Ripeness Inspection of Oil Palm Fruits by Applying Hardness Test

Technique

Thiensak Chucheep

1,2

, Narissara Mahathaninwong

1,2

, Suphatchakorn Limhengha

1,2

,

Duangrudee Petchui

3

and Pattraporn Templong

3

1

Industrial Management Technology Division, Faculty of Science and Industrial Technology, Prince of Songkla University

Surat Thani Campus, Surat Thani, Thailand

2

The Center of Excellence in Materials Engineering (CEME) and Intelligent Automation Research Center (IARC),

Faculty of Engineering, Prince of Songkla University Hat Yai Campus, Songkhla, Thailand

3

Formerly Student, Industrial Management Technology Division, Faculty of Science and Industrial Technology,

Prince of Songkla University Surat Thani Campus, Surat Thani, Thailand

Keywords: Hardness Technique, Indenting Technique, Palm Ripeness.

Abstract: The objective of this study was to investigate whether the ripeness of oil palm fruits could be estimated based

on their hardness. The hardness was examined by indenting with a steel ball on the exocarp of the fruit with

the required indentation force (kgf) measured. Five steel balls with diameters of 4, 6, 8, 10, and 12 mm were

tested on CIRAD and COMPACT varieties of oil palm, with the fruits in unripe, under-ripe, and ripe stages.

The results reveal that, on using five ball indenters, the average hardness of unripe oil palm fruit differs from

those of under-ripe and ripe fruit, on both CIRAD and COMPACT varieties. In contrast, the average hardness

of under-ripe and ripe stages did not differ, while the hardness in three stages oil palm fruits reflects the oil

and moisture percentages. Oil percentages in the COMPACT oil palm fruit in unripe, under-ripe, and ripe

stages were 27.71%, 75.11%, and 76.78%, respectively, and for CIRAD variety of oil palm these were

59.42%, 76.67%, and 75.79%, respectively. The empirical dependence of hardness on oil content was y=-

1.47x

2

+11.20x+55.36 for the COMPACT oil palm and y=-1.90x

2

+3.21x+77.49 for the CIRAD oil palm.

1 INTRODUCTION

Indonesia and Malaysia have been the largest palm oil

producers in the world, and Thailand is the third in

the global rankings. Oil palm is an important

economic crop in Thailand and it has been mostly

cultivated in the southern parts of the country,

because of suitable climate with abundant rainfall.

Oil palm cultivation has expanded to the North,

Northeast and Central regions of the country during

2008-2012 because the government planned to

increase and support palm oil production for

developing alternative energy supplies

(Petchseechoung, 2017). Nowadays, Thai oil palm

agriculture faces a slump in the price of oil palm fresh

fruit bunch (FFB), and this price is set without

consideration of FFB grade in terms of oil extract

yield. There is a lack of incentives to develop higher

yielding oil palms. Farmers may also harvest the FFB

before the ripe stage, although the ripe stage gives the

highest oil extraction yields. It is important to provide

ripe fruits to mills for oil extraction in order to

produce high quality crude oil. The overripe and

unripe FFB in the mills reduces quality of extracted

oil. On the other hand, agricultural product quality

conventionally plays a fundamental role in nearly all

food industry quality assessments. Generally, skilled

workers grade the oil palm FFB subjectively, mainly

visually with color criteria, to determine the prices

paid to the farmers. Oil palm fruit as unripe are

usually black and turn reddish brown when they reach

the ripe stage (Makky, 2016). However, human errors

often occur in the grading, especially for workers with

less experience.

Various techniques have been studied to

determine the ripeness of oil palm fruit or their

maturity stage. Near infrared image for classifying oil

palm fruit was proposed by Kassim et al. (2014). Hue,

Saturation and Intensity (HSI) approach was

proposed by Shabdin et al. (2016) for ripeness

detection of oil palm fresh fruit bunches. On the other

hand, the ability of oil palm fruits to resist

Chucheep, T., Mahathaninwong, N., Limhengha, S., Petchui, D. and Templong, P.

Ripeness Inspection of Oil Palm Fruits by Applying Hardness Test Technique.

DOI: 10.5220/0009981500002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 279-283

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

279

compressive load has been investigated, and is related

to their ripeness. Azli et al. (2009) investigated the

relation between forces (injection) with the ripeness

level of palm oil fruit. Keshvadi et al. (2011)

determined the relationship between palm oil

development in mesocarp and kernel and mechanical

properties of fresh fruit bunches during the ripening

process of Tenera clonal variety of oil palm (Elaeis

guineensis) and found that compressive load of fruit

grown for 8 weeks significantly increased till 16

weeks, but after that, it had a downward trend. In

addition, the oil content in fruit clearly still increased

from 16 weeks to 20 weeks. From these results, the

firmness of mesocarp against compressive loads is

associated with the ripening process of oil palm fruits.

Unfortunately, the relationship between compressive

strength and oil yield of oil palm fruits has not been

investigated.

Therefore, this work aimed to measure the

ripeness of oil palm fruits by using a hardness test,

and determine the relationship between compressive

strength and oil yield.

2 MATERIALS AND METHODS

2.1 Test Samples of Oil Palm Fruits

The study was performed in June of 2019. The

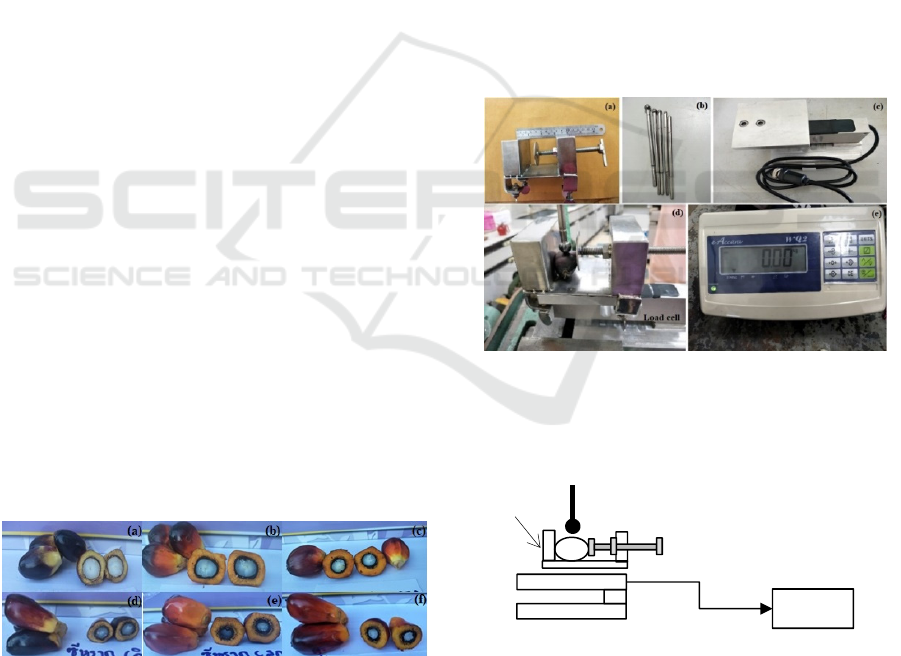

samples (Figure 1) were oil palm fresh fruits (Elaeis

guineensis) of COMPACT and CIRAD varieties from

a private farm (32,000 m

2

) in Muang district, Surat

Thani province, Thailand. All samples were taken

from 8 year old plants and represented the three stages

of unripe, under-ripe and ripe, as estimated by

farmers visually based on color criteria. Samples of

each stage were collected from the middle region of

each oil palm fresh fruit bunch (FFB). The number of

fruit sampled from each bunch was ten. All

measurements were done at room temperature.

Figure 1: Oil palm fresh fruit samples of COMPACT

variety in (a) unripe, (b) under-ripe, and (c) ripe stages; and

of CIRAD variety in (d) unripe, (e) under-ripe, and (f) ripe

stages.

2.2 Testing Methods

The testing apparatus designed and implemented had

a sample holder, five alternative indenter tip sizes,

and a load cell, as shown in Figure 2 (a)-(c). Figure 2

(d) and (e) show the sample holder fixed on a load cell

and readout connection to the load cell. The testing

apparatus schematic is shown in Figure 3. Oil palm

fresh fruit samples were placed on the sample holder

and the indenter with steel ball tip for various

diameter 4, 6, 8, 10, or 12 mm was loaded. The

indenter tip was compressed against the middle of an

oil palm fruit to a depth of 2 mm from outer mesocarp

surface. The compressive force curve was recorded

during the test over 15 seconds, as shown in Figure 4,

and the peak compressive force represented the

strength or hardness of oil palm mesocarp. This

testing method is based on a common hardness testing

technique. The size or depth of indentation is

measured at a constant compressive force in a typical

hardness test, while this work controlled the depth of

indenting instead of the compressive force (kgf).

Figure 2: (a) Specimen holder, (b) five sizes of steel ball

indenters, (c) load cell, (d) setup of the experiment, and (e)

load cell readout.

Figure 3: Schematic diagram of the testing set up (not to

scale).

Fixture

Load cell

Load

Load cell read out

Display

16th AFC 2019 - ASEAN Food Conference

280

Figure 4: Compressive force recorded during testing.

2.3 Mesocarp Oil Yield and Moisture

Content Measurements

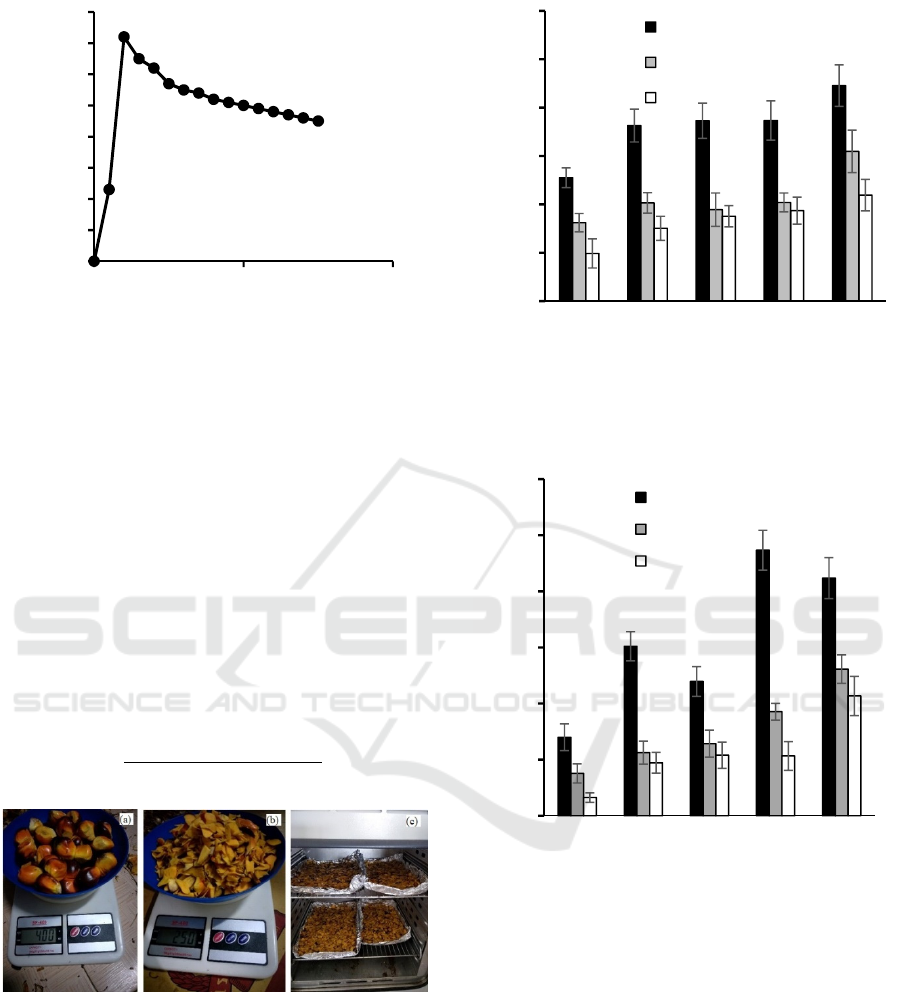

Oil palm fruit samples (400 g) were collected from

the middle of each FFB (the same FFBs as in ripeness

testing), as shown in Figure 5 (a), and 250 g mesocarp

of oil palm fruits was collected. The chopped samples

were dried at 60°C for two days to remove water in

the mesocarp, as shown in Figure 5 (c). The dried

samples were then sent for analysis of oil yields to

Surat Thani Oil Palm Research Center.

Moisture of

oil palm mesocarp was measured from 5 g of fresh

mesocarp, which was chopped up and then dried at

60°C for two days. The mesocarp moisture content

was determined as follows:

% Moisture = (fresh weight-dried weight) x 100%

(fresh weight)

(1)

Figure 5: Sample preparation for mesocarp oil yield

measurement.

3 RESULTS AND DISCUSSION

The average compressive forces of oil palm fruits

(COMPACT and CIRAD variety) were higher in the

unripe stage than in under-ripe and ripe stages, for all

steel ball sizes, as shown in Figures 6 and 7.

Figure 6: Average compressive forces of three stages of

COMPACT oil palm fruits, tested with five indenter tip

diameters.

Figure 7: Average compressive forces of three stages of

CIRAD oil palm fruits, tested with five indenter tip

diameters.

The average compressive forces of COMPACT

oil palm fruits in unripe stage were 5.10±0.41,

7.26±0.68, 7.46±0.73, 7.47±0.81 and 8.91±0.86 kgf

with steel ball diameters of 4, 6, 8, 10 and 12 mm,

respectively. The CIRAD oil palm fruits in unripe

stage had average compressive forces of 2.80±0.48,

6.04±0.52, 4.79±0.53, 9.47±0.71 and 8.47±0.73 kgf

with steel ball diameters 4, 6, 8, 10 and 12 mm,

respectively. The average compressive forces for both

COMPACT and CIRAD oil palm fruits decreased

notably for the under-ripe stage. The COMPACT oil

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

01020

Compressive Force (kgf)

Time (s)

0

2

4

6

8

10

12

4681012

Compressive Forces (kgf)

Steel ball indenter size (mm)

Unripe

Under-Ripe

Ripe

0

2

4

6

8

10

12

4 6 8 10 12

Compressive Forces(kgf)

Steel ball intenter size (mm)

Unripe

Under-Ripe

Ripe

Ripeness Inspection of Oil Palm Fruits by Applying Hardness Test Technique

281

palm fruits had average compressive forces of

3.24±0.38, 4.06±0.42, 3.78±0.69, 4.08±0.39 and

6.19±0.88 kgf for 4, 6, 8, 10 and 12 mm diameter

indenters, respectively. For CIRAD, the average

compressive forces were 1.51±0.34, 2.25±0.41,

2.57±0.48, 3.71±0.30 and 5.23±0.51 kgf for 4, 6, 8,

10 and 12 mm diameter indenters, respectively.

However, there was mostly no difference in average

compressive forces between under-ripe and ripe

stages, for either oil palm variety, when indented by

steel ball sizes of 6, 8 or 12 mm. The 4 mm ball

diameter could distinguish oil palm fruits between

under-ripe and ripe stages for both COMPACT and

CIRAD varieties. In addition, the 4 mm steel ball

diameter gave the lowest average compressive forces

among the steel ball sizes tested. These results match

an investigation by Azli et al. (2009) who found that

compressive resistance of oil palm fruits grows

significantly from unripe stage to under-ripe stage.

Mesocarp oil yield and moisture content of

COMPACT and CIRAD oil palm fruits of unripe,

under-ripe and ripe stages were determined, with

results summarized in Table 1. The oil yield was low

in unripe stage but increased significantly for under-

ripe and ripe stages. The investigation of Keshvadi et

al. (2011) also found that oil yield of oil palm fruits

(Tenera species) increased significantly during

ripening for 16 to 20 weeks. The oil palm moisture

varied inversely to oil yield. The oil yields of oil palm

fruits in unripe stage were 27.71% for COMPACT

and 59.42% for CIRAD. Both oil palm varieties had

75-76% oil yields for under-ripe and ripe stages. It

could be seen that oil yield of oil palm fruits in under-

ripe stage was not different from that of ripe stage. On

the other hand, the hardness of oil palm mesocarp was

measured in terms of compressive force and the

results from testing with a 6 mm diameter steel ball

indenter was selected, as shown in Table 1.

Table 1: Mesocarp oil yield, moisture content, and

compressive forces.

Variety

Stage Mesocarp

oil yield

(%)

Moisture

content

(%)

Force

(kgf)

COMPACT

Unripe

27.71 53.33 7.26±0.68

Under-

ripe

75.11 32.33

4.06±0.42

Ripe

76.78 28.08 3.01±0.50

CIRAD

Unripe

59.42 83.71 6.04±0.52

Under-

ripe

76.67 27.86

2.25±0.41

Ripe

75.79 23.71 1.89±0.37

The compressive force results with this indenter were

associated with mesocarp oil yield, more so than with

the other indenter sizes tested. The oil yield increased

in accordance with the ripening, while the

compressive strength of mesocarp in the oil palm

fruits decreased. Oil yield was almost stable after the

under-ripe stage, and so was the hardness of oil palm

mesocarp. This is in line with Keshvadi et al. (2011)

who state that it is difficult to recognize the fruit

maturity stage.

Figure 8: Relationship between oil content and compressive

force on indenting COMPACT and CIRAD oil palm fruit

with a 6 mm diameter steel ball.

Relationship between oil yield and compressive force

on indenting COMPACT and CIRAD oil palm fruits

can be seen in Figure 8, with least squares regression

fits to the data.

4 CONCLUSIONS

The ripeness inspection of oil palm fruits by a

hardness test was investigated, and the outcomes

found were:

(1) The compressive indentation force be can used

to estimate the grade of oil palm fresh fruits,

distinguishing between unripe and either under-

ripe or ripe stages. However, this is unable to

distinguish between under-ripe and ripe stages.

(2) The compressive force measured is associated

with mesocarp oil yield.

(3) The empirical relationships between oil content

and indentation force depended on variety: y=-

1.47x

2

+11.20x+55.36 for COMPACT oil palm

fruits and y=-1.90x

2

+3.21x+77.49 for CIRAD

oil palm fruits.

y = -1.47x

2

+ 11.20x + 55.36

y = -1.90x

2

+ 3.21x + 77.49

0

10

20

30

40

50

60

70

80

90

0510

Oil content (%)

Compressive force (kgf)

COMPACT

CIRAD

16th AFC 2019 - ASEAN Food Conference

282

ACKNOWLEDGEMENTS

We would like to express our gratitude to Prince of

Songkla University, Surat Thani Campus, The Center

of Excellence in Materials Engineering (CEME) and

Intelligent Automation Research Center (IARC),

Faculty of Engineering, Prince of Songkla University

Hat Yai Campus for granting financial support to this

project. In addition, the authors would like to thank

Assoc. Prof. Dr.Seppo Karrila for commenting on the

manuscript.

REFERENCES

Azli, A.R., Shahril, K., Nor Hayati, S., Sukarnur, C.A.,

2009. Novel Method of Grading Fresh Fruit Bunches

(FFB) of Oil Palm Fruit. Conf Sci Soc Res. March

2009:1-8.

Keshvadi, A., Endan, J.B., Harun, H., Ahmad, D., Saleena,

F., 2011. The Relationship Between Palm Oil Index

Development and Mechanical Properties in the

Ripening Process of Tenera Variety Fresh Fruit

Bunches. Res Jour App Sci Eng Tech. 3(3): 218-226.

Kassim, M.S.M., Ismail, W.I.W., Teik, L.H., 2014. Oil

Palm Fruit Classifications by using Near Infrared

Images. Res Jour App Sci Eng Tech. 7(11): 2200-2207.

Makky, K., 2016. A Portable Low-Cost Non-Destructive

Ripeness Inspection for Oil Palm FFB. Inter Conf Food

Agric Nat Reso 2015. Agric Agricul Sci Proc 9: 230-

204.

Shabdin M.K., Shariff, A.R.M., Johari, M.N.A., Saat, N.K.,

Abbas, Z., 2016. A study on the oil palm fresh fruit

bunch (FFB) ripeness detection by using Hue,

Saturation and Intensity (HSI) approach. IOP Conf.

Ser.: Earth Environ. Sci. 37: 1-10.

Petchseechoung, W., 2017. Thailand Industry Outlook

2017-19 Oil Palm Industry. Krungsri Res. June 2017.

Bangkok: Krungsri Bank: 1-8. https://www.

krungsri.com/bank/getmedia/ac87c171-db74-442b-ae

29-5b69572896ca/IO_Oil_Palm_2017_EN.aspx [Aug

30, 2019]

Ripeness Inspection of Oil Palm Fruits by Applying Hardness Test Technique

283