Effect of Steaming Treatment on Physical Properties

and Shelf Life of Hae-Kuen

Kanyawi Kolakul, Panadda Nonthanum and Wiramsri Sriphochanart

Faculty of Agro-Industry, King Mongkut’s Institute of Technology Ladkrabang, Ladkrabang, Bangkok, Thailand

Keywords: Physical Properties, Sensory Evaluation, Shelf-life, Shrimp Roll, Steaming Treatment.

Abstract: This research aimed to extend the shelf life of Hae-Kuen, Thai traditional shrimp roll, by effect of steaming

temperature (80 and 85C) and steaming time (5 and 10 minutes) on microbial contents, textural properties

and sensory evaluation. Results of the study showed that the microbial contents of steaming Hae-Kuen were

decrease as compared with the control sample (without steaming). While the initial microbial content of the

control sample was 6.410

7

CFU/g, there are steamed at 80C for 5 and 10 minutes had the microbial levels

of 5.310

2

and 2.310

2

CFU/g, respectively. The microbial contents decreased to 4.710

2

and 1.710

2

CFU/g

as higher steaming temperature (85C) was used for 5 and 10 minutes, respectively. Being stored at 4C,

microorganisms detected from unsteamed Hae-Kuen increased to the level of 7.7×10

6

CFU/g. which was

higher than the Community Product Standards Agency Criteria, at day 3. While, the microbial contents of

Hae-Kuen steamed at 80 and 85C for 5 and 10 minutes were in the range of 10 to 95 CFU/g after storing for

15 days. The texture profile analysis showed that all steamed Hae-Kuen samples had higher values of

hardness, springiness, cohesiveness and chewiness when compared to the control sample.

1 INTRODUCTION

Hae-Kuen or shrimp roll is the famous Chinese dish

in Thailand. It is made from shrimp and pork fat

mixed with corn flour, egg and seasoning, and

crushed or pounded until sticky, then wrapped with

bean curd skin into long and round pieces. The Hae-

Kuen is fried and served with plum sauce. Nowadays,

many Thai-Chinese style restaurants classified in the

appetizer menu. The restaurants prepared and stored

it in refrigerator as uncooked product. Unfortunately,

the shelf life of uncooked limited predominantly

because of spoilage contamination. Microorganism

content of uncooked was higher than 10

6

CFU/g after

3 days which was higher than the Community Product

Standards Agency criteria. Spoilage of Hae-Kuen is

mostly accompanied with physical properties

changes including souring, slimy meat juice exudates

and swelling (Purwanto et al, 2017).

It is important to improve Hae-Kuen to meet the

Community Product Standards Agency criteria and

maintenance of the quality characteristics of Hae-

Kuen. Therefore, the aim of this research was to

extend the shelf life by steaming treatment. An effect

of steaming temperatures at 80 and 85 C and

steaming times including 5 and 10 minutes on

microorganism content and physical properties of

Hae-Kuen were evaluated. Sensory test and shelf life

were also conducted.

2 MATERIALS AND METHODS

2.1 Preparation of Shrimp Roll,

Hae-Kuen

The Hae-Kuen ingredients comprised as following:

ground shrimp (80.91%), salt (2.1%), pepper

(0.81%), wheat flour (8.09%) and egg (8.09%). The

120 g of mixture were thoroughly mixed and wrapped

with bean curd sheet into 5 cm diameter and 15 cm

length. Each piece of Hae-Kuen was then packed in a

heat resistant nylon laminate bag in vacuum

condition.

2.2 Effect of Steaming Treatment

The Hea-Kuen samples were divided into five

separated batches, (1) no steaming treatment

(control), steaming at (2) 80 C 5 min, (3 80 C 10

Kolakul, K., Nonthanum, P. and Sriphochanart, W.

Effect of Steaming Treatment on Physical Properties and Shelf life of Hae-Kuen.

DOI: 10.5220/0009984000002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 251-255

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

251

min, (4) 85 C 5 min, and (5) 85 C 10 min. The

samples was steaming in the temperature control

batch (MEMMERT Model: WNB series, Germany)

at 80 C and 85 C which measured at the middle of

sample. The sample were incubated for 5 and 10 min

and cooled down immediately. The collected samples

were kepts at 4 C until analysis.

2.2.1 Microbiological Analysis

After removing the outer plastic casing, a 25-gram of

Hae-Kuen samples were aseptically transferred to a

sterile plastic bag containing 225 mL of Butterfield s

phosphate sterile (0.1% w/v) solution and agitated

vigorously for one minute. Tenfold dilution series of

the sample solutions were prepared using sterile

peptone solution and 1 mL of each dilution was pour

plated on selective agar plates in triplicate.

The total viable count (TVC) was determined on

plate count agar (PCA) incubated at 35 C for 48 h

and yeast and mold on yeast malt agar (YM)

incubated at 35 C for 72-96 h. Bacterial counts were

expressed as colony-forming units per gram of

sample (CFU/g) The mean standard deviation of the

count will be calculated by using three replicates for

each culture time S. aureus were analyzed according

to ISO 6888-1:1999/Amd 1:2003 by adding 1 ml of

suspension to Baird-Parker agar for 3 plates by

separating 0.3, 0.3 and 0.4 ml. respectively (make

a duplicate). Spread suspension in each plate and

incubated at 37 C for 22 2 h. Marked the typical

colonies which were black or gray color and

surrounding with opaque zone Then continued

incubated at 37 C for 22 2 h, marked all new

typical colonies and atypical colonies which were

black or gray color without opaque zone, recorded

number of all colonies. Selected 5 colonies in each

typical and atypical colonies to confirm coagulase

test. Selected colonies were inoculated to Brain -

heart infusion broth (BHI) and incubated at 37 C for

24 2 h. 0.1 ml culture was transferred to 0.3 ml of

rabbit plasma and incubated at 37 C for 6 h for clot

formation. Detection of E. coli in samples was done

according to BAM Chap. 4 (2002) by making at least

3 serial dilutions, inoculated 1 ml from each dilution

into 3 lauryl tryptose (LST) tubes for a 3 tubes MPN,

incubated at 35 0.5 C for 22 h and observed for the

presence of gas, the positive tubes were producing

gas. Transferred one loop of each suspension to a tube

of EC broth, incubated at 44.5 C for 24 + 2 h and

observed for the presence of gas, the positive tubes

were producing gas. One loop of culture was streaked

on Eosin Methylene Blue Agar) EMB incubated at

35 0.5 C for 21 3 h. Characteristics of E. coli

colonies were dark purple colonies, with or without

a green metallic sheen. Transferred up to 5 suspicious

colonies from each EMB plate to PCA slants,

incubated at 35 05°C for 21 3 h and use for further

testing (IMViC test, Gram test and also reinoculated

back into LST to confirm gas production

C.perfringens were tested according to ISO

7937:2004 by adding 1 ml into petri dish, adding SC

agar and mixing with rotation overlay 10 ml of

Perfringens Agar and incubated at 37 °C for 20 2 h

in an anaerobic atmosphere. The colonies were then

inoculated into Fluid Thiogly-collate Medium at

37 °C for 21 3 h in an anaerobic atmosphere.

For confirmation, the culture was inoculated to

lactose sulphite medium at 46°C aerobic atmosphere

in a water bath for 21 3 h.

2.2.2 Physical Analysis

Moisture Content of Hae-Kuen sample was

determined according to AOAC methods (2002) with

the analytical No. 35.1.13.

Water activity was determined by water activity

analyzer (AQUALAB Model 4TE, Decagon Devices,

Inc., USA).

Texture profile analysis (TPA) was measured by

TA.XT-plus Texture Analyzer (Stable Micro System,

UK). Each Hae-Kuen was cut into 3 cm diameter x

3 cm length pieces and fried before texture

measurement. Five replicates were carried out with an

aluminium compression platen (50 mm diameter)

with a head speed of strain 5 mm/sec. Two 50 %

compression deformations were done with an interval

of 5 sec between them. The characteristics of

hardness, springiness, cohesiveness, gumminess and

chewiness were determined.

2.3 Shelf Life Analysis

The Hae-Kuen samples from the selected condition

were stored in refrigerator at 4 1°C. Samples were

taken at 0, 3, 6, 9, 12, and 15 days following the start

of incubation. Microbial content was determined in

total viable count as descripted in microbiological

analysis.

2.4 Sensory Analysis

Rating for preference tests were performed by 30

trained panellists to compare between (1) unsteamed

and (2) steamed Hea-Kuen at 80 C for 5 min, and (3)

steamed Hea-Kuen at 80 C for 10 min. All sample

were fried before serving. The 5 hedonic scale was

carried out to evaluate the taste attributes including

16th AFC 2019 - ASEAN Food Conference

252

appearance, color, aroma, taste and overall

preference.

2.5 Statistical Analysis

A completely randomized design (CRD) was used as

experimental design. Analyses were done in

triplicate. The data was statistical analyzed using

one–way analysis of variance (ANOVA) by SPSS

program. The Duncan’s Multiple Range test at 5%

level of significance was applied for all statistical

analyses and the statistical significance of differences

among mean values was established at (p< 0.05). The

data were expressed as mean SD (standard

deviation).

3 RESULTS AND DISCUSSIONS

3.1 Microbial Profiles of Unsteamed

Hae-Kuen

Samples were collected from 3 restaurants and

analyzed for pathogenic microorganisms according to

the guideline. After 3 days of production, the

microbial results observed that the growth of E. coli

yeast and molds increased as shown in Table 1.

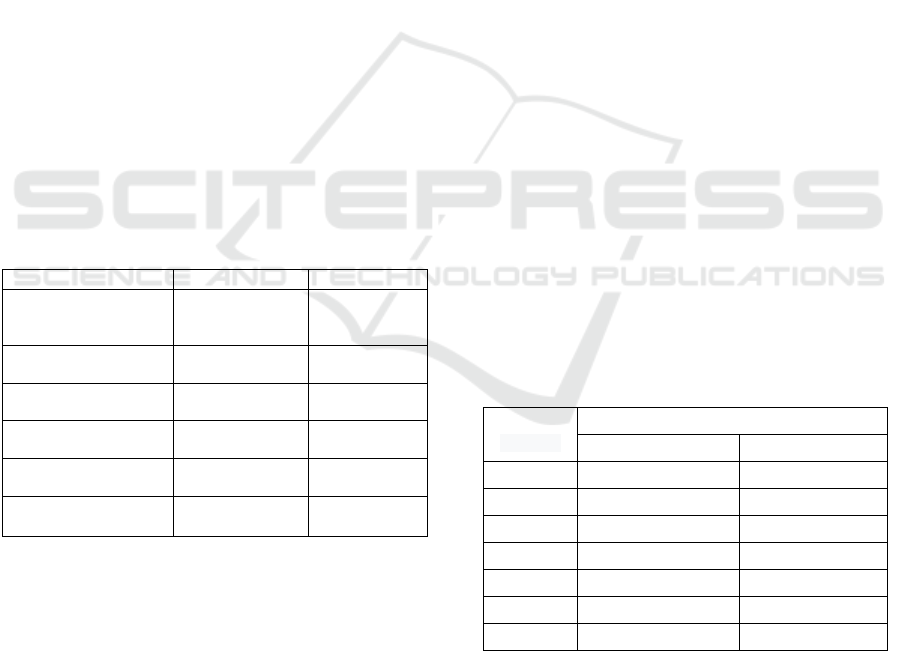

Table 1: Microbial profiles of unsteamed Hae-Kuen.

Microbial

Initial

Day 3

Total Plate Count

(TPC)

(CFU/g)

6.37x10

8

±3.27x10

7

7.77x10

8

±5.40

x10

7

C. perfringens

(Per 0.1 g)

Not Detected

Not Detected

E. coli

(MPN/g)

˂3.0

8.87 ±12

S. aureus

(Per 0.1 g)

Not Detected

Not Detected

Salmonella spp.

(Per 25 g)

Not Detected

Not Detected

Yeasts and Mold

(CFU/g)

1.2110

3

±7.7110

2

7.4210

3

±1.0

10

4

The initial amount of TPC and yeast and mold

were found at 6.37x10

8

± 3.27 x10

7

CFU/g and

1.21x10

3

± 7.71x10

2

CFU/g, respectively. After 3

days, the amount of TPC and yeast and mold

increased to 7.77x10

8

± 5.40 x10

7

CFU/g and

7.42x10

3

± 1.0 x10

4

CFU/g, respectively.

Additionally, E. coli was observed at 8.87 ± 12

MPN/g after 3 days. C. perfringens, S. aureus and

Salmonella spp. were not detected. Kanatt et al.

(2006) also reported that E. coli were usually found

in shrimps and their products. Therefore, one of the

important characteristics of both the shrimp and

shrimp product is that, if processed properties, they

receive a cook that is sufficiency to inactivate

negative cells of bacteria that are pathogenic to

humans Buchanan, 1991.

3.2 Effect of Steaming Temperature

and Steaming Time on Microbial

Content

Hae-Kuen samples were then steamed at 80 C and

85 C for 10 min. Microbial contents of steamed Hae-

Kuen were determined as TPC. The results as shown

in Table 2. As time increased, the microbial content

decreased in both Hae-Kuen samples.

The Hae-Kuen sample steamed at 80 C for 5 and

10 minutes had the microbial levels of 53 CFU/g and

23 CFU/g, respectively. The microbial content of

Hae-Kuen sample steamed at 85 C was lower than

that of Hae-Kuen sample steamed at 80 C. The

microbial content of Hae-Kuen steamed at 85 C

decreased from 4.4510

3

CFU/g to 48 CFU/g and 18

CFU/g at 5 and 10 minutes, respectively. Therefore,

the steaming temperature and time can decrease

microbial contents in Hae-Kuen product. The TPC of

steamed Hae-Kuen samples met the Office of

Community Product Standards (2003) which state

that the survival of microorganisms shall not exceed

110

3

CFU/g sample. The previous study found that

TPC of chicken drumsticks cooked for 2 min at 70C

reduced from 10

7

CFU/g to < 10 CFU/g (Can and

Haran, 2015)

Table 2: Effect of steaming treatment on microbial content

of Hae-Kuen.

Time

(minutes)

Total Plate Count (CFU/g)

80 ˚C

85 ˚C

0

7.1510

4

±4.95 10

2

4.4510

3

±7.7810

2

1

1.23 10

4

±1.2210

4

5.4510

3

±1.4910

3

2

1.06 10

4

±1.20 10

3

1.07 10

2

±95

3

3.9010

3

±3.90 10

3

83±4

4

93±1.10 10

2

43±18

5

53±60

48±32

10

23±

18±11

The heat of steam causes microbial cells to change

their condition as follows; resulting in hardening and

settling of proteins (protein coagulation) within the

cell, resulting in breakage and degradation of genetic

material, both ribonucleic acid (RNA) and

deoxyribonucleic acid (Deoxyribonucleic Acid,

Effect of Steaming Treatment on Physical Properties and Shelf life of Hae-Kuen

253

DNA) as well as destroying the membrane of the

microbes causing microbial cells to be destroyed

(Office of Community Product Standards, 2003)

3.3 Physical Characteristics of

Hae-Kuen Samples

Five Hae-Kuen samples were analyzed for physical

characteristics including moisture content, water

activity and texture.

3.3.1 Moisture Content

Moisture content of Hae-Kuen samples steamed at 80

C and 85 C was not different which ranged from

70.95–71.57% (as presented in Table 3). Control

(unsteamed Hae-Kuen) had the highest moisture

content at 75.06%. Water in the product was

dehydrated by steaming condition. Heat is supplied

by steam or heated fluid through a heat exchanger to

decrease the moisture in sample (Audibert, 2019).

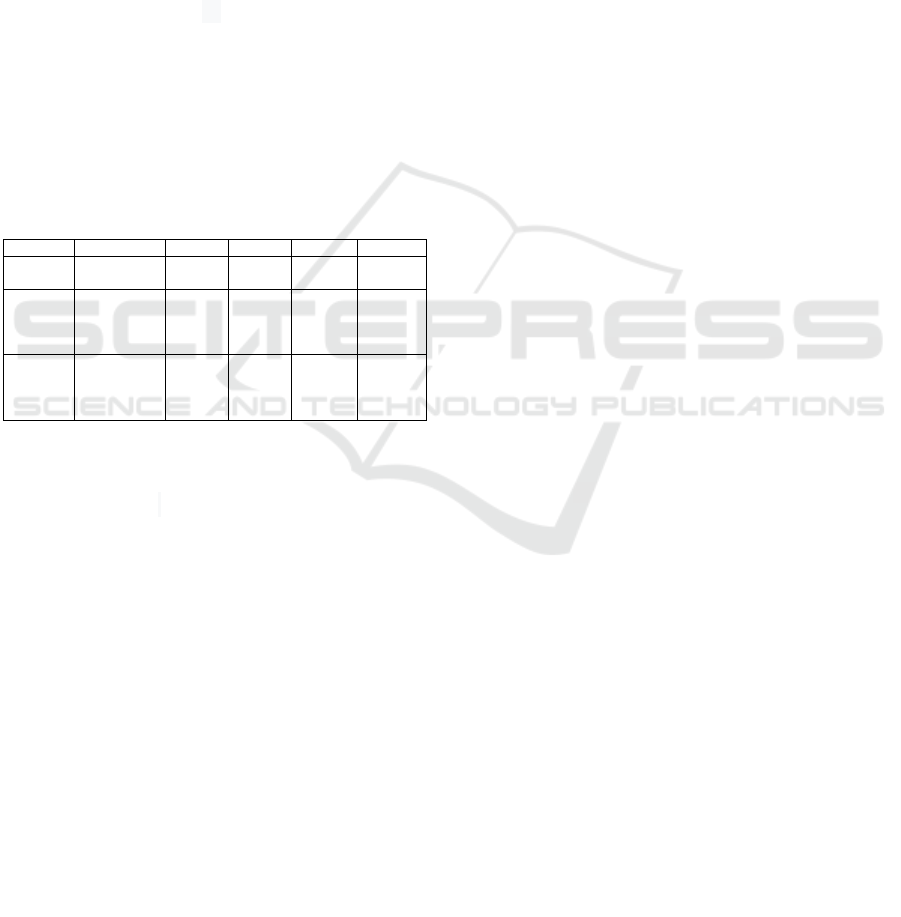

Table 3: The moisture content and water activity of Hae-

Kuen.

Sample

Moisture

Content (%)

Water Activity (a

w

)

Control

75.06 ± 0.528

a

0.9593 ± .00389

b

Sample No.1

(80°C, 5 min)

71.57 ± 0.450

b

0.9650 ± .00289

a

Sample No.2

(80°C, 10 min)

71.14 ± 0.153

b

0.9647 ± .00092

a

Sample No.3

(85°C, 5 min)

70.95 ± 0.346

b

0.9643 ± .00105

a

Sample No.4

(85°C, 10 min)

70.91 ± 0.157

b

0.9618 ± .00338

ab

Mean values in the same column with mean in the same row with

different lowercase letters are significantly different (p<0.05).

3.3.2 Water Activity (a

w

)

The water activity (a

w

) of all steamed Hea-Kuen

products were approximately at 0.9618-0.9650 as

shown in Table 3.

3.3.3 Textural Properties

Textual profiles as shown in Table 4 revealed that all

steamed Hae-Kuen samples had significantly higher

hardness, springiness, cohesiveness and chewiness

values than control (unsteamed Hae-Kuen) (p< 0.05).

It was found that Gumminess, Chewiness,

Hardness and Springiness values of Hae-Kuen

steamed at 85 C for 5 and 10 min were not different.

On the other hand, the values of Hardness,

cohesiveness and Gumminess obtained from Hae-

Table 4: Texture profiles of Hae-Kuen samples.

Sample

Hardness

(kg)

Springiness

(mm/mm

)

Cohesiveness

(mm/mm

)

Gumminess

(mm/mm

)

Chewiness

(kg/mm)

Control

3895±

407.752

b

3338±

377.627

b

5975±

696.443

c

0.651±

0.015

a

0.851±

0.038

b

Sample

No.1

(80°C,

5min)

4490±

910.984

b

4589±

1240.371

a

7803±

1065.680

b

0.592±

0.044

bc

0.901±

0.021

a

Sample

No.2

(80°C,

10min)

6331±

736.627

a

5702±

768.750

a

10,140±

1302.780

a

0.623±

0.026

ab

0.907±

0.013

a

Sample

No.3

(85°C,

5min)

6098±

1919.689

a

4725±

1314.354

a

10,064±

2365.910

a

0.573±

0.049

c

0.894±

0.016

a

Sample

No.4

(85°C,

10min)

5048±

495.780

ab

4588±

433.500

a

8,791±

404.915

ab

0.570±

0.032

c

0.906±

0.009

a

Values are expressed as mean ± standard deviation. Means within

a column with different superscript lowercase letters are

significantly different (p < 0.05)

Kuen steamed at 80 C for 5 and 10 min were

significantly difference (p< 0.05). Springiness values

were not different among steamed Hae-Kuen

samples.

3.4 Shelf Life of Hae-Kuen

Five Hae-Kuen samples were stored at 4 ± 1 C and

taken every 3 days until 15 days for microbial

analysis as TPC. The results are presented in Table 5.

Unsteamed Hae-Kuen had higher microbial content

(7.7×10

6

CFU/g) than the Community Product

Standards Agency Criteria (2013), at day 3. On the

other hand, the microbial content of Hae-Kuen

steamed at 80 and 85

C for 5 and 10 minutes were in

the range of 10 to 95 CFU/g after storing for 15 days.

Table 5: Microbial content of Hae-Kuen samples during

storage at 4 C.

Day

Total Plate Count (CFU/g)

Sample No.1

(80°C,

5 min)

Sample No.2

(80°C,

10 min)

Sample No.3

(85°C,

5 min)

Sample No.4

(85°C,

10 min)

0

˂10

aa

˂10

aa

˂10

aa

˂10

aa

3

˂10

aa

˂10

aa

˂10

aa

˂10

aa

6

5.210

2ab

5.210

2ab

8.410

2ab

2.910

2ab

9

3.010

2 aa

1.410

2 aa

80

aa

25

aa

12

1.910

2aa

75

aa

30

aa

35

aa

15

95

aa

˂10

aa

˂10

aa

45

aa

16th AFC 2019 - ASEAN Food Conference

254

The descriptive data of the Hae-Kuen samples

indicated that changes occurred in product

characteristics during storage. At day 3, the unsteamed

Hae-Kuen had slime on the surface and sour taste,

while the steamed Hae-Kuen samples were not have.

Assessments of the taste of the product varied

significantly (p<0.01) with storage time (Can and

Haran, 2015). The results of the present study indicate

that it can be stored for 42 days at 2°C and present

acceptable sensory quality.

3.5 Sensory Profiles

Hae-Kuen steamed at 80

o

C for 5 and 10 min and the

control sample were then tasted for the acceptance in

appearance, color, aroma, taste and overall liking.

The Hae-Kuen samples were presented to 30 trained

panellists. The result of the sensory test is presented

in Table 6. The appearance, color, aroma and taste

scores were not statistically significant among Hae-

Kuen samples.

Table 6: Sensory evaluation.

Sample

Appearance

Color

Aroma

Taste

Overall

Control

4.031±

0.782

a

3.906±

0.777

a

3.906±

0.837

a

3.813±

0.693

a

4.063±

0.670

a

Sample

No.1

(80°C,

5min)

3.687±

0.693

a

3.875±

0.707

a

3.844±

0.847

a

3.750±

0.803

a

3.688±

0.896

ab

Sample

No.2

(80°C,

10min)

3.781±

0.706

a

3.594±

0.875

a

3.531±

0.950

a

3.594±

1.011

a

3.469±

1.106

a

a

Mean values in the same column with mean in the same row with different

lowercase letters are significantly different (p < 0.05).

The sensory evaluation also revealed that Hae-

Kuen steamed at 80

C for both 5 and 10 min received

the overall liking scores similar to the control sample.

It indicated that the steamed Hae-Kuen had

acceptable sensory quality similar to the traditional

Hae-Kuen.

4 CONCLUSIONS

This study indicated that unsteamed Hae-Kuen was an

unsafe and risky for consumption without further

cooking. The results showed that effect of steaming at

80 C and 85 C for 5 and 10 min could decrease

microbial content of Hae-Kuen and maintain product

properties. For safety improvement of Hae-Kuen

product, the processing method should examine. The

using of temperature and time for steaming conditions

can control good hygienic practice. It is important to

prevent cross-contamination during raw material

preparation, processing, storage, product distribution

and transportation or cross contamination for extend

shelf-life of Hae-Kuen. There are useful to extend the

shelf life of product that can apply to production

process in restaurant and to reduce the foodborne

illnesses.

ACKNOWLEDGEMENTS

We are obliged to a Thai Chinese restaurant that

participated in this study. This work is in part

supported the presentation expense by King

Mongkut’s Institute of Technology Ladkrabang,

Bangkok.

REFERENCES

Association of Official Analytical Chemists (AOAC)

2000. Official Methods of Analysis. 16th ed. AOAC

International, Arlington, Virginia, USA.

Audibert, F. 2019. Leading Industrial and non-industrial

Processes. [online] Science Direct. Available at:

https://www.sciencedirect.com/topics/earth-and-plane

tary-sciences/dehydration.

Buchanan, R. 1991. Microbiological criteria for cooked, ready-

to-eat shrimp and crabmeat. Food Technology, 45(4),

pp.157–160.

Can, Ö. and Harun, F. 2015. Shelf Life of Chicken Meat Balls

Submitted to Sous Vide Treatment. Brazilian Journal of

Poultry Science, 17(2), pp.137–144.

International organization for standardization. 1999.

Microbiology of food and animal feeding stuffs-horizontal

method for the enumeration of coagulanse-possitive

Staphylo- coccus (Staphylococcus aureus and other

species). 2th ed. ISO, Genewa, Switzerland.

International organization for standardization. 2004.

Microbiology of food and animal feeding stuffs-horizontal

method for the enumeration of Clostridium perfringens-

colony-count-technique. 3th ed. ISO, Genewa,

Switzerland.

Kanatt, S.R., Chawla, S.P., Chander, R. and Sharma, A. 2006.

Development of shelf-stable, ready-to-eat (RTE) shrimps

(Penaeus indicus) using 𝛾-radiation as one of the

hurdles. LWT, 39(6), pp.621–626.

Office of communities product standard. 2003. Standard of

communities product, Hae-kuen. Office of communities

product standard.

Purwanto, F.H., Kurnia, Y.F. and Purwati, E. 2017.

Microbiological quality and safety of meatball sold in

Payakumbuh city, West Sumatra, Indonesia. Journal of

nutrition and food engineering. 11(4), pp.337-341.

U.S. Food and Drug Administration. 2002. Bacteriological

Analytical Manual Chapter 4 Enumeration

of Escherichia coli and the Coliform Bacteria. [online]

FDA. Available at: https://www.fda.gov/food/ laboratory-

methods-food/bam-4-enumeration-escheri chia-coli-and-

coliform-bacteria.

Effect of Steaming Treatment on Physical Properties and Shelf life of Hae-Kuen

255