Characteristics of Chili Powder (Capsicum Frutescens L.) with

Maltodexstrin Encapsulants from Starch of White Yam (Dioscorea

Alata)

Dedin Finatsiyatull Rosida

*

, Anisa Eka Yuliana Dewi and Dahlia Elianarni

Department of Food Technology, Universitas Pembangunan Nasional Veteran Surabaya, East Java, Indonesia

*

Corresponding author email

Keywords: Encapsulation, Chili Powder, Maltodextrin, White Yam, Arabic Gum.

Abstract: Encapsulation is technique for coating a core in the form of a solid, liquid, gas, or cell active compound with

a certain protective material that can reduce the damage to an active compound. Chili is perishable and the

capsaicin compounds it contains are volatile. Therefore it is necessary to protect the active compound of

capsaicin by encapsulating chili powder. One of the protective materials that can be used in the manufacture

of encapsulants is maltodextrin and gum arabic. The purpose of this study was to determine the effect of the

addition of maltodextrin from white yam starch and Arabic gum, as well as the addition of chilli powder

concentration to the characteristics of the encapsulant produced. The design used in this study was a

Completely Randomized Design consisting of two factors. The first factor was the concentration of chili

powder (20% and 25%) and the second factor was the proportion of Arabic gum: maltodextrin (70: 30; 80:

20; 90: 10). The results of the best chili powder encapsulation were on the treatment of 25% chilli powder

concentration and the proportion of Arabic gum and maltodextrin (90: 10) with a moisture content of 4.174%;

Trapped Capsaicin 1.781 mg / gr; Capsaicin Total 2.764 mg / gr; encapsulation efficiency of 64.436%; loading

capacity27.640 mg / gr; color L 49.30; color a 32.95; color b 29.60 which is red.

1 INTRODUCTION

Chili has the active compound of capsaicin which has

a spicy taste (Borges, 2001). Capsaicin can be used as

an inhibitor of leukemia cancer (Ito, 2002), prostate

cancer (Mori, 2006), and diabetes (Razavi, 2006). But

chili is perishable and the capsaicin compounds it

contains are volatile. Therefore it is necessary to take

action to protect the active compound capsaicin. Post-

harvest processing technology that can be done is

encapsulation.

The coating material commonly used as

encapsulant from gum, carbohydrates, and proteins

such as skim milk, lactose, sucrose, maltodextrin,

alginate, arabic gum, starch, agar, gelatin,

carrageenan, albumin, and casein. Encapsulation

aims to protect active ingredients that are sensitive to

damage due to oxidation, loss of nutrients, protect

flavor, aroma, pigment, and increase solubility. For

water-soluble materials, the encapsulation method

has great potential to convert unstable liquids into

powders that are easier to handle and easily mixed in

dry food systems (Versich, 2000). Maltodextrin can

be produced from modified starch. Starch is found in

many tubers. One of the tubers that has not been

widely used is the tubers of white yam (Dioscorea

alata).

Maltodextrin has a variety of functions including

enlargement and film forming properties, the ability

to bind to taste and fat, and reduce the oxygen

permeability in the wall matrix. Some of the reasons

underlying maltodextrin for encapsulation materials

are: maltodextrin can reduce the reactivity of the core

material with the environment, controlled release

suitable for the core ingredients of drugs,

maltodextrin can improve the process and texture,

maltodextrin can strengthen solubility (Bae et al.,

2008). Maltodextrin with low DE (Dextrose

Equivalene) is non-hygroscopic, whereas

maltodextrin with high DE tends to absorb water

(hygroscopic) (Blancard, 1995).

Kunarto (2017) research the Dextrose Equivalen

(DE) value of durian starch maltodextrin ranges

between 8.33-13.42. At 25-50 minutes hydrolysis

Rosida, D., Dewi, A. and Elianarni, D.

Characteristics of Chili Powder (Capsicum Frutescens L.) with Maltodexstrin Encapsulants from Starch of White Yam (Dioscorea Alata).

DOI: 10.5220/0009984100002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 19-25

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

19

there was no increase in DE value, but hydrolysis of

more than 50 minutes showed an increase in DE value

because the breakdown of starch would further

facilitate the hydrolysis of glycosidic bonds.

Sajjaanakantakul and Mukprasirt (2004) stated that

the longer the hydrolysis, the longer the α-amylase

contact with starch so that more monomers-mononers

can be hydrolyzed by enzymes.

In the research of Sukatiningsih (2011) the form

of antioxidant capsules with Arabic gum capsules

substituted with modified starch (90:10) 25% core

material. In the study of Purwaningsih et al (2013),

maltodextrin and gum coatings were used as matrix

forming the microcapsule wall. This matrix network

is important in the wall system, with good

maltodextrin matrix tissue properties in the wall

system and also good gum properties in forming the

film layer, the extract conditions can still be

maintained. For that reason, in this study we want to

know the characteristics of chili powder

encapsulation using maltodextrin from starch of yam

and arabic gum.

2 METHODOLOGY

2.1 The Making of Maltodextrin of

White Yam

A total of 1 kg of white yam flour was added with 2

L of water, then filtered. White yam paste was mixed

with 2 L of water and refined. The filtrate obtained

was then deposited for 12 hours. The obtained starch

was then dried at 50 ° C for 6 hours, then grind and

sieved (80 mesh) to obtain fine starch flour.

A total of 20 grams of dried starch was dissolved

into 100 ml distilled water containing CaCl

2

200 ppm,

then added 0.1 N NaOH to pH 7. A 0.09% α-amylase

enzyme was added to the starch suspension of 0.1 mL.

The starch suspension was hydrolyzed by enzymes in

the waterbath shaker, for 120 minutes at 40ºC. The

starch suspension was cooled to 30 ºC. Then the

addition of 0.1 N HCl to pH 4, then heated in boiling

water to stop the enzyme activity. 0.1N NaOH

reagent was added to reach the pH range of 5.

Washing was carried out to remove residual chemical

residues added in the process. The results obtained

were dried at 50 ºC. for 6 hours, then smoothed and

sieved with an 80 mesh sieve.

2.2 Procedure for Making Chili

Powder

Chili were weighed and sorted, washed and cleaned.

The chili was dried at 50ºC for 6 hours. Chili dry was

then mashed and sieved using an 80 mesh sieve, until

a fine chili powder was obtained.

2.3 Procedure for Making Rawite Chili

Powder Encapsulation

Encapsulan was made from Arabic gum and

maltodextrin with proportions of 70: 30; 80: 20; 90:

10. Chili powder and encapsulan (50 gr) are added in

proportions of 20% and 25%, then dissolved in 100

ml of distilled water 50 ̊C. The mixture of materials

was homogenized with a magnetic stirer for 10

minutes. The results obtained were then dried at 50

ºC. for 6 hours, then smoothed and sieved with an 80

mesh sieve

.

3 RESULTS AND DISCUSSION

The analysis resulted of raw chili powder including

water content, yield, solubility, dextrose equivalent

and color in chili powder, starch and white yam

maltodextrin can be seen in Table 1.

3.1 Trapped Capsaisin and Total

Capsaisin of Chili Powder

Encapsulation

Trapped Capsaisin (KE) is a capsaicin that is trapped

in a capsule. Capsaicin trapped is the amount of

capsaicin found in encapsulants. Products with high

trapped capsaicin show that capsaicin can be well

protected by a protective matrix. In Figure 1. Showed

the higher concentration of Chili and the higher

proportion of Arabic gum or the lower proportion of

maltodextrin, the trapped capsaicin encapsulation of

chili powder increased.

In the treatment of 25% chili powder

concentration and the proportion of arabic gum and

maltodextrin (90:10), the highest mean value of

Trapped Capsaisin encapsulation was 1.781 mg / gr.

whereas in the treatment of 20% chili powder

concentration and the proportion of arabic gum and

maltodextrin (70:30) had the lowest trapped capsaisin

encapsulation value of 1.263 mg / g. The relationship

between the treatment of chili powder concentration

and the proportion of arabic gum and maltodextrin

was shown in Figure 1.

16th AFC 2019 - ASEAN Food Conference

20

Table 1: Result of raw material analysis.

Parameter Chili Powder White yam Starch White yam Maltodextrin

Water (%) 5.463 ± 0.173 5.575 ± 0.147 5.416 ± 0.070

Yield (%) 23.936 ± 0.195 6.946 ± 0.148 98.417 ± 0.362

Solubility (%) - - 99.131 ± 0.227

Dextrose

Equivalen

- - 9.861 ± 0.196

Colour

L 42.90 ± 0,141

a 33.25 ± 0,071

b 30.65 ± 0,071

_ _

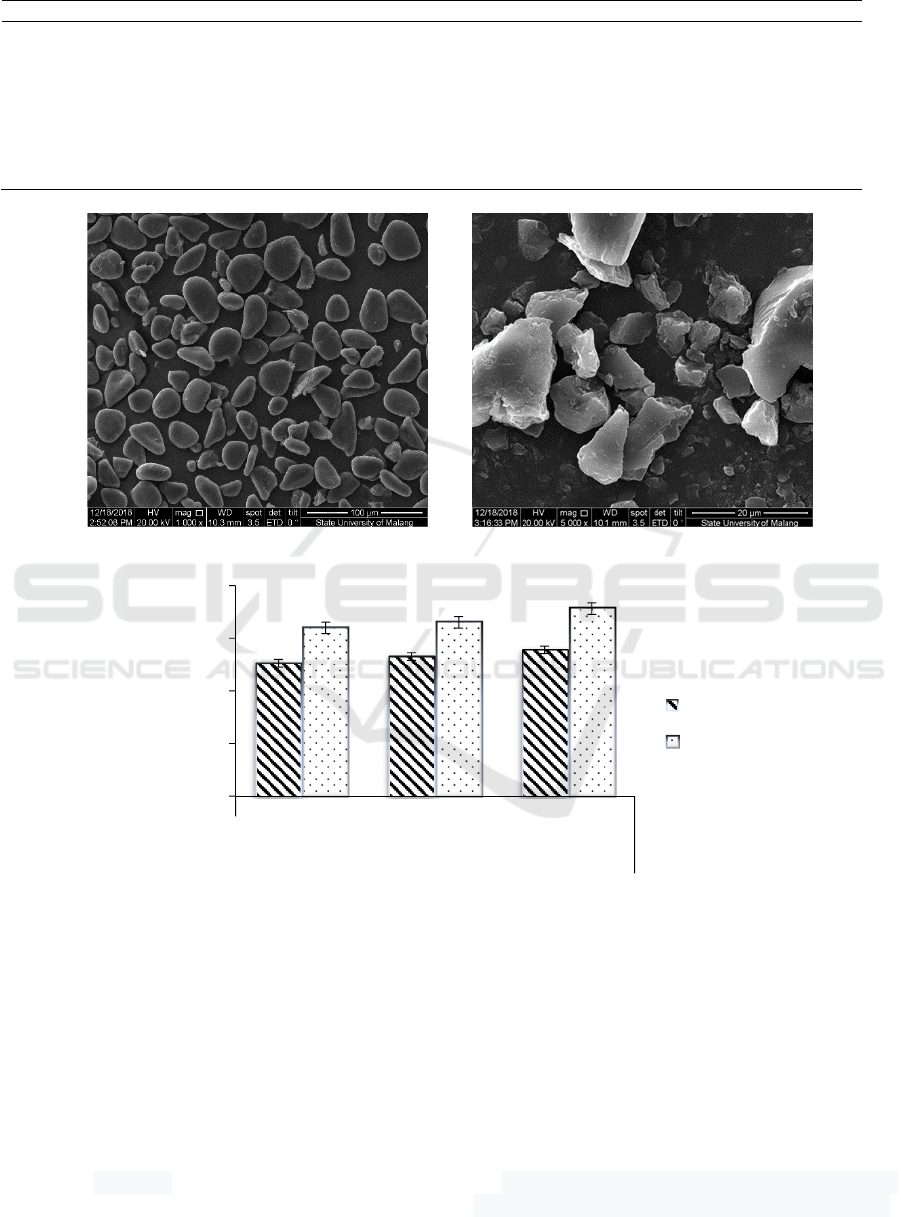

White yam native starch White yam modified starch

Figure 1: Histogram of KE (trapped capsaisin) values on encapsulation of chili powder.

This is due to the ability of Arabic gum to increase

the viscosity of a solution. High viscosity during the

drying process will make the skin layer formed firmly

so that the core material will be protected, and the

presence of maltodextrin combined with Arabic gum

will improve the quality of encapsulants formed

because maltodextrin has a small size so that it can

cover the pores of encapsulant and maltodextrin also

has plastic properties that work to prevent the

cracking of the protective matrix.

This is supported by Lin et al., (2009) that more

and more core materials are encapsulated with

increasing concentrations of added core ingredients.

Gharsallaoui et al, (2010) maltodextrin influences the

quality of the encapsulant produced because

maltodextrin has a smaller size compared to Arabic

gum, so that it can cover the pores of the encapsulant

and reduce the amount of core material that comes out

of the encapsulant. Ton et al. (2016) the combination

of maltodextrin and arabic gum as a coating material

can increase stability and better protection of the core

material.

In the treatment of 25% chili powder

concentration and the proportion of Arabic gum and

1.263

1.326

1.389

1.598

1.651

1.781

0.00

0.50

1.00

1.50

2.00

M1(70:30) M2(80:20) M3(90:10)

GUMARAB:MALTODEKSTRIN

KE (mg/gr)

C1(20%)

C2(25%)

Characteristics of Chili Powder (Capsicum Frutescens L.) with Maltodexstrin Encapsulants from Starch of White Yam (Dioscorea Alata)

21

Figure 2: Histogram KT (Total capsicin) value on encapsulant of chili powder.

Figure 3: Histogram loading capacity of encapsulation of chili powder.

maltodextrin (90:10) had the highest average

encapsulant KT value of 2.764 mg / gr. Whereas in

the treatment of 20% chili powder concentration and

the proportion of Arabic gum and maltodextrin

(70:30) had the lowest mean encapsulant KT value of

2.146 mg / g. The relationship between the treatment

of chili powder concentration and the proportion of

Arabic gum and maltodextrin was shown in Figure 2.

KT is total capsaicin, i.e. the amount of capsaicin

found in encapsulants, both inside and outside the

encapsulated surface. In Figure 2. Showed the higher

concentration of the addition of chili powder and the

higher proportion of Arabic gum or the lower

maltodextrin, the total capsaicin (KT) of chili powder

encapsulation increased. This was due to the higher

concentration of chili powder added, so that the total

capsaicin also be higher.

3.2 Loading Capacity (LC)

In the treatment of 25% chili powder concentration

and the proportion of Arabic gum and maltodextrin

(90:10) has the highest loading capacity value of

27.640 mg / gr. Treatment of 20% chili powder

concentration and proportion of Arabic gum and

maltodextrin (70: 30) had the lowest average loading

capacity, which was 21.460 mg / gr. The relationship

between the treatment of cayenne powder

concentration and the proportion of arabic gum and

maltodextrin was shown in Figure 3.

Loading capacity was the amount of total

capsaicin in the encapsulant which is calculated based

on the ratio of the total active ingredients in the

encapsulant to the overall encapsulant weight. Figure

3. Showed the higher concentration of the addition of

chili powder and the higher proportion of Arabic gum

or the lower maltodextrin, the loading capacity of

chili powder encapsulation increased. This was due to

the higher concentration of chili powder added, so

that the capsaicin contained in the encapsulant also

increased.

In addition to the addition of chili powder, Arabic

gum and maltodextrin also influence the increase in

loading capacity. Arabic gum has the ability to

increase the viscosity of a solution. High viscosity

during the drying process make the skin layer formed

2.146

2.242

2.311

2.572

2.600

2.764

0.00

0.50

1.00

1.50

2.00

2.50

3.00

M1(70:30) M2(80:20) M3(90:10)

GUMARAB:MALTODEKSTRIN

KT (mg/gr)

C1(20%)

C2(25%)

21.460

22.420

23.110

25.720

26.000

27.640

0.00

5.00

10.00

15.00

20.00

25.00

30.00

M1(70:30) M2(80:20) M3(90:10)

GUMARAB:MALTODEKSTRIN

LoadingCapacity (mg/gr)

C1(20%)

C2(25%)

16th AFC 2019 - ASEAN Food Conference

22

Figure 4: Histogram of the encapsulation efficiency on chili powder encapsulation.

firmly so that the core material be protected, and the

presence of maltodextrin combined with Arabic gum

improve the quality of encapsulants formed because

maltodextrin has a small size so that it can cover the

pores of encapsulant and maltodextrin also has plastic

properties that work to prevent the cracking of the

protective matrix.

Syamsir (2013) states that maltodextrin also has

good plastic properties so that it can prevent cracking

of the protective matrix. Ton et al. (2016) researh the

combination of maltodextrin and arabic gum as a

coating material can increase stability and better

protection of the core material. Krishnan et al., (2005)

state the encapsulant wall layer is very influential on

the amount of core material produced, the addition of

arabic gum can affect the thickness of an encapsulant

wall, the more robust an encapsulant wall layer cause

the core material contained in the encapsulant to be

well protected .

3.3 Encapsulation Efficiency (EE)

Treatment of 25% chili concentration and proportion

of Arabic gum and maltodextrin (90:10) had the

highest average value of encapsulation efficiency of

64.436%. Whereas in the treatment of 20% chili

powder concentration and the proportion of arab gum

and maltodextrin (70: 30) had the lowest average

encapsulation efficiency value of 58.854%. The

relationship between the treatment of chili powder

concentration and the proportion of Arabic gum and

maltodextrin was shown in Figure 4.

Encapsulation efficiency is used to determine the

success rate of the encapsulation process. The

efficiency referred to in this study is the comparison

between trapped capsaicin and total capsaicin. The

higher the encapsulation efficiency means the better

the coating's ability to protect its core material. Based

on Figure 4. Showed the higher concentration of chili

powder and the higher proportion of Arabic gum or

the lower proportion of maltodextrin, the

encapsulation efficiency of chili powder increased.

This was due to the higher concentration of chili

powder added, so that the capsaicin contained in the

encapsulant also increased. In addition of chili

powder, arabic gum and maltodextrin also influence

the increase in encapsulation efficiency. Arabic gum

has the ability to increase the viscosity of a solution.

High viscosity during the drying process will make the

skin layer formed firmly so that the core material can

be well protected, and the presence of maltodextrin

combined with Arabic gum will improve the quality

of the encapsulants formed because maltodextrin has

a small size so that it can cover the pores of the

encapsulant and Maltodextrin also has plastic

properties which function to prevent the cracking of

the protective matrix.

This is supported by the statement of Mcnamee et

al., (2002) that Arabic gum has the ability to form a

strong protective matrix around the core material,

resulting in a higher encapsulation efficiency value by

increasing the concentration of arabic gum in the

coating material. The mechanism of retention of the

active substance in the capsule during the drying

process is a film layer formed on the surface of the

58.854

59.129

60.162

62.131

63.500

64.436

54.00

56.00

58.00

60.00

62.00

64.00

66.00

M1(70:30) M2(80:20) M3(90:10)

GUMARAB:MALTODEKSTRIN

EfisiensiEnkapsulasi (%)

C1(20%)

C2(25%)

Characteristics of Chili Powder (Capsicum Frutescens L.) with Maltodexstrin Encapsulants from Starch of White Yam (Dioscorea Alata)

23

droplet. This film is more permeable to water

molecules that act as solvents as long as the solid is

dried and the pore size is smaller than the molecules

of the active substance. Because active substance

molecules have lower solubility and are larger in size

than water molecules, active molecules cannot diffuse

out through the surface of the film and are trapped in

dry droplets (Supriyadi et al., 2013). Young et al.

(1993) explain that the encapsulation efficiency is

higher with an increase in the core material. Frascareli

et al. (2012) also states that one of the factors that

influence the efficiency of encapsulation is the

concentration of core material. The higher

concentration of core material, it cause high viscosity,

high viscosity will increase the efficiency of

encapsulation. The same results were obtained from

research conducted by Minemoto et al. (2002), where

the increased core weight increases the value of the

encapsulation efficiency.

3.4 Color Intensity

On the results of the analysis of raw materials of chili

powder obtained color intensity L 42.90. The L

encapsulant value of chili powder was greater than

the raw material that is 49.90-51.22. The intensity of

the color L indicates lightness or brightness where the

range of numbers is from 0 to 100. The smaller or

closer to 0, it means that the material display darker

colors and the higher the number up to 100 will

display brighter colors (Hutchings, 1999).

In Table 2. Showed that the higher the

concentration of chili powder, the lower the color

intensity of the L encapsulant value of chili powder.

This was due to the increasing concentration of chili

powder increased the red pigment in the encapsule.

This is supported by the research of Maryanto and

Yuwanti (2005) that the higher the level of solids in a

solution cause more colors to be absorbed than what

is transmitted so that the color will look concentrated

and the higher the core material added will increase

the color pigment in the product.

Table 2: The value of encapsulant color intensity with the

treatment of chili powder concentration.

Concentratio

n of Chili

Powder (%)

L

Value

A

value

B

value

20

25

51.22

b

49.90

a

30.48

a

31.85

b

27.68

a

28.97

b

Note: The average value followed by the same letter means

that it is not significantly different (p <0.05).

In Table 3. Showed that the higher the proportion of

Arabic gum or the lower proportion of maltodextrin,

the color intensity of the L encapsulant of chili

powder decreased. This was because arabic gum has

a slightly darker white color while maltodextrin has a

yellowish white color. This is supported by the

statement of Blanchard et al., (1995) that Arabic gum

and maltodextrin have different base colors. Arabic

gum has a rather dark white color while maltodextrin

has a yellowish white color. Therefore the greater the

addition of arabic gum the encapsulant color gets

darker, while the addition of large maltodextrin

causes the intensity of the lightness color to be

brighter.

Table 3: The value of encapsulant color intensity by the

treatment of Arabic gum and maltodextrin proportions.

Proportion

Gum :

Maltodekstrin

(%)

L

Value

A

value

B

value

70 : 30

80 : 20

90 : 10

51.03

c

50.58

ab

50.08

a

30.25

a

31.23

b

32.03

b

27.73

a

28.40

b

28.85

b

Note: The average value followed by the same letter means

that it is not significantly different (p <0.05)

The more the addition of Arabic gum proportion or

the lower the addition of maltodextrin, the color

intensification of the value of increase. This is

because Arabic gum has a rather dark white color,

while maltodextrin has a yellowish white color.

Therefore, the greater the addition of gum arabic

encapsulant chilli color, proclaim the more

concentrated.

The results of the analysis of raw chili obtained

the value of b 30.65. The encapsulant value of chili

powder has a lower value compared to the raw

material that is 27.68-28.97. The value of b in the

color intensity shows yellow - blue. The yellow color

ranges from 0 to +100 while the blue color ranges

from 0 to -80. The greater the positive value b

indicates yellow while if the negative value is higher

it indicates blue (Hutchings, 1999). The higher the

concentration of chili, the higher the color intensity of

the encapsulant of chili. This is due to the increasing

concentration of chili will increase the red pigment in

the encapsule.

16th AFC 2019 - ASEAN Food Conference

24

4 CONCLUSION

Capsaisin in chili (Capsicum frutescens L.) needs to

be protected by the encapsulation process. The

coating material commonly used as encapsulant is

maltodextrin and arabic gum. Maltodextrin is often

produced from cassava. In this researches of

maltodextrin from white yam (Dioscorea alata). The

best treatment was obtained using 25% chili powder

concentration and the proportion of arabic gum and

maltodextrin (90:10) which produced a characteristic

water content of 4.174%; trapped capsaisin 1.781 mg

/ gr; capsaicin total 2.764 mg / gr; encapsulation

efficiency 64.436%; loading capacity 27.640 mg / gr;

with a color value of L 49.30; a 32.95; b 29.60 (red).

ACKNOWLEDGEMENT

Our gratitude goes to the Ministry of RISTEKDIKTI

for providing funding to Based Research scheme as

well as to the LPPM UPN Veteran Jawa Timur,

Indonesia who have facilitated this activity a lot.

REFERENCES

Bae E.K., and Lee S.J. Microencapsulation of avocado oil

by spray drying using whey protein and maltodextrin.

Journal of Microencapsulation, 2008; 25 (8): 549-560

Blancard P.H. and Katz F.R. Starch hydrolysis in food

polysaccharides and their applications. Marcell

Dekker, Inc.New York.1995.

Borges R.M. Why are chillies pungent. Journal of

Biosciences. 2001: 26 (3): 289-291

Frascareli E.C., Silva V.M., Tonon R.V. and Hubinger

M.D. Effect of process conditions on the

microencapsulation of coffee oil by spray drying. Food

and Bioproducts Processing. 2012: 90, 413-424.

Gharsallaoui A., Saurel R., Chambin O., Cases E., Voilley

A and Cayot P. Utilisation of pectin coating to enhance

spray-dry stability of pea protein-stabilised oil-in-

water emulsions. Food Chem. 2010: 122: 447–454.

DOI: 10.1016/j.foodchem

Hutchings J.B. Food Color and Appearance. Springer-

Verlag US. 1999

Ito K., Nakazato T., and Yamato K. Induction of apoptosis

in leukemic cells by homovanillic acid derivative,

capsaicin, through oxidative stress. Cancer Research.

2002: 64: 1071–1078

Krishnan S., Kshrisagar A.C., and Singhal R.S. The use of

gum arabic of modified starch in the

microencapsulation of a food flavouring agent.

Carbonhydrate Polymer. 2005: 62:309-315.

Kunarto B and Sani E.Y.Making maltodectrin from durian

seed starch (Durio zibethinus murr.) Using the α-

amylase enzyme. Thesis. Department of Agricultural

Product Technology, University of Semarang.

Semarang. 2017

Maryanto and Yuwanti S. Physical properties of food and

agricultural products. Textbooks. Department of

Agricultural Product Technology, Faculty of

Agricultural Technology. State University of Jember.

Jember. 2005

Mcnamee B.F., O’Riordan E.D and O’Sullivan M.

Emulsification and microencapsulation properties of

gum arabic. Journal of Agricultural and Food

Chemistry. 2002: 46:4551–4555.

Mori A., Lehmann S and O'Kelly J. Capsaicin a component

of red peppers, inhibits the growth of androgen-

independent, p53 mutant prostate cancer cells. Cancer

Research. 2006:66 (6): 3222–3229.

Purwaningsih D., AgungW and Ireno, M. Formulation of

ethanol extract of cocoa beans (Theobroma cacao L.)

as natural antioxidant candidates through

microencapsulation technology. Thesis. Faculty of

Pharmacy, Hasanuddin University, Makassar. 2013.

Razavi R., Chan, Y., Afifiyan F.N., Liu X.J., Wan X. and

Yantha J. TRPV1 sensory neurons control beta cell

stress and islet inflammation in autoimmune diabetes.

Cell. 2006: 127 (6):1123-35.

Sajjaanantuakul K. And Mukprasirt A. Physico-chemical

properties of flour and starch from jackfruit seed

(Artocarpus heterophyllus Lam.) compared with

modified starch. Internatioanl journal of Food Sciece

and Technology. 2004: 39: 271-276.

Sukatiningsih.. Encapsulation of antioxidant extracts of

coffee fruit skin using a combination of Arabic gum and

modified tapioca as a capsule. Thesis. Department of

Agricultural Product Technology, Faculty of

Agricultural Technology, Jember University. Jember.

2011

Supriyadi and Rujita. Characteristics of galangal essential

oil microcapsules with maltodextrin as encapsulants.

Journal of Technology and Industry Food. 2013.: Vol.

24 (2): 201-208. ISSN: 1979-7788

Syamsir, E. .Flavor Encapsulation by Using Modified

Starch. Food Chem. 2013: 22: 145–151. DOI:

10.1026/j.foodchem.

Ton N.M.N., Tran T.T.T. and Le,V.V.M.

Microencapsulation of rambutan seed oil by spray-

drying using different protein preparations.

International Journal Food Research. 2016.. 23(1): 123-

128

Versich, R.J. Flavour encapsulation an overview.

American Chemical Society, Washington, D.C. 2000.

Young S. L., Sarda X and Rosenberg, M.

Microencapsulating properties of Whey Proteins.

Journal of Dairy Science. 1993: Vol 76:2868-2877.

Characteristics of Chili Powder (Capsicum Frutescens L.) with Maltodexstrin Encapsulants from Starch of White Yam (Dioscorea Alata)

25