Design of Waste Water Treatment Plant for Hospital

Nizar Kamil Perwira

1

, Kris Tri Basuki

1

, Nofriady Aziz

2

and Nuradam Effendy

3

1

Teknokimia Nuklir, Sekolah Tinggi Teknologi Nuklir STTN BATAN, Yogyakarta, Indonesia

2

Pusat Teknologi Bahan Bakar Nuklir, Serpong, Indonesia

3

Pusat Reaktor Serba Guna, Serpong, Indonesia

Keywords: WWTP, Chlorination, Quality Standards.

Abstract: Many methods have been done to treat hospital waste water before it’s disposed into the environment because

it's containing high organic matters and chemical compounds so it's harmful for environment. In this research,

we designed Wastewater Treatment Plant (WWTP) so the output will fulfil environmental quality standard

and can be disposed into the environment. The design of WWTP uses chemical and physical process to reduce

high chemical compounds and organic matters in hospital waste water. The purpose of this research is to

design WWTP in hospital, determine the output waste from WWTP and can be used as a basis in the

calculation of WWTP. The research method is to design WWTP and calculation result output of design

WWTP (Waste Water Treatment Plant). The WWTP design is consist of equalization bath, bath coagulation,

chlorination and sump. Based on the result, one of waste water of hospital in Indonesia with discharge is 60

m3/day, the result BOD is 44.87 mg/L, COD is 19.24 mg/L, and TSS is 56.68 mg/L. Waste water of hospital

processed from this WWTP can to be disposed into environment based on Minister of Health decree.

1 INTRODUCTION

Source of water pollution can be come from the

hospital. Sources of hospital wastewater can be

derived from bathrooms, kitchen rooms, the

examination rooms, laboratories, operating rooms

and other rooms containing hazardous materials and

germs. Various kinds of toxicities such as

pharmaceutical waste, radio-nuclides, solvents and

disinfectants for medical purposes with a high

concentration for laboratory activities. Hospital waste

as well as other waste containing organic and

inorganic materials, which the containing level can be

determined by testing waste water such as BOD,

COD, pH, microbiological, TSS and others. Water

waste from hospitals is one source of water pollution

potential because the hospital waste water is

containing organic compounds, chemical compounds

and pathogenic microorganisms that can cause

disease to the surrounding community. Pursuant to

Law No. 32 of 2009 in Indonesia about Protection and

Management of the Environment, an activity is

required to process and manage wastes produced by

its activities, in order to conserve the environmental

functions so the waste must be processed and managed

with the applicable quality standards. Kep-

MENLH/12/1995 concerning effluent quality

standards for hospital activities that requires every

hospital must treat wastewater to a permitted standard.

From the explanation above, those can be used as

a guide for the hospital to process and manage the

waste till get the environmental quality standards that

applicable. Hospitals need to build Wastewater

Treatment Plant to produce safe effluent which can be

disposed to the environment that passed the quality

standards. In this research, we make the WWTP so

that the result processed can be disposed into

environment. The main characteristics of the

hospital’s waste water is the content of coliform

bacteria, because it has very high value. In addition to

the high content of coliform bacteria, the

characteristics that is high of the waste water are

BOD, COD, and TSS. The objectives of this research

are to are to design WWTP in hospital, determine the

output waste from WWTP and can be used as a basis

in the calculation of WWTP.

2 BASIC THEORY

Wastewater Treatment Plant (WWTP) is a structure

that is designed to dispose of biological and chemical

102

Perwira, N., Basuki, K., Aziz, N. and Effendy, N.

Design of Waste Water Treatment Plant for Hospital.

DOI: 10.5220/0010541700003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 102-106

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

waste from the water thus allowing the water to be

reused at other activities. The main purpose of

wastewater treatment is to decompose the content of

pollutants in the water, especially organic

compounds, suspended solids, pathogens and organic

compounds that cannot be decomposed by

microorganisms found in nature. For treating

wastewater parameters, processing units that will be

applied consists of several treatment plant. Based on

the selection it has been done, then in WWTP will be

used unit - of processing unit as follows:

a. Equalisation

The use of equalization tank aims to generate a

uniform flow so that the processing units in the

installations be able to avoid shock loading. Form of

equalization tank that will be used are rectangular.

During the equalization stirring to prevent the

precipitation of solid and odor. Biological oxidation

due to the agitation in the tank, according to Metcalf

& Eddy (2004), can reduce the concentration of 10-

20% total COD, TDS and TSS by 15-20%.

b. Coagulation and Flocculation

In the process of coagulation and flocculation, the

water will be very role, because the chemical must be

mixed with water. Stirring / Agitation process will

very quickly and uniform dispersion of compounds in

water, the coagulation process occurs with rapid

stirring. In this case the process of coagulation and

flocculation chemical and physical reactions will

occur precipitation: Poly Aluminium Chloride. After

the formation of deposits caused by the large floc

settles, and this process occurs with slow stirring. A

fast stirrer is very important in the change of physical

factors as well as the efficiency of coagulant addition,

the flocculation is a method for taking particles and

highly dependent on particle size.

c. Sedimentation

Particles that are in the water may be eliminated in the

sedimentation vessel (Clarifier). In the sedimentation

tank types horizontal removed particles is dependent

upon over flow rate (Vo), in this type there are several

assumptions:

1. Particles and velocity vectors are distributed on a

cross-section of the tank, as a function of the inlet

zone.

2. Transfer the liquid will looking down on the length

of the tank.

3. Particles below will be removed from the tank.

d. Chlorination Tank

Chlorine is commonly used for disinfecting; the term

is usually used as a disinfectant is: Cl

2

; NaOCl or

CaOCl

2

. When chlorine is added to water, the mixture

Hipochlor (HOCl) and HCl will be formed by the

reaction:

Cl

2

(g) + H

2

O HOCl + H

+

+ Cl (1)

The above reaction depends on pH, when the pH ≈ 1

reaction will occur right and very sidikit Cl2 in a

solution. HOCl is a weak acid and dissociates at pH ≈

6, at a pH between 6 to 8.5 dissociation occurs to

HOCl.

HOCl =H

+

+ Cl pK = 7.537 at 25 ° C (2)

This chlorination with Cl2 generate HOCl at pH

between 4 - 6. Below pH = 1 then it will be left to

form Cl2 HOCl. While salt dissociates hypoklorida

such as:

NaOCl === Na

+

+ OCl

-

(3)

Ca(OCL)

2

=== Ca

2+

+ 2. OCl

-

(4)

The presence of chlorine will tend to lower the pH,

every mg / L of chlorine that is added will reduce

hardness of 1.4 mg / L (equivalent to the

concentration of CaCO3). Disinfectants will be well

on the pH interval 6.5 - 7.5. Chlorine reacts with

water to produce chlorine acts as an "oxidizing" very

destructive of the organism.

3 RESEARCH METHOD

3.1 Study of Literature

Overview and Hospital Waste, Technique

Wastewater Treatment and Design Options WWTP.

3.2 Data Collection

Wastewater discharge and the characteristics of the

hospital.

3.3 Data Processing

The calculation of hospital waste, Determination of

the quality standard as the basis of design, and

Calculation of Dimension WWTP earned by each

process.

3.4 Data Processing and Conclusion

Calculation of Dimension WWTP, The calculation of

the final result output WWTP design results and

Conclusion.

Design of Waste Water Treatment Plant for Hospital

103

4 RESULT AND DISCUSSION

In this planning, hospital waste flow of water

obtained as follows: 28 m3 / day. It refers of literature,

including the text book Decentralised Wastewater

Treatment in Developing Countries and Treatment

and Reuse Fourth Edition by Metcalf and Eddy both

in obtaining design criteria of planning and

calculating the dimensions of the WWTP:

1. Equalization Tank.

The use of equalization tank aims to generate a

uniform flow so that the processing units in the

installations be able to avoid shock loading. Form of

equalization tank that will be used are rectangular.

During the equalization stirring to prevent the

precipitation of solid and odor. Biological oxidation

due to the agitation in the tank, according to Metcalf

& Eddy (2004). After doing calculation, it will be

shown at Table 1:

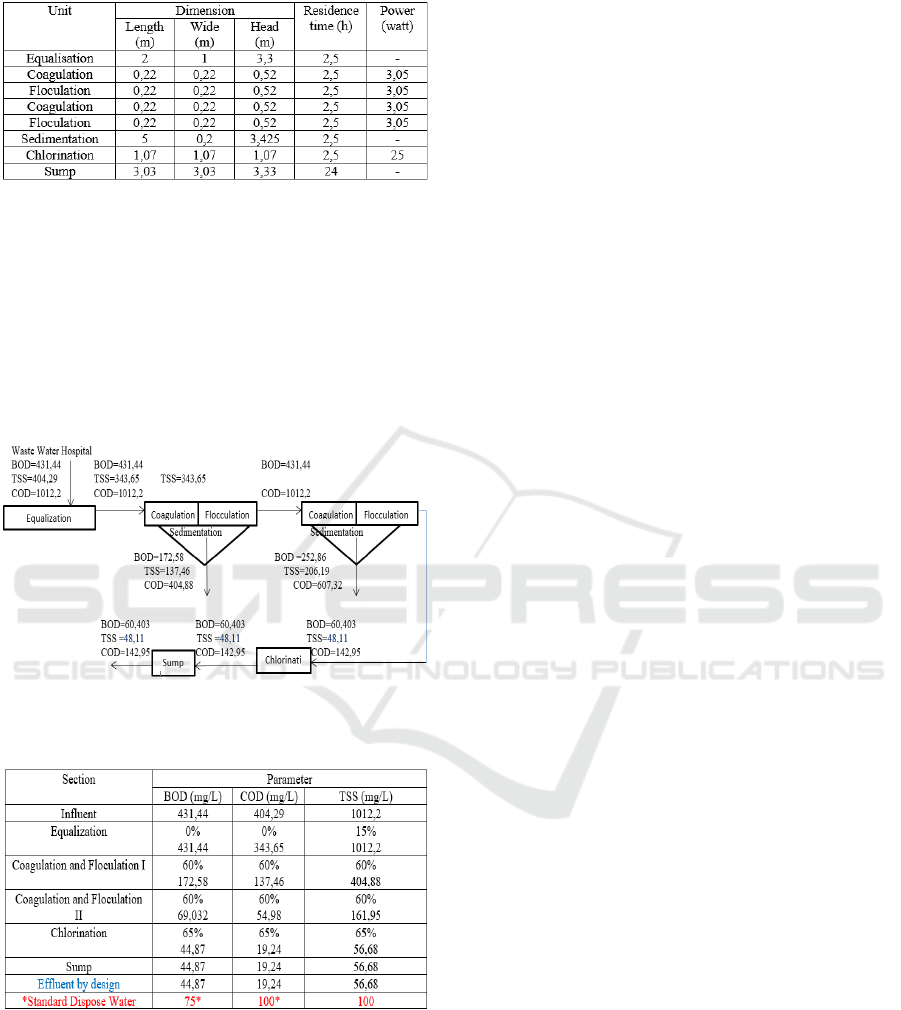

Table 1: Design Equalization from WWTP Hospital.

2. Coagulation and Flocculation.

In the process of coagulation and flocculation, the

water will be very role, because the chemical must be

mixed with water so that the process will very quickly

and uniform dispersion of compounds in water, the

coagulation process occurs with rapid stirring. In this

process of coagulation and flocculation, coagulant

Poly Aluminium Chloride will be used.

Concentration of PAC : 80 ppm

Diameter Stirrer : 0,26 m

Flow rate PAC : 0,2 kg/d

Solution PAC : 5%

Flow rate water : 3,8 kg/d

Total volume : 1,76 m

3

After doing calculation, it will be shown at Table 2:

Table 2: Design Coagulation and Floculation from WWTP

Hospital.

3. Sedimentation.

Over Flow Rate : 30 m

3

/hari.m

2

Number of Weir Loading : 1

Weir Loading : 150 m

3

/day.m

Scour Velocity :12,53cm/s

Horizontal Velocity : 0,83 cm/s

The slope of the Wall Channels : 0,00097

After doing calculation, it will b shown at Table 3:

Table 3: Design Sedimentation from WWTP Hospital.

4. Chlorination.

Debit (Q) = 0.138 L / dt

*The planned concentration = 4%

Chlorine that is used contains = 60% Chlorine

(Solution)

Chlorine density = 1.2 kg/L

Capacity affixing maximum = 600 cc / min

Chlorine binding force = 1.18 mg/L DPC

Residual chlorine planned = 0.4 mg / L

*Efficiency = 65%

Dose Chlorine = DPC + Time chlorine =

1.18 mg / L + 0.4 mg / L = 1.58 mg / L

Requirement for 2.5 hours = 0.00327 kg

*Chlorination basin capacity = 1,242 m3

After the chlorination process, the treated water

supplied to the sump. As for the design of a tank

shown in Table 5. The calculation can be shown at

Table 4:

Table 4: Design Chlorination from WWTP Hospital.

Table 5: Design Sump from WWTP Hospital.

Generally, calculation of dimensions in the

planning of these is shown in Table 6:

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

104

Table 6: Design WWTP Hospital.

5. Calculation Result WWTP.

In this planning, hospital waste flow of water

obtained as follows: 60 m

3

/ day so that calculation

Result WWTP refers to parameters of efficiency

reduction of some of the literature includes text book

Decentralised Wastewater Treatment in Developing

Countries and Treatment and Reuse Fourth Edition by

Metcalf and Eddy. After calculation can be shown at

Picture 3 dan Table 7:

Figure 3: Mass Balance Desain IPAL.

Table 7: Mass Balance and Efficiency Design WWTP.

*based on KEPUTUSAN MENTERI NEGARA

LINGKUNGAN HIDUP NO. 58 TAHUN 1995

TANGGAL 21 DESEMBER 1995

4 CONCLUSIONS

Hospital Waste water treatment at one of the hospitals

in Indonesia. debits 60 m

3

/ day. WWTP hospital

building consists of equalization bath, flocculation

coagulation bath, chlorination bath and sump.

Wastewater treatment plant at the hospital are

planned can be disposed into environment because

has fit to the standards.

ACKNOWLEDGEMENTS

The authors say thank you to the Hospital in

Indonesia.

REFERENCES

Ayu Taurini, Putri. 2014. Perencanaan Pengolahan Air

Limbah Sistem Setempat (On Site) dengan Sistem

Tangki Septik Bersusun dengan Filter pada Perumahan

PT Pertamina UP III Plaju Palembang). Fakultas

Teknik Jurusan Teknik Sipil, Universitas Sriwijaya.

Basak, NN. 2003. Environmental Engineering. Tata Mc

Graw Hill: New Delhi.

Batterman S. (2004). Findings on an Assessment of Small-

scale Incinerators for Health-care Waste. WHO,

Geneva, Switzerland.

Batterman S, (Website Updated April 9, 2008),

Mozambique Program for Healthcare facility waste

treatment, The Regents of the University of Michigan

School of Public Health (MSPH).

Crites, Tchobanoglous. 2003. Small and Decentralized

Wastewater Management System. McGraw-Hill.

Singapore.

Depkes RI, 2004. Keputuan Menteri Kesehatan

No.1204/MENKES/SK/2004 tentang Persyaratan

Kesehatan Lingkungan Rumah Sakit, Jakarta:

DepkesRI.

Eckenfelder, W Wesley Jr. 2000. Industrial Water

Pollution Control. The McGraw Hill Companies.

Singapore.

Ginting Perdana, 2007. Sistem Pengelolaan Lingkungan

dan Limbah Industri,Bandung : CV. Yrama Widya.

Hermana, Joni. 2010. Dasar - dasar Teknik Pengelolaan

Air Limbah. Jurusan Teknik Lingkungan. Institut

Teknologi Sepuluh November, Surabaya.

Kementerian Pekerjaan Umum. 2012. Pedoman

Pengelolaan Program Hibah Air Limbah, Direktorat

Jenderal Cipta Karya, Jakarta.

Kementrian Kesehatan RI. 2011. Seri Sanitasi Lingkungan:

Pedoman Teknis Instalasi Pengolahan Air Limbah

Dengan Sistem Biofilter Anaerob Aerob Pada Fasilitas

Pelayanan Kesehatan. Kementrian Kesehatan RI,

Direktorat Jenderal Bina Upaya Kesehatan.

Metcalf & Eddy, Inc. 2004. Wastewater Engineering:

Treatment, Disposal and Reuse 4th Edition. Mc Graw

Hill. New York.

Siregar A., 2005. Instalasi Pengolahan Air Limbah,

Yogyakarta: Kanisius.

Design of Waste Water Treatment Plant for Hospital

105

Said, Nusa Idaman, 2006. Instalasi Pengolahan Air Limbah

Rumah Sakit. Kelompok Tehnologi Pengolahan Air

Bersih dan Air Limbah, Pusat Pengkajian dan

Penerapan Lingkungan, BPPT, Jakarta.

Zaenal, A.Z, 2005. Analisis Bangunan: Menghitung

Anggaran Biaya Bangunan. Gramedia PustakaUtama,

Jakarta.

Wulanarum, Rina. 2008. Laporan Tugas Akhir:

Perancangan Sistem Penyaluran dan Bangunan

Pengolahan Air Buangan Domestik Kelurahan

Rejowinangun Selatan Kecamatan Magelang Selatan.

Teknik Lingkungan UNDIP. Semarang.

Verlicchi, P et al., “Hospital effluents as a source of

emerging pollutants: An overview of micropollutants

and sustainable treatment options.” Journal of

Hydrology: Elsevier, (2010).

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

106