Extraction of Pectin from Durian Rind and Its Minimum Inhibitory

Concentration towards Staphylococcus Aureus and Escherichia Coli

Mufti Ghaffar

1

, Harsi Dewantari Kusumaningrum

2

and Nugraha Edhi Suyatma

2

1

Study Program of Food Science, Graduate School, IPB University, Bogor 16680, Indonesia

2

Department of Food Science and Technology, IPB University, Bogor 16680, Indonesia

Keywords: Durian Rind, Macrodilution, MIC, Pectin Isolate.

Abstract: Durian is a big tropical fruit grown in Indonesia that leaves many waste from its rind. Recently, some reports

shows that durian rind can be extracted for its pectin that showing a potential antimicrobial activity toward

pathogen. The aim of this study was to characterized durian pectin isolate from two different extraction

methods and to determine the minimum inhibitory concentration (MIC) of durian pectin isolate against

pathogenic bacteria. Inhibitory activity of durian pectin isolate against two bacterial strain: Staphylococcus

aureus and Escherichia coli, was determined by using macrodilution methods, and amoxicilline used as

positive control. Results showed that water content of the two extraction methods resulted in around 96%.

Yield of durian pectin isolate in methods A (5,45 ± 0,10 %) more than extraction B (3,46 ± 0,06 %). MIC of

isolates durian pectin in mueller hinton broth (MHB) medium against E. coli was 500 mg/ml and S. aureus

was 110 mg/ml, this concentration showed no sign of bacterial growth, this condition was same as positive

control.

1 INTRODUCTION

Indonesia is tropical country that has many fruit can

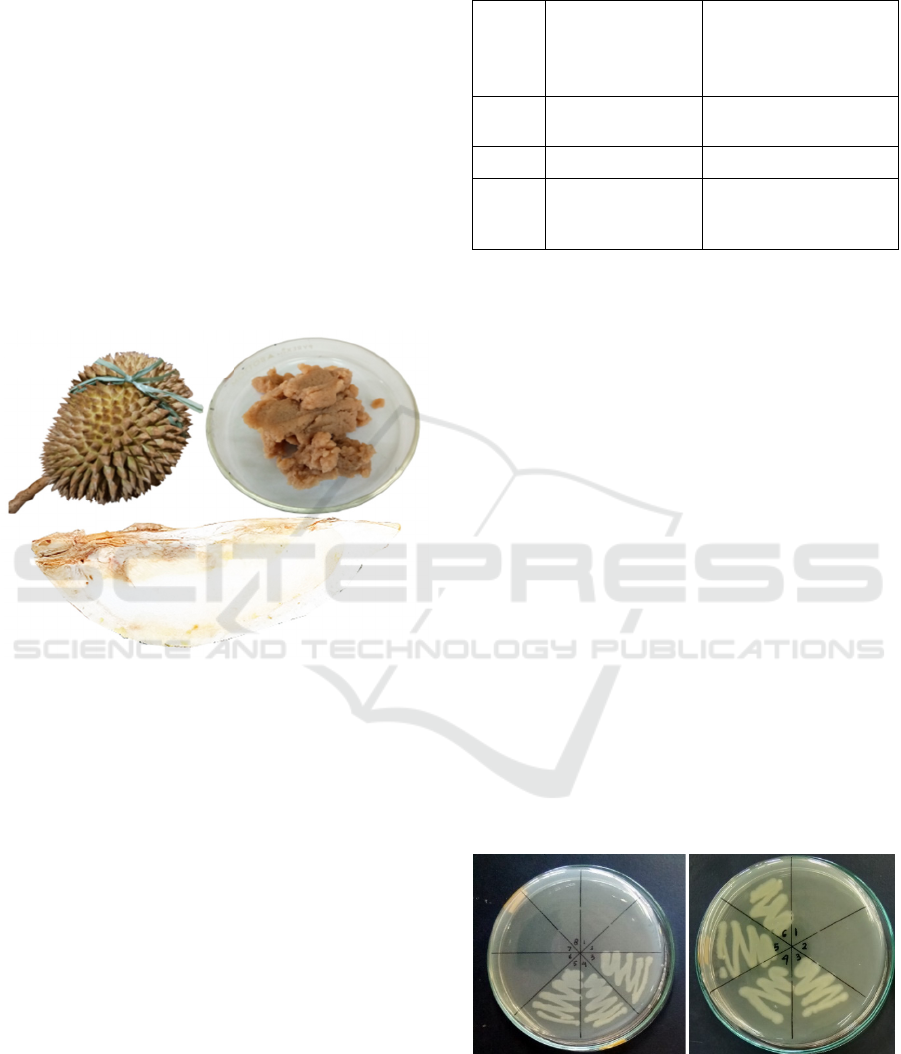

grow, one of that fruit is Durian (Figure 1a). Durian

is a popular fruit in Indonesia, a tropical, seasonal

climateric fruit belonging to the Bombacaceae family.

Durian fruit is quite large, round or oval, green

(brownish when ripe), has a thick outer shell, hard,

and covered with many thorns shaped like a pyramid.

Durian fruit has a short shelf life, it is known to be

damaged 36 to 72 hours from the time the durian fruit

falls (Manoharan, 2013). Durian grows well in 75-

80% humidity conditions with rainfall between 1600

and 4000 ml a year, and with an average temperature

of 24-30

o

C. Requires a tropical climate to grow, and

not grow well in areas over 3000 feet (Ashraf et al.,

2011).

It is customary for people in several regions in

Indonesia to use durian rind as a drinking container

after eating durian fruit. It is said that by drinking

water from durian rind can eliminate the pungent odor

of durian fruit, and can reduce durian motion sickness

due to consumption of durian in large quantities.

Based on this, there is a possibility that the durian rind

contains active components, but has not been much

studied. It is reported in some literature that durian

rind has a number of therapeutic benefits such as: has

anti-diabetic properties, anti-hyperlipidemic effect,

anti-proliferative activity, and antimicrobial activity.

Pectin can be extracted from durian rind which has

antimicrobial activity. Pectin from durian rind has the

ability to inhibit the growth of Vibrio harveyi 1526

(MIC = 6.3 and 12.5 mg / mL) in black tiger / tiger

shrimp (Pholdaeng and Pongsamart, 2010). Durian

rind pectin has anti microbial activity against E. coli, S.

aureus (Lipipun et al., 2002). Films made from durian

rind pectin also have antibacterial properties when

tested on several bacteria (Ho and Bhat, 2015).

Utilization of durian rind has not been done much

by households, or industries that process durian fruit.

Pectin can be extracted from durian rind which has

antimicrobial properties that have the potential to be

developed. This study aims to characterized durian

pectin isolate and to determine the minimum

inhibitory concentration of durian pectin isolate

against pathogenic bacteria E. coli and S. aureus.

2 MATERIALS AND METHODS

2.1 Materials

Durian was obtained from the Warso Farm durian

72

Ghaffar, M., Kusumaningrum, H. and Suyatma, N.

Extraction of Pectin from Durian Rind and Its Minimum Inhibitory Concentration towards Staphylococcus Aureus and Escherichia Coli.

DOI: 10.5220/0009978600002833

In Proceedings of the 2nd SEAFAST International Seminar (2nd SIS 2019) - Facing Future Challenges: Sustainable Food Safety, Quality and Nutrition, pages 72-76

ISBN: 978-989-758-466-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

farm, Bogor, Indonesia. Staphylococcus aureus

ATCC 25923 and Escherichia coli ATCC 25922 use

as test bacteria were obtained from the food

microbiology laboratory of Food Science and

Technology Department IPB University. The initial

treatment of raw materials begins with durian rind cut

and separated mesocarp (the inner part of durian rind)

and exocarp (the outer part of durian rind). Mesocarp

was cut to a size of ± 0.5 cm to maximize the process

of drying and crushing the material. The durian peel

was placed into aluminum foil and dried in an oven at

60

o

C for 48 hours, then crushed to powder and

wrapped in adhesive plastic or stored in a desiccator.

2.2 Methods

2.2.1 Durian Pectin Extraction

The extraction method in this study uses the

extraction method from Amaliah (2014) and

Hokputsa et al. (2004) and compared the

characteristics of durian rind pectin isolates obtained.

The following was the Amaliah extract method

(2014) with a modification (extraction A). The

process of extracting pectin from durian rind is

carried out through several stages, heating, filtering,

concentrating, extracting. Durian rind powder was

mixed with distilled water (durian rind powder:

aquades = 1: 25 w / v) and stirred until it becomes an

acidic solution with a pH of 2 by adding 2 N HCl acid

solution and extracted at 85

o

C for 2 hours. Then

filtered using a cloth, then added an acid-ethanol

solution (4% HCl in 95% ethanol) with a ratio of 1: 1

v / v and incubated at room temperature for 1 hour.

To separate the gel (durian pectin isolate) filtering is

done in vacuum conditions. The resulting gel is rinsed

twice using 95% ethanol (1: 1, v / v) and shaken for

15 minutes (Amaliyah, 2014).

The following was a method of extraction

Hokputsa et al. (2004) with the modification

(extraction B). Durian skin powder was mixed with

distilled water (durian skin powder: aquades = 1: 25

b / v) and stirred to form an acidic solution with a pH

of 4.5 with citric acid solution added and extracted at

a temperature of 90-100

o

C for 20 minutes. Then

filtered using a cloth, then added an acid-ethanol

solution (4% HCl in 95% ethanol) with a ratio of 1: 1

v / v and incubated at room temperature for 1 hour.

To separate the gel / durian pectin solate filtering

done by vacuum conditions. The resulting gel is

rinsed twice using 95% ethanol (1: 1, v / v) and

shaken for 15 minutes. The resulting sludge was a

durian pectin isolate (DPI). The DPIs obtained were

then characterized in the form of measurements of

water content, yield, and pH values.

2.2.2 Measurement Antibacterial Activity

from Durian Pectin Isolate

Microorganism that used in this macrodilution

method are common contaminating microorganism in

food products, namely: Eschericia coli and

Staphylococcus aureus. Macrodilution is one of the

basic antimicrobial testing methods. Before the

macrodilution was carried out the sterilization

process was done on samples of DPI. The procedure

begins by testing an antimicrobial agent DPI with a

concentration of 1) 100%, 50%, 25%, 12.5%, 6.25%,

3.125% (E. coli) and 2) 100%, 25%, 6,25%, 1,56%,

0,39%, 0,09 % (S. aureus) in 2 mL (E. coli) and 3 mL

(S. aureus) microbial growth medium (Mueller

Hinton Broth) in a tube. Then each tube was

inoculated with a bacterial inoculum prepared in the

same medium. The size of the inoculum microbe is

around 5 x 10

5

CFU / mL. After mixing well, each

tube was incubated at 30

o

C for 20 hours. Then each

tube was inoculated on the Mueller Hinton Agar

medium by scratching, because DPI covers the

detection of microbial growth with its color. This

procedure was repeated three times (Balouiri et al.,

2016).

3 RESULTS AND DISCUSSIONS

3.1 Durian Pectin Isolate

Characterization

To get durian pectin isolate, the initial preparation

process of durian rind raw material was done to

separate the mesocarp (Figure 1b) and exocarp. From

this part (mesocarp) had yield approximately 29.63 ±

0.02% from all part of durian rind. Mesocarp is a raw

material that used to obtain durian rind powder. And

the yield of durian rind powder was 10,44 ± 0.06

(Table 1).

Table 1: Yield and water content of mesocarp and durian

powder.

Sample Yield (%)

Water

content (%)

Mesocarp 29,63 ± 0.02 -

Durian rind powder 10,44 ± 0.06 1,01 ± 0,17

Extraction of Pectin from Durian Rind and Its Minimum Inhibitory Concentration towards Staphylococcus Aureus and Escherichia Coli

73

Characterization of durian pectin isolate (Figure

1c) was performed, giving values of water content,

yield and pH value (Table 2). Water content of both

methods resulted about 96%% which indicated that

durian pectin isolate was composed of large amounts

of water. Extraction method A (pH: 2.00,

temperature: 85

o

C, t: 2 hours) has bigger yield (5,45

± 0,10) than extraction B (pH: 4.5 and temperature:

90-100

o

C, t : 20 minutes that had yield 3,46 ± 0,06,

which indicates extraction A had more yield than

extraction B. The more extraction yield are related to

differences of pH. The lower the pH, the more yield

of pectin will be obtained. The yield of both methods

is in the range of the previous report's yield, which

ranges from 1.04% - 10% (Arlofa et al., 2015;

Pholdaeng and Pongsamart, 2010; Wai et al., 2009).

Figure 1: a) Durian fruit, b) Mesocarp of durian fruit, and

c) Durian pectin isolate.

Lower pH value result in more yield of pectin can

be extracted (Ardiansyah et al., 2014). The principle

of extraction of pectin is the overhaul of protopectin

which does not dissolve into pectin which can

dissolve with acid solvents. In the extraction process

with a high level of acidity will increase the

hydrolysis of protopectin from durian rind tissue to be

dissolved in water faster, so that the yield of pectin is

higher. Protopectin does not dissolve easily because

it is in the form of calcium and magnesium salts.

Hydrolysis of protopectin with acids causes hydrogen

ions to replace calcium ions and magnesium ions in

the protopectin molecule. This is due to a pH of 1.5

which is more acidic and has more hydrogen ions so

that the possibility of substituted calcium and

magnesium is greater (Prasetyowati et al., 2009).

Table 2: Yield, pH, and water content from extraction

method A and extraction method B.

Para-

meter

Extraction A

(acid: HCl 2 N, pH:

2, Temperature:

85

o

C, time: 2 hour)

Ekstraction B

(acid: citric acid, pH: 4.5,

Temperature: 90-100

o

C,

time: 20 minutes)

Yield

(%)

5,45 ± 0,10 3,46 ± 0,06

pH 2,03 ± 0,10 3,75 ± 0,09

Water

content

(%)

96,26 ± 0,1 96,4 ± 0,04

3.2 Antibacterial Activity of Durian

Pectin Isolate

Durian pectin isolates (DPI) obtained through the

extraction process were tested for their antibacterial

activity. The test results showed that there were two

concentrations of DPI and positive control that could

inhibit the E.coli bacteria as indicated by the clear

growth media (Figure 1). Both concentrations are

100% and 50% for E. coli and concentration 100%

and 25 % for S.aureus. From that figure we can get

the value of the minimum inhibitory concentration

(MIC) of each bacteria (Table 3). Based on the results

it was found that the MIC value of DPI in E. coli was

500 mg/ml and S. aureus was 110 mg/ml.

The difference in antibacterial activity that occurs

in Gram-positive (S. aureus) and Gram-negative (E.

coli) bacteria is probably caused by differences in the

composition and structure of cell walls in the two

types of bacteria. The structure of the cell wall of

Gram-positive bacteria is simpler, that is single layer

with a low lipid content (1-4%) making it easier for

bioactive materials to enter the cell. The structure of

the cell wall of Gram negative bacteria is more

Figure 2: a) Growth Escherichia coli inhibited by durian

pectin isolate in MHA medium (1: 100%, 2: 50%, 3: 25%,

4: 12.5%, 5: 6.125 %, 6: clear media, 7: amoxicilin as

positive control), b) Growth Staphylococcus aureus

inhibited by durian pectin isolate in MHA medium

(1: 100%, 2: 25%, 3: 6,25%, 4: 1,56%, 5: 0,39 %.

a)

b)

c)

a

b

2nd SIS 2019 - SEAFAST International Seminar

74

Table 3: Microbial growth and minimum inhibitory concentration of durian pectin isolate against E. coli dan S. aureus.

Bacteria Antibacterial concentration (%) MIC (%)

100 50 25 12,5 6,25 positive control

E. coli 1 - - ++ ++ ++ - 50

2 - - ++ ++ ++ - 50

3 - - ++ ++ ++ - 50

100 25 6,25 1,56 0,39 positive control

S. aureus 1 - + ++ ++ ++ - 25

2 - - ++ ++ ++ - 25

3 - - ++ ++ ++ - 25

- : no growth or no colony

+ : there is growth or there is colony

++ : many growth or many colony

bioactive materials to enter the cell. The structure of

the cell wall of Gram negative bacteria is more

complex, three layers, namely the outer layer of

lipoprotein, the middle layer of lipopolysaccharide

which acts as a barrier to the entry of antibacterial

bioactive material, and the inner layer is in the form

of peptidoglycan with high lipid content (11-12%)

(Magdalena and Kusnadi, 2015).

4 CONCLUSIONS

Durian pectin isolate of both extraction methods

resulted in water content aproximately 96 %.

Extraction method A (pH: 2.00, temperature: 85

o

C, t:

2 hours) had bigger yield (5,45 ± 0,10) than extraction

B (pH: 4.5 and temperature: 90-100

o

C, t: 20 minutes)

that had yield 3,46 ± 0,06 %. Minimum inhibitory

concentration of durian pectin isolate against

pathogenic bacteria E. coli was 500 mg/ml and S.

aureus was 110 mg/ml.

ACKNOWLEDGEMENT

Thanks to Beasiswa Unggulan Kemendikbud

Republik Indonesia that sponsored author study in

IPB University.

REFERENCES

Amaliyah, D.M., 2014. Pemanfaatan Limbah Kulit Durian

(Durio zibethinus) dan Kulit Cempedak (Artocarpus

integer) sebagai edible film. J. Ris. Ind. Has. Hutan 6,

27–34.

Ardiansyah, G., Hamzah, F., Efendi, R., 2014. Variasi

Tingkat Keasaman Dalam Ekstraksi Pektin Kulit Buah

Durian. JOM FAPERTA 1.

Arlofa, N., Safuari, A., Gunawan, I.G., 2015. Pektin Kulit

Durian Sebagai Bahan Baku Biosorben Logam Berat

Timbal (Pb). J. Chemtech 1, 6–11.

Ashraf, M.A., Maah, M.J., Yusoff, I., 2011. Estimation of

Antioxidant Phytochemicals in Four Different Varieties

of Durian. Int. Conf. Biosci. Biochem. Bioinforma. 5,

131–135.

Balouiri, M., Sadiki, M., Ibnsouda, S.K., 2016. Methods for

in vitro evaluating antimicrobial activity: A review. J.

Pharm. Anal. 6, 71–79. https://doi.org/10.1016/j.jpha.

2015.11.005

Ho, L.H., Bhat, R., 2015. Exploring the potential

nutraceutical values of durian (Durio zibethinus L.) -

An exotic tropical fruit. Food Chem. 168, 80–89.

https://doi.org/10.1016/j.foodchem.2014.07.020

Hokputsa, S., Gerddit, W., Pongsamart, S., Inngjerdingen,

K., Heinze, T., Koschella, A., Harding, S.E., Paulsen,

B.S., 2004. Water-soluble polysaccharides with

pharmaceutical importance from Durian rinds (Durio

zibethinus Murr.): isolation, fractionation, characterisa-

tion and bioactivity. Carbohydr. Polym. 56, 471–481.

Lipipun, V., Nantawanit, N., Pongsamart, S., 2002.

Antimicrobial activity ( in vitro ) of polysaccharide gel

from durian fruit-hulls. Songklanakarin J. Sci. Technol.

24, 31–38.

Magdalena, N.V., Kusnadi, J., 2015. Antibakteri dari

ekstrak kasar daun gambir (Uncaria gambir var

Cubadak) metode microwave-assisted extraction

terhadap bakteri patogen. J. Pangan dan Agroindustri 3,

124–135.

Manoharan, S., 2013. Synergistic Activity of Chloroform

Extract of Durio zibethinus Wood Bark With Penicillin

G Against Staphylococcus aureus . Int J Biol Med Res.

3, 3025–3027.

Pholdaeng, K., Pongsamart, S., 2010. Studies on the

immunomodulatory effect of polysaccharide gel

extracted from Durio zibethinus in Penaeus monodon

shrimp against Vibrio harveyi and WSSV. Fish

Extraction of Pectin from Durian Rind and Its Minimum Inhibitory Concentration towards Staphylococcus Aureus and Escherichia Coli

75

Shellfish Immunol. 28, 555–561. https://doi.org/

10.1016/j.fsi.2009.12.009.

Prasetyowati, Sari, K.P., Pesantri, H., 2009. Ekstraksi

Pektin Dari Kulit Mangga. 42 J. Tek. Kim. 16, 42–49.

Wai, W.W., Alkarkhi, A.F.M., Easa, A.M., 2009.

Optimization of pectin extraction from durian rind

(durio zibethinus) using response surface methodology.

J. Food Sci. 74, 637–641. https://doi.org/10.1111/

j.1750-3841.2009.01331.x.

2nd SIS 2019 - SEAFAST International Seminar

76