Cloud Manufacturing: An Approach to Strengthen

Global Competitiveness of the Indonesian Small and Medium

Manufacturing Enterprises

Khamdi Mubarok and Mahrus Khoirul Umami

Department of Mechanical Engineering, University of Trunojoyo Madura, Bangkalan, Indonesia

Keywords: Industry 4.0, Making Indonesia 4.0, Small and Medium Manufacturing Enterprises, E-Smart IKM, Cloud

Manufacturing

Abstract: The World is moving into a new industrial revolution era and new industrial competition. Driven by the

advanced development of computer science and information and communication technologies (ICT), the

German strategic initiative Industry 4.0 has triggered many countries to establish their national strategies.

Responding to this trend, the Indonesian government launched “Making Indonesia 4.0” as a roadmap to

strengthen industrial competitiveness. Focusing on small and medium manufacturing enterprises (SMMEs)

or IKM, the Ministry of Industry released E-Smart IKM to help them improve their productivity and expand

their market. However, these initiatives paid less attention to the collaboration worth among companies. In

order to build a close relationship and strong collaboration among SMMEs, cloud manufacturing concept is

adopted in this research. By utilizing the Internet of things (IoT), service-oriented architecture (SOA)

technologies and cloud computing technologies, a cloud manufacturing platform for the Indonesian SMMEs

is developed. First, Making Indonesia 4.0 initiative and E-Smart program as the background of this research

are observed. Second, cloud manufacturing definition and basic concept are discussed. Finally, three

supporting conditions for the adoption of cloud manufacturing and nine implementation strategies for the

Indonesian context are proposed. The initial work of this implementation is also presented.

1 INTRODUCTION

Industry 4.0 (or Industrie 4.0) refers to the fourth

industrial revolution in which manufacturing

industries will be occupied by intelligent machines

and products to create intelligent systems and

networks which can communicate each other

autonomously (Oztemel and Gursev, 2020). This

concept was first introduced by National Academy

of Science and Engineering (Acatech) Germany at

Hannover Messe trade fair in 2011 as the strategic

initiative to secure Germany position as the world

leader in manufacturing industries (Kagermann et.

al., 2013). Industry 4.0 can be seen as a collection of

emerging information and communication

technologies (ICT) that drive future manufacturing.

Those technologies include Internet of Things (IoT),

cloud computing (CC), big data and analytics

(BDA), system integration, advanced robotics,

additive manufacturing or 3D printing, augmented

reality (including virtual reality and mixed reality),

advanced simulation, knowledge graph, blockchain,

digital twin, and cyber secrity (Mubarok, 2020).

Initiated from the manufacturing domain, the

application of Industry 4.0 technologies gain more

and more attention from both industry experts and

academic researchers. Those technologies have to

improve manufacturing life cycle processes in the

most suitable areas of application (Zheng et al.,

2020). Additive manufacturing is one of the newly

technologies taking fast advantages in this new era

enabling rapid product development by utilizing IoT

technologies (Wang et al., 2019).

Similar to Industry 4.0, General Electric and

other leading industries in the United States also

introduced the concept of Industrial Internet, putting

intelligent machines, advanced analytics and

connected people as the key elements of future

manufacturing (Evans and Annunziata, 2012). Other

countries also develop their unique strategies for

future manufacturing competition. Made in Sweden

2030 (Ersson and Sagström, 2013), Smart Industry –

Dutch Industry fit for the future (FME, 2014) and

Mubarok, K. and Umami, M.

Cloud Manufacturing: An Approach to Strengthen Global Competitiveness of the Indonesian Small and Medium Manufacturing Enterprises.

DOI: 10.5220/0010305900003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 185-192

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

185

Made in China 2025 (Liu, 2016) are some of the

examples.

Following this trend, on April 4th, 2018, the

government of Indonesia launched “Making

Indonesia 4.0” (Kemenperin, 2018a) as a roadmap

for guiding the reinforcement programs to boost

national industries globally. This is the way how

Indonesia revitalize the manufacturing sector to

achieve the vision to be among the tenth largest

world economy in 2030. Another initiative, focusing

on IKM or small and medium manufacturing

industries (SMMEs), the Indonesian Ministry of

Industry also created a digital technology project

called “E-Smart IKM” (Kemenperin, 2017). E-Smart

IKM is a government exertion to SMMEs to enter

online marketplace so that their product can reach

global markets.

Both initiatives, however, still lack focus on

strengthening the relationship and collaboration

between industries or among similar industries. Even

though those similar industries have been placed in

certain location forming an industrial cluster, the

collaboration between those industries is still very

low. As a result, they only able to undertake a small

project individually. They are incapable of

accomplishing big projects. Close collaboration

between those industries will allow them to

overcome this challenge. Based on this conditions, a

close collaboration network program applying a new

manufacturing paradigm called cloud manufacturing

(CMfg) is proposed. Cloud manufacturing platform

enable diverse industries to access and use

manufacturing resources from a pool of resources

provided by other companies (Ghami et al., 2019).

This approach will enable SMMEs to build a close

collaboration with other companies to carry big

projects together and enhance their global

competitiveness.

To enable on-demand access, manufacturing

equipment need to be connected to the Internet and

provide required data analytics tools as to assess

their capabilities and availabilities (Lu and Xu,

2019). These technologies will benefit Small and

Medium Sized Enterprises (SMEs) in term of

competitive advantage, flexibility, efficiency, and

quality. However, most of the SMEs have financial

and knowledge constaints to adopt those typical

Industry 4.0 technologies (Masood and Sonntag,

2020). Therefore, before integrate modern and smart

manufacturing equipment, SMEs are required to

analyze technological, organizational, and

environmental determinants of digital technology

adoption and implementation (Ghobakhloo and

Ching, 2019). In addition, other critical factors

comprised in this implementation are the support

and involvement of SME managers, training support

from expertise and academic researchers, also the

collaboration among SMEs in the industrial network

(Moeuf et al., 2020).

The main objective of this paper is to develop a

cloud manufacturing platform for Indonesian

SMMEs based on their typical characteristics. The

rest of this paper is organized as follow. Section II

highlights the new Indonesian government initiative

“Making Indonesia 4.0” and “E-Smart IKM”

program scheme as the background of this research.

Section III discusses the basic concept of cloud

manufacturing and its suitability for Indonesian

context. Section IV describes the adoption process

and the implementation strategy. Finally, Section V

concludes the paper and define future work.

2 MAKING INDONESIA 4.0 AND

E-SMART IKM

This section describes Making Indonesia 4.0, the

Indonesian national strategy to compete in today’s

global market, and “E-Smart IKM’ project.

Following that, we identify some beneficial factors

as well as some drawbacks of government programs.

2.1 Making Indonesia 4.0

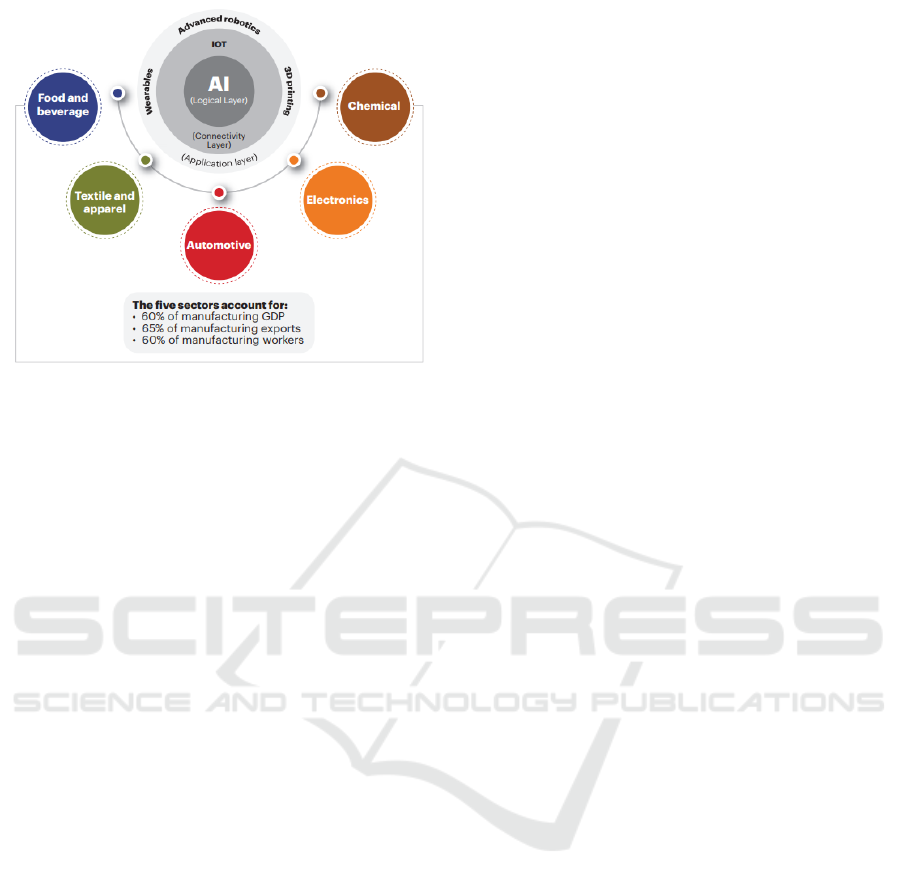

The main contents of Making Indonesia 4.0 roadmap

are five industrial sectors as the pillars and ten

national development priorities (Kemenperin,

2018a). Based on the real condition of the

Indonesian manufacturing environment, the Ministry

of Industry has selected five leading industries that

have enormous potential to be expanded globally.

Those leading industries are the main strength of

future Indonesian manufacturing. Those five sectors

are food and beverage, textile and apparel,

automotive, electronics and chemical. Figure 1

shows the five industry pillars and the main enabling

technologies such as artificial intelligence (AI), IoT,

wearables, advanced robotics and 3D printing.

However, other Industry 4.0 technologies as

mentioned on the first section will also be utilized.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

186

Figure 1: Five main industrial sectors (Kemenperin,

2018a)

Based on the study of the obstacle factors to the

development of manufacturing industries in

Indonesia, the government has placed ten national

priorities that urgently required to faster industrial

growth. Those ten priorities are fixing material

supply chain, redesigning industrial zone,

accommodating sustainability standards,

empowering SMEs, building national digital

infrastructure, attracting foreign investments,

improving human resource skills, forming

innovation-based ecosystems, offering incentives for

technological investments, and harmonization of

rules and policies (Kemenperin, 2018a). In this

research, the empowering SMEs (SMMEs) and

redesigning industrial zone or industrial cluster are

highlighted. Re-design industrial cluster can be

referred to re-managing industries within a cluster

for close collaboration.

2.2 E-Smart IKM Project

E-Smart IKM is a Ministry of Industry project to

improve the productivity of small and medium-sized

enterprises by introducing digital technology. The

government encourages SMMEs to trade their

products through the online marketplace on the

Internet that the government has created or

collaborated. Within this project, the government

also offer help and support on capital investment,

process and product standardization, intellectual

property right, raw material access, human resource

development, etc. This Internet-based project is a

good start. To this end, many SMMEs have joined

and experienced the benefits. To further improve

their global competitiveness, this project can be

improved further by building cloud manufacturing

platform to support collaboration.

Another government scheme to support SMMEs

is the industrial machinery restructuration project

that has been run since 2009. In this project, the

Ministry of Industry reimburses 25-30% of the total

money a company spent on purchasing new

machines or equipment (Kemenperin, 2018b).

Although this project can augment SMMEs

production capability, enlarge their production

capacity, and improve their competitiveness, this

project is less effective. This is because only the

companies which receive the grant can take benefits.

Other industries still suffer from their restricted

capability. Therefore, it is necessary for the

government to review this scheme as to have more

companies take benefits. Cloud manufacturing

approach holds this potential to share the use of

machines or equipment in a community or public-

based. On the other way, the Ministry of Industry

can manage under cloud manufacturing platform in

which machinery and equipment in one company

can be accessed by other companies. As a result,

many companies will benefit from access to that

machinery and equipment. This will be more

effective and efficient to improve global

competitiveness for many SMMEs.

3 CLOUD MANUFACTURING

Cloud manufacturing is a collaborative

manufacturing concept based on cloud computing

technology and service-oriented architecure (Li et

al., 2010). Hundreds of papers have been published

on this topic. In addition, several research projects in

Europe and China have also toughened the

foundation of this concept. However, the real

implementation of this concept still scarce.

3.1 Definition and Basic Concept

Cloud manufacturing is a cloud computing

application in manufacturing. Before cloud

computing technology introduced, software installer

was provided on compact disc (CD). Also, files were

stored on PC hard disk which holds a certain

capacity. Since cloud computing is introduced,

software installer, storage, and other services are

available in the cloud which can be accessed from

everywhere as long as internet connection are

available. Similarly, in cloud manufacturing,

machines, robots, and other manufacturing facilities

Cloud Manufacturing: An Approach to Strengthen Global Competitiveness of the Indonesian Small and Medium Manufacturing Enterprises

187

are virtualized and offered as a service that can be

accessed or used by anyone (cloud users).

One of the formal definition of cloud

manufacturing is mirroring the definition of cloud

computing. Cloud manufacturing is ‘‘a model for

enabling ubiquitous, convenient, on-demand

network access to a shared pool of configurable

manufacturing resources (e.g., manufacturing

software tools, manufacturing equipment, and

manufacturing capabilities) that can be rapidly

provisioned and released with minimal management

effort or service provider interaction.’’(Xu, 2012).

In cloud manufacturing, companies that have idle

resources, such as machines, equipment, and other

manufacturing facilities register their virtualized

resources in the cloud via cloud operator and offer

them as services. This means other companies can

access and use their resources on “pay as you go”

bases. The benefit of this concept, among other

benefits, is the users do not need to purchase

resources. They can use other companies’ resources

(cloud providers) and pay based on how long they

use those resources.

The other benefit of cloud manufacturing is

shortened time to market. A company which receive

high demand but its facilities incapable of doing so,

then this company must find other companies which

have similar facilities. Traditionally, an industry

catalogue or normal online search engine will be

used as a reference to discover dedicated companies.

However, this way is time-consuming, and it is

difficult to find the exact machines or equipment

needed. Cloud manufacturing platform will

eliminate this process and directly provide options

on lower facility level such as machines and

equipment. It can search available resources on its

system. To illustrate the cloud manufacturing

process, Figure 2 shows how cloud manufacturing

principle work. In general, a customer or cloud user

has the design of a product in CAD file. By

submitting this CAD file into cloud manufacturing

platform, which in this case illustrated as Google

search, the system will pop up different machines

that can process their product can be found. For

simplicity, this process is similar to Google search

engine when searching for a specific sentence. In

cloud manufacturing, a typical search engine is

developed. So, by inserting a CAD file into a cloud

manufacturing platform, a cloud user can find a

number of machines that capable to process the

product as required on CAD file. Then, this cloud

user can select the best machine based on machine

specification, price per hour, geographical location,

availability status (scheduling), etc.

Figure 2: Cloud manufacturing process illustration

There are different topics to realize this concept,

such as manufacturing resource virtualization,

service selection, service composition, scheduling,

pricing strategies, and so on. Despite the limited

implementation of cloud manufacturing concept, the

development of cloud manufacturing

implementation for the Indonesian SMMEs will be a

good example for other countries. The complexity of

the system, the technology enablers, and industrial

awareness are some of the challenges. Other factors

influence this implementation also include the

typical manufacturing companies, geographical

conditions, government policy, etc. Based on the

conditions of the Indonesian SMMEs, we propose

Industry 4.0 implementation for small and medium

manufacturing enterprises for Indonesia context,

which focuses on cloud manufacturing technologies.

3.2 Business Process

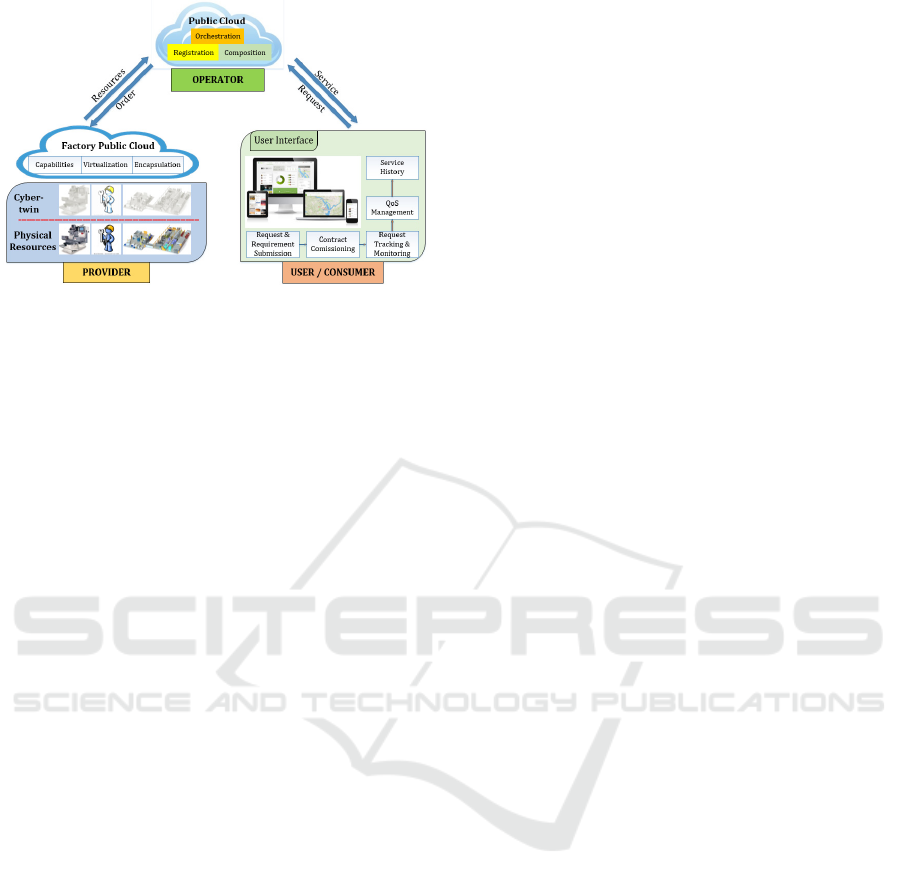

Figure 3 below shows the cloud manufacturing

participants and business process. Ideally, machines

and equipment are connected to the internet and

available to be accessed for real-time monitoring and

responsiveness. Data are gathered through intelligent

devices (sensors, cameras, RFIDs, smartphones,

wearable) and stored in the cloud. The cloud can be

accessed privately for internal purposes or open to

public for data sharing with other business partners.

Big data analytic helps smart factories to analyse the

data and to derive useful information for certain

decision-making purposes.

In cloud manufacturing, there are three main

participants, i.e. service providers, a cloud operator,

and cloud users/consumers, either individual entity

or business organization.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

188

Figure 3: Cloud manufacturing business process

First, companies which have manufacturing

resources will participate as service providers.

Machines, equipment and other devices on physical

resources are virtualized. In advanced version, these

virtual machines produce data. To keep internal data

safe and secure, data are saved in the factory private

cloud. Only data related to resources for sharing are

uploaded via factory public cloud. Service providers

virtualize resources and provide manufacturing

resources information database to be uploaded to the

cloud. This database consists of physical

manufacturing resources, such as machine tools,

cutting tools, materials, etc., and their manufacturing

capabilities. Then, those data are virtualized and

connected to the internet for ubiquitous access. IoT

sensing provides real-time resource monitoring

showing availability status of each resource.

Second, the cloud operator. Cloud operator is

responsible for taking control of the whole service

activities, such as service registration, orchestration,

and composition. The main role of the cloud

operator is to find matching user requests with

suitable resources. Then, offer the list of matching

resources for users to select based on their

requirements. The operator also manages to provide

the best service to users and providers. In addition,

the operator also concerns with cybersecurity issue

in a cloud environment to protect intellectual

property (IP) of the requests (products) and other

private data. Dealing with faulty in some extent also

need operator attention.

Third, cloud users or cloud consumers. Users

submit their request, such as product data, and select

the best resources from the list of matching

resources provided by the operator. They will be

given access to track and monitor the request status

in real-time based. Any feedback for both operator

and provider are submitted to measure the quality of

service.

The overall processes is developed based on a

knowledge-based system to determine

manufacturing related decision making as well as to

optimize the systems. All data and events, in the

overall processes are captured to building the basis

of this knowledge. Rules then created to drive the

systems.

4 IMPLEMENTATION

STRATEGY

This research focuses on finding the way for cloud

manufacturing implementation in the Indonesian

context. Therefore, some characteristic of SMMEs

and typical government organization is described

first. Then, step by step implementation procedure is

proposed. Following that, an initial development

process in our laboratory is also presented.

4.1 Business Process

Indonesia as a developing country has a large

number of SMMEs. Therefore, the government

through the Ministry of Industry pay attention more

to this industrial sector. Based on our investigation,

we define three supporting conditions for the

adoption and implementation of cloud

manufacturing concept in Indonesia. First, the

establishment of industrial clusters or industrial

zones in many cities. Those industrial clusters are

developed mainly based on similar products. For

example, central for foundry industry which located

in Klaten, furniture industries in Jepara, leather

industries in Sidoarjo, and so on. These industrial

clusters simplify the collaboration format that needs

to be established as the beginning step.

Second, support from local government.

Indonesia has local representatives for the ministry

of industries, called “Dinas UMKM” or “Dinas

IKM” that focus on developing local SMMEs. They

have data and information regarding the type of

industries, the size of the industries, etc. in their

local area. The local government also has a good

relationship and communication with the industries.

Within this good circumstances, the local

government can play the role as cloud operator

which facilitate the industries to provide their

manufacturing resource capabilities information.

Third, the new infrastructure development such

as highway and transportation systems. Since cloud

manufacturing concept is overlooked geographical

location, which means the manufacturing resources

Cloud Manufacturing: An Approach to Strengthen Global Competitiveness of the Indonesian Small and Medium Manufacturing Enterprises

189

can be located anywhere as well as cloud users also

can have access from anywhere, the role of transport

systems must be influenced. This new huge

improvement on the infrastructure facilities enables

the cloud manufacturing implementation in

Indonesia.

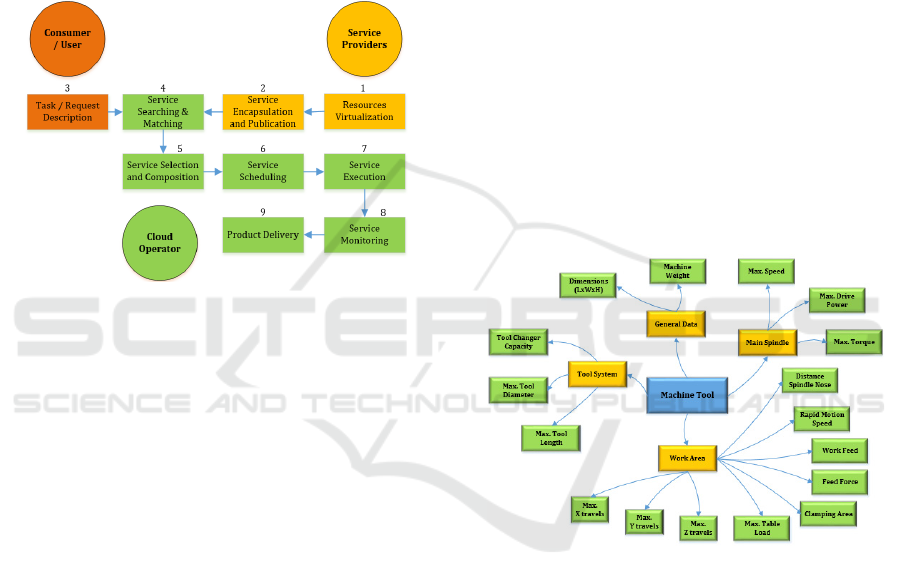

4.2 Step-by-Step Implementation

To implement the cloud manufacturing concept, we

define nine steps based on the cloud manufacturing

service management proposed by Tao et al. (2015).

Figure 4: Cloud manufacturing implementation procedure

The implementation procedure is divided into

nine steps as below:

1. Resource description and virtualization.

Manufacturing resources such as machines

and equipment are virtualized using cloud

computing technologies and agent-based

technologies. Beside those hard manufacturing

resources, soft manufacturing resources such

as a person (smart talents), software, and other

computational resources also can be offered as

s service.

2. Service encapsulation and publication.

Resource capabilities are translated into

service modelling language (using ontology

modelling) and published on public cloud

pool.

3. Task/request description. Tasks and other

specific requirements are represented as

product data in semantic description language.

4. Service searching and matching. Similarity

algorithms are commonly used for service

discovery to search and match user tasks with

suitable cloud services.

5. Service selection and composition.

Knowledge-based systems or other approach

and methodology can be used for optimal

selection and service composition.

6. Service scheduling. Selected resources are

scheduled using scheduling algorithms based

on resources real-time availability

7. Service execution. Production processes are

executed based on the scheduling.

8. Service monitoring. Users can access the real-

time status of their request.

9. Product delivery. Finished tasks/requests are

delivered to users.

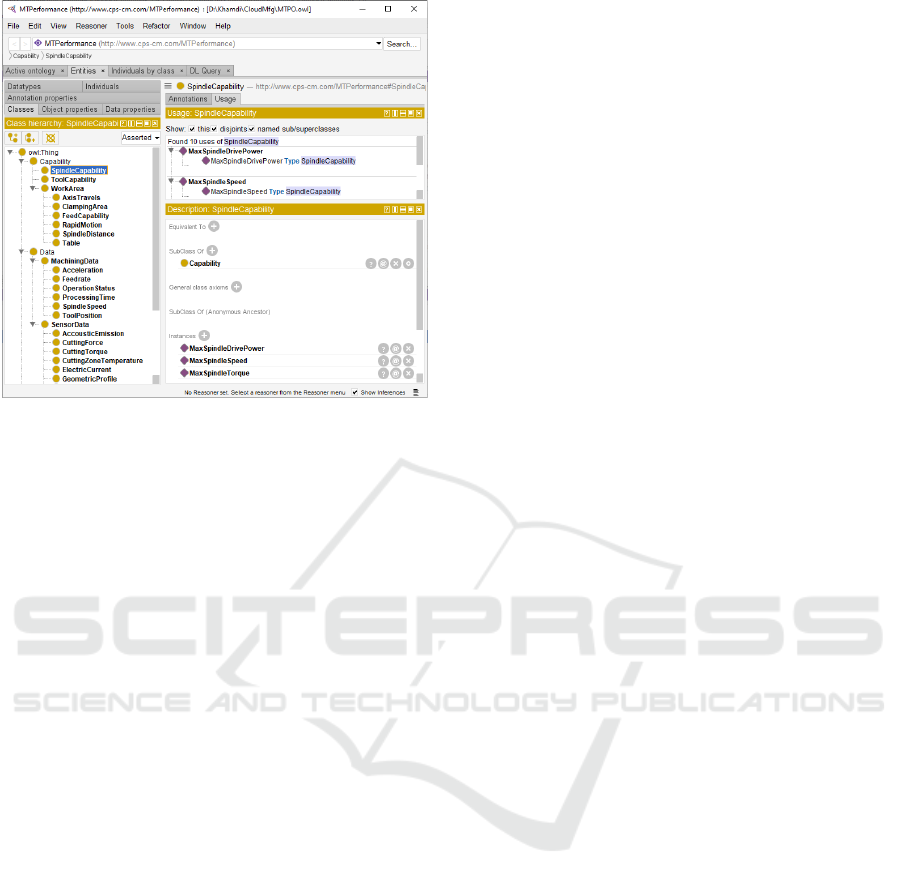

4.3 Application Development

We have initiated this work in our lab, the

Laboratory of Robotics and Automation Laboratory,

University of Trunojoyo Madura. We have 2 CNC

milling machines, 2 CNC turning machines, and one

robot welding, also one robot assembly. The initial

project currently performed is how to virtualize the

CNC and robots in the machine (computer) readable

format. Ontology modelling is the best option so far

to virtualize the manufacturing resources. Figure 5

shows CNC milling machine characteristics that

need to be virtualized.

Figure 5: CNC milling data and characteristics

In compliance with cloud manufacturing

environment, these characteristics are required to be

transformed into ontology modelling (Talhi et al.,

2019). Figure 6 shows an example of the

development of machine tools ontology using

Protégé software.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

190

Figure 6: CNC Milling ontology

5 CONCLUSION

This research proposed a strategy for cloud

manufacturing implementation in the Indonesian

context to strengthen SMMEs global

competitiveness by building close collaboration

among SMMEs. The concept of cloud

manufacturing is described and the suitability with

the Indonesian context is discussed. As a result,

three supporting conditions are defined and nine

implement strategies for the cloud manufacturing

adoption are developed. However, following the step

by step procedure proposed, the real implementation

of this project is still in the initial stage. Therefore,

for future research, the efforts will be focused on the

next steps as presented in this paper. Furthermore,

by utilizing cyber-physical systems (CPS) and big

data analytics, the opportunity to gather data from

machines and process the data for prediction process

purpose and process simulation needs to be

investigates. So that, the cloud users will be able to

simulate the overall process before placing a request

on the cloud manufacturing platform. In addition,

cybersecurity issues also will be our concern.

REFERENCES

Ersson, C. W. and E. Sagström, E., 2013. Made in Sweden

2030. Stockholm. Available:

https://www.productdevelopment.se/wp-

content/uploads/2018/03/made-in-sweden-2030-

engelsk.pdf [Accessed: 23-Oct-2020]

Evans, P. C. and Annunziata, M., 2012. Industrial

Internet: Pushing the boundaries of minds and

machines. General Electric. Novemb., vol. 26, p. 21.

FME, 2014. Smart Industry – Dutch Industry fit for the

future. Available: https://ec.europa.eu/growth/tools-

databases/dem/monitor/sites/default/files/DTM_Smart

%20Industry%20v1.pdf [Accessed: 23-Oct-2020]

Ghobakhloo, M., and Ching, N. T., 2019. Adoption of

digital technologies of smart manufacturing in SMEs.

Journal of Industrial Information Integration, 16,

100107.

Ghomi, E. J., Rahmani, A. M., & Qader, N. N. (2019).

Cloud manufacturing: challenges, recent advances,

open research issues, and future trends. The

International Journal of Advanced Manufacturing

Technology, 102(9-12), 3613-3639.

Kagermann, H, Wolfgang, W and Helbig, J., 2013.

Securing the future of German manufacturing

industry. Recommendations for implementing the

strategic initiative INDUSTRIE 4.0. Final report of

the Industrie 4.0 Working Group.

Kemenperin (Kementerian Perindustrian RI), 2017.

Kemenperin Rilis ‘E-Smart’ IKM. Available:

https://kemenperin.go.id/artikel/16170/Kemenperin-

Rilis- [Accessed: 23-Oct-2020]

Kemenperin (Kementerian Perindustrian RI), 2018a.

Making Indonesia 4.0. Available:

https://www.kemenperin.go.id/download/18384.

[Accessed: 23-Oct-2020]

Kemenperin (Kementerian Perindustrian RI), 2018b.

Restrukturisasi Mesin dan/atau Peralatan IKM.

Available: https://kemenperin.go.id/restrukturisasi-

ikm.[Accessed: 23-Oct-2020]

Li, B. et al., 2010. Cloud manufacturing: a new service-

oriented networked manufacturing model. Comput.

Integr. Manuf. Syst., vol. 16, no. 1, pp. 1–16.

Liu, S. X., 2016. Innovation Design: Made in China 2025.

Des. Manag. Rev., vol. 27, no. 1, pp. 52–58.

Lu, Y., & Xu, X. (2019). Cloud-based manufacturing

equipment and big data analytics to enable on-demand

manufacturing services. Robotics and Computer-

Integrated Manufacturing, 57, 92-102.

Masood, T., and Sonntag, P., 2020. Industry 4.0: Adoption

challenges and benefits for SMEs. Computers in

Industry, 121, 103261.

Moeuf, A., Lamouri, S., Pellerin, R., Tamayo-Giraldo, S.,

Tobon-Valencia, E., and Eburdy, R., 2020.

Identification of critical success factors, risks and

opportunities of Industry 4.0 in SMEs. International

Journal of Production Research, 58(5), 1384-1400.

Mubarok, K., 2020. Redefining Industry 4.0 and Its

Enabling Technologies. In Journal of Physics:

Conference Series (Vol. 1569, No. 3, p. 032025). IOP

Publishing.

Oztemel, E., and Gursev, S., 2020. Literature review of

Industry 4.0 and related technologies. Journal of

Intelligent Manufacturing, 31(1), 127-182.

Cloud Manufacturing: An Approach to Strengthen Global Competitiveness of the Indonesian Small and Medium Manufacturing Enterprises

191

Talhi, A., Fortineau, V., Huet, J. C., & Lamouri, S., 2019.

Ontology for cloud manufacturing based product

lifecycle management. Journal of Intelligent

Manufacturing, 30(5), 2171-2192.

Tao, F., Zhang, L., Liu, Y., Cheng, Y., Wang, L. and Xu,

X., 2015. Manufacturing service management in cloud

manufacturing: overview and future research

directions. Journal of Manufactruing Science and

Engineering, vol. 137, no. 4, p. 40912, 2015.

Wang, Y., Lin, Y., Zhong, R. Y., and Xu, X., 2019. IoT-

enabled cloud-based additive manufacturing platform

to support rapid product development. International

Journal of Production Research, 57(12), 3975-3991.

Xu, X, 2012. From cloud computing to cloud

manufacturing. Robotics and Comput. Integrated

Manufacturing, vol. 28, no. 1, pp. 75–86.

Zheng, T., Ardolino, M., Bacchetti, A., and Perona, M.,

2020. The applications of Industry 4.0 technologies in

manufacturing context: a systematic literature review.

International Journal of Production Research, 1-33.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

192