Optimizing Process Conditions for Sterilization of Plastic Tray

Products in Water Spray Retort

Korawan Plodklaew and Saowakon Wattanachant

Department of Food Technology, Faculty of Agro-industry, Prince of Songkla University, Songkhla 90112, Thailand

{korawan.p, saowakon.w}@psu.ac.th

Keywords: Plastic Tray Product, Sealing Conditions, Thermal Process, Water Spray Retort.

Abstract: Effect of some parameters in packing and retorting on the thermal process of a two-hole plastic tray product,

were investigated. The research aimed to obtain a high-quality product with a safe procedure for thermal

processed ready to eat rice and fried chicken with garlic and pepper product. Effects of head space, vacuum

level, sealing temperature, delay time of product, temperature and pressure of retort on defect occurrence of

package were investigated. Heat penetration profile and sterility test of product were examined to obtain target

F

o

value. The optimum process conditions for the products packed in the two-holes plastic trays were 115C

and 1.5 bar. The total come up time was 25 minutes and process time was 45 minutes to achieve the target F

o

value of the products. The cooling period was applied by holding products at 1.5 bar for 2 mins at temperature

of 100°C. The head space of the product, rice and fried chicken with garlic and pepper” in the tray should be

less than 3/16 inch and 4/16 inch, respectively. Sealing conditions without leakage of the two-hole plastic tray

product with film were achieved when spend 0.5 sec to reach the vacuum condition and sealed at 195°C for

1.3 sec. In addition, the changes in chemical and sensory characteristics of the products during storage for 12

months at room temperature were determined. The acceptable quality of the products during storage were

obtained.

1 INTRODUCTION

Plastic trays is the alternative from semi rigid

packaging to tin cans for the thermal processing of

ready to eat. In the commercial heat sterilization of

foods in cans or retortable pouches and plastic trays,

the container is heated in pressurized steam or hot

water retort at certain condition of temperature and

time. (Mokwena, K. K. and Tang, J, 2012) The

optimum process temperature, which guarantees

destruction of all spoilage factors and maximum

preservation of quality constituents depends, among

other things, on the rate that heat penetrates to the

coldest point in the container to good test and

appearance of products.

The original products of factory were ready to eat

rice and Thai style food packed separately in retort

pouch and plastic cup, then new package type was

applied to be two holes plastic tray for more

convenience.

The aim of the study was to obtain the optimum

conditions of package sealing and thermal process for

producing the product packed in two holes plastic tray

to achieve both safe to consume and good appearance

for quality of food and packaging.

2 MATERIALS AND METHODS

2.1 Materials

2.1.1 Rice

The solution for cook rice consisted with citric acid

0.08 % and salt 1.0%. The rice was precooked at

100C for 5 mins. The rice storage period of 5 months

or old rice that used for experimental. The moisture

of rice after cooked was 58.6 %. (AOAC,1995)

2.1.2 Chicken

The chicken breast were sliced and mixed with exact

ratio of baking powder. The precooked at 100C for

7 mins. (Drotz, H, .2012) Precooked chicken was

mixed with garlic and pepper sauce in the ratio of

70:30.

Plodklaew, K. and Wattanachant, S.

Optimizing Process Conditions for Sterilization of Plastic Tray Products in Water Spray Retor t.

DOI: 10.5220/0009993000002964

In Proceedings of the 16th ASEAN Food Conference (16th AFC 2019) - Outlook and Opportunities of Food Technology and Culinary for Tourism Industry, pages 91-96

ISBN: 978-989-758-467-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

91

2.1.3 Trays

The size of two holes plastic tray is 118x179x40 mm.

The layer structure is PP/PP + Additive/Tie

/EVOH/Tie/PP + Additive/PP and their thickness is

1000 micron as shown in figure 1.

2.2 Methods

Factors have been analyzed since the preparation of

raw materials filling, sealing condition and

sterilization profile in retort.( Lakshmana, ., Kumar

R., Kumaraswamy, T. JH., Jayaprahash,

CNadanasabapathi, ,2013) Figure 2 shown that the

factors were headspace, delay time of products,

temperature sealing vacuum level and profile of

retort. The resulted from plastic cup were tested and

compared with two holes plastic tray to find suitable

condition and reduce defect of product.

2.2.1 Condition Process

The old products were ready to eat rice in plastic cup

size 109x59 mm and stirred fried chicken with garlic

and pepper in plastic cup size 109x37mm and retort

pouch. To combine the packaging into one, the two

holes plastic tray was selected. However, we found

that the problem of defect caused by products from

rice. Therefore, it represents the development of

products for packing in two holes plastic trays.

2.2.2 Over Pressure Water Spray Retort

The pilot-scale overpressure retorting FM, Thailand

consisting of retort, boiler, air compressor, centrifugal

pump, and the control system (PLC) was used for

thermal processing. The FMC retort used in the study

is similar to the commercial-scale equipment, which

trays a high degree of process reproducibility and

accuracy. After processing the trays to a required Fₒ

value, they were cooled rapidly to 50 ± 10°C by

spraying water under pressure and further cooled in

chilled water immediately after taking out from the

retort. (Williams, T.S., 2012).

2.2.3 Thermol Process Evaluation

The temperature Microprocessor “ Ellab” Evalflex

was connected through the body of the retort by

copper with constant thin wire leads and scaled into a

pressure tight gland fitted. The 15 leads terminated in

male Ecklund plugs inside the retort for direct

connection to compatible Ecklund stainless steel

sheathed needle copper constant thermocouple,

another terminated side is connected to Temperature

Modules available in 15 channels module (Measuring

Range: -60 ° C …+170 ° C, Measuring Accuracy : +/-

0. 1 ° C) . Heat penetration characteristics of thermal

process of ready to eat rice and fried chicken with

garlic and pepper was determine ( Stowe, C .H .,

Smith, G .L., Thomas, R .L., Whiteside, W .S.,2016).

Figure 3 showed the middle of trays were fixed with

thermal couple. The intention of the temperature

distribution study was to set an appropriate come- up

cycle for the retort in order to achieve an efficient

come- up which may effect the rate of heat transfer

and process lethality during the cooking cycle of the

process. (Tang, F.,,Xia, W.,Xt, Y., Jiang, Q., Zhang,

Q., Zhang, W.,Zhang, L,2014)

2.2.4 Filling and Sealing

Determine the optimum weight for packing the rice

and chicken meat in the two-hole plastic tray

packaging to suit the consumption per 1 serving of

150 grams of rice and fried chicken with garlic and

pepper was at 75 grams. Then weight of heat

penetration was 165 grams of rice and fried chicken

with garlic and pepper was at 95 grams. Total net

weight was 260 grams. Adequate numbers of retort

pouches were fixed with thermocouples and the tip of

the thermocouple was inserted into the rice and

chicken pieces as shown in figure 3. The trays were

sealed with a pneumatic machine (SAMRAK

engineering, Thailand). The sealed tray were

subjected to thermal processing for optimizing the Fₒ

value at process temperature.( Abhishek, V., Kumar,

R., Geroge, J., Nataraju, S., Lakshmana, J. H.,

Kathiravan, T., Madhukar, N. Nadanasabapathi.,

2014).

Figure 1: The size of two holes plastic tray 118x179x40 mm

with layer structure is PP/PP + Additive/Tie

/EVOH/Tie/PP + Additive/PP.

16th AFC 2019 - ASEAN Food Conference

92

Figure 2: Factor affecting of defect from product of rice in

plastic cup.

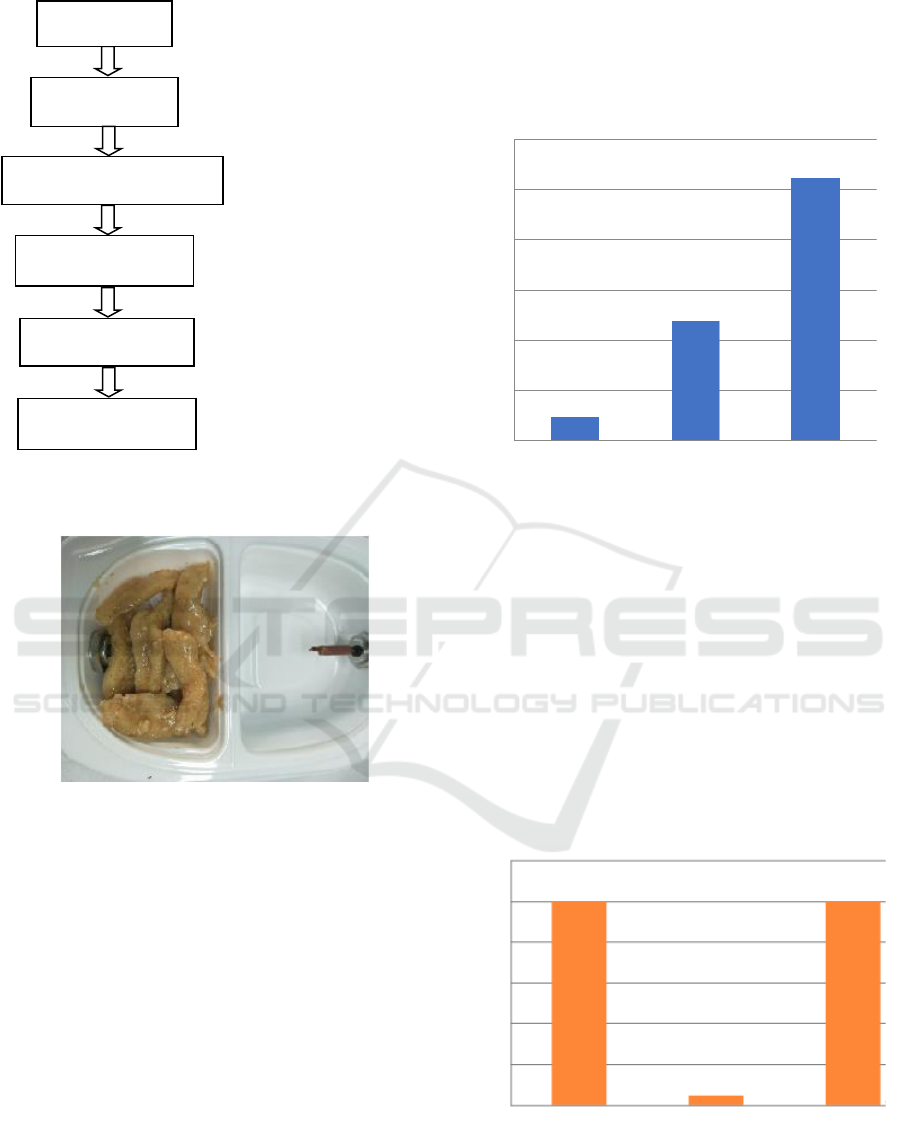

Figure 3: Placed the largest possible pieces of chicken on

the thermocouple.

3 RESULTS AND DISCUSSION

3.1 Head Space

Headspace, the distance between the surface of food

and the underside of the lid, allows for expansion of

food solids or bubbling up of liquid during

processing. Adequate headspace allows a vacuum to

form during the processing of the food. The samples

rice of cup and two holes plastic trays were pressed

for three different headspace to 4/16, 7/16 and 9/16

inches. They placed in retort at 116C for 40 mins at

pressure 1.6 bar and pressure cooling hold at 1 . 6 bar

and reduce temperature from 115°C to 110°C within

2 mins. The results from figure 6 showed the largest

amount of defect was at 9/16 inches of the head space

in two holes plastic tray. The small amount of defect

were found pound in two-hole plastic tray for 4/16

inches.

Figure 4: Effect of head space on defect of two-hole plastic

trays .

3.2 Sealing Temperature

Sealing Process: Proper sealing conditions include

temperature, pressure and sealing time. Figure 5

showed that sealing temperature of two holes plastic

tray at 185C were leak 100% and the other sealing

temperature at 195C were pound 4.5 . %The sealing

temperature at 205C was burn. At present, the plant

used sealing temperature at 195C for two holes

plastic tray by Samrak machine .

Figure 5: Effect of sealing temperature on defect of two-

hole plastic trays.

4/16

7/16

9/16

Head space (inch)

Waste (%)

30

25

20

15

10

5

0

Pre-cooking

Washing precook rice

Filling

Sealing

Retorting

Washing

Head space

Sealing temperature,

Vacuum level,

Delay time of products

Profile retort

185

195

205

Temperature (°C)

Defect (%)

0

20

40

100

60

120

80

Optimizing Process Conditions for Sterilization of Plastic Tray Products in Water Spray Retort

93

3.3 Vacuum Level

Table 1: Effect of different vacuum level on defect of

plastic cup.

Vacuum Level (sec) Sample (cup) Defect (cup)

0.3 90 90 (100%)

0.4 90 18 (20%)

0.5 90 0

The factor vacuum level for products in cup with

three different level were 0 . 3, 0 . 4 and 0.5 sec that

sealed by G.Mondini machine. The result showed on

table 1 that the best vacuum level was 0 . 5 .The

vacuum level affected pound and leak for semi rigid

packaging that were determined for two holes plastic

trays.

3.4 Target Temperature

For thermal process evaluation, filled and sealed cups

and trays were heat processed to the required Fₒ

values. Ellab Eval Flex sixteen Channel Thermal

Validation and Sterilization Monitoring System,

Thermometer and Fₒ value integrator was used to

record core temperature, retort temperature, Fₒ value,

and cook value (CV) at a specific time interval of 60

s. The Fₒ constants were programmed at T = 121.1C,

Z= 10C. Thermocouple outputs ( time- temperature

data) were analysed using a computer. The heat

penetration data were plotted on a semi- log paper

with temperature deficit (retort temperature-cold spot

temperature) on log scale against time. Lag factor for

heating ( J

h

) , slope of the heating curve ( F

h

) , time in

minutes for sterilization at retort temperature (U), and

lag factor for cooling ( Jc) were determined. The

process time was calculated by a mathematical

method. Total process time was determined by

general method and the 58% of the come- up time.

CV, a measure of heat treatment with respect to

texture changes that occur during processing. The

samples process at suitable for Fₒ value were

incubated at 37 for 15 days and at 55C for a

minimum of 5 days). The sample was done according

to AOAC (AOAC,1995).

Table 2 shown the results that the target

temperature at 115C were 100% of pound but the 5%

at vacuum level 0.5 sec at pressure in retort 1.5 bar.

3.5 Profile Cooling

The suitable come up time profile retort was 115C at

1 . 5 bar and the cooling profile was dropped the

Table 2: The effect of vacuum and pressure level during

heating in retort on defect of two-hole plastic tray.

Temp

(C)

Vacuum

level

Pressure

Defect

115

0.5

1.4

leak100%

1.5

Pound5%+normal 95%

1.6

Pound 100%

1.0

1.4

Pound 100%

1.5

Pound 100%

1.6

Pound 100%

1.5

1.4

Pound 100%

1.5

Pound 100%

1.6

Pound 100%

Table 3: Effect of profile cooling on defect of two- hole

plastic tray.

Temperature

step 1 (°C)

Pressure in

retort (bar)

defect

110

1.5

Pound 32 %

1.3

Pound+leak + damage seal

22%

100

1.5

Normal

1.3

Leak42%

90

1.5

Leak 100 %

1.3

Pound+leak + damage seal

16%

temperature from 115°C to 100°C and hold the

pressure at 1.5 bar for 2 mins as shown in Table3.

3.6 Processing Time

Temperature (°C)

Time (min)

Figure 8: Total process time taken to reach the F

0

value of

rice. The ready to eat rice was thermally processed at 4.21

mins. F

0

value for 45 min at 115°C, 1.5 bar in retort.

1 5 9 13 17 21 25 29 33 37 41 45 49 53 57 61 65 69 73 77 81 85 89 93 97 101 105 109

140

120

100

80

60

40

20

CT

RT

F

0

16th AFC 2019 - ASEAN Food Conference

94

Temperature (°C)

Time (min)

Figure 9: Total process time taken to reach the F

0

value of

chicken with garlic and pepper. The ready to eat chicken

with garlic and pepper was thermally processed at 6.26

mins. F

0

value for 45 min at 115°C, 1.5 bar in retort.

Laced the test pouches in the established slowest

heating point in FM retort (DrotZ H, 2012). The retort

was full of dummy trays that 7%solution starch was

contained. The retort temperature up by following the

come up time procedure as per heat distribution study

was 25 mins. The ready to eat rice and fried chicken

with garlic was thermally processed at 4.21 and 6 . 26

F

o value

for 45 mins at 115C, 1.5 bar (Ali A.A, 2006,

Abhishek V, 2014) in retort that showed from figure

8 and 9 .

3.7 Shelf-Life of Products

The changes in the color parameters during thermal

processing of ready to eat rice and fried chicken with

garlic and pepper by hunter lab (L*a*b*) that showed

that all products increase in lightness (L*value) and

yellow color (b*value) (Hunter lab colorimeter)

method Chen,Lu and Lii (1999). Inspection period are

1,2,3,6,9 and 12 months.( Tang, F.,,Xia, W.,Xt, Y.,

Jiang, Q., Zhang, Q., Zhang, W.,Zhang,2014)

The maximum force required to cut the sample

was determined by shear force. The piece of sample

was placed on its side in Texture analyzer ( Texture

Analyzer model CT3, Brookfield, UK) ( R. K.

Majumdar., D. Roy., A. Saha. 2017.) The resut shown

on table 4 and 5.

4 CONCLUSIONS

The optimum process conditions for the products

packed in the two-holes plastic trays were 115°C and

Table 4: Sensory score of ready to eat rice of two holes tray.

Rice

time

(month)

color

Body

texture

Overall

acceptance

0

5.25±0.45

4.51±0.51

4.16±0.57

4.66±0.49

1

5.08±0.51

4.83±0.57

4.66±0.49

4.66±0.49

2

4.75±0.62

4.66±0.49

4.33±0.49

4.75±0.45

3

5.00±0.42

5.41±0.51

4.75±0.45

4.83±0.38

6

4.58±0.51

5.25±0.45

4.75±0.45

5.16±0.57

9

4.28±0.11

5.55±0.53

4.80±0.45

5.06±0.17

12

4.21±0.52

5.36±0.38

4.65±0.15

5.10±0.5

Table 5: Sensory score of ready to eat chicken with garlic

and pepper of two holes tray.

time (month)

color

Texture

Overall

acceptance

0

4.83±0.38

4.58±0.51

5.00±0.42

1

4.58±0.51

4.58±0.51

4.75±0.45

2

4.50±0.52

4.33±0.49

4.58±0.51

3

4.33±0.49

4.00±0.73

4.33±0.49

6

4.13±0.38

4.03±0.38

4.03±0.38

9

3.93±0.11

4.15±0.27

4.22±0.33

12

3.78±0.18

4.00±0.18

4.10±0.28

1.5 bar. The total come up time was 25 minutes and

process time was 45 minutes to achieve the target F

0

value of the products. The cooling period was applied

by holding products at 1.5 bar for 2 mins at

temperature of 100°C. The head space of the product,

rice and fried chicken with garlic and pepper in the

tray should be less than 3/16 inch and 4/16 inch,

respectively. Sealing conditions without leakage of

the two-hole plastic tray product with film were

achieved when spend 0.5 sec to reach the vacuum

condition and sealed at 195°C for 1.3 sec. In addition,

the changes in chemical and sensory characteristics of

the products during storage for 12 months at room

temperature were determined. The acceptable quality

of the products during storage were obtained.

ACKNOWLEDGEMENTS

We would like to thanks Prince of Songkla University

for funding support.

1 6 11 16 21 26 31 36 41 46 51 56 61 66 71 76 81 86 91 101 106

140

120

100

80

60

40

20

CT

RT

F

0

Tim

Optimizing Process Conditions for Sterilization of Plastic Tray Products in Water Spray Retort

95

REFERENCES

Ali, A.A., Sudhir, B., Gopal, T.K.S., 2006. Effect of

rotation on the heat penetration characteristics of

thermally processed tuna in oil in retort pouches.

International Journal of Food Science and Technology

41: 215-219.

AOAC. 1995 . Official Methods of Analysis. 16

ed.Virginia: The Association of Official Agricultural

Chemist.

Abhishek, V., Kumar, R., Geroge, J., Nataraju, S.,

Lakshmana, J. H., Kathiravan, T., Madhukar, N.

Nadanasabapathi, S. 2014 . Development of retort

process for ready-to-eat ) RTE) soy-peas curry as a

meat alternative in multilayer flexible retort pouches.

International Food Research Journal .21)4 :(1153-

1158 .

Drotz, H .2012 .Development of thermal process for Gaeng

Ped Gai in retort pouches .Master thesis Natural

Resources and Agricultural Science.Swedish

University .

Lakshmana, JH., Jayaprahash, C., Kumar R.,

Kumaraswamy, T., Nadanasabapathi, S. 2013.

Development and evaluation of shelf stable retort pouch

processed ready to eat tender jackfruit (Artocarpus

heterophyllus) curry. Journal food process technical 4:

274.

Mokwena, K .K. and Tang, J .2012 .Ethylene vinyl alcohol :

A review of barrier properties for packaging shelf stable

foods .Food Science and Nutrition .52 :640-650 .

R.K. Majumdar., D. Roy., A. Saha. 2017. Textural and

sensory characteristics of retort-processed freshwater

prawn in curry. medium. International Journal of Food

Properties: 2487-2498.

Stowe, C .H . , Smith, G .L., Thomas, R .L . , Whiteside, W .

S .2016 .Effects of packaging geometry on heat

penetration time in retortable semi rigid plastic trays .

International Journal of Advanced Packaging

Technology .4)1 :(246- 257.

Tang, F.,,Xia, W.,Xt, Y., Jiang, Q., Zhang, Q., Zhang,

W.,Zhang, L. Effect of thermal sterilization on the

selected quality attributes of sweet and sour carp. 2014.

International Journal of Food Properties, 17:8, 1828-

1840.

Williams, T.S., 2012. Which retort is best for your container

Retrieved 11 Jan 18 from: http://www.retorts.com/

white-papers/which-retort-is-best-your-container

R.K. Majumdar., D. Roy., A. Saha. 2017. Textural and

sensory characteristics of retort-processed freshwater

prawn (Macrobrachium rosenbergii) in curry medium.

International Journal of Food Properties: 2487-2498.

16th AFC 2019 - ASEAN Food Conference

96