Micro Topography on Tool Steel Processed using Wire Electrical

Discharge Machining

Rifky Maulana Yusron

1

, Dhika Aditya Purnomo

2

Saiful Arif

3

and Rahayu Mekar Bisono

3

1

Department of Mechanical Engineering, University of Trunojoyo Madura,, Bangkalan, Indonesia

2

Department of Design and Manufacture Engineering, Shipbuilding Institute of Polytechnic Surabaya, Surabaya, Indonesia

3

Dept. Mechanical Engineering, Polytechnic State of Malang, Malang, Indonesia

Keywords: Measurement, micro surface topography, open voltage, pulse on-time, surface roughness, Wire-EDM.

Abstract: Wire Electrical Discharge Machining (Wire-EDM) using electrical energy to cutting materials, they penetrate

material not continuously instead penetrate with a specific interval that called as a pulse on time. Open voltage

is a variable to control value of penetrate energy. Material removal rate caused melted and evaporation work

piece material. Flushing by dielectric fluid affected quenching on the surface machined materials. During

Wire-EDM process, re-heating of melted material. Constant quenching and re-heating also caused the craters

to be relatively deep and width on a microscale. That’s craters affected has impact on surface roughness on

macro scale. In Wire-EDM process, surface roughness is important to describe deviation characteristic on

surface of workpiece. A research conducting to observe micro topography by using variable pulse on time

and open voltage, including surface roughness on tool steel surface who has processed using Wire-EDM. This

research using design experiment factorial 3x3. Surface roughness measurement conducting using Mitutoyo

surftest. Surface electron measurement (SEM) used to observe micro topography on workpiece surface. From

this research we can conclude that pulse on-time and open voltage directly proportional to surface roughness

response variable. From this research was achieve lowest surface roughness 1,33 μm on combination pulse

on time 2 µs and open voltage 75V and the highest surface roughness 2,52 μm on combination pulse on time

6 µs and open voltage 105V.

1 INTRODUCTION

Although equipped with advanced technology

conventional machining processes, still insufficient to

process high hardness material and complex contours

which cannot be complete with conventional

machining processes. To solve the problem, the

machining industry is now wide applied non-

conventional machining processes. Wire-EDM

process is one of nonconventional machining who use

electrical energy to produce sparks between anode

and cathode, then convert spark into thermal energy

with temperature about 8.000

o

C to 20.000

o

C

(Kutuzova & Melnik, 2018). Current penetrate from

electrode to workpiece with frequency about 20.000

Hz to melting 30.000 Hz, it made both melting and

evaporating (Jaiswal, Peshwani, Shivakoti, &

Bhattacharya, 2018). During Wire-EDM process,

cutting process not conducted continuously. It come

since pulse on-time phase and stop when it entering

pulse off-time phase (Liu et al., 2017). During Wire-

EDM process, the cutting process not conducted

continuously. It come since pulse on-time phase and

stop when it pulse off-time phase. It might to avoid

wire rupture caused stress during machining process

(Calvo, Daniel, Calvo, & Daniel, 2020).

Wire-EDM applied on industrial since 1950

(Bravo et al., 2018) and has continuous development

technology, the current research has asynchronous

control mode to meet Industrial 4.0 requirement

(Zhou, Jing, Yang, Yao, & He, 2018). It has an ability

to processing mechanical part who require complex

shape, high precision and low surface roughness

(Zhou, Wu, Xu, Mu, & Dou, 2018). There is wide

application of Wire-EDM including aerospace,

nuclear, automotive, tools, jewellery, mould, dies,

and also medical equipment industries (Wälder et al.,

2018). Wire-EDM have a capability to process hard

materials more effective than conventional

machining process, those materials such as titanium,

nimonic alloy, and zirconium. But, Wire-EDM

machining process has their own problems such as

Yusron, R., Purnomo, D., Arif, S. and Bisono, R.

Micro Topography on Tool Steel Processed using Wire Electrical Discharge Machining.

DOI: 10.5220/0010305600003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 165-172

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

165

forming of micro heat affective zone (HAZ), recast

layer, micro-crack, porosity, local hardening or

annealing, grain growth and forming of alloy

incidentally because element transfers phenomena

from wire or dielectric, its might new alloy formed on

recast layer (Soundhar, Zubar, Thariq, Haji, &

Sultan, 2019).

On this research Buderus 2080 tool steel applied

as material specimen. This material has high

resistance against wear, stability on heat treatment. It

wide applied on industrial manufacture, it is common

being material to make deep drawing dice, shearing

blade, broaching tool, sand blasting nozzle, trimming

dies and plastic mould. Buderus 2080 tool steel has

chemical composition Carbon about 1.90-2.00%.

Silicon about 0.20-0.30%. Manganese about 0.25-

0.30% Chromium about 9.80-12.00%. Based on

carbon composition, this material classified as high

carbon steel. High carbon steel is strong but brittle, to

improve mechanical properties by applied heat

treatment such as austenizing, quenching, and

tempering (Jatti, 2018). Tempering can transform

their grain be martensite, then make material not just

hard but also ductile. This process cover the original

material disadvantage (Kou & Han, 2018).

The aim from this research is to observe influence

from parameters pulse on-time and open voltage to

surface roughness and micro topography on Buderus

2080 tool steel using Wire-EDM.

2 METHODS

On this research Wire-EDM using CHMER CW

32GF. Movement direction followed by five axis (x,

y, z, u, and v) Wire diameter holder 0,15–0,30 mm.

Maximum wire cutting 250 mm/second. Table

dimension 600 mm x 400 mm. Before cutting process

using wire EDM, each specimen had heat treatment

to reduce stress and increase hardness. Specimen has

dimension length 200 mm, width 30 mm and depth

15 mm. Specimen cutting began from left side for 10

mm with distance of each specimen about 5 mm.

After all cutting process complete and cutting length

for each experiment has measured, cut material 5mm

perpendicular from first cutting edge.

Aquadestilata applied as dielectric during machining

process. Parameter based on recommendation from

manual book of material. This research runs based on

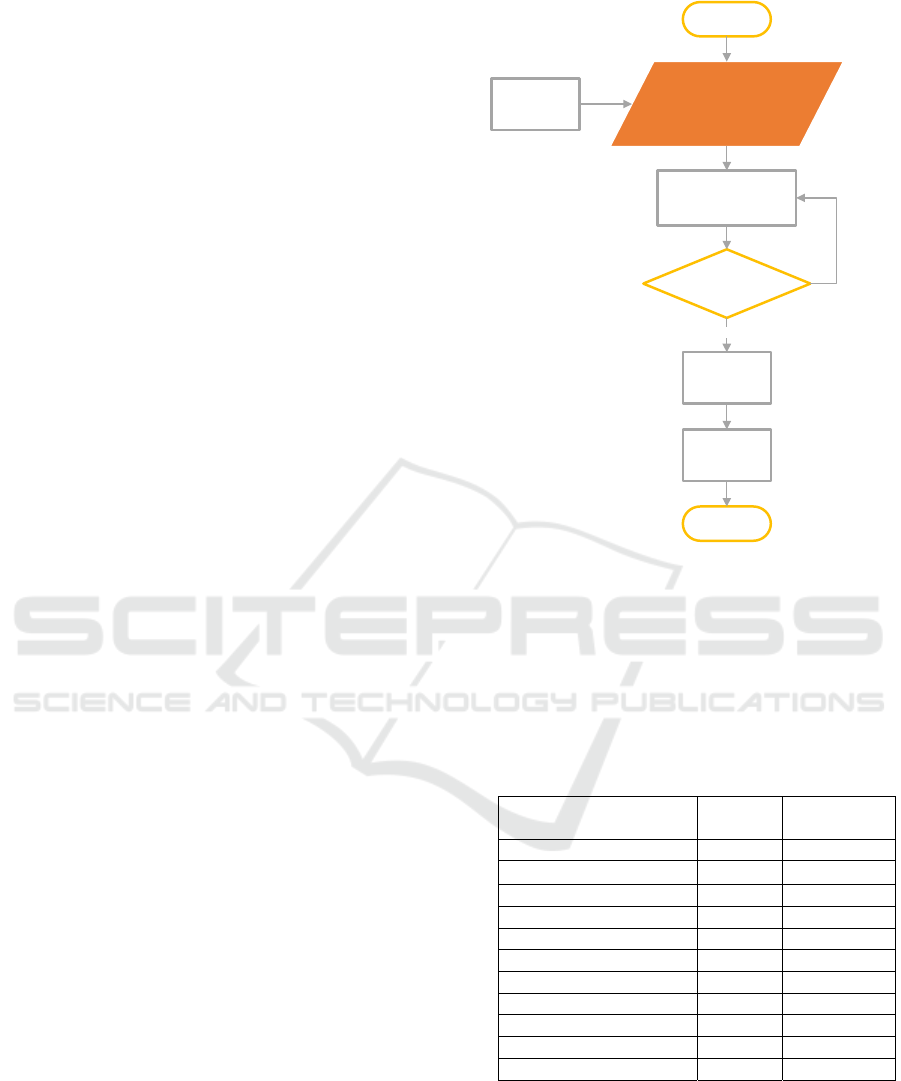

flowchart that shown on Figure 1.

START

Parameter:

pulse on-time 2, 4

and 6 µs

open voltage 75,

85 and 105 V

replicationhas

significantdifferent?

Observinguse

SEM

Yes

Literature

Review

Cuttingmaterial

Buderus2080use Zinc

coatedwire

No

Analyze

END

Figure 1: Research flowchart.

2.1 Material

This research using Buderus 2080 tool steel had heat

treatment before. The Heat treatment process shown

on Table 1. During heat treatment specimen hardness

increased from 55 HRC to 60 HRC.

Table 1: Specimen Heat Treatment Process.

Process Temp

(

o

C)

Time

(minute)

Soft Annealing

Stress Revealing

Preheating 600 45

Preheatin

g

II 850 45

Austenizin

g

960 45

Quench Media -5 Su

d

d

en

Tempering I 180 120

Tempering II 180 120

Tem

p

erin

g

II 180 120

Carburizin

g

Nitro Carburizin

g

Wire electrode using AC CUT VS 900 zinc-

coated brass wire with chemical composition Cu

about 65% and Zn about 35%. Wire tension 880

N/sq.mm. Elongation 2%. Tolerance about ± 0.001

mm.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

166

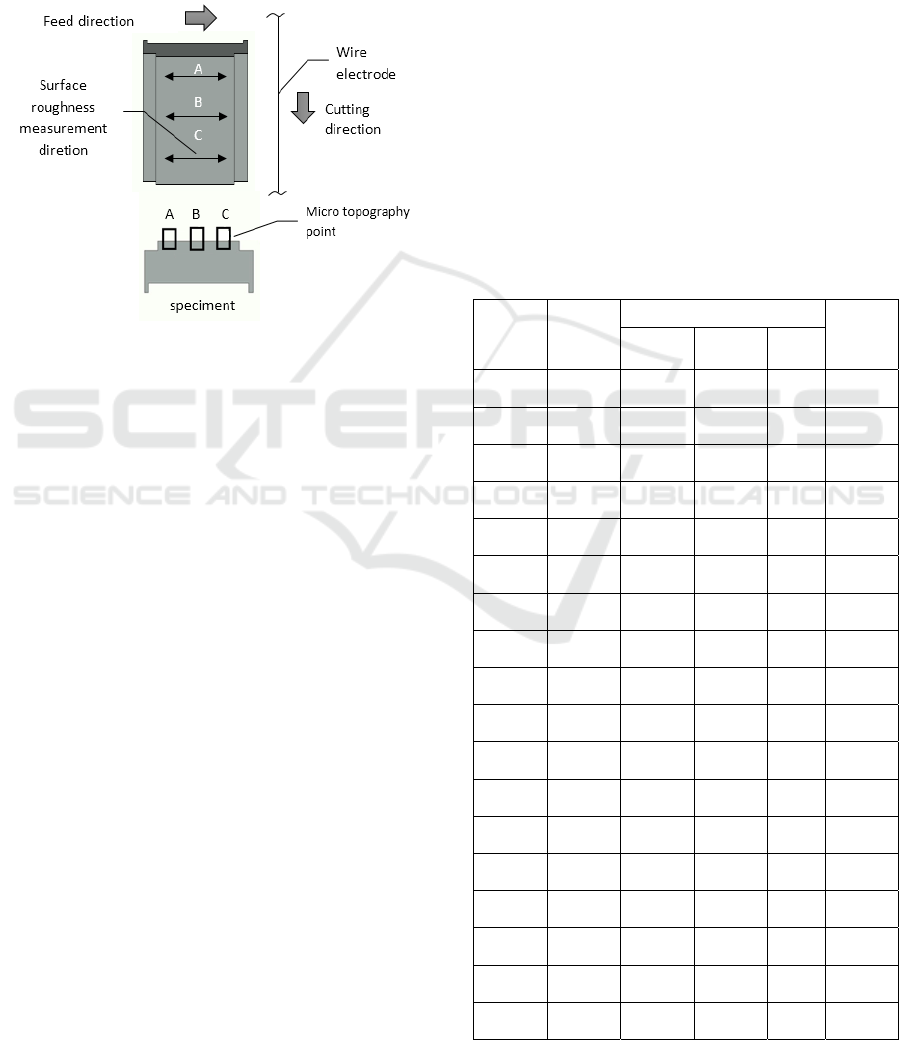

2.2 Measurement

Surface roughness measurement perpendicular to

wire cutting direction on workpiece. Mitutoyo

surftest 301 use to observe surface roughness dan

Scanning Electron Microscope (SEM) using to

observe micro topography on workpiece. Cutting

direction scheme by electrode and direction with

position of surface roughness shown on Figure 2.

Figure 2: Cutting direction scheme and surface roughness

measurement on speciment.

From Figure 2 we can see there is three point of data

collectin fron surface roughness, that collecting data

to observe is there any different surface roughness

value from each points. Image of micro surface

topography captured using 2000x zoom Scanning

Electron Microscope. Potition of micro surface

topography position shown on figure 1 below

showed with black box. This to observe is there any

different from begining, midlle and end of material

cutting.

2.3 Parameters

This research using design experiment factorial 3x3

because there is two process variable, they are pulse

on-time 3 level (2 µs, 4 µs and 6 µs) and open voltage

3 level (75 V, 85 V and 105 V). Constant variable on

this research are:

Low power (10 DCEN)

Arc off time (13 µs)

Feed rate override (9mm/s)

Wire tension (8 g)

Wire feed (10 mm/s)

Water Flow (6 kg/cm

2

)

Feed rate mode (0 servo)

Feed rate (1mm/s)

Arc on time (2 A)

Off time (12 µs)

Servo voltage (50V).

Because with this design experiment we had many

parameters using less materials. This research using

two replications for surface roughness and surface

micro topography on specimens, because we want

make sure there is no significant different in one

parameter. Surface rouhness data collecting using

Mitutoyo Surftest 301.

3 RESULT AND DISCUSSION

The implementation of research conducting with

combination variable pulse on time and open voltage

on wire EDM machining. Both process variable has

significant influence to surface roughness

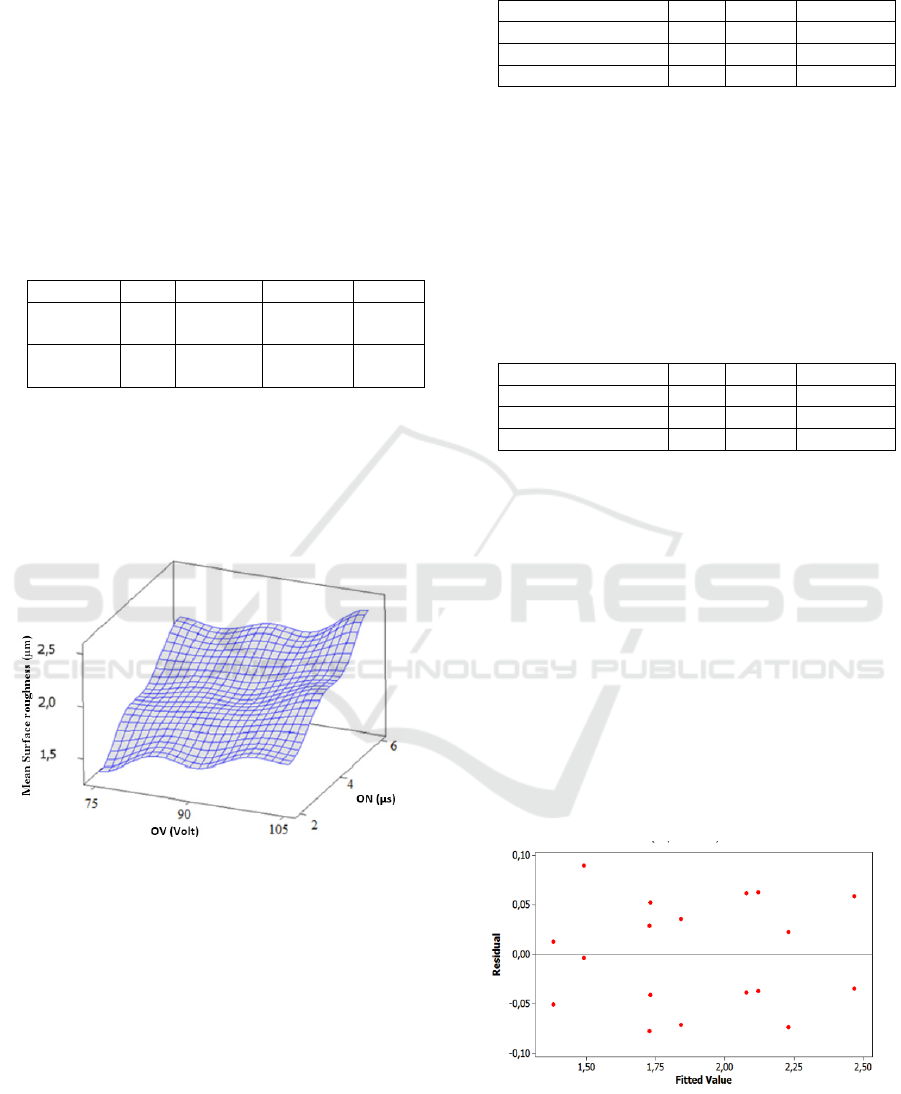

Experiment result based on design experiment

factorial 3x3 shown Table 2.

Table 2: Experimental Data of Surface Roughness.

Pulse on

time

(µs)

Open

voltage

(V)

Surface roughness (µ)

Average

Point A Point B

Point

C

2 75

1,33 1,35 1,31

1,33

2 90

1,47 1,43 1,56

1,48

2 105

1,65 1,63 1,67

1,65

4 75

1,73 1,65 1,69

1,69

4 90

1,91 1,83 1,89

1,87

4 105

2,10 2,03 1,99

2,04

6 75

2,01 2,20 2,04

2,08

6 90

2,28 2,19 2,29

2,25

6 105

2,50 2,49 2,31

2,43

2 75

1,42 1,39 1,37

1,39

2 90

1,42 1,67 1,65

1,58

2 105

1,83 1,71 1,73

1,75

4 75

1,77 1,80 1,78

1,78

4 90

1,78 1,81 1,72

1,77

4 105

2,18 2,04 2,20

2,14

6 75

2,20 2,18 2,17

2,18

6 90

2,12 2,16 2,19

2,15

6 105

2,45 2,61 2,52

2,52

Micro Topography on Tool Steel Processed using Wire Electrical Discharge Machining

167

3.1 Influence Pulse on Time and Open

Voltage to Surface Roughness

Experiment result data statistically tested to

determine which process variable has a significant

effect on the response variable. Analysis of variants

(ANAVA) used to identified is there variables pulse

on-time and open voltage has affected significantly to

surface roughness response. Variable pulse on-time

and open voltage have significant inluence to surface

roughness response shown on Table 3.

Table 3: Result from Table ANAVA.

Source DF SS MS F

Pulse on

time

2 1,64431 0,82216 68,98

Open

Voltage

2 0,37788 0,18894 14,62

From Tabel 2 determined there is pulse on time

factor have significant influence to seuface roughness

on speciment, this value 68,98 % if comparing with

open voltage 14.62%. Surface plot for each variable

shown on Figure 2. Statistically pulse on time is a

dominant variable.

Figure 3: Surface plot ANAVA from each variable.

From surface plot on figure 2 shown incresing in

pulse on-time variable and open voltage will

increaing surface roughness value.

Beside ANAVA test we conducted Tukey Test, it

to determine level from each variable Pulse on Time

and Open Voltage who influence to surface

roughness. Table 4 show result from Tukey test on

Pulse on Time variable.

Table 4: Result from Table ANAVA.

Pulse on Time

(μ

s

)

N Mean Grou

p

in

g

66 2,3 A

46 1,9 B

26 1,5 C

Result of Tukey test on table 4 show different

result of surface roughness from pulse on time

parameters are different. The lowest mean value (1,5)

on pulse on time 2 μs and highest mean value (2,3) on

pulse on time 6 μs. Statically increasing on pulse on

time will affected on surface roughness. Based on this

test we can conclude pulse on time variable is directly

proportional to surface roughness. Tabel 5 show

result from Tukey test on Open Voltage Variable.

Table 4: Result from Table ANAVA.

O

p

en Volta

g

e

(

V

)

N Mean Grou

p

in

g

105 6 2,1 A

90 6 1,9 B

75 6 1,7 C

Like Table 4 result of Tukey test on table 5 show

different result of surface roughness from Open

Voltage parameters are different. The lowest mean

value (1,5) on Open Voltage 75V and highest mean

value (2,1) on Open Voltage 105 V. Statically

increasing open voltage will affected on surface

roughness. Based on this test we can conclude pulse

on time variable is directly proportional to surface

roughness, but Pulse on Time has more significant

volume than Open Voltage. It shows that result of

surface roughness is different at the three different

Open Voltage levels. Analysis of variance requires

that the residuals must meet three assumptions;

identical, independent and normality distributed with

zero mean with a certain variance.

Result of identical test show on figure 4

Figure 4: identical test diagram.

Figure 4 shows that the residuals (marked with re

dots) are randomly distributed around the zero line

and not form a specific pattern. Thus the identical

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

168

residual assumption is fulfilled. this shows that all

data are different

Independent test on this research conducted using

auto correlation function (ACF). Based on ACF show

on figure 5, there is nothing ACF value lag out from

interval. This proves that there is no correlation

between residuals, meaning that the residuals are

independent.

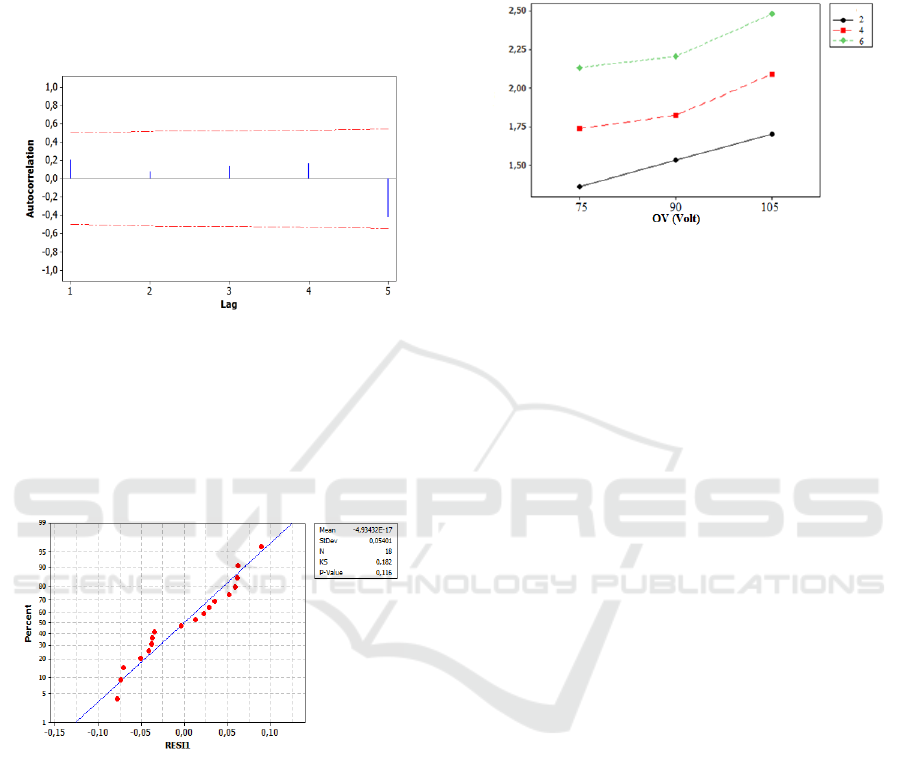

Figure 5: Plot ACF on surface roughness respons.

Residual normality test residual conducted using

Kolmogorov-Smirnov test. Hipotesis that applied are:

H

0

: Residuals are normally distributed

H

1

: Residuals are not normally distributed

H

0

rejected if p-value less than α = 0,05. Result of

normality test show on Figure 6.

Figure 6: Plot of normality distribution test on surface

rouhness response.

From Kolmogorov-Smirnov test conclude:

p-value 0,116 it mean bigger than α = 0,05.

Therefore, it can be concluded that H

0

failed to

be rejected or that residuals were normally

distributed.

Mean value about -4,9343x10-17 it mean very

small and close to zero.

Variance on residual is about (0,182)2 =

0,03312

Thus the assumption of a normally distributed

residual with a mean value equal to zero (or close to

zero) and having a certain variation (amounting to

0.03312) has been fulfilled. Graphically, the

relationship between the Pulse on Time and Open

Voltage factors in the Wire EDM machining process

to the surface roughness response is shown in Figure

7.

Figure 7: Plot graphic influence factor Pulse on Time and

Open Voltage to surface roughness.

A fter passing, identical, independent and

normality test. It can be concluded that the pulse on

time and open voltage have an influence on the

surface roughness statistically. phenomena can be

explained that high pulse on-time lead to consequence

a phenomena called “double sparkling” and higher

local spark, it confirmed by another research (Nur,

Muas, & Risal, 2019) (Dabade & Karidkar, 2016).

Double sparkling come while high pulse on time, it

might produce higher frequency of spark. That spark

penetrates to work piece then followed with next

spark briefly. a higher pulse on-time make frequency

of thermal energy who transferred on work piece get

higher (Degenhardt, Stief, Dantan, Etienne, & Siadat,

2018). It leads to heat transfer from out surface of

workpiece to next layer (Klocke, Welschof, Herrig, &

Klink, 2018). That heat transfer conducted deeper,

then more work piece will erode. Work piece erode

randomly on a length cutting area, there deviates from

linear reference. If deviation got higher, it will have

affected on surface roughness value. Double

sparkling phenomena appear on pulse on time 4 µs

and 6 µs. High open voltage parameter causes a

voltage between work piece and wire electrode be

higher. Voltage bring out to a discharge. High

discharge energy, followed by increasing thermal

energy transferred to work piece. That will erode

work piece and lead to material removal. On micro

scale it brings out a crater on surface of work piece.

Increasing of thermal energy who transferred from

workpiece forming deeper crater (Özerkan, 2018)

(Marelli, Singh, Nagari, & Subbiah, 2020).

Micro Topography on Tool Steel Processed using Wire Electrical Discharge Machining

169

3.2 Micro Surfae Topography on Work

Piece

Globule is a part of molten metal, it spotted on surface

of work piece randomly. Globule formed by trap gas

and stack up on material and quenched by dielectric

during machining (Kou & Han, 2018). Pockmark

formed by erosion material during machining, then

turn out concavity profile like crater on surface of

workpiece. During machining process there current

between wire electrode and materials, it leads to

spark. That spark penetrates on workpiece, then

performed craters on workpiece. Debris is part from

workpiece and spreads eroded during machining

process. Bouncing out Material and re-attaching from

workpiece because laminar wave performed by

electrode flushing (Jagtap, 2018). Figure 8 to 10 is

image result processing using SEM with 2000x.

Figure 8: Micro surfaec topography on workpiece with

combination parameters 2µs and open voltage 105 V.

Figure 8 shown micro-topography performed by

pulse on-time 2 µs and open voltage 105 V, from this

combination formed rare pockmark, but have large

diameter pockmark. Current from discharge erode

work piece during machining process. Diameter size

of pockmark and current are directly proportional, it

means the highest current lead to a large diameter of

pockmark. On this combination founded a few

globules.

Figure 8 show pockmark and crater spotting rare

and with small diameter comparing from figure 4. On

this figure show surface micro-topography on

workpiece combination parameters 6µs and open

voltage 105 V. Observing on figure show surface

from work piece covered by pockmark as long as

surface of material, but with small diameter

pockmark. Many globules formed and concentrate in

specific area. There is much crater formed on material

surface on this combination. Surface of workpiece

spotting debris. Much pockmark and spread on

surface of materials phenomena, caused by high pulse

on-time on this combination. As a consequences

spark penetrate to materials with high frequency, then

more material eroded. Open voltage and discharge are

directly proportional. Low discharge makes penetrate

on material shallow, then forming low depth of

pockmark. By and large that open voltage is a

variable that influencing size of pockmark, pulse on-

time is variable influencing number of pockmarks.

Figure 9: Micro surface topography on workpiece with

combination parameters pulse on-time 2 µs and open

voltage 75 V.

Figure 9 show that pockmark covered major

surface of material and have big size comparing to

figure 8. From this image visibly large diameter crater

formed.

Figure 10: Micro surfaec topography on workpiece with

combination parameters pulse on-time 2 µs and open

voltage 75 V.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

170

Figure 10 shown surface micro topography with

6000 x zoom from variable pulse on time 6us and

open voltage 105V, visible presence of micro-crack

on surface. It impact of double spark, it make spark

penetrate twice simultaneously, followed by flushing.

These event like quenching. From this image deep

crater visible.

Figure 11: Micro crack visible on 6000x scale.

4 CONCLUSIONS

On wire-EDM machining, variable pulse on-time set

frequency from cutting phase. Open voltage variable

set value energy consumption during cutting process.

On micro scale high pulse on-time increasing number

of pockmark and crater, high open voltage increasing

size of pockmark and crater. Number and size of

pockmark and crate influencing surface micro

topography on work piece. Profile of micro

topography influencing surface roughness of work

piece on macro scale. Surface roughness parameters

are widely used to identify surface characteristics.

Because the surface roughness value is more sensitive

detecting changes that occur in machining process.

Thus, if there are signs of increasing surface

roughness then quick taking prevention. The results

of statistical analysis of experimental data show that

surface roughness increases with increasing Pulse on

Time then Open Voltage value.

ACKNOWLEDGEMENTS

Authors wishing to acknowledge to DIPA Faculty of

Engineering University of Trunojoyo Madura 2020 to

fouding this article publication.

REFERENCES

Bravo, H., Ayesta, I., Sanchez, J. A., Zamakona, I.,

Izquierdo, B., Flaño, O., & Campo, J., 2018. Study of

interpolation strategies to dress electrodes by means of

EDM. Procedia CIRP, 68(April), 393–398.

https://doi.org/10.1016/j.procir.2017.12.101

Calvo, R., Daniel, M., Calvo, R., & Daniel, M., 2020.

ScienceDirect ScienceDirect ScienceDirect Wire

electrical discharge machining ( EDM ) setup

parameters influence in functional surface roughness

Wire electrical discharge machining ( EDM ) setup

parameters influence in functional surface roughness 8

th Ma. Procedia Manufacturing, 41, 602–609.

https://doi.org/10.1016/j.promfg.2019.09.048

Dabade, U. A., & Karidkar, S. S., 2016. Analysis of

Response Variables in WEDM of Inconel 718 Using

Taguchi Technique. Procedia CIRP, 41, 886–891.

https://doi.org/10.1016/j.procir.2016.01.026

Degenhardt, U., Stief, P., Dantan, J., Etienne, A., & Siadat,

A., 2018. ScienceDirect ScienceDirect ScienceDirect

Investigation on Wire-EDM Finishing of Titanium

Nitride Doped Investigation Wire-EDM Finishing of

Titanium Nitride Doped Silicon Nitride in CH-based

Dielectrics Silicon Nitride in CH-based Dielectrics A

new method. Procedia CIRP, 77(Hpc), 650–653.

https://doi.org/10.1016/j.procir.2018.08.185

Jagtap, S., 2018. ScienceDirect ScienceDirect

ScienceDirect Optimization of Micro EDM Drilling

Process Parameters for Optimization of Micro EDM

Drilling Process Parameters for Titanium Alloy by

Rotating Electrode Titanium Alloy by Rotating models

for capacity optimization . Procedia Manufacturing,

20, 119–126.

https://doi.org/10.1016/j.promfg.2018.02.017

Jaiswal, A., Peshwani, B., Shivakoti, I., & Bhattacharya, A.,

2018. Multi response Optimization of Wire EDM

Process Parameters. IOP Conference Series: Materials

Science and Engineering, 377(1).

https://doi.org/10.1088/1757-899X/377/1/012221

Jatti, V. S., 2018. Multi-characteristics optimization in

EDM of NiTi alloy, NiCu alloy and BeCu alloy using

Taguchi’s approach and utility concept. Alexandria

Engineering Journal, 57(4), 2807–2817.

https://doi.org/10.1016/j.aej.2017.11.004

Klocke, F., Welschof, L., Herrig, T., & Klink, A., 2018.

ScienceDirect ScienceDirect ScienceDirect Evaluation

of Contemporary Wire EDM for the Manufacture of

Highly of Loaded Titanium Wire Parts EDM for Space

Applications Evaluation Contemporary for the

Manufacture of Highly Loaded Titanium Parts for

Space Appl. Procedia Manufacturing, 18, 146–151.

https://doi.org/10.1016/j.promfg.2018.11.019

Kou, Z., & Han, F., 2018. Machining mechanisms and

characteristics of moving electric arcs in high- speed

EDM milling. Procedia CIRP, 68(April), 286–291.

https://doi.org/10.1016/j.procir.2017.12.075

Kutuzova, T., & Melnik, M., 2018. Market basket analysis

of heterogeneous data sources for recommendation

Micro Topography on Tool Steel Processed using Wire Electrical Discharge Machining

171

system improvement. Procedia Computer Science, 136,

246–254. https://doi.org/10.1016/j.procs.2018.08.263

Liu, Y., Qu, Y., Zhang, W., Ma, F., Sha, Z., Wang, Y., …

Zhang, S., 2017. The Effect of High Frequency Pulse

on the Discharge Probability in Micro EDM. IOP

Conference Series: Materials Science and Engineering,

281(1), 0–7. https://doi.org/10.1088/1757-

899X/281/1/012031

Marelli, D., Singh, S. K., Nagari, S., & Subbiah, R., 2020.

Optimisation of machining parameters of wire-cut

EDM on super alloy materials–A review. Materials

Today: Proceedings.

https://doi.org/https://doi.org/10.1016/j.matpr.2020.01.

306

Nur, R., Muas, M., & Risal, S., 2019. Effect of Current and

Wire Speed on Surface Roughness in the manufacturing

of Straight Gear using Wire-cut EDM Process Effect of

Current and Wire Speed on Surface Roughness in the

manufacturing of Straight Gear using Wire-cut EDM

Process. https://doi.org/10.1088/1757-

899X/619/1/012002

Özerkan, H. B., 2018. Effect of electrode polarity on fatigue

life in EDM. MATEC Web of Conferences, 224.

https://doi.org/10.1051/matecconf/201822401107

Soundhar, A., Zubar, H. A., Thariq, M., Haji, B., & Sultan,

H., 2019. Data in Brief Dataset on optimization of EDM

machining parameters by using central composite

design. Data in Brief, 23, 103671.

https://doi.org/10.1016/j.dib.2019.01.019

Srinivas, D., & Madhu, S., 2018. Performance Analysis of

Removal Rate of Material and Roughness of a Surface

by Electric Discharge in Wirecut Machine on En-19a

Material. IOP Conference Series: Materials Science

and Engineering, 455(1). https://doi.org/10.1088/1757-

899X/455/1/012095

Wälder, G., Fulliquet, D., Foukia, N., Jaquenod, F., Lauria,

M., Rozsnyo, R., … Perez, R., 2018. Smart Wire EDM

machine. Procedia CIRP, 68(April), 109–114.

https://doi.org/10.1016/j.procir.2017.12.032

Zhou, M., Jing, H., Yang, J., Yao, S., & He, L., 2018. An

extended adaptive control system for EDM. Procedia

CIRP, 68(April), 672–677.

https://doi.org/10.1016/j.procir.2017.12.152

Zhou, M., Wu, J., Xu, X., Mu, X., & Dou, Y., 2018.

Significant improvements of electrical discharge

machining performance by step-by-step updated

adaptive control laws. Mechanical Systems and Signal

Processing, 101, 480–497.

https://doi.org/10.1016/j.ymssp.2017.06.041

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

172