Purslane (Portulaca Oleracea L.) Leaves Extract Addition in Jelly

Candy Making

Ratna Handayani, Melina Christine and Bryan Anders

Food Technology Department, Universitas Pelita Harapan, Jl. M.H Thamrin Boulevard, Tangerang, Indonesia

Keywords: Candy, Jelly, Purslane, Linolenic Acid, Maceration.

Abstract: Purslane or krokot (Portulaca oleracea L.) can grow in warm climates (tropics and subtropics). Purslane

plant is known to contain 41.4-66.4% of the omega-3 fatty acids, linolenic fatty acids (C18:3, n-3). Purslane

extract contains unsaturated fatty acids, and more than 10 % consisted of alpha linolenic acid. This study is

done to utilize purslane extract in candy jelly production that can be accepted by panelists. Maceration is

used to extract purslane leave with three types of solvents (ethanol, ethyl acetate and hexane). The best

extract was obtained by calculating the total yield and GC-MS analysis of purslane leaf extract components.

The addition of purslane leaf extract to jelly candy uses concentrations of 0.5%, 1.0%, 1.5% and 2.0%

(w/w). The observed parameters include physicochemical analysis (Total Dissolved Solids and pH), color,

texture and sensory analysis. Selected jelly candies have a concentration of 0,5% purlsane leaf extract.

Selected jelly candy has characteristics including ° Hue of 91.54 °, Total Dissolved Solids of 34.68 ° Brix,

moisture content of 46.49%, fat content of 1.59%, protein content of 0.43%, ash content of 0.87 % and

carbohydrate levels of 50.72%. Then based on the results of GC-MS analysis the selected jelly candy

contains linolenic acid.

1 INTRODUCTION

Purslane (Portulaca olearacea L.), in Indonesia is

known by the name of krokot. Krokot is a type of

ornamental plant that can grow on warm climate. In

some countries (e.g. China), krokot is commonly

used in traditional medicine to treat diabetes and

hypotension; and it is also known for its antifungal,

antibiotic, antiinflammation, antiestrogenic, and

anticancer properties (Agil, et al., 2015; Uddin, et

al., 2014; Sultana dan Rahman, 2013; dan Zhou, et

al., 2015; Hanan et al., 2014). The leaves contain

41.4-66.4% (1.0-1.6 mg/g) omega-3 fatty acids,

which are higher compared to its root and stem.

Omega-3 fatty acid has many beneficial effects

to human body, namely its anticoagulative and anti-

inflammatory properties. It is also known to be good

for the brain. Moreover, omega-3 fatty acids are able

to prevent chronic diseases, such as cardiovascular

related diseases, hypertension, inheritance of

diabetes on fetus during pregnancy, inflammation,

hyperlipidemia, and cancer (Diana, 2012; Zhou, et

al., 2015; Yessoufou, et al., 2015; Calviello and

Serini, 2010).

Jelly

candy is a type of confectionary with soft,

chewy, and elastic texture. Gelatin used in the

making of jelly candies comes from connective

tissues of pig, cow, or skin from poultries

(Subaryono and Utomo, 2006; Riaz dan Chaudry,

2004). Due to its non-halal origin, other

hydrocolloids such as carrageenan is used as a

substitute for gelatin (Atmaka, Nurhartadi and

Karim, 2013).

This research is done to determine the addition of

krokot leaf extract in the production of jelly candies,

based on its sensory analysis and physic analysis.

2 MATERIALS AND METHODS

The materials used are fresh krokot leaves obtained

from BALITRO, Bogor, food grade solvents

(ethanol, ethyl acetate, and hexane), granulated

sugar, citric acid, kappa-carageenan, konjac, high

fructose syrup (HFS), and orange flavoring.

Materials used for analysis consist of distilled water,

pro-analysis grade hexane, K

2

SO

4

, selenium, H

2

SO

4

97%, H

2

O

2

, and saturated boric acid. The equipment

used are “Ohaus U-1800 AR 2140” analytical

Handayani, R., Christine, M. and Anders, B.

Purslane (Portulaca Oleracea L.) Leaves Extract Addition in Jelly Candy Making.

DOI: 10.5220/0009992400002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 83-90

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

83

balance, heater, cabinet dryer, oven, Tyler sieve (35

mesh), “Buchi” rotary evaporator, “Konica Minolta

CR-400” chromameter, furnace, “Aglient 7890B”

Gas Chromatograph, “Aglient 5977B” Mass

Selective Detector, and desiccator.

2.1 Extraction of Krokot Leaf

The extraction of krokot leaf is done using

maceration method. The leaves are dried using

cabinet dryer at 50°C for 24 hours (Abdolshahi, et al.

(2015);Kaveh, et al. (2017), with modification). The

dried leaves are reduced in size and sieved using 35-

mesh Tyler sieve to obtain krokot leaf powder. The

powder is macerated using three types of solvent

(ethanol, ethyl-acetate, and hexane) with the ratio of

1:4 (w:v) powder to solvent for 72 hours. The liquid

is then filtered using Whattman No.1 filter paper and

the solvent is evaporated by using rotary evaporator

at 45°C with adjusted vacuum pressure based on each

solvent to obtain krokot leaf extract.

2.2 Production of Jelly Candy

The production of jelly candy is done by combining

the hydrocolloid (carrageenan and konjac) with

water at 80-90°C in a separate container for each

hydrocolloid. Then, in another container, mix high

fructose syrup with granulated sugar. When the

sugar has dissolved, mix the sugar and syrup mixture

with carrageenan and konjac solution, followed by

heating. When the mixture temperature reaches

80°C, add the citric acid and flavoring.

After cooling down to 60°C, krokot leaf extract

is added to the mixture (Sugiharto, et al., 2015). The

jelly candy mixture is then poured to the mold, that

has been applied with molding starch. The jelly

candy is left to cool down in room temperature (23-

30°C) for an hour before transferring to the

refrigerator (4-5°C) and left for 24 hours. During

refrigeration, the gel sets. Compared to konjac, the

gel from carrageenan sets faster. Carrageenan gel

sets at around 40-70°C. However, its setting

temperature is highly affected by the sugar content

of the jelly candy, thus it is hard to determine the

specific set temperature for carrageenan (Williams

dan Phillips, 2004; Williams and Phillips

1

, 2009).

2.3 Characterization of Krokot Leaf

Powder

Characterization of krokot leaf powder was done to

determine the chemical composition through

proximate analysis (AOAC,2015)

2.4 Characterization of Krokot Leaf

Extract

The extracts from three different solvent was

calculated for its yield using the formula:

Yield (%) =

100%

Furthermore, the identification of omega-3 fatty acid

is determined using GC-MS.

2.5 Analysis of Krokot Leaf Extract

Added Jelly Candy

The produced jelly candy will be analysed for its pH

(AOAC, 2005), Total Soluble Solid (Hasyim 2015),

Color (Nielsen, 2010), Texture (Azizah 2012),

Sensory Evaluation (Lawless and Heymann, 2010;

Kemp, et al. 2009), and proximate analysis (AOAC

2015).

3 RESULTS AND DISCUSSION

3.1 Characteristics of Krokot Leaf

Powder

The chemical composition of krokot leaf powder is

shown in Table 1. Based on the analysis done, the

moisture content of the krokot leaf powder is

8.44±0.13%, which according to Puspitasari and

Proyogo (2017), the moisture content of dry plant

sample must not exceed 10%. Thus, krokot leaf

powder obtained can be used for the next step,

maceration.

Table 1: Krokot leaf chemical composition.

Chemical composition Result (%)

Moisture content 8.44 ± 0.13

Fat 3.96 ± 0.07

Protein 31.75 ± 0.06

Ash 18.24 ± 0.03

Carbohydrate 37.60 ± 0.03

3.2 Characterization of Krokot Leaf

Extract

Based on the extract yield on Table 2., food grade

ethanol gives the highest yield among the solvents

used, with the value of 8.30±0.02%. Similar result is

obtained from a research by Adiyasa, Wrasiati and

Wartini (2015), where ethanol gives the highest

extract yield.

16th AFC 2019 - ASEAN Food Conference

84

Based on the component identification result

with GC-MS, all solvent used shows similar result

qualitatively, where every extract contains omega-3

fatty acid. Table 3. shows the identification result

Table 2: Krokot leaf extract yield.

Solvent Type Yield (%)

Ethyl-acetate 4.78±0.14

Ethanol 8.30±0.02

Hexane 2.99±0.01

In a research done by Schmid, et al., (2016),

ethanol gives higher PUFA (Polyunsaturated Fatty

Acid) yield in the extraction of seaweed.

Furthermore, ethanol solvent is able to extract higher

amount of total fatty acid (TFA). Hence, it is

possible that the krokot leaf extract obtained by

using ethanol as solvent contain high level of PUFA

and TFA. Thus, ethanol is chosen as the best solvent

for the extraction of krokot leaf.

Table 3: Total component identification of Krokot leaf

extract with GC-MS.

Solvent Type Retention Time Qual

Ethyl-acetate 10.314 minutes 98%

Ethanol 10.968 minutes 99%

Hexane 10.540 minutes 94%

3.3 Effect of Krokot Leaf Extract

Concentration on Total Soluble

Solid of Produced Jelly Candy

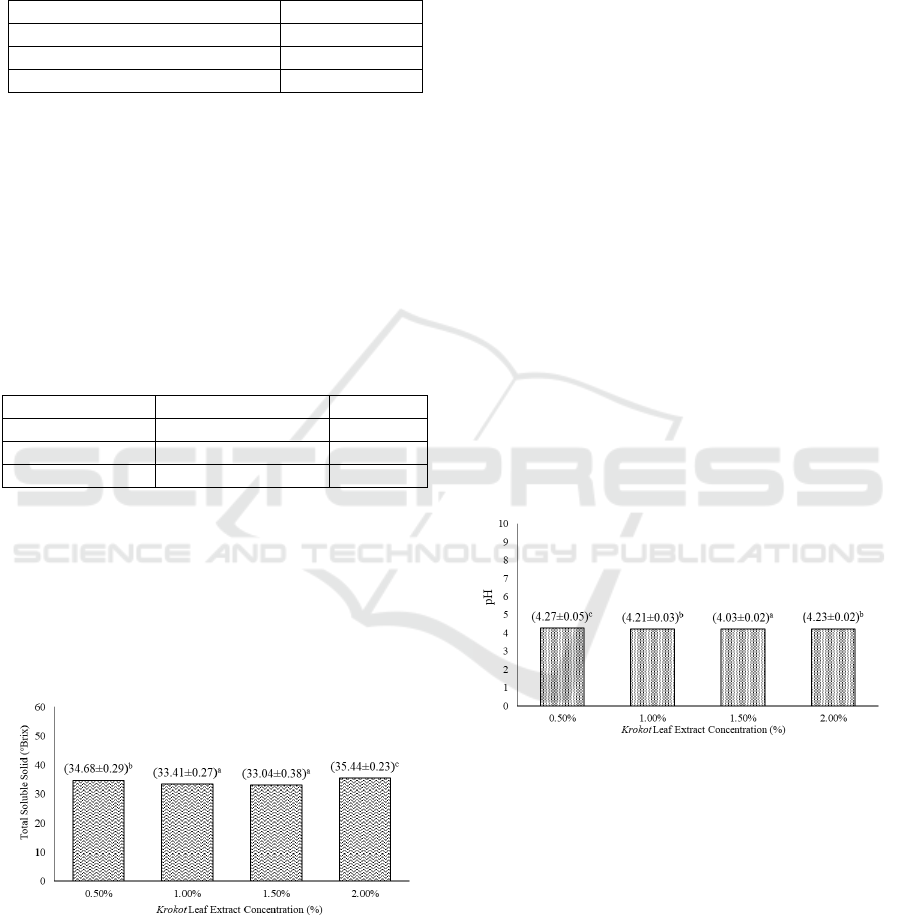

Based on Figure 1, there is a significant difference in

total soluble solids between jelly candy with

different level of extract concentration.

Figure 1: Effect of extract concentration on the value of

jelly candy total soluble solid. (Note: Different letter

notations indicates a significant difference at p≤0.05).

It can be seen that there is an increasing trend of

total soluble solid when higher level of extract is

added. Similar trend is seen on a research by

Charoen, et al. (2015), where the total soluble solid

of the jelly candy produced increases as the level of

guava leaf extract is increased. Another possibility is

that increase in total soluble solid is caused by the

bonding of free water and other particle through

stabilizer, thus increasing the total soluble solid and

reducing formation of precipitate (Farikha, et al.,

2013).

3.4 Effect of Krokot Leaf Extract

Concentration on pH of Produced

Jelly Candy

Based on Figure 2., there is a significant difference

in pH value between jelly candies with different

levels of krokot leaf extract. In Figure 2, an inverse

relationship can be seen on the pH of jelly candy and

the addition of krokot leaf extract. This is due to the

addition of citric acid in the making of jelly candy.

The decrease in pH can also be explained due to the

addition of carrageenan (Septiani, et al. (2013). The

presence of anhydrogalactose group on carrageenan

decreases the dispersion of carrageenan, thus

reducing the (H

+

) ion that is bound in the jelly

candy, effectively reducing the pH of the product.

The jelly candies from every treatment is

categorized as acidic to less than 7 pH value.

According to Sperbe and Doyle (2009), pH value in

candies have range between 2.0 until 8.0.

Figure 2: Effect of extract concentration on the value of

jelly candy pH. (Note: Different letter notations indicates

a significant difference at p≤0.05).

3.5 Effect of Krokot Leaf Extract

Concentration on Color of

Produced Jelly Candy

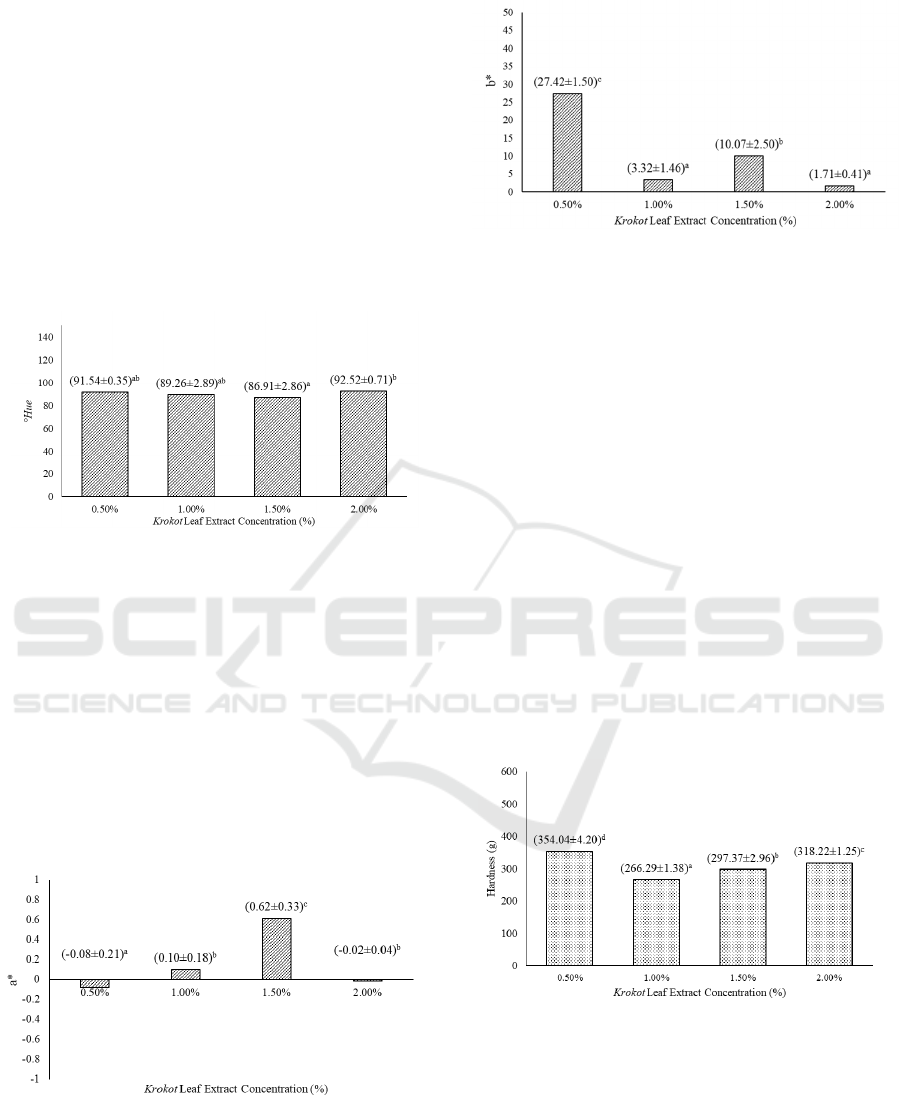

The °Hue value of the candy can be seen on Figure

3, where there is no significant difference on °Hue

value between jelly candy with different

concentration of krokot leaf extract. The °Hue value

of the product ranges between 86.91 to 92.52°,

where according to Munsell color system, the jelly

candy color is categorized as yellow. Increasing the

Purslane (Portulaca Oleracea L.) Leaves Extract Addition in Jelly Candy Making

85

concentration of krokot leaf extract will increase the

°Hue value of the jelly candy. However, the result

obtained is different from visual observation, where

the candy shows dark green color. This is due to the

presence of antioxidant in the extract used.

According to a research by Liu, et al. (2000), krokot

contains high level of antioxidant in form of beta-

carotene (22-30 mg/g). MacDougall (2002) said that

beta-carotene gives yellow orange to food product.

According to USDA (2015), a cup of raw carrot

contains 10605 µg or 10.6 mg beta-carotene. Due to

high level of beta-carotene in the krokot leaf extract,

it affects color perceived as yellow.

Figure 3: Effect of extract concentration on the value of

jelly candy

o

Hue. (Note: Different letter notations

indicates a significant difference at p≤0.05).

In color analysis, °Hue value is directly affected

on the values a* and b*. Based on Figure 4 and

Figure 5, the range of a* and b* value for the candy

is between -0.08 to 0.61 and 1.71 to 27.42

respectively. From the result, it can be perceived that

every jelly candy has different color. Lower a* value

indicates green color. While higher b* value

indicates yellow and lower b* value will lean

towards blue color (Nielsen, 2010). Because of this,

°Hue value obtained leans toward yellow color.

Figure 4: Effect of extract concentration on the value of

jelly candy a* value. (Note: Different letter notations

indicates a significant difference at p≤0.05).

Figure 5: Effect of extract concentration on the value of

jelly candy b*. (Note: Different letter notations indicates a

significant difference at p≤0.05).

3.6 Effect of Krokot Leaf Extract

Concentration on Texture of

Produced Jelly Candy

Texture is an important parameter when determining

the physical characteristic of jelly candy. The type

and concentration of gelling agent used will

determine the texture of jelly candy produced

(Imeson, 2010). The observed parameters used in

texture analysis of jelly candy are hardness,

springiness, cohesiveness, chewiness, and

gumminess.

Based on Figure 6, krokot leaf extract has a

significant effect towards the hardness of jelly candy

produced. Hardness value tend to decrease as the

lever of extract is increased. Lower hardness value

indicates softer texture, and vice versa (Octaviana,

Purwijantiningsih and Pranata, 2013).

Figure 6: Effect of extract concentration on the value of

jelly candy hardness. (Note: Different letter notations

indicates a significant difference at p≤0.05).

Decrease in hardness can also due to jelly candy,

which considered hygroscopic, absorbs water when

exposed to environment with high humidity and

temperature, making the product softer when

analyzed (Koswara, 2009; Rahmi, et al., 2012).

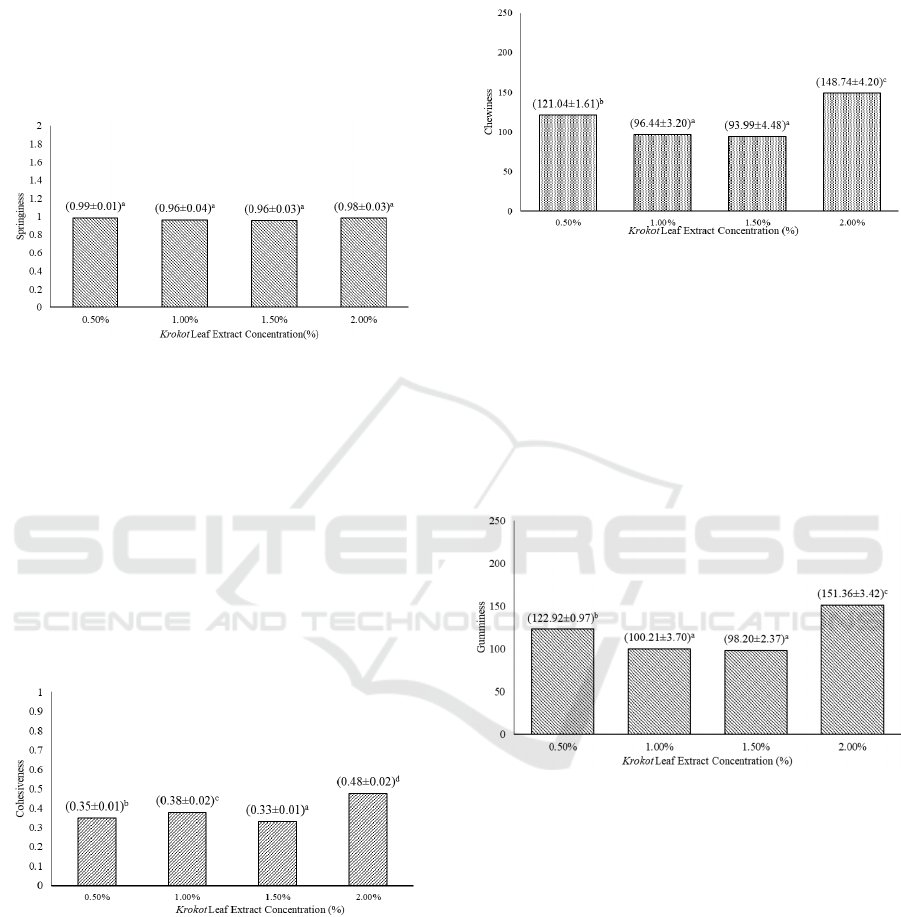

Based on Figure 7., no significant difference is

shown between different level of extract

16th AFC 2019 - ASEAN Food Conference

86

concentration towards the springiness of jelly candy.

Springiness of jelly candy is usually not affected by

the addition of different levels of extract

concentration. Similar result is shown in a research

by Atmaka, Nurhartadi and Karim (2013), where

different Curcuma zanthorrhiza extract

concentration shows no significant effect to the

elasticity of jelly candy produced.

Figure 7: Effect of extract concentration on the value of

jelly candy springiness. (Note: Different letter notations

indicates a significant difference at p≤0.05). at p≤0.05).

Based on Figure 8., there is a significant

difference towards the cohesiveness of jelly candy

between different levels of extract. Cohesiveness

value of jelly candy tends to increase as the amount

of extract added is increased. The increase and

decrease in cohesiveness value is affected by things

like moisture content, sugar, and other minor

components, which may affect the molecular bond

of the gel structure (Rahmi, et al., 2012; Delgado

and Bañón, 2014).

Figure 8: Effect of extract concentration on the value of

jelly candy cohesiveness. (Note: Different letter notations

indicates a significant difference at p≤0.05).

As seen on Figure 9., there is a significant

difference of jelly candy chewiness between

different levels of extract concentration. A research

by Purwaningtyas, Suhartatik and Mustofa (2017),

however, shows no effect on chewiness from the

addition of suji and sirih leaf exract. The increase in

chewiness of the jelly candy produced may be

attributed by the moisture content, total soluble

solids, and gelling agent working synergistically

(Delgado and Bañón, 2014).

Figure 9: Effect of extract concentration on the value of

jelly candy chewiness. (Note: Different letter notations

indicates a significant difference at p≤0.05).at p≤0.05).

Despite increasing value, the gumminess of jelly

candy produced shows no significant difference

between different levels of extract added.

Gumminess shows gel strength, where it is affected

by moisture content, total soluble solids, and

presence of other minor components. (Delgado and

Bañón, 2014; Rahmi, et al., 2012).

Figure 10: Effect of extract concentration on the value of

jelly candy guminess. (Note: Different letter notations

indicates a significant difference at p≤0.05). at p≤0.05).

3.7 Effect of Krokot Leaf Extract

Concentration on Sensory

Evaluation of Produced Jelly

Candy

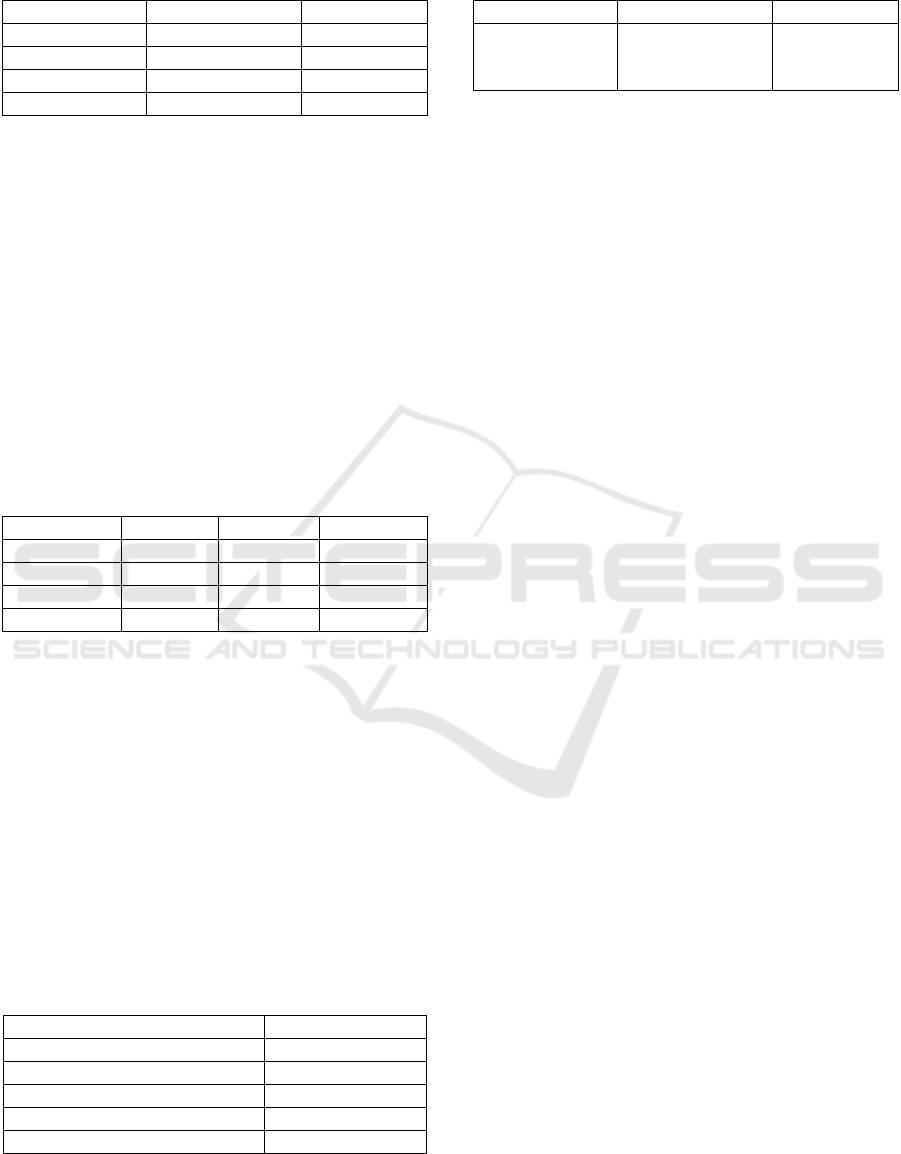

As shown on Table 4., higher extract concentration

shows an increase score in color albeit not

significant. Higher level of extract will show greener

color jelly candy.

Purslane (Portulaca Oleracea L.) Leaves Extract Addition in Jelly Candy Making

87

Table 4: Effect of Krokot Leaf Extract to scoring of jelly

candy.

Concentration Color Flavor

0.5% 4.04±1.9

a

4.40 ±1.03

c

1% 5.11±1.22

b

3.53±1.10

b

1.5% 5.00±1.15

b

3.33±1.40

b

2% 5.36±1.12

b

2.89±1.48

a

Addition of higher extract concentration exhibit

significant effect to the flavor score of jelly candy.

According to Table 4., panelist gives lower score on

higher extract concentration due to addition of

higher amount extract affects the flavor of candy

negatively. Based on the result, addition of krokot

leaf extract to jelly candy up to 2.0% shows no

significant difference to the aroma and chewiness

score.

Hedonic sensory evaluation is done by

determining the likeability of panelist towards color,

flavor, and overall. The result is expressed in Table

5.

Table 5: Effect of Krokot Leaf Extract to hedonic of jelly

candy.

Concentration Color Flavor Overall

0.5% 5.08±0.99

b

5.47±1.06

c

5.29±0.87

c

1% 4.23±1.20

a

4.73±1.27

b

4.74±1.16

b

1.5% 4.14±1.32

a

4.37±1.53

ab

4.44±1.28

ab

2% 3.90±1.44

a

4.11±1.67

a

4.29±1.54

a

3.9 Effect of Krokot Leaf Extract

Concentration on Proximate

Analysis of Produced Jelly Candy

The chosen jelly candy is the one with 0.5% krokot

leaf extract. The proximate analysis of the chosen

jelly candi is shown on Table 6. Based on the

identification result of jelly candy with chosen

krokot leaf extract using GC-MS, it is shown that the

jelly candy contains alpha-linolenic, which is an

omega-3 fatty acid. The total component analysis of

jelly candy is shown on Table 7.

Table 6: Effect of Krokot Leaf Extract to scoring of jelly

candy.

Composition Result (%)

Moisture Content 46.49±0.30

Ash Content 0.87±0.00

Fat 1.59±0.01

Protein 0.43±0.00

Carbohydrate (by difference) 50.72±0.13

Table 7: Effect of Krokot Leaf Extract to scoring of jelly

candy.

Sample Retention Time Qual

Jelly candy with

0.5% krokot leaf

extract

13,636 minutes 99%

4 CONCLUSIONS

Proximate analysis shows krokot leaf powder has

moisture content of 8.44%, which will be extracted

using by maceration on the next stage. Highest

extract yield is obtained by using food grade ethanol

as solvent, with 8.30% yield. From GC-MS analysis,

it is shown that extract using food-grade solvents

(ethanol, ethyl acetate, hexane) contains alpha-

linolenic fatty acid. Addition of krokot leaf extract

decreases the lightness of jelly candy produced.

While the texture of jelly candy produced is

improved, the chewiness is not affected. The °Hue

value is not affected by the increase of extract

concentration. The jelly candy with 0.5% krokot leaf

extract is chosen based on panelist acceptance with

overall acceptance score of 5.29. The chosen jelly

candy has color of yellowish green with °Hue value

of 91.54%. The characteristic of chosen jelly candy

produced has total soluble solids of 34.68 °Brix,

46.49% moisture content, 1.59% fat content, 0.43%

protein content, 0.87% ash content, and 50.72%

carbohydrate content. Based on GC-MS result, the

chosen jelly candy contains alpha-linolenic acid with

retention time of 13.636 minutes and 99% qual.

REFERENCES

Abdolshahi, A., Majd, M., Rad, J., Taheri, M., Shabani, A.

and Teixeira da Silva, J. (2013). Choice of solvent

extraction technique affects fatty acid composition of

pistachio (Pistacia vera L.) oil. Journal of Food

Science and Technology, 52(4), pp.2422-2427.

Adiyasa, I., Wrasiati, N. and Wartini, N. (2015). Efektivitas

Jenis Pelarut dan Lama Ekstraksi Terhadap

Karakteristik Concrete Minyak Atsiri Kulit Jeruk

Mandarin (Citrus reticulata) [Effectivity of Solvent

Type and Extraction Time to the Concrete

Characteristic of Mandarin Orange (Citrus reticulata)

peel essential oil]. Jurnal Rekayasa dan Manajemen

Agroindustri, 3(4), [online] pp.21-29. Available at:

https://ojs.unud.ac.id/index.php/jtip/article/view/16929.

Atmaka, W., Nurhartadi, E. and Karim, M. (2013).

Pengaruh penggunaan campuran karaginan dan konjak

terhadap karakteristik permen jeli temulawak

(Curcuma xanthorrhiza Roxb.) [Effect of carrageenan

16th AFC 2019 - ASEAN Food Conference

88

and konjac mixture towards curcuma (Curcuma

xanthorrhiza Roxb.) jelly candy]. Jurnal Teknosains

Pangan, [online] 2(2), pp.66-74. Available at:

https://jurnal.uns.ac.id/teknosains-pangan/article/view/

4380

Azizah, N. (2012). Pembuatan Permen Jelly dari

Karaginan dan Konjak dengan Aplikasi Prebiotik

Xilo-Oligosakarida [Production of Carrageenan and

Konjac Based Jelly with application of Xylo-

Oligosaccharide Prebiotic]. Bogor: Institut Pertanian

Bogor

Calviello, G. and Serini, S. (2010). Dietary Omega-3

Polyunstaturated Fatty Acids and Cancer. New York:

Springer Science+Business Media B.V.

Charoen, R., Savedboworn, W., Phuditcharnchnakun, S.

and Khuntaweetap, T. (2015). Development of

Antioxidant Gummy Jelly Candy Supplemented with

Psidium guajava Leaf Extract. KMUTNB International

Journal of Applied Science and Technology, 8(2),

pp.145-151.

Delgado, P. and Bañón, S. (2014). Determining the

minimum drying time of gummy confections based on

their mechanical properties. CyTA - Journal of Food,

13(3), pp.329-335.

Diana, F. (2012). Omega 3. Jurnal Kesehatan Masyarakat,

2(6).

Farikha, I., Anam, C. and Widowati, E. (2013). Pengaruh

jenis dan konsentrasi bahan penstabil terhadap

karakteristik fisikoimmia sari buah naga merah

(Hylocereus polyrhizus) selama penyimpanan [Effect

of Type and Concentration of Stabilizer towards

Physicochemical Characteristic of Red Dragonfruit

(Hylocereus polyrhizus) Juice during Storage]. Jurnal

Teknosains Pangan, 2(1), pp.30-38.

Hasyim, H. and Rahim, A. (2015). Karakteristik Fisik

Kimia dan Organoleptik Permen Jelly dari Sari Buah

Srikaya pada Variasi Konsentrasi Agar-Agar

[Physical, Chemical, and Organoleptic Characteristic

of Soursop Juice Jelly Candy with Carying Agar

Concentration]. . Abrotekbis, 3(4), pp.110-116

Hunterlab. (2012). Measuring Color using Hunter L, a, b

versus CIE 1976 L*a*b*. [online] Available at:

http://www.hunterlab.com [Accessed 21 Nov. 2017].

Imeson, A. (2010). Food Stabilisers, Thickeners and

Gelling Agents. New Delhi: Blackwell Publishing Ltd.

Kaveh, M., Eidi, A., Nemati, A. and Boskabady, M.

(2017). The Extract of Portulaca oleracea and Its

Constituent, Alpha Linolenic Acid Affects Serum

Oxidant Levels and Inflammatory Cells in Sensitized

Rats. Iran J Allergy Asthma Immunol., 16(3), pp.256-

270. Available at: http://ijaai.tums.ac.ir/index.php/

ijaai/article/view/1078.

Kemp, S., Hollowood, T. and Hort, J. (2009). Sensory

Evaluation a Practical Handbook. United Kingdom:

Wiley-Blackwell.

Koswara, S. (2009). Teknologi Pembuatan Permen

[Confectionary Processing Technology].

Lawless, H. and Heymann, H. (2010). Sensory Evaluation

of Food. New York: Springer.

MacDougall, D. (2002). Colour in Food. England:

Woodhead Publishing.

Nielsen, S. (2010). Food Analysis Laboratory Manual.

20th ed. New York: Springer Science+Business Media

LLC.

Octaviana, P., Purwijantiningsih, L. and Pranata, S.

(2013). Kualitas Permen Jelly dari Albedo Kulit Jeruk

Bali (Citrus grandis L. Osbeck) dan Rosela (Hibiscus

sabdariffa L.) dengan Penambahan Sorbitol [Quality

of Grapefruit Albedo (Citrus grandis L. Osbeck) and

Roselle (Hibiscus sabdariffa L.) Jelly Candies with the

Addition of Sorbitol]. Jurnal Biologi, [online] pp.1-12.

Available at: http://e-journal.uajy.ac.id/id/eprint/4386.

Official Methods of Analysis of AOAC International.

(2005). 15th ed. Washington, D.C.: The Association of

Official Analytical Chemists, p.212.

Purwaningtyas, H., Suhartatik, N. and Mustofa, A. (2017).

Formulasi Permen Jelly Ekstrak Daun Sirih (Piper

betle L.) dan Daun Suji (Pleomele angustofolia)

[Formulation of Jelly from Candy Betel (Piper betle

L.) – Suji (Pleomele angustofolia) Leaf Extract].

Jurnal Teknologi dan Industri Pangan, [online] 2(1),

pp.25-30. Available at:

http://ejurnal.unisri.ac.id/index.php/jtpr/article/view/1

532.

Puspitasari, A. and Proyogo, L. (2017). Perbandingan

Metode Ekstraksi Maserasi dan Sokhletasi terhadap

Kadar Fenolik Total Ekstrak Etanol Daun Kersen

(Mutingia calabura) [Comparison Between

Maceration and Soxhlation Extraction Method

Towards Total Phenolic Content of Kersen (Mutingia

calabura) Leaf Ethanol Extract]. Jurnal Ilmiah

Cendekia Eksakta, [online] 2(1). Available at:

https://www.publikasiilmiah.unwahas.ac.id/index.php/

CE/article/view/1791.

Rahmawati, P. and Adi, A. (2016). Daya Terima dan Zat

Gizi Permen Jeli dengan Penambahan Bubuk Daun

Kelor (Moringa oleifera) [Acceptance and Nutritional

Value of Jelly Candy with the Addition of Moringa

(Moringa oleifera) Leaf Powder]. Media Gizi

Indonesia, [online] 11(1), pp.86-93. Available at:

https://e-journal.unair.ac.id/MGI/article/view/4413.

Rahmi, S., Tafzi, F. and AnggrainiQ, S. (2012). Pengaruh

Penambahan Gelatin Terhadap Pembuatan Permen

Jelly Dari Bunga Rosella (Hibiscus sabdariffa Linn)

[Effect of Gelatin Addition Towards the making of

Jelly Candy from Rosella (Hibiscus sabdariffa Linn)

Flower]. Jurnal Penelitian Universitas Jambi, 14(1),

pp.37-44.

Riaz, M. and Chaudry, M. (2004). Handbook of halal food

production

. Washington, D.C: CRC Press LCC.

Schmid, M., Guihéneuf, F. and Stengel, D. (2016).

Evaluation of food grade solvents for lipid extraction

and impact of storage temperature on fatty acid

composition of edible seaweeds Laminaria digitata

(Phaeophyceae) and Palmaria palmata (Rhodophyta).

Food Chemistry, 208, pp.161-168.

Septiani, I., Basito, B. and Widowati, E. (2013). Pengaruh

Konsentrasi Agar-agar dan Karagenan terhadap

Karakteristik Fisik, Kimia, dan Sensori Selai

Purslane (Portulaca Oleracea L.) Leaves Extract Addition in Jelly Candy Making

89

Lembaran Jambu Biji Merah (Psidium guajava L.)

[Effect of Agar-agar and Carrageenan towards its

Physical, Chemical, and Sensory Characteristic of

Guava (Psidium guajava L.) Sheeted Jam]. Jurnal

Teknologi Hasil Pertanian, 4(1), pp.27-35.

Sperber, W. and Doyle, M. (2009). Compendium of

Microbiological Spoilage of Foods and Beverages.

London: Springer Science+Business Media, LLC.

Subaryono and Utomo, B. (2006). The Use of

Carrageenan–Konjac in Jelly Candy Production.

Jurnal pascapanen dan bioteknologi kelautan dan

perikanan, 1(1), pp.19-26.

Sugiharto, R., Setyani, S. and Rikafilanti, N. (2015). Efek

fortifikasi minyak ikan terhadap kadar omega-3 dan

sifat sensori roti tawar selama penyimpanan [Effect of

fish oil fortification to the level of omega-3 and

sensory of bread during storage]. Jurnal Teknologi

Industri & Hasil Pertanian, 20(1), pp.38-50.

Uddin, M., Juraimi, A., Hossain, M., Nahar, M., Ali, M.

and Rahman, M. (2014). Purslane Weed (Portulaca

oleracea): A Prospective Plant Source of Nutrition,

Omega-3 Fatty Acid, and Antioxidant Attributes. The

Scientific World Journal, 2014, pp.1-6.

U.S Departemen of Agriculture National Nutrient Data

(USDA). (2015). USDA National Nutrient Data Base

for Standard Reference “Beta Carotene”.

Williams, P. and Phillips, G. (2004). Gums and Stabilizer

for Food Industry 12. UK: The Royal Society of

Chemistry.

Williams, P. and Phillips, G. (2009). Handbook of

Hydrocolloids, 2nd edition. UK: Woodhead

Publishing Limited

Yessoufou, A., Nekoua, M., Gbankoto, A., Mashalla, Y.

and Moutairou, K. (2015). Beneficial Effects of

Omega-3 Polyunsaturated Fatty Acids in Gestational

Diabetes: Consequences in Macrosomia and

Adulthood Obesity. Journal of Diabetes Research,

2015, pp.1-11.

Zhou, Y., Xin, H., Rahman, K., Wang, S., Peng, C. and

Zhang, H. (2015). Portulaca oleracea L: A Review of

Phytochemistry and Pharmacological Effects. BioMed

research international.

16th AFC 2019 - ASEAN Food Conference

90