirements. The physicochemical analysis included

water content (AOCS Official Method Aa 3-38 year

2003), free fatty acid (AOCS Official Method Ca 5a-

40 year 2003), peroxide number (AOCS Official

Method Cd 8- 53 year 2003), iodic number (AOCS

Official Method Cd 1-25 year 2003), fatty acid

composition (AOCS Official Method Ce 2-66 year

2003), acylglyserol fraction (AOCS Official Method

Cd 11b-91 year 2003, with modification), and profiles

of triacylglycerol (AOCS Official Method Ce 5b-89

year 2003).

2.3 Synthesis of MDAG at Laboratory

Scale

The laboratory-scale MDAG synthesis conformed to

method of Triana (2014). Sampling was carried out

each 30 min to measure the acylglycerol fraction. The

repetition of MDAG synthesis in laboratory scale as

a verification stage was carried out five times in a

series of tests aimed at finding out the consistency of

the formation of the MDAG.

2.4 Physicochemical Properties of

MDAG Products

The chemical characterization of MDAG included

water content, iod number, acylglycerol fraction, free

fatty acid value, as well as fatty acid profile, while

physical characterization included slip melting point

Laboratory-scale Synthesis of Mono-diacylglycrol from Palm Oil Stearin using Glycerolysis

113

(referring to Official Method Cc 3-25 AOCS year

2005) and visual color measurement.

3 RESULTS AND DISCUSION

3.1 Physicochemical Characteristics of

Raw Materials

RBDP stearin is a by-product of CPO fractionation

and is previously refined. The standard for RBDP

stearin conformed to SNI 01-0021-1998, i.e.

maximum level of free fatty 0.15%, maximum water

and impurities content of 0.1%, maximum iodine

number of 40 mg / g, and arsenic contamination of 0.1

mg / kg. The characteristics of palm oil stearin as raw

material included water content, free fatty acid (FFA),

iodine number, peroxide number, fatty acid

composition, acylglycerol fraction, and

triacylglycerol (TAG) profile.

Table 1: Physicochemical characteristics of stearin.

Parameters Value

Water Content (%) 0.020 ± 0.00

Free Fatty Acids (%) 0.073 ± 0.00

Iod Number (mg/g) 34.45 ± 0.68

Peroxide Number

(meq O

2

/kg)

1.225 ± 0.05

Slip melting point (°C) 50.0-50.5

The results showed that water content in stearin

reached 0.02%. As investigated by Triana (2014), the

high level of moisture content enabled to induce oil

damage due to hydrolysis process, resulting in

increased level of FFA as indicator of the reduced oil

quality. Besides, FFA level was found at 0.073%. The

presence of high free fatty acids allowed to react with

alkaline catalysts and caused saponification, thereby

reducing the effectiveness of the catalyst (Rousseau

et al. 2017).

Furthermore, stearin possessed iod number of

34.45 mg / g, while peroxide number of the stearin

was 1,225 meq O

2

/ kg. Based on the results, the

strearin used as raw material is chemically acceptable

since it fits the standards. Physically, slip melting

point (SMP) of the stearin ranged from 50.0-50.5 °C.

Profile of TAG demonstrated two main fractions:

POP (36.95%) and PPP (15.81%). According to

O'Brien (2009), when TAGs are saturated, the texture

of the raw material is hard; conversely, at high level

of unsaturated TAGs, the texture tends to be softer.

Thus, the stearin used as raw material has a soft

texture. TAG profile analysis was performed to

determine the highest TAG type as a reference for

stochiometric calculations in MDAG synthesis. The

calculation is based on POP TAG type as a mole base

because it is present at the highest proportion. TAG

profile of palm oil stearin can be seen in Table 2,

while TAG chromatograms is depicted in Figure 1.

Table 2: Profile of triacylglycerol in palm oil stearin (n=4).

TAG type ECN

a,b

Triglyceride Composition

(%)

PLL 44 1.24 ± 0.09

OLO 46 0.54 ± 0.02

PLO 46 4.56 ± 0.10

PLP 46 8.36 ± 0.21

OOO 48 1.32 ± 0.24

POO 48 11.67 ± 0.31

POP 48 36.94 ± 0.49

PPP 48 15.81 ± 0.67

POS 50 7.00 ± 0.19

SOS 52 3.42 ± 0.10

Others - 9.14 ± 0.12

Information:

P: Palmitate (C16: 0); S: Stearic (C18: 0); O: Oleat (C18:

1); L: Linoleic (C18: 2)

Source:

a

Costales-Rodriguez et al. (2009);

b

Adhikari et al.

(2009)

Figure 1: TAG profile chromatogram of raw material for

palm oil stearin with High Performance Liquid

Chromatography.

FFA analysis of the stearin is important since it

remarkably affect fatty acid characteristics of the

MDAG. The results indicated that saturated fatty

acids (SFA) dominated the composition with

proportion of 61.67 ± 0.25%, mainly consisting of

palmitic acid (C16: 0) at 55.03 ± 0.24%. Besides,

monounsaturated fatty acid (MUFA) was observed at

total amount of 30.57 ± 0.14, mainly composed of

Retention time (min)

Area response (nRIU)

2nd SIS 2019 - SEAFAST International Seminar

114

oleic acid (C18: 1cis) at percentage of 30.47 ± 0.14%.

The profile of fatty acid is presented in Table 3, while

chromatogram of the fatty acid composition of palm

oil stearin is exhibited in Figure 2.

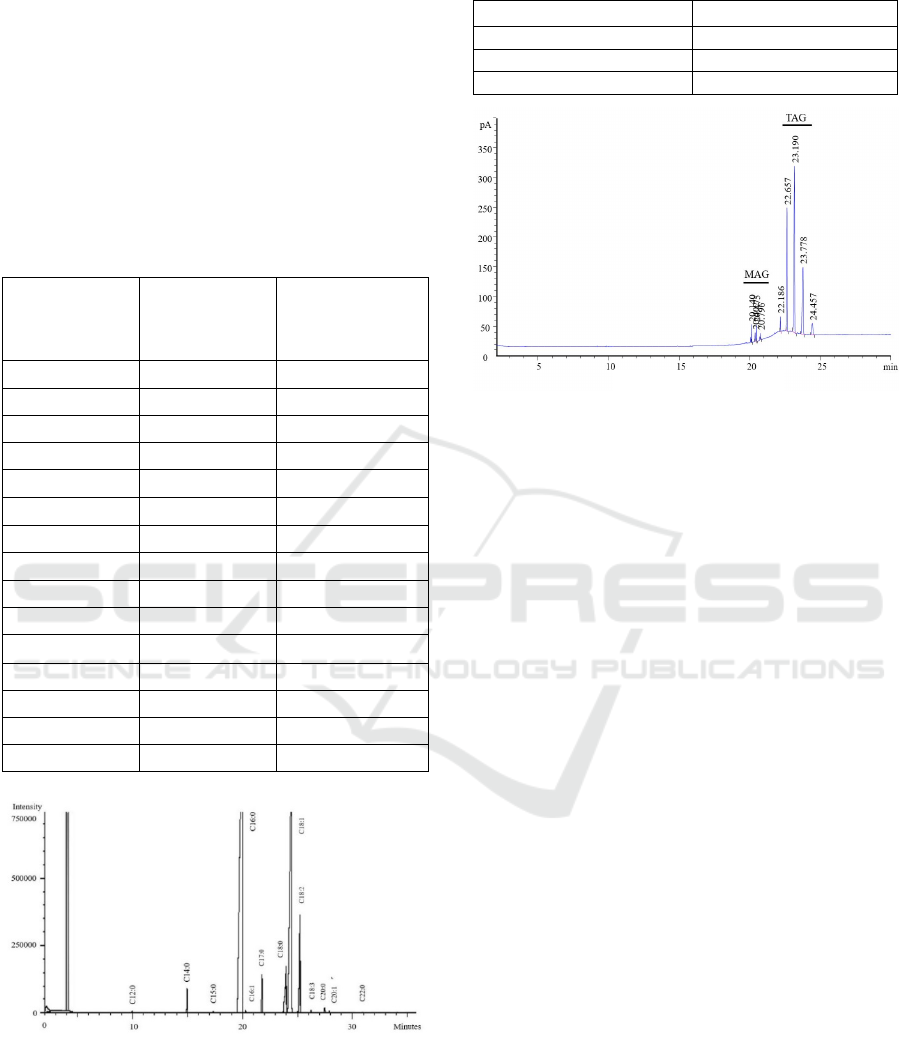

Analysis of acylglycerol fraction was carried out

to determine the total percentage of initial MAG,

DAG and TAG fractions present in palm oil stearin.

The results exhibited that DAG and TAG fractions

became two major components, i.e. 4.60% and

95.40%, respectively. The chromatogram of the

acylglycerol fractions can be seen in Figure 3.

Table 3: Composition of fatty acids in palm oil stearin.

Fatty Acid

Average

concentration of

fatty acids g /

100g of oil

Average fatty

acids from total

fatty acids (%)

C12:0 0.11 ± 0.00 0.11 ± 0.00

C14:0 1.00 ± 0.01 1.04 ± 0.01

C16:0 52.76 ± 0.19 55.03 ± 0.24

C18:0 4.77 ± 0.02 4.97 ± 0.02

C20:0 0.32 ± 0.00 0.34 ± 0.00

C22:0 0.17 ± 0.00 0.18 ± 0.00

Total SFA 59.13 ± 0.21 61.67 ± 0.25

C16:1 0.10 ± 0.00 0.10 ± 0.00

C18:1 cis 29.21 ± 0.12 30.47 ± 0.14

Total MUFA 29.31 ± 0.12 30.57 ± 0.14

C18:2 cis 6.60 ± 0.02 6.89 ± 0.03

C18:3 0.14 ± 0.00 0.14 ± 0.00

Total PUFA 6.74 ± 0.02 7.03 ± 0.03

Unknown FA 0.71 ± 0.33 0.74 ± 0.35

Total area 95.88 ± 0.50 100

Figure 2: Chromatogram of fatty acid composition of palm

oil stearin analyzed by Gas Chromatography.

Table 4: The fraction of acylglycerol in palm oil stearin.

Acylglycerol fractions Value (%)

MAG 0.00

DAG 4.60

a

TAG 95.40

a

Figure 3: Chromatogram of acylglycerol fractions in palm

oil stearin detected by Gas Chromatography.

3.2 Glycerolysis for MDAG Synthesis

As depicted in Figure 4, formation of MAG and DAG

could be grouped into 2 phases. First, conversion of

TAG into MAG and DAG increased sharply within

30 min, reaching up to 42.95 ± 1.59% and 27.85 ±

2.18%, respectively. Second, after 30 min, sloping

phase occurred in which formation of MAG tended to

be stagnated, constantly at range of 42%. However,

formation of DAG continously increased during

glycerolysis, reaching up to 29-34%.

The optimum reaction condition was determined

according to the highest total percentage of MAG and

DAG, statistically evaluated using Duncan test in

SPSS statistical software. ANOVA test results

showed that production of MAG in reaction time of

90 min did not differ significantly compared to that in

reaction time of 30 and 180 min (p >0.05), but differ

significantly (p <0.05) in comparison with the

reaction time of 60, 120, and 150 min. Level of DAG

fraction in 90 min-reaction time was significantly

different (p <0.05) compared that in 60 min-reaction

time, but did not show significant difference

compared to subsequent reaction times (p> 0.05), i.e.

120, 150, and 180 min. For this reason, the most

desirable reaction time was achieved at 90 min.

Additionally, such condition was performed at

reaction temperature of 180 °C, substrate ratio

(stearub:glycerol) of 1:2.3, NaOH 18 N of 0.5%.

Further, the condition needs to be verified, ensuring

the consistency as well as determining the

physicochemical characteristics of the product.

Retention time (min)

Laboratory-scale Synthesis of Mono-diacylglycrol from Palm Oil Stearin using Glycerolysis

115

Figure 4: Average percentage of MDAG acylglycerol

fractions during glycerolysis for 180 min.

3.3 Characteristics of MDAG

The characterization of MDAG is necessary, enabling

to compare with current regulations. The results

exhibited that the resulting MDAG possessed total

fraction of acylglcerol MAG and DAG of 46.68 ±

0.26% and 32.57 ± 0.82%, respectively, as depicted

in Figure 5.

The results suggested that saturated fatty acids

(SFA) dominated the composition of fatty acids,

reaching up to 62.28 ± 0.42%, in which palmitic acid

(C16: 0) showed the greatest proportion at 55.71 ±

0.41%. In addition, monounsaturated fatty acids

(MUFA) also existed at appreciable quantity, i.e.

29.57 ± 0.15%, with oleic acid (C18: 1 cis) at 29.48 ±

0.15% as major fatty acid. Fatty acid composition of

MDAG is presented in Table 5, while the

chromatogram of the fatty acid composition in

MDAG is depicted Figure 6.

Figure 5: Chromatogram of acylglycerol fraction of MDAG

synthesized from palm oil stearin.

In terms of chemical properties, FFA level of

MDAG reached 1.91 ± 0.07%, with iod number of

6.08 mg / g. This suggests that iod number in MDAG

is lower than that in stearin as raw material, i.e. 34.56

mg /g. The significant depletion is caused by

glycerolysis which promotes reduction of unsaturated

fatty acids in MDAG products. Besides, moisture

content was recorded at 0.57 ± 0.02%.

Regarding to physical properties, slip melting

point (SMP) of MDAG ranged from 48.5 to 50 °C.

The product visually appeared as brownish yellow in

color. The color of product resulted from combination

of yellow in stearin and clear in glycerol.

Physicochemical characteristics of MDAG are

presented in Table 6.

Figure 6: Chromatogram of fatty acid composition of

MDAG products from palm oil stearin with Gas

Chromatography.

Table 5: Composition of fatty acids in MDAG made from

palm oil stearin.

Fatty Acid

Average

concentration of fatty

acids g / 100g of oil

Average fatty acids

from total fatty

acids (%)

C12:0 0.07 ± 0.00 0.09 ± 0.00

a

C14:0 0.83 ± 0.00 1.03 ± 0.01

a

C16:0 44.93 ± 0.18 55.71 ± 0.41

a

C18:0 3.99 ± 0.03 4.94 ± 0.04

a

C20:0 0.27 ± 0.00 0.33 ± 0.00

a

C22:0 0.14 ± 0.00 0.17 ± 0.00

a

Total SFA 50.23 ± 0.18 62.28 ± 0.42

a

C16:1 0.08 ± 0.00 0.09 ± 0.00

a

C18:1 cis 23.77 ± 0.25 29.48 ± 0.15

a

Total MUFA 23.85 ± 0.25 29.57 ± 0.15

a

C18:2 cis 5.25 ± 0.06 6.51 ± 0.03

a

C18:3 0.10 ± 0.00 0.13 ± 0.00

a

Total PUFA 5.35 ± 0.06 6.64 ± 0.03

a

Unknown FA 1.22 ± 0.29 1.51 ± 0.35

a

Total area 80.65 ± 0.63 100

Retention time

2nd SIS 2019 - SEAFAST International Seminar

116

Table 6: Characteristics of MDAG products.

Characteristics Value

MAG (%) 46.68 ± 0.26

a

DAG (%) 32.57 ± 0.82

a

TAG (%) 6.78 ± 0.47

a

ALB (%) 1.91 ± 0.07

a

Water Content (%) 0.57 ± 0.02

a

Iod Number (mg/g) 6.08 ± 0.04

a

Slip melting point (°C) 48.5-50.0

a

Colour Brownish Yellow

4 CONCLUSION

Synthesis of mono-diacylglycerol (MDAG) could be

performed using different stirring speeds. The

formation of MAG and DAG and decomposition of

TAG at the stirring speed of scale 4 was evidenced to

follow order of reaction 0. At lower scale of speed, ,

the formation of MAG and DAG followed order of

reaction 0, but decomposition of TAG followed order

of reaction 1. Verification of MDAG synthesis

suggested high accuracy as represented by

Coefficient of Variance (CV) of <5%. Besides,

verification procedure successfully described

acylglycerol fractions of MDAG, resulting in MAG

(46.68 ± 0.26%), DAG (32.57 ± 0.82%), and TAG

(6.78 ± 0.47%). The physicochemical characteristics

of MDAG could be clearly stated as follows: palmitic

acid (C16:0) of 55.71 ± 0.41%, oleic acid (C18: 1 cis)

of 29.48 ± 0.15%, moisture content of 0.57 ± 0.02%,

FFA of 1.91 ± 0.07%, iod number of 6.08 ± 0.04 mg

/ g, and melting point at range of 48.5-50 °C.

REFERENCES

Adhikari P, Shin JA, Lee JH, Hu JN, Hwang KT, Lee KT.

2009. Enzymatic production of transfree hard fat

stock from fractionated rice bran oil, fully

hydrogenated soybean oil, and conjugated linoleic acid.

Journal of food science. 74(2): 87-96.

[AOCS] American Oil Chemist’s Society. 2003.

Official Methods and Recommended Practices of the

AOCS. Edisi ke-5. Illinois (US): AOCS.

[AOCS] American Oil Chemist’s Society. 2005.

Official Methods and Recommended Practices of the

AOCS. Edisi ke-6. Illinois (US): AOCS.

Baeza-Jiménez R, Miranda K, García, HS, Otero C. 2013.

Lipase-catalyzed glycerolysis of fish oil to obtain

diacylglycerols. Grasas y Aceites. 64(3): 237- 242.

[CFR] Code of Federal Regulations, Title 21, Vol. 2,

Section 182.4505. Washington (US): Office of the

Federal Register United States.

Cheirsilp B, Jeamjounkhaw P, H-Kittikun A. 2009.

Optimizing an alginate immobilized lipase for

monoacylglycerol production by the glycerolysis

reaction. Journal of Molecular Catalysis B: Enzimatic.

59: 206-211.

Costales-Rodríguez R. Gibon V, Verhé R, De Greyt W.

2009. Chemical and enzymatic interesterification of a

blend of palm stearin: soybean oil for low trans-

margarine formulation. Journal of the American Oil

Chemists' Society. 86(7): 681-697.

[GAPKI] Gabungan Pengusaha Kelapa Sawit Indonesia.

2014. Mengenal Minyak Sawit dengan Beberapa

Karakter Unggulnya. Jakarta (ID): GAPKI.

Ketaren S. 2008. Pengantar Teknologi Minyak dan Lemak

Pangan. Jakarta (ID): Universitas Indonesia Press.

Larasati N, Chasanah S, Machmudah S, Winardi S. 2016.

Studi analisis ekonomi pabrik CPO (Crude Palm Oil)

dan PKO (Palm Kernel Oil) dari buah kelapa sawit.

Jurnal Teknik ITS. 5(2): 212-215.

Malik A. 2015. Fraksinasi olein dan stearin minyak sawit

kasar menggunakan larutan dengan berat jenis antara.

Jurnal Edukasi dan Sains Biologi. 2(2): 18- 22.

Ministry of Agriculture. 2015. Rencana Strategis

Kementerian Pertanian Tahun 2015-2019. Jakarta (ID):

Kementerian Pertanian Republik Indonesia.

Ministry of Agriculture. 2017. Komoditas Pertanian Sub

Sektor Perkebunan: Kelapa Sawit. Jakarta (ID):

Kementerian Pertanian Republik Indonesia.

O’Brien RD. 2009. Fats and Oils: Formulating and

Processing for Applications. Third Edition. Florida

(USA): CRC Press.

Rousseau D, Ghazani SM, Marangoni AG. 2017. Chemical

Interesterification of Food Lipids: Theory and Practice,

editor: Akoh CC. Food Lipids: Chemistry, Nutrition,

and Biotechnology. Florida (US): CRC Press.

Silalahi RLR, Sari DP, Dewi IA. 2017. Pengujian free fatty

acid (FFA) dan colour untuk mengendalikan mutu

minyak goreng produksi PT. XYZ. Industria: Jurnal

Teknologi dan Manajemen Agroindustri. 6(1): 41-50.

Triana RN. 2014. Sintesis mono dan diasilgliserol (MDAG)

dari fully hydrogenated palm kernel oil (FHPKO)

dengan metode gliserolisis. [Tesis]. Bogor (ID): Institut

Pertanian Bogor.

Laboratory-scale Synthesis of Mono-diacylglycrol from Palm Oil Stearin using Glycerolysis

117