3D Printed Human Foot Splint, Designed from MRI of the Luffa

Cylindrica Dried Fruit

Sergio Cerón-Escutia

1a

, Axayácatl Morales-Guadarrama

2b

, Silvia B. González-Brambila

3c

and David Vidal-García

1d

1

Universidad Autónoma Metropolitana - Azcapotzalco/CyAD, St. Pablo’s Ave. 180, Azcapotzalco, Mexico City, Mexico

2

Universidad Autónoma Metropolitana - Iztapalapa/Department of Electrical Engineering, CI3M, Researcher, St. Rafael

Atlixco 186 Ave., Iztapalapa, Mexico City, Mexico

3

Universidad Autónoma Metropolitana - Azcapotzalco/System Departament, St. Pablo’s Ave. 180, Azcapotzalco,

Mexico City, Mexico

Keywords: Bio-design, Reverse Engineering, 3D Print, Luffa Cylindrica, MRI, Splint.

Abstract: This article presents a method to design a splint from the MRI (Magnetic Resonance Imaging) of the dried

fruit of a tropical plant called Luffa (Luffa cylindrica (L.) M.Roem), which shows the possibility of using

synthetic forms in Nature to reproduce and apply them in the development of products, a concept known as

bio-design. This fruit –similar to a cucumber-, when dried it becomes a fibrous and imbricated structure that

confers interesting stiffness and lightness properties, which were used to design a splint for a human foot,

different from the conventional plaster, through a reverse engineering process. Such structure was copied,

with the help of a 7T MRI scanner (Magnetic Resonator of seven Tesla Varian). The images of the Luffa

processed with the OSIRIX

®

and AMIRA

®

programs then converted to the STL (STereo Lithography) format

for manipulated with CAD / CAM (Computer-Aided Design / Computer-Aided Manufacturing) programs.

The results have been successful since it was possible to print by FDM (Fused Deposition Modeling) a scale

model of the splint in ABS (Acrylonitrile butadiene styrene), from a module that extracted from the MRI,

which tested in a model of a human foot.

1 INTRODUCTION

The bio-design represents an alternative to produce

orthopedic products such as splints - and in general,

for any product type, because the traditional ones

made from bandages covered with plaster, are

uncomfortable and somewhat heavy for the user, in

addition to producing itching and bad smell, to

mention the most representative inconveniences. On

the other hand, the current development of NT (New

Technologies), has given a great boost to creativity

and proposition of better designs that were once

unimaginable: from X-rays to scanners and from

bandages to smart textiles, the Technological

advance, (it goes without saying), has become a

valuable tool –together with the inspiration in Nature-

a

https://orcid.org/0000-0002-3168-0112

b

https://orcid.org/0000-0002-4072-2572

c

https://orcid.org/0000-0001-7298-4094

d

https://orcid.org/0000-0003-2809-5315

of generating new concepts, forms, processes,

materials and techniques.

Bio-design, as the name implies, combines the

science of biology with industrial design, that is, the

application of biological principles in the search for

solutions to design problems, principles that –

according to Michael Pawlyn- are backed “from a 3.8

billion year research and development period”

(Pawlyn, 2011). However, since these solutions do

not always appear at first sight, that is, by direct

observation, it is necessary to do an abstraction work

to be able to reach them.

Based on this, a review of certain existing

structures in nature (both organic and inorganic) was

made to find that way that could solve the design of

the splint raised, bearing in mind the drawbacks of the

150

Cerón-Escutia, S., Morales-Guadarrama, A., González-Brambila, S. and Vidal-García, D.

3D Printed Human Foot Splint, Designed from MRI of the Luffa Cylindrica Dried Fruit.

DOI: 10.5220/0008958701500155

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 2: BIOIMAGING, pages 150-155

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

plaster splints mentioned above, in order to propose a

design that was comfortable, light and with sufficient

ventilation to avoid bad smell and itching; in addition

–of course- to protect and help the healing of the

affected limb of the patient.

Thus, the focus was on the Luffa (family

Cucurbitáceae), whose fruit –once dry- acquires a

peculiar structural order, which can fully cover a

surface without increasing the mass, which gives it

firmness, rigidity, and lightweight. It is a plant of

tropical origin that belongs to the same family of

pumpkins that gives an oblong green fruit similar to a

cucumber, only larger; It is commonly known as

smooth loofah, sponge gourd or vegetable sponge

(PROTA, 2018), since when drying –and without a

shell- it takes on a matted straw like appearance

similar to that of a bath sponge, which is why it is

usually used in body or object cleaning. The dried

fruit in question has proven to have interesting

mechanical properties (Chen, Shi, Gorb, & Li, 2014,

Shen, Min Xie, Huang, Zhou, & Ruan, 2012), that

prove its resistance and resilience that its peculiar

structure confers, (apart from its chemical

components); this is why it was ideal for designing

the splint. It should be clarified that in this

investigation, its chemical-organic composition is not

specifically addressed, but rather, the analysis of the

form.

Now, it was one thing to find the ideal biological

organism and another to replicate it. Given its

peculiar structure –fibrous and tangled- it would have

been somewhat complicated to achieve it, so that the

next step was to find a way to copy it as faithfully as

possible, so the magnetic resonator was thought for,

through a reverse engineering process, obtain an

exact duplicate of the fruit and that in the end, it

would be modeled with CAD / CAM programs.

The use of MRI is widely known and used in the

medical area, where it acquires its highest expression

(Backstrom, Nazari, Gu, & Jakola, 2018), (Bouchet,

Pastore, Brun, & Ballarin, 2015), although not only

limited to it, but also for other types of investigations

(Cole-Hamilton, Ka-ye, Chudek, & Hunter, 1995,

Ghisalberti & Godfrey, 1998). On the other hand, the

treatment of computerized images is very widespread,

what was previously done with radiographs, today we

work with the Computed Tomography, the MRI or

the Ultrasound, through specialized software from

which not only images can be obtained every

increasingly accurate, useful for diagnosis, but can

reach three-dimensionality, (Al Jabbari, Abu Saleh,

Patel, Igo, & Rear-don, 2016, Ehricke, Hauser,

Nägele, Schult, & Klose, 2018, Bezinque et al.,

2018), which significantly improves the knowledge,

analysis and understanding of the object of study, be

it the human anatomy or some organic or inorganic

specimen.

On the other hand we have splints, an external

device used to immobilize parts of the body in order

to help in its healing or correction, in case of fractures

or orthopedic treatments; splints are made of various

materials such as aluminum, fabric, wood, plastic or

plaster (Pal, 2016), but first of all it must be resistant.

The most used material is plaster based on bandages.

Plaster is uncomfortable and heavy, in addition to

causing discomfort to patients such as sores, itch and

bad smell by “encapsulating” the affected part. This

article is focused on designing a splint for human

foot, which avoids the aforementioned

inconveniences.

Unlike the splint designed by Jake Evill (Jake

Evill cited by Kim & Jeong, 2015), the structure

proposed here was not created from a generative

design program after scanning the contours of the

human limb in 3D, but it was achieved from the

tessellation of a module extracted from the dried fruit

of the Luffa.

One of the main contributions of this work is that

you can take advantage of the qualities of a biological

structure to design a splint more efficient than the

traditional ones made with plaster, since significant

improvements related to comfort, ventilation, weight

and the amount of material required, to name a few.

And that through an inverse engineering process, the

exact replication of said structure is possible using

MRI technology. The design process presented can be

used to create diverse products based on the same

principle.

2 MATERIALS AND METHODS

2.1 The Organic Specimen

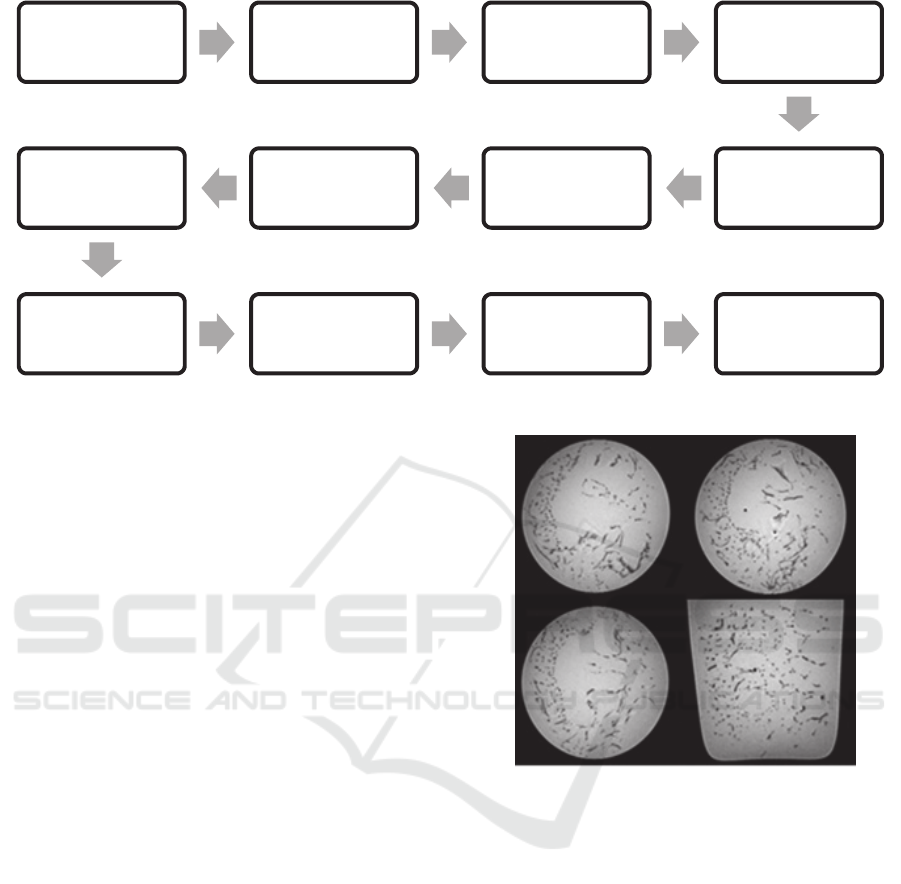

The process diagram that was followed to model the

splint is shown in Figure 1. Five samples from

different parts of the same specimen of the Luffa fruit

of approx. 27 cm

3

and an average weight of 10 g.

submerged in a gelatinous solution. The gelatinous

solution prepared with 5 parts of grenetina (15 g) per

liter of water, which was poured into 5 cylindrical

glass containers 5.5 cm in diameter by 13 cm high

with capacity 295 ml (10 oz); in each one a sample of

the fruit was submerged, and at room temperature

until they took the firm consistency, then keep them

in refrigeration. This preparation was done because

3D Printed Human Foot Splint, Designed from MRI of the Luffa Cylindrica Dried Fruit

151

Figure 1: Process diagram for splint modeling.

the scan that produces a resonator requires a contrast

volume so that it can detect the sample since it would

not register something if it was introduced as is.

2.2 Magnetic Resonance Imaging

For this project a 7T MRI was used; each sample

scanned with a standard sequence weighted in T1

type Gradient-Echo in three-dimensional acquisition

(GE3D), with the parameters: TR 4 ms, TE 2.3 ms,

FA 20

o

, FOV 60x60 mm, MAT 256x256, slice 0.39

mm and Avg. 10 (Fig. 2). The studies acquired were

exported in DICOM format for post-processing.

2.3 The Software and 3D Printing

The MRI software consists basically of the OSIRIX

®

and AMIRA

®

programs, used in order to post-process

MRI (semi-automatic segmentation), generating the

Luffa model by polygonal approaches and exported to

STL format. The STL were processes with

Rhinoceros

®

CAD / CAM, its Grasshopper

™

plug-in,

Netfabb

®

by Autodesk and Stratasys Dimension

Elite

™

, thread fusion printer. The printing material

was thermoplastic ABS.

3 RESULTS AND DISCUSSION

An image obtained by a scanner such as the MRI is

made up of a point-cloud. The point-cloud is a set of

data collected by the scanner using the means in

three-dimensional structures. These points constitute

vertices in a three-dimensional coordinate field, so

they can be interpreted in a graphic format such as the

Figure 2: GE3D acquired in the 7T MRI scanner, without

post-processing.

STL the digital model is made up of multiple

polygons, which makes easy manipulate information

–as if it will be a physical object- in some program

such as Rhinoceros

®

(Fig. 3).

One of the images in STL was processed. First it

was increased by 1200% its size and debugging in the

Netfabb

®.

Next was printed in 3D (Fig. 4). As 3

rd

step,

verify its materialization and check its structure’s

behavior. The experiments worked quite well, so the

project continued, dissecting the virtual sample to

create a cubic module of approximately 15.6 cm

3

(Fig. 5), with which the splint structure could be

formed.

1)SAMPLING

• ObtainingsamplesoftheLuffa

specimen

•SamplepreparationforMRI

2)7TMRI

• Scanningofeachsample

• Postprocessingoftheimages

obtained

3)SELECTION

• Selectionofthebestimageby

structuralconformation

4)CONVERSION

•Conversionoftheselectedimage

toSTLformat

5)1st.PREPARATION

• Debuggingandcorrectingthe

imageinSTLwithNetfabb,for

printingtest

6)1st.PRINT

•STLmodelprintingtestinABS

plastic,tocheckprintingfeasibility

7)DISSECTION

• Digitaldissectionofapartofthe

imageinSTL,usingtheRhinoceros

8)CUBICMODULE

•Creationofthecubicmoduleusing

theRhinoceros

9)GEOMETRIZATION

• Geometryofthecubicmodule

usingtheGrasshopper

10)TESSELLATION

• Tessellationofthegeometrized

cubicmodule,onthesurfaceofa

humanfootmodeltocreatethe

splint,occupyingtheGrasshopper

11)2nd.PREPARATION

• Debuggingandcorrectingthesplint

model,withtheNetfabb program,

for3Dprinting

12)2nd.PRINT

•3DplasticprintingonABSscale

modelofthesplint

BIOIMAGING 2020 - 7th International Conference on Bioimaging

152

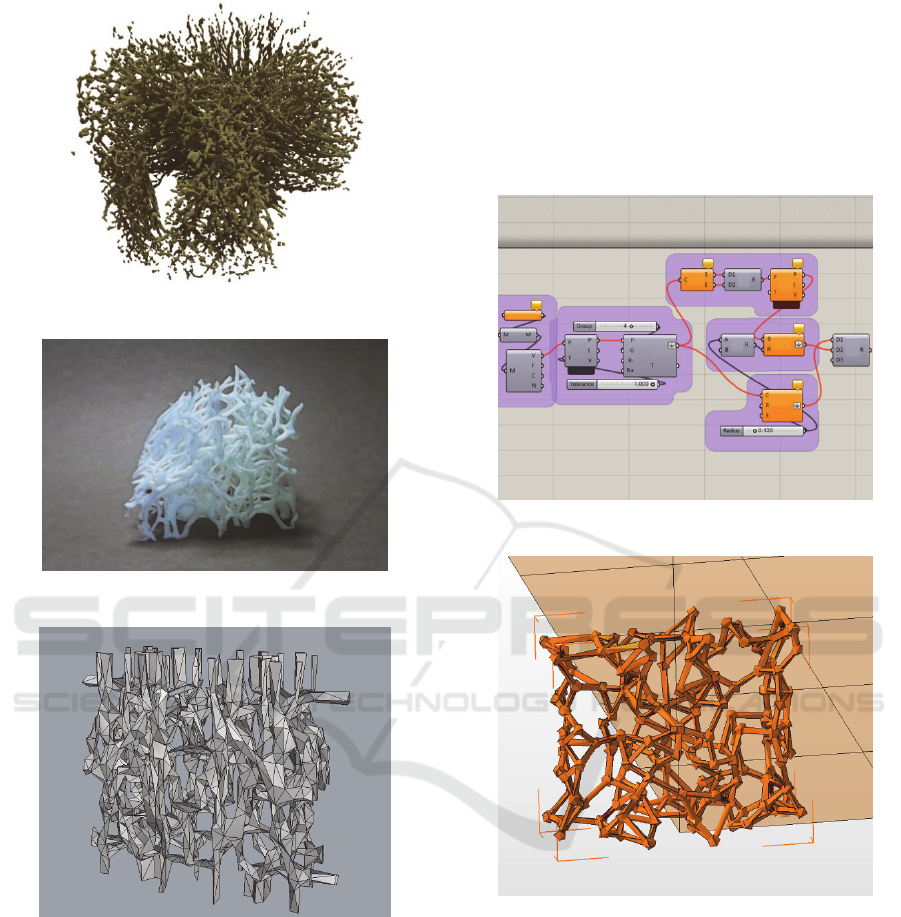

Figure 3: STL digital model of the Luffa sample.

Figure 4: 3D printing test on ABS plastic.

Figure 5: Dissected cubic module of the selected sample.

The dissected cubic module was made using

symmetry in the 3D planes, a section of the virtual

sample. In the splint modeling, was used the

Grasshopper

™

visual programming language that is

part of the Rhinoceros

®

program; this plug-in works

based on graphic algorithms called ‘variables’ with

which they can model and create shapes, through a set

of instructions called "definition".

To be able to work the cubic module, it was

necessary to convert it to geometric figures through

the Grasshopper

™

program, since images made based

on geometric figures are easier to handle due to their

low "weight", than those made of polygons. So a

“definition” was created for this purpose (Fig. 6) that

linked the "points" through cylinders coupled with

spheres, the result of which is seen in Figure 7. A

second “definition” (Fig. 8) was created to tessellate

the geometrized cubic module on the surface of a

virtual model of average human foot to generate the

splint.

Figure 6: “Definition” to geometrize the cubic module.

Figure 7: Geometrical cubic module.

“A tessellation is a special pattern, as it is formed

by different modules that splice together, according

to different symmetry principles, without overlapping

or leaving empty spaces” (Roncoroni Osio, 2017, p.

229).

Several dissected cubic modules accommodated

to determine which of them best covered the surface

(the distribution surface was the form of the human

foot), the optimum being 30 modules on the x-axis by

15 on the y-axis (fig. 9). It was observed that two

factors influence the formation of the splint a) the

dissected cubic module size and b) the size of the

distribution surface. For smaller modules, the mesh

3D Printed Human Foot Splint, Designed from MRI of the Luffa Cylindrica Dried Fruit

153

Figure 8: Second “definition” to tessellate the cubic

module.

becomes more closed and compact; on the contrary if

it is enlarged it becomes more open. The same goes

for the surface; more modules create a larger size of

the model and less for smaller. It is important to

mention that the surface where the module is

tessellated must be “closed”.

Figure 9: Result of the tessellation of the cubic module on

the foot model.

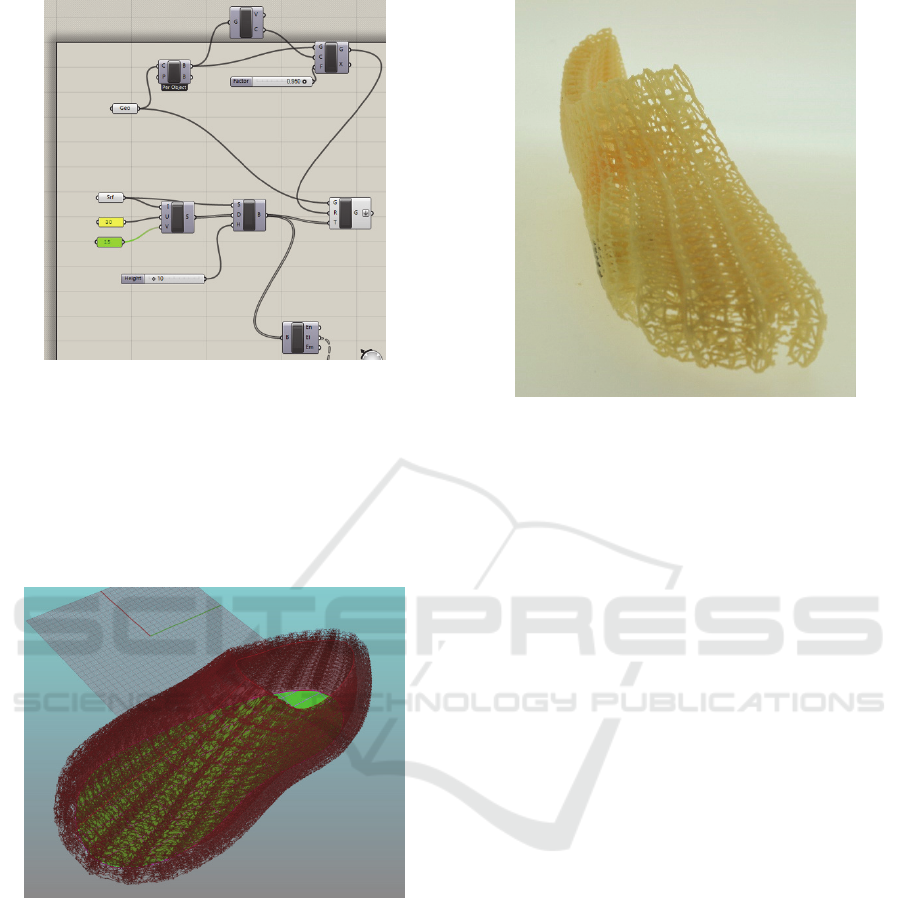

Next, it was exported to the Netfabb

®

program to

correct the file and prepare the model for ABS

printing, using the FDM process. Since the printer

used has a print volume of 8 in

3

, it was necessary to

reduce the dimensions of the splint by proportional

scaling so that the formal properties of the cubic

module was not lost so that it entered the printing tray,

in addition divided in half to appreciate the thickness

and arrangement it would acquire (fig. 10). The

printing process took 72 h, plus the removal of

soluble support material.

Figure 10: The First model of the foot splint, printed in ABS

plastic.

The results of this first phase were successful,

since the task of replicating the structure of the

organism as well as its application in the design of the

splint was achieved.

However, the work does not end here; it will

continue to improve in one case and resolve in

another, certain aspects such as the system of

attachment and coupling to the member, the final

material, the copy of the user's anthropometry and the

processing time. It is very important to compare the

three-dimensional model against the model printed by

FDM, since the first one exhibits a different behavior

from the second, especially due to the printing

trajectories of the filament, so that stress analysis and

resistance tests will also be done.

4 CONCLUSIONS

Bio-design, in conjunction with the NT –particularly

the MRI and 3D printing - is a good alternative in

product development, as demonstrated in this project.

Relying on principles backed by millions of years of

testing, in the great laboratory that is Nature, becomes

a great advantage when it comes to solving design

problems. Although the use of MRI is associated with

the medical area, it can be used equally for other

research; in this case it was used to obtain an exact

reproduction of the structure of a biological organism,

which otherwise would have been complicated to

achieve: the dried fruit of the Luffa. Its peculiar

structure gives it interesting mechanical properties

that make it resistant to deformation, which is why it

BIOIMAGING 2020 - 7th International Conference on Bioimaging

154

was thought that this advantage could be used to

design a splint for the human foot, which improves on

the traditional ones made of coated bandages with

plaster This research can serve as a basis for creating

diverse and varied bio-designed products, not only

from the medical area, but also from other fields and

specialties of human activity.

ACKNOWLEDGMENTS

We thank the National Center for Research in

Medical Imaging and Instrumentation (CI

3

M) of the

Universidad Autónoma Metropolitana, Iztapalapa

Unit, for the loan of the 7T MRI scanner and the use

of its facilities, as well as the Materialization and 3D

Modeling Laboratory of the Universidad Autónoma

Metropolitana Azcapotzalco Unit for the realization

of this project. Thanks to the Librarian César

Saavedra-Alamillas, for his help in the bibliographic

review.

REFERENCES

Al Jabbari, O., Abu Saleh, W. K., Patel, A. P., Igo, S. R., &

Reardon, M. J. (2016). Use of three-dimensional

models to assist in the resection of malignant cardiac

tumors. Journal of Car-diac Surgery, 31(9), 581–583.

https://doi.org/10.1111/jocs.12812

Backstrom, K., Nazari, M., Gu, I. Y.-H., & Jakola, A. S.

(2018). An efficient 3D deep convolutional network for

Alzheimer’s disease diagnosis using MR images. 2018

IEEE 15th International Symposium on Biomedical

Imaging (ISBI 2018), 149–153. https://doi.org/

10.1109/ISBI.2018.8363543

Bezinque, A., Moriarity, A., Farrell, C., Peabody, H.,

Noyes, S. L., & Lane, B. R. (2018). Determination of

Prostate Volume. Academic Radiology, 25(12), 1582–

1587. https://doi.org/10.1016/j.acra.2018.03.014

Bouchet, A., Pastore, J. I., Brun, M., & Ballarin, V. (2015).

Segmentation of Lateral Ventricles in Magnetic

Resonance Images. En A. Braidot & A. Hadad (Eds.),

VI Latin American Congress on Biomedical

Engineering CLAIB 2014, Paraná, Argentina 29, 30 &

31 October 2014 (Vol. 49, pp. 457–460).

https://doi.org/10.1007/978-3-319-13117-7_117

Chen, Q., Shi, Q., Gorb, S. N., & Li, Z. (2014). A multiscale

study on the structural and mechanical properties of the

luffa sponge from Luffa cylindrica plant. Journal of

Biomechanics, 47(6), 1332–1339. https://doi.org/

10.1016/j.jbiomech.2014.02.010

Cole-Hamilton, D. J., Kaye, B., Chudek, J. A., & Hunter,

G. (1995). Nuclear Magnetic Resonance Imaging of

Waterlogged Wood. Studies in Conservation, 40(1), 41.

https://doi.org/10.2307/1506610

Ehricke, H.-H., Hauser, T.-K., Nägele, T., Schult, T., &

Klose, U. (2018). Magnetic resonance angiography

contrast enhancement and combined 3D visualization

of cerebral vasculature and white matter pathways.

Computerized Medical Imaging and Graphics, 70, 29–

42. https://doi.org/10.1016/j.compmedimag.

2018.09.005

Ghisalberti, E. L., & Godfrey, I. M. (1998). Application of

nuclear magnetic resonance spectroscopy to the

analysis of organic archaeological materials. Studies in

Conservation, 43(4), 215–230. https://doi.org/10.1179/

sic.1998.43.4.215

Kim, H., & Jeong, S. (2015). Case study: Hybrid model for

the customized wrist orthosis using 3D printing.

Journal of Mechanical Science and Technology,

29(12), 5151–5156. https://doi.org/10.1007/s12206-

015-1115-9

Pal, A. (2016, julio 25). Orthopedic Splints—Principles,

Types and Use. Retrieved on September 19, 2019, from

Bone and Spine website: https://boneandspine.com/

orthopedic-splints/

Pawlyn, M. (2011). Biomimicry in architecture (1th

edition). London: Riba Publishing.

PROTA. (2018). Luffa cylindrica. Retrieved on March 19,

2019, from https://www.prota4u.org/database/protav8

.asp?h=M4&t=Luffa,cylindrica&p=Luffa+cylindrica#

Synonyms

Roncoroni Osio, U. (2017). Manual de diseño generativo.

Retrieved from https://ra.ocls.ca/ra/algologin.aspx?inst

=algonquin&url=http://search.ebscohost.com/login.asp

x?direct=true&scope=site&db=nlebk&AN=1601346

Shen, J., Min Xie, Y., Huang, X., Zhou, S., & Ruan, D.

(2012). Mechanical properties of luffa sponge. Journal

of the Mechanical Behavior of Biomedical Materials,

15, 141–152. https://doi.org/10.1016/j.jmbbm.

2012.07.004.

3D Printed Human Foot Splint, Designed from MRI of the Luffa Cylindrica Dried Fruit

155