Force Monitor for Training Manual Skills in the Training of

Chiropractors

Juan-Mario Gruber

1

, Daniel Mühlemann

2

, Darius Eckhardt

1

and Ibrahim Evren

1

1

Institute of Embedded Systems Zurich University of Applied Sciences, Winterthur, Switzerland

2

Department of Chiropractic Medicine, University of Zurich, Switzerland

Keywords: Spinal Manipulation, Training, Skill, Biomechanics, Teaching Aid, Force Monitoring Device, Biofeedback.

Abstract: As part of their training, students of Chiropractic Medicine at Zürich are trained to acquire and then improve

their manual and manipulative skills, especially their ability to deliver manipulative thrusts with a defined

preloading force, an impulse that is delivered with an adequate and reproducible force within a defined time

without letting up on the preload-pressure. In order to facilitate this process, objective feedback is

paramount. This led to the idea of developing a force-measurement and -monitoring system. The newly

developed system consists of a wireless device with a force sensor and an app that is running on standard

smartphones. The device records the force applied to the sensor and transmits it via Bluetooth Low Energy

(BLE) to the app. There it is visualised as a graph and can be evaluated. The system allows us to provide all

students with a tool to develop their manual skills, and especially their thrusting technique. As the feedback

given by the system can be recorded, progress can be monitored and students can be mentored accurately

according to their strengths and weaknesses.

1 INTRODUCTION

Chiropractic Medicine at Zürich University is a 6-

year program consisting of a 3-year Bachelor’s

degree in Medicine and a 3-year Master’s degree in

Chiropractic Medicine at the university’s medical

faculty. Throughout the curriculum, students are

instructed and trained to acquire and then constantly

improve their manual and manipulative skills.

To support the students training it is necessary

for the instructors to be able to give objective

feedback.

2 FAST, ACURATE AND

REPRODUCABLE MANUAL

THRUSTS

One particular challenge has been to train the

student’s ability to deliver manipulative thrusts with

a defined preloading force, an impulse that is

delivered with an adequate and reproducible force

within a time of 100-150 ms without letting up on

the preload-pressure.

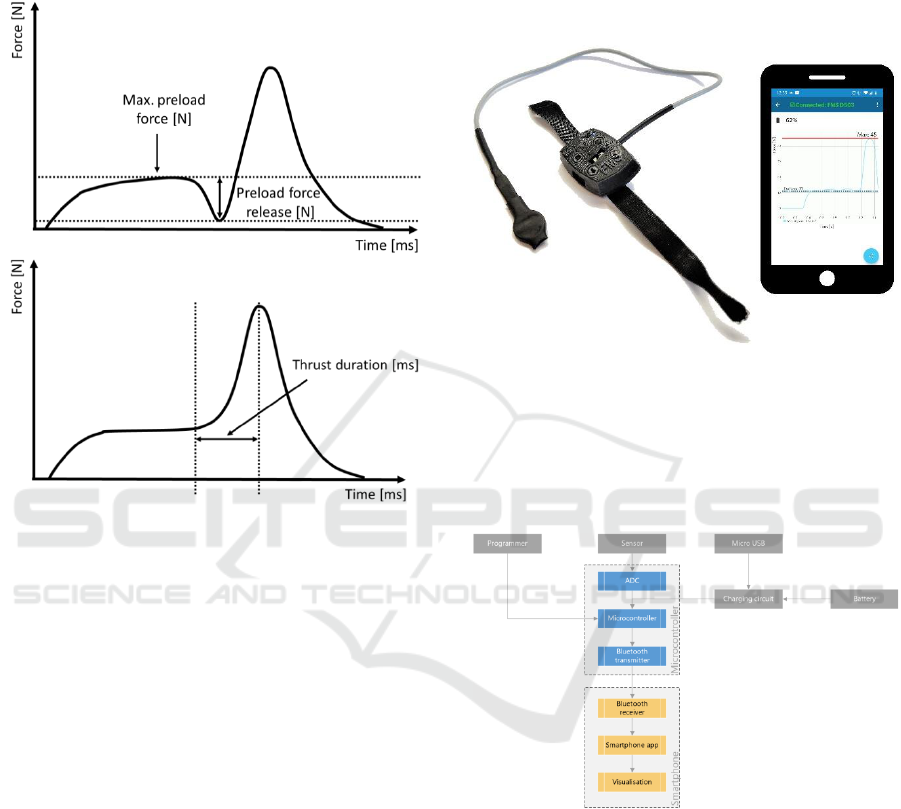

2.1 Typical Force Path

A graph showing the correct delivery of a high

velocity, low amplitude thrust is shown in figure 1.

Figure 1: Correct delivery of a high velocity, low

amplitude thrust (Triano et al., 2004; Triano et al., 2002;

Triano et al., 2012).

The challenge is to deliver a reproducible preload-

force, which may vary with the technique, then a

fast, accurate, and reproducible thrust (impulse),

which may vary again according to the technique

chosen and then to back off completely as fast as

possible (unload). The slew rate in both delivering

Force [N]

Max. preload

force [N]

Peak of force [N]

Thrust duration [ms]

Time [ms]

Resolution

phase

Preload

period phase

Thrust

phase

Gruber, J., Mühlemann, D., Eckhardt, D. and Evren, I.

Force Monitor for Training Manual Skills in the Training of Chiropractors.

DOI: 10.5220/0008902100810085

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 81-85

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

81

the impulse as well as in unloading must be as high

as possible, the impulse as a whole as short as

possible. A typical mistake is to reduce the preload

prior to thrust-delivery (figure 2, upper graph).

Figure 2: Incorrect delivery (upper graph) against correct

delivery (lower graph).

2.2 Using Force Measurement Systems

in Chiropractic Education

In the past years, force sensors have been developed

to visualize the impulses delivered.

The students are able to analyse and compare the

force path during practice. To improve mobility and

handling, the latest version works with a force

sensor connected via Bluetooth to a smartphone to

visualize the data.

This newly developed system allows us to

provide all students with a tool to develop their

manual skills, and especially their thrusting

technique. As the feedback given by the system can

be recorded, progress can be monitored and students

can be mentored accurately according to their

strengths and weaknesses.

3 FORCE MONITORING DEVICE

The developed system consists of a wireless device

with a force sensor and an app that is running on

standard smartphones. Figure 3 is showing the

prototype.

The device measures an applied force and transmits

it via Bluetooth Low Energy (BLE) to the

smartphone. The app evaluates the data and displays

it as a graph.

Figure 3: Prototype.

3.1 System Concept

The System consists of two main parts: The

embedded electronics with sensor and the

smartphone application (Figure 4).

Figure 4: System Block Diagram.

The sensor measures the applied force. The

microcontroller device reads the analogue data,

converts it into digital data and transmits it via

Bluetooth Low Energy to the smartphone. An

Android app receives the data, does calculations and

visualises it as a graph. Further data analysis is made

to show a preload-force and the maximum force. In

addition, the data can be exported and shared. The

device and the app are simple to use.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

82

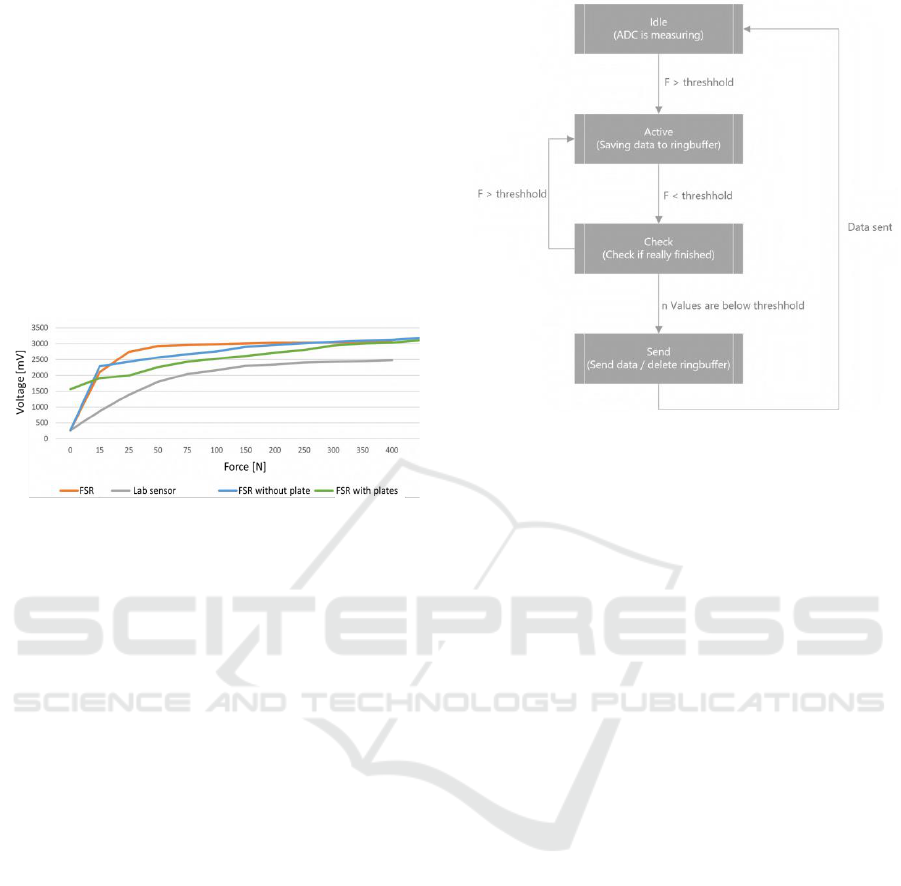

3.2 Sensor

The sensor is built of a force sensitive resistor (FSR)

in combination with two metal plates. It changes the

resistance when a force is applied. The sensor is

quite affordable, but it is nonlinear. This is why it

needs additional compensation during calibration.

During calibration an accurate piezoelectric sensor is

used as reference and mounted into a hand press.

Several reference points are measured over a range

of 500 Newton and interpolated for the FSR. This

results in a reasonable accuracy of the FSR (Figure

5).

Figure 5: Sensor calibration of different sensor types.

3.3 Measurement Device

The measure device is in a custom-built case. It is

worn at the wrist of the user.

For the prototype this case is produced with a 3D

printer based on the stereolithographic (SLA)

principle. The electronics are integrated on a custom

printed circuit board (PCB). A system on chip (SoC)

from Nordic Integrated, the nRF52840 model, is the

core of the device. This is a Microcontroller with a

built in Bluetooth module. The device is powered by

a rechargeable lithium battery. It can be charged by

a micro USB connector. The sensor is attached to a

short cable, which allows the user to measure a force

at different positions, such as at the heel of the hand.

By sliding the main switch, the device is

powered on and is visible over BLE. When

connected to the app, the device starts to read the

sensor data (Figure 6).

As soon as a force is applied to the force sensor,

the device is recording the data. When the sensor is

released, the raw sensor data is converted into a

force and transmitted over BLE to the app.

Figure 6: State Machine Measurement.

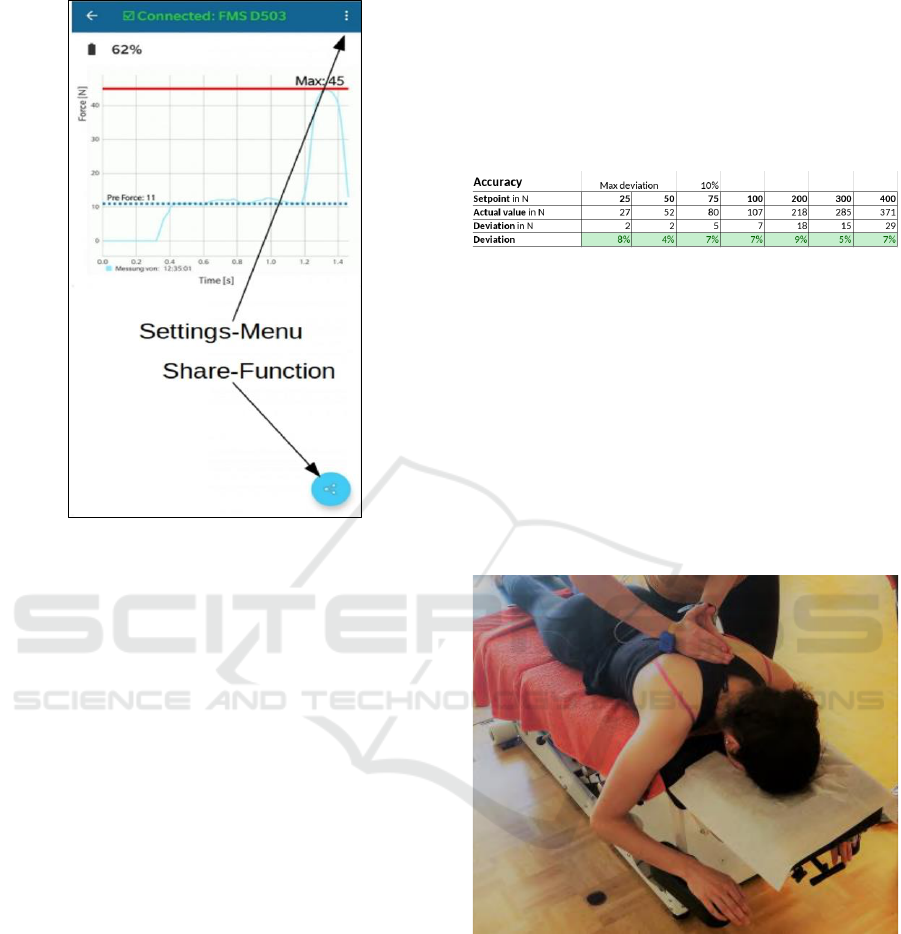

3.4 Smartphone Application

An Android App has been developed as a user-

friendly interface. The aim of the App is to visualize

the applied Force and highlight for chiropractor

students useful data such as the peak force and the

preload force of an exercise (Figure 7).

When a measurement is started a starting flag is

sent to display this in the app. At the end of a

measurement the data is transmitted to the app.

The data evaluation starts as soon as the required

measurement data has been received. The starter

packet passes a byte with the value 0x6 and lets the

display know that the measurement has started.

Before visualization, the received bytes are checked

for completeness and then buffered in a 2-

dimensional array. For the representation an array

list with the respective x- and y-coordinates is

created. The x-axis is defined by the scanning

frequency and can be returned for the respective y-

values. The graph is plotted and the maximum force

as well as the pre-force is shown as numbers. This

helps the chiropractic students to assess whether the

impulse was produced directly after the pre-pressure

or whether the pre-pressure has decreased.

Furthermore an export function has been added to

save the measured force locally on the phone and to

share the .csv File via installed Apps on the

Smartphone.

Force Monitor for Training Manual Skills in the Training of Chiropractors

83

Figure 7: App showing force diagram.

3.5 Wireless Communication

The Connection between the Device and the

Smartphone is established via Bluetooth Low

Energy, while the Smartphone acts as the BLE-

Central and the device as the BLE-Peripheral. The

Connection can be established in three steps

assuming the device is switched ‘On’. The device

starts in Advertising-Mode automatically. The app

scans at start for nearby compatible devices which

are advertising and will show a list of all available

FMS-devices. After choosing a device a connection

using BLE GATT will be established and the system

is ready for data transfer of measured values.

4 DEVICE TESTS AND

CONCLUSIONS

4.1 Test Setup

The device was tested for accuracy and consistency

with an accurate piezoelectric sensor and a hand

press. Furthermore, the battery duration was tested.

Finally, the device was tested by chiropractor

students. Primarily the user friendliness and the

utility of the system were tested.

4.2 Lab Tests

During the accuracy test of the force value the

medium deviancy from the actual value was 7%

(Table 1).

Table 1: Sensor Accuracy.

This is in the acceptable range, because the relative

value is more important than the absolute. In the

consistency test the mean deviation was 9 Newton.

The battery test identified a system uptime of almost

50 hours. This means that the device needs to be

recharged after 24 days if it is used for two hours per

day.

4.3 Practical Tests

At Zürich University instrumented bio-feedback has

been used for teaching motor skills for a few years

with a predecessor device.

Figure 8: Device Test at University Zurich.

The results regarding the improvement of motor-

and manipulative skills of the students are very

good. The students appreciate the immediate

feedback on their performance and are motivated to

take the initiative to improve on their manual skills-

deficits.

The new model is easier to use, as it is highly

portable and, using a smartphone interface, PC-

independent which will make it very attractive for

the students. The feedback from our students of

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

84

Chiropractic Medicine was mostly positive (Figure

9).

Figure 9: Feedback from Acceptance Test.

88% liked the device very much, the others liked it.

No one had problems connecting the device to the

app. 81% would appreciate it if there was as well an

iOS app for the system.

REFERENCES

Triano Jj1, Bougie J, Rogers C, Scaringe J, Sorrels K,

Skogsbergh D, Mior S., 2004. Procedural skills in

spinal manipulation: do prerequisites matter?. In The

Spine Journal. Sep-Oct;4(5):557-63.

Triano JJ1, Rogers CM, Combs S, Potts D, Sorrels K.,

2002. Developing skilled performance of lumbar spine

manipulation. In Journal of manipulative and

physiological therapeutics. Jul-Aug;25(6):353-61.

Triano Jj1, Descarreaux M, Dugas C., 2012.

Biomechanics--review of approaches for performance

training in spinal manipulation. In Journal of

electromyography and kinesiology. Oct;22(5):732-9.

Force Monitor for Training Manual Skills in the Training of Chiropractors

85