Optical Spectroscopy for the Quality Control of ATMP Fabrication:

A New Method to Monitor Cell Expansion and to Detect

Contaminations

B. Wacogne

1,2

, D. Legrand

1

, C. Pieralli

1

and A. Frelet-Barrand

1

1

FEMTO-ST Institute, Univ. Bourgogne Franche-Comte, CNRS,

15B Avenue des Montboucons, 25030, Besançon, Cedex, France

2

Centre Hospitalier Universitaire de Besançon, Centre d’Investigation Clinique,

INSERM CIC 1431, 25000, Besançon, France

Keywords: Optical Spectroscopy, Advanced Therapy Medicinal Product, Cell Growth Monitoring, Contamination

Detection.

Abstract: Fabrication of Advanced Therapy Medicinal Products takes currently place in clean and sterile environment

and is highly sensitive to any contamination sources. It lasts for several days and is extremely expensive.

Quality controls must be performed throughout the process, especially to monitor cell growth during the

expansion phase and to detect any contaminations. Regular sampling of the bioreactor’s content is required

and subsequent biological investigation are conducted. Major drawbacks are first, a delayed result of the

quality control and second, an added risk to induce new contaminations when sampling the content of the

bioreactor. Here, we present a real time optical spectroscopy method which can be used in a closed system

manner, hence reducing the risk of sampling-related contamination. Analysing the shape of the absorption

spectrum of the bioreactor content allows monitoring the cell growth and alerting users in case of

contamination. Cell concentrations are measured with an accuracy of ± 5% and contamination can be detected

about 3 hours after it occurred. This allows stopping the fabrication as soon as a problem arises leading to

several tens of thousand dollars savings. Consequently, the price of these products should be greatly reduced

and they may be proposed to more patients.

1 INTRODUCTION

ATMPs (Advanced Therapy Medicinal Products)

have recently emerged to offer new treatment

solutions for patients with no further therapeutic

options. For some, they are based on the use of "drug"

cells derived from genetic modification or tissue and

cell engineering. These "living" drugs are subject to

substantial manipulations that allow cells to acquire

new physiological functions, biological

characteristics or reconstruction properties. The

development of new biological drugs is inspired by

the natural processes of the body such as the use of

stem cells for tissue regeneration, lymphocytes for

cancer immunotherapy or apoptotic cells for anti-

inflammatory purposes.

However, the fabrication of these drugs requires

the implementation of complex technologies of cell

sorting, amplification, genetic transduction,

amplification-division, activation, and this at several

stages of production and in sterile clean room type

environment. As for industrial products, their

production is expensive, mainly because of the

complex infrastructure required, the time needed to

complete the production stages and the complex

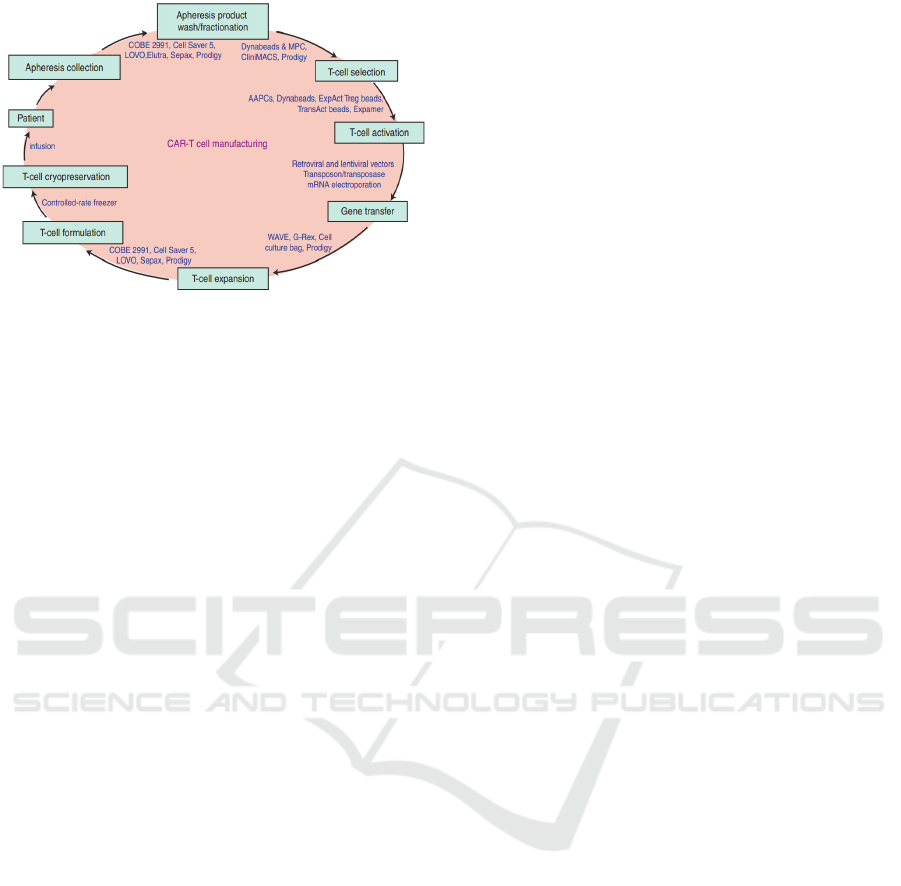

quality control processes. A schematic description of

the fabrication process of CAR-T cells is given in

figure 1 (Wang 2016). It also applied to other ATMPs

fabrications.

The basic principle consists in sampling the

patient's blood and extract the cells of interest (T cells

for figure 1). These cells are transduced to acquire the

desired therapeutic properties. A sorting step then

makes it possible to keep only the correctly

transduced T cells. From this moment, these

genetically modified cells are amplified/expanded in

a bioreactor for a period that can extend up to 1 week.

At the end of the process, the ATMP is injected to the

patient or cryo-preserved before injection. The goal

of our project (see acknowledgements) is to realize all

64

Wacogne, B., Legrand, D., Pieralli, C. and Frelet-Barrand, A.

Optical Spectroscopy for the Quality Control of ATMP Fabrication: A New Method to Monitor Cell Expansion and to Detect Contaminations.

DOI: 10.5220/0009130000640072

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 64-72

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Fabrication process of CAR-T cells (Wang 2016).

these operations within a miniaturized and

autonomous device. One of the main constraints that

needs to be lifted is the following.

The requirement of no contamination of the

products requires working in a controlled

environment and preserving the closed system as

often as possible. This is frequently made difficult by

the absence of containers, reagents or materials

adapted to the protocol. This constraint implies many

samplings during the protocol such as sampling for

the evaluation of bacteriological contamination. This

increases the risk of contamination, the time of

completion and requires increased traceability. These

evaluations being long, the fabrication process

continues in parallel, sometimes requiring to stop

production after several days in case of a

contamination. These stops actually increase the cost

and delay or even stop the delivery of the drug to the

patient.

The work presented in this paper addresses the

constraint of closed system and real time control of

what happens in the bioreactor during the expansion

phase. The goal is twofold, monitor the cell growth

and detect early contaminations. In-line or real time

measurement techniques have been widely studied

either for cell culture or contaminant development

monitoring, very rarely for both.

For example concerning cell culture, various

techniques have been presented in Teixeira review

(Teixeira, 2009). Techniques based on ultrasonic

measurements (Melchor, 2018) or capacitive

techniques (Lee, 2016) have been proposed.

Impedance monitoring, either in a bulk system

(Cacopardo, 2019) or in a microfluidic chip (Fong

Lei, 2014) has also been presented. In these

references however, indications whether or not the

proposed method can be adapted in a closed system

configuration were not discussed.

Concerning bacteria detection or monitoring,

different sensors to detect Escherichia coli (hereafter

E. coli) have been proposed by Ikonen (Ikonen,

2017). These bacteria can also be detected using

modified Field Effect Transistors (Thakur, 2018).

Detecting several contaminants with a single device

has been demonstrated. The use of fiber optic Fourier

Transform Infra-Red spectroscopy (Hassan, 2016),

quartz crystal sensors (Chang, 2006), and

electrochemistry (Safavieh, 2014) has been reported.

Only very few papers mention both cell

monitoring and contaminant detection. For example

in (Liu, 2017), advanced signal processing applied to

Raman spectroscopy has been proposed. Together

with normal operation condition monitoring, authors

demonstrated the detection of growth problems 5

hours after they stopped feeding the cells. They also

detected effects of contamination with their

monitoring algorithm. However, the nature of the

contamination and the time required to detect it was

not specified.

In this paper, we propose a proof of concept based

on white light absorption spectroscopy used to

continuously monitor the evolution of cells

concentration in a bioreactor and to issue an alarm

signal about 3 hours after a contamination occurred.

The next section of the paper describes the

experimental set-up and biological samples used in

this study. Section 3 presents the results obtained

using two methods based on spectra shape analysis

and Principal Component Analyses (PCA)

respectively. Short discussions of these early results

and aspects concerning socio-economic impacts will

be given in section 4.

2 MATERIALS AND METHODS

For this proof of concept, measurements are not

performed in a closed system configuration.

Adaptation of the method in this particular

environment is shortly discussed in section 4.

2.1 Experimental Set-up

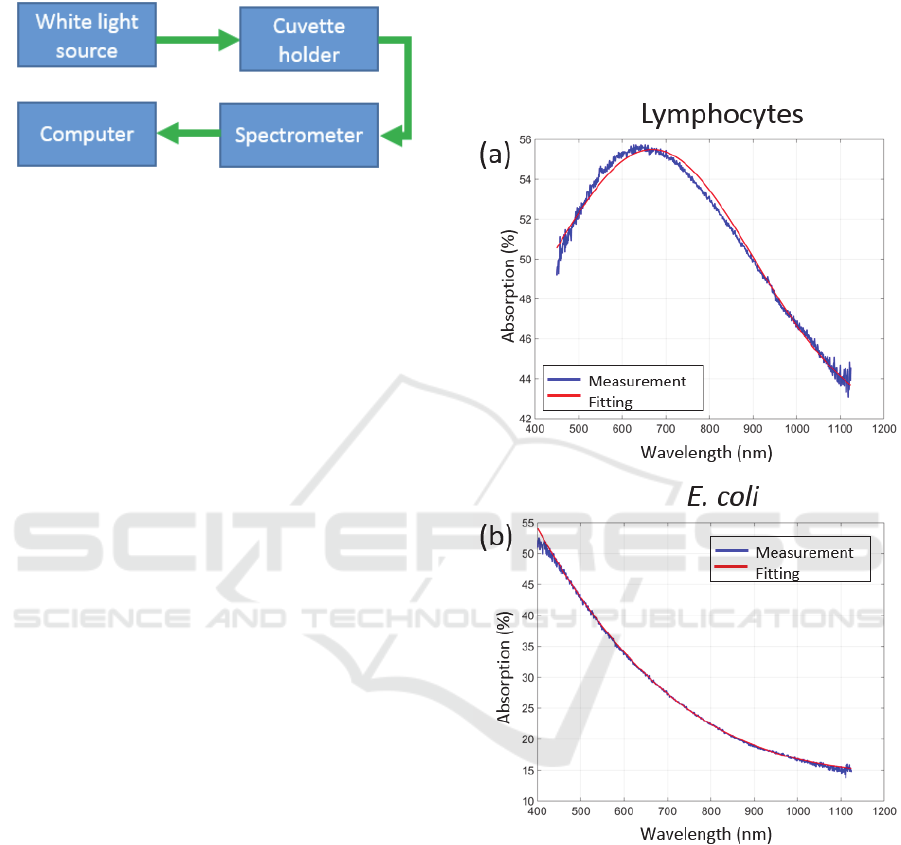

The extremely simple experimental set-up is

schematically presented in figure 2.

The set-up was composed of a white light source

(Ocean Optics HL 2000) connected to a cuvette

holder (Avantes CUV-UV/VIS) via conventional step

index optical fibers (Thorlabs M25L01). After

propagation through the cuvette, light was launched

into a spectrometer for absorption spectra acquisition

(Ocean Optics QE-Pro). Fluorimeter

Optical Spectroscopy for the Quality Control of ATMP Fabrication: A New Method to Monitor Cell Expansion and to Detect

Contaminations

65

polymethacrylate cuvettes were filled up to 3 mL with

solutions of cells and bacteria (Sigma-Aldricht

C0793-100EA).

Figure 2: Description of the experimental set-up.

Absorption spectra were measured using the

specific feature available in the SpectraSuite software

from Ocean Optics. Reference was obtained with a

cuvette filled with PBS only. After transfer to PC,

data processing was performed using MATLAB™

R2014b version. Spectra used in section 3.2 were

slightly smoothed using a cubic spline algorithm in

order to maximize the R

2

of the spectra fittings.

Principal Component Analysis was performed with

smoothed and normalized spectra.

2.2 Lymphocyte and E. coli

Preparation

Lymphocyte cell lines (Ramos, ATCC, USA) were

cultured in X-Vivo (Lonza, Switzerland) with 5%

FBS (Gibco™ 10270106) and 10%

streptomycine/penicillin (100 µg/mL+100 UI/mL,

CABPES01-0U, Eurobio) in a humidified 37°C, 5%

CO

2

incubator. Cells were recovered after 2-3 days

culture by centrifugation at 700 g, 10 min, 25°C.

Different cell concentrations (10

4

×[1, 2, 4, 6, 8, 10,

20, 30, 40, 50, 60, 70, 80, 90, 100] cells/mL) were

prepared after dilution in autoclaved PBS 1x pH7.4

(Sigma, USA).

Escherichia coli DH5α (NEB, USA) were

cultured in Luria Bertani overnight at 37°C, 180 rpm

in a MaxQ incubator. They were recovered by

centrifugation at 5000 g, 15 min, 20°C and re-

suspended in autoclaved PBS 1x pH7.4 (Sigma,

USA). Optical density of the re-suspension was

measured in a spectrophotometer Shimadzu at 595

nm. Afterwards, different bacteria concentrations

(10

6

×[1, 2, 4, 6, 8, 10, 20, 30, 40, 50, 60, 70, 80, 90,

100] bacteria/mL) were prepared for experiments.

In this work, so-called contaminated spectra

presented below are artificial and made by adding

spectra of lymphocyte and E. coli. This aspect will be

discussed in section 4.

3 EXPERIMENTAL RESULTS

3.1 Calculating Concentrations of Both

Species: A Difficult Way

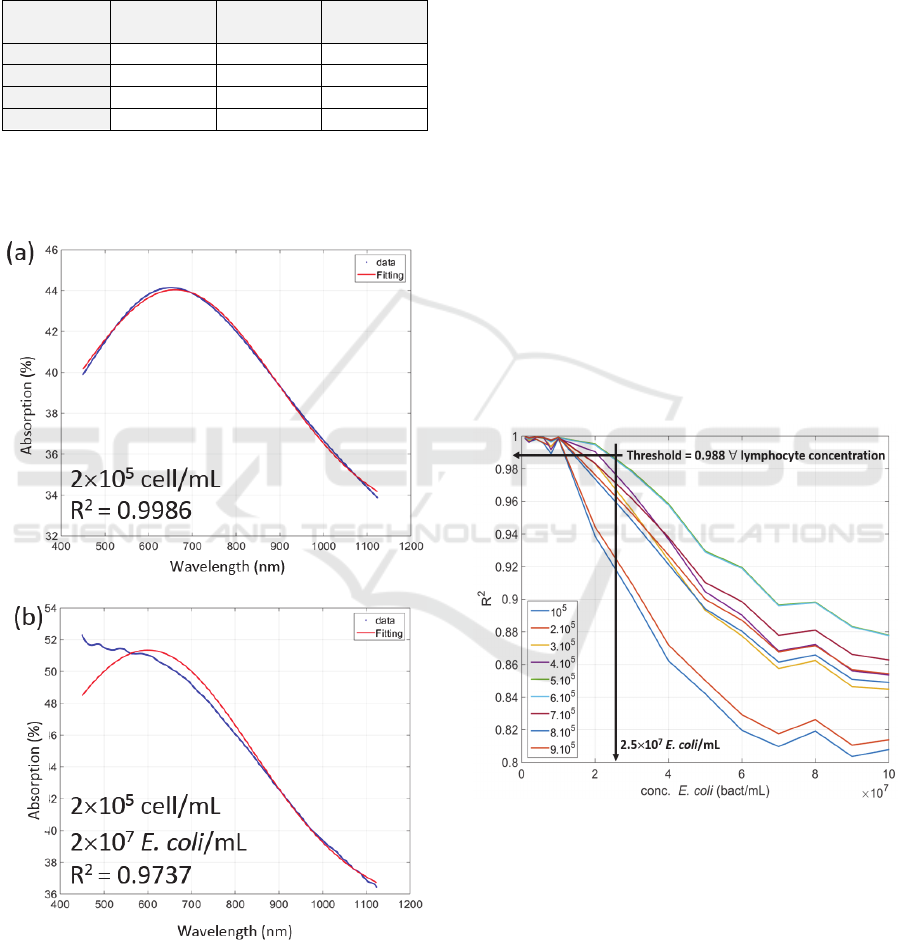

Examples of spectra recorded with lymphocytes and

E. coli are given in figure 3.

Figure 3: Examples of absorption spectra. (a) Lymphocytes,

(b) E. coli.

Noting that the shapes of the spectral absorptions

of the two species are different, the goal was to

measure the absorption spectrum of the contents of

the bioreactor continuously. For each recorded

spectrum, the idea is to analyse the shape, to separate

the part due to the contribution of lymphocytes from

that due to E. coli and to calculate their respective

concentrations.

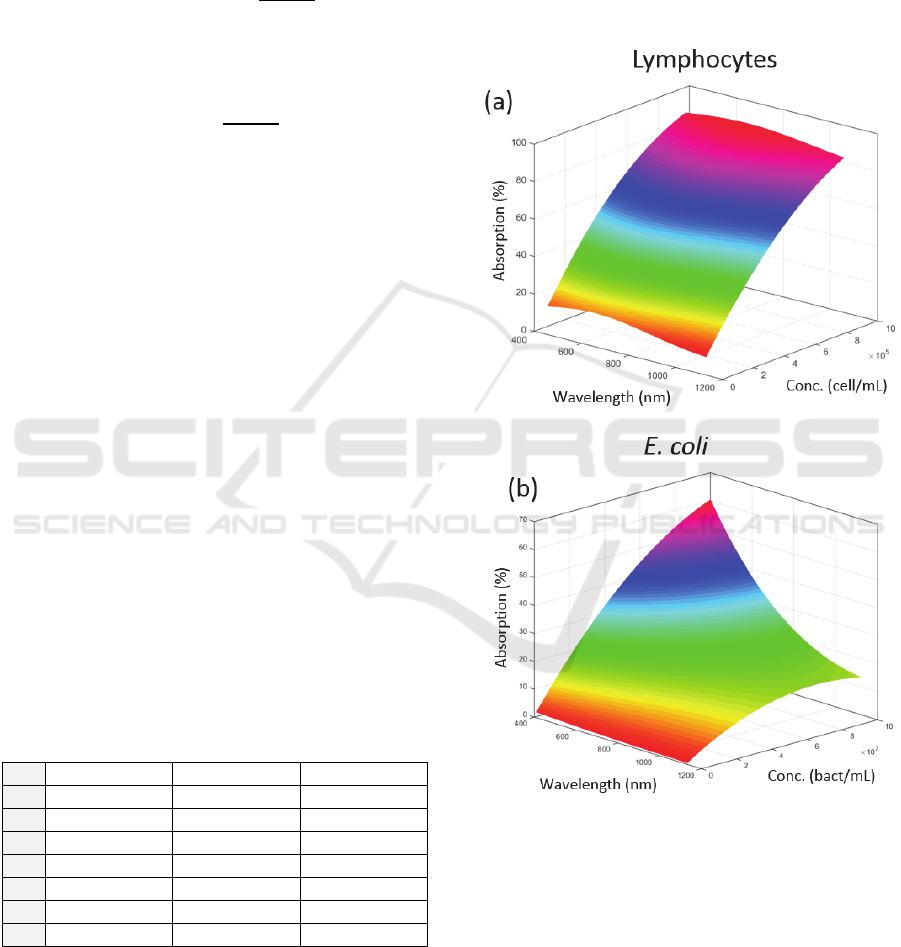

To do this, it was necessary to determine the

evolution of the spectra of the two species as a

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

66

function of the concentration. Concentration ranges

of the two species were used and, by fitting, it was

possible to express their spectral evolutions as a

function of their concentrations.

Equations (1) to (5) represents the evolution for

lymphocytes.

Spec

(

λ

)=p1.exp−

λ

−p2

p3

(1)

Here, λ is the wavelength and functions “pi”

functions are given by:

p1=a1.exp−

𝐂−a2

a3

(2)

p2=b1.𝐂+b2

(3)

p3=c1.𝐂

+c2.𝐂+c3

(4)

p4=d1.𝐂

+d2.𝐂+d3

(5)

where C is the lymphocytes concentration.

Equations (6) to (10) represents the evolution for

lymphocytes.

Spec

.

(

λ

)

=q1

λ

+q2

λ

+q3

λ

+q4

(6)

Here, λ is the wavelength and functions “qi”

functions are given by:

q1=e1.𝐂

+e2.𝐂+e3

(7)

q2=f1.𝐂

+f2.𝐂+f3

(8)

q3=g1.𝐂

+g2.𝐂+g3

(9)

q4=h1.𝐂

+h2.𝐂+h3

(10)

where C is the E. Coli concentration.

Coefficients used in these equations are given in

table 1.

Table 1: Coefficients used in the above equations.

p1

a1=14.32

a2=4.1×10

5

a3=6.145×10

5

p2

b

1=7.21×10

-5

b2=647

p3

c1=1×10

-10

c2=-1.9×10

-5

c3=325.7

p4

d1=-5×10

-11

d2=1.3×10

-3

d3=6.791

q1

e1=1.2×10

-23

e2=-1.6×10

-15

e3=1.2×10

-9

q2

f1=-3.3×10

-20

f2=5.1×10

-12

f3=-1.7×10

-6

q3

g1=2.8×10

-17

g2=-5.5×10

-09

g3=-8.3×10

-4

q4

h1=-1×10

-14

h2=2.4×10

-6

h3=1.234

These evolutions are represented in figure 4 (they

were used to fit the experimental spectra presented in

figure 3 (red curves)).

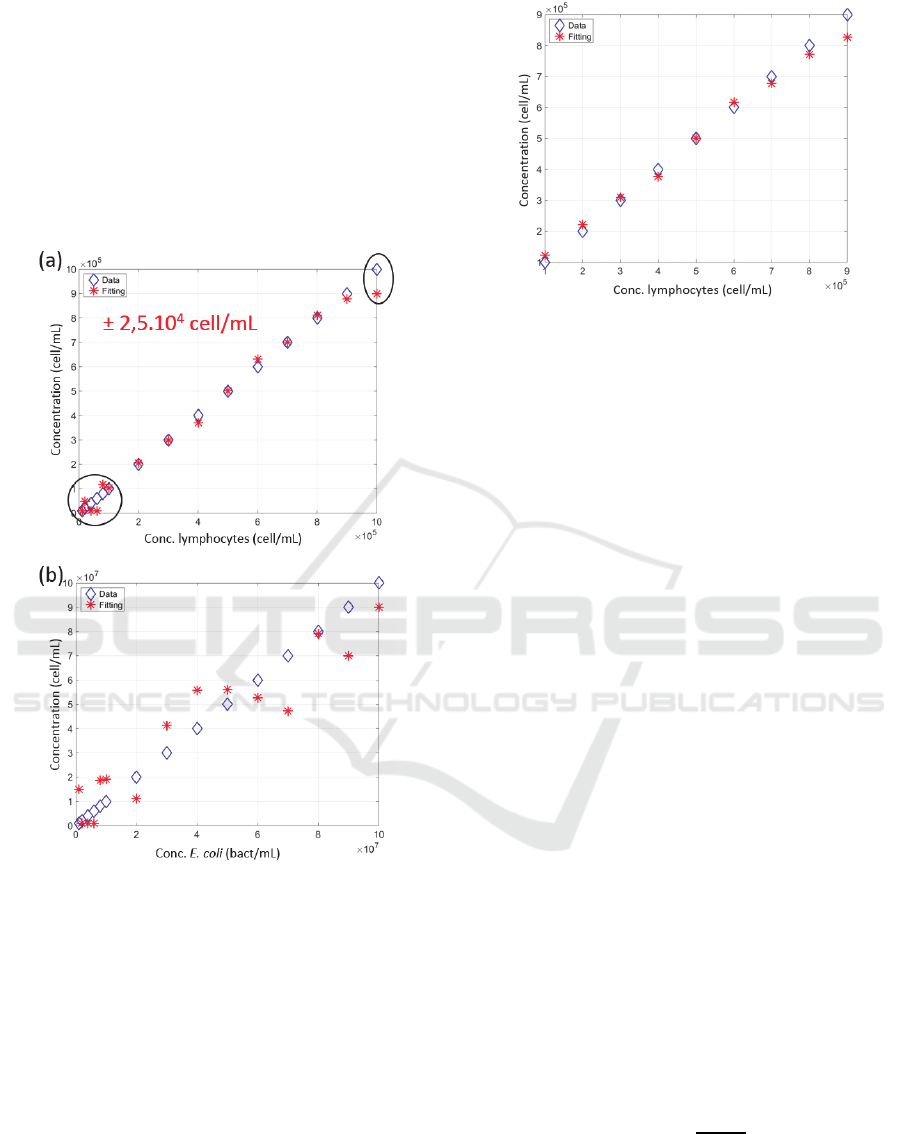

From there, for each recorded spectrum and

considering either lymphocytes or E. coli, we

compared the actual concentration values with those

calculated with the above functions by fitting the

spectra. Figure 5 shows the results obtained.

It was found that the exploitation of the shape of

the spectra to calculate concentrations was effective

only for lymphocyte concentrations ranging from 10

5

to 9×10

5

cell/mL (black circles in figure 5(a) where

the fitting was not effective). In the validity range, an

accuracy of ± 5% was measured.

Figure 4: Theoretical evolutions of the absorption spectra

with concentrations. (a) Lymphocytes, (b) E. coli.

We have also studied other descriptors of the

spectra. By considering their associated colour, it is

shown that, in the HSV base, the “Value” variable

made it possible to describe the concentrations of the

two species. The same is true if we consider the

entropy of spectra. However, when considering

spectra of lymphocytes and E. coli mixtures, it is

extremely difficult to separate their respective

Optical Spectroscopy for the Quality Control of ATMP Fabrication: A New Method to Monitor Cell Expansion and to Detect

Contaminations

67

contributions. The problem becomes insoluble when

several types of pathogens are considered.

Indeed, as long as only lymphocytes are present in

the bioreactor (no contamination), fitting the shape of

the spectra to monitor the cell growth leads to the

same accuracy as what we obtained using

conventional turbidimetry as presented in figure 6.

For the concentration range considered, the area

under the spectra can be modelled using a second

order polynomial function.

Figure 5: Calculating the concentration from the shape of

experimental spectra (a) Lymphocytes, (b) E. coli. Blue

diamonds: real concentrations, red crosses: fitted

concentrations. Black circles in (a): concentration ranges

for which the method does not work.

However, detecting contaminations can be

achieved by considering things differently. This is the

subject of the next section.

Figure 6: Calculating the lymphocyte concentrations from

the area under the spectra (turbidimetry). Blue diamonds:

real concentrations, red crosses: fitted concentrations.

3.2 Monitoring Cell Concentrations

and Detecting Contaminations: A

New Approach

3.2.1 Fitting the Shape of the Absorption

Spectra

We must understand the problem differently. During

the expansion phase, as long as everything is normal

(no contamination), cells concentration can be

monitored using turbidimetry. Now, if contamination

occurs, the shape of the spectrum resulting from the

contribution of the lymphocytes and the contaminant

differs from the ones corresponding to lymphocytes

alone.

The idea is this. During the expansion phase,

absorption spectra are recorded and fitted with a

function representing the shapes of the lymphocytes

spectra when they are alone. An accurate fitting (high

R

2

) means that no contamination has occurred and

lymphocyte concentration is calculated by integrating

the area under the spectra. On the contrary, a bad

fitting (R

2

less than a threshold to be determined)

means that contamination occurred indicating that the

production must be stopped.

This can be achieved using a much simpler

equation than the one depicted in figure 4(a). Indeed,

we do not calculate a concentrations, we only fit the

shape of the recorded spectrum. The following

spectrum description can efficiently be used.

𝐴

𝑏𝑠

(

𝜆

)

=𝑎.𝑒𝑥𝑝−

𝜆−𝑏

𝑐

+𝑑

(11)

The goal is to fit any spectra with this equation.

To do this, constraints were put to coefficients a, b, c

and d. Otherwise, the fitting algorithm (“trust region”

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

68

in Matlab™ Curfitting toolbox) always find set of

parameters to describe even contaminated spectra.

The fitting bounds and starting points are summarized

in table 2.

Table 2: Bounds and starting points for fitting lymphocytes

spectra.

Coefficient

Lower

bound

Upper

bound

Starting

p

oint

a 0 200 100

b 600 750 675

c 0 500 250

d 0 200 100

Figure 7 shows example of lymphocytes

absorption spectra fittings using equation (11).

Spectra were slightly smoothed as mentioned above.

Figure 7: Examples of spectra fitting using equation (11).

(a) Lymphocyte concentration = 2×10

5

cell/mL, R

2

=

0.9986. (b) Lymphocyte concentration = 2×10

5

cell/mL, E.

coli concentration = 2×10

7

bact/mL, R

2

= 0.9737.

Figure 7(a) shows a fitting performed with pure

lymphocytes at 2×10

5

cell/mL with R

2

=0.9986.

Considering only pure lymphocyte solutions, R

2

coefficients were always greater than 0.99 for except

for 10

4

and 10

6

cell/mL. Indeed, for these

concentrations, absorption is either too weak or too

strong for our method to work. We did not consider

these concentrations in what follows.

Figure 7(b) shows a fitting performed with the

same lymphocyte concentration contaminated with

2×10

7

E. coli/mL. Because of the contamination, R

2

decreases to 0.9737.

The evolution of R

2

with increasing

concentrations of E. coli for different initial

lymphocyte concentrations is shown in figure 8. Each

curve corresponds to one lymphocyte concentration.

For each lymphocytes concentration, the evolution of

R

2

is plotted as a function of E. coli concentration.

It was found that, whatever the lymphocyte

concentration is, the bacterial detection limit was

about 2.5.10

7

cells/mL with a positivity threshold R

2

= 0.988 (arrows in the figure). Knowing that E. coli

divides every 20 min and considering that the

contamination is due to 1000 bacteria, the warning

signal can be issued 4h52 min post contamination.

Figure 8: Evolution of the R

2

coefficient with the

concentration in E. coli for different lymphocytes

concentrations. The legend corresponds to lymphocyte

concentrations in cell/mL.

3.2.2 Using Principal Component Analysis

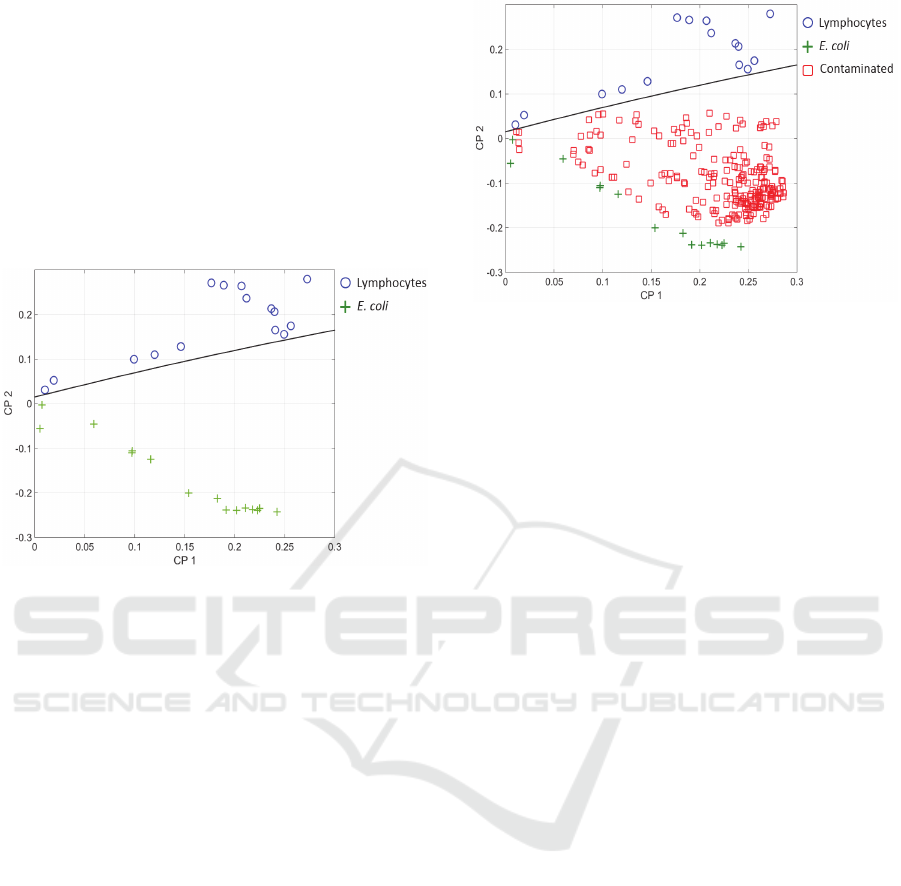

Principle Component Analysis was used to further

reduce the time required to issue the alert signal.

Spectra used here were smoothed and normalized as

mentioned above.

Optical Spectroscopy for the Quality Control of ATMP Fabrication: A New Method to Monitor Cell Expansion and to Detect

Contaminations

69

First, it was applied to spectra of pure lymphocytes

and E. coli. The result considering PC1 and PC2 is

shown in figure 9. The two populations were clearly

separated. The black line represents the frontier

between these populations. It was defined by either the

minima of the coordinates of lymphocytes (circles) and

maxima of E. coli (crosses) or the analysis of the mean

and variance of the two distributions. Taking into

account these data, a straight line which separates the

CP1-CP2 domain in two zones was defined (Janné,

2001).

Figure 9: Principal Component Analysis. Blue circles:

lymphocytes, green crosses: E. coli, black line: separation

between lymphocytes and E. coli.

Second, we added the so-called contaminated

spectra. The 30 data used to generate figure 9 form a

base for the pure lymphocytes and E. coli populations.

Contaminated spectra correspond to all possible

combinations of lymphocyte spectra added to E. coli

spectra. They were processed one by one. Each

contaminated spectrum was considered as a 31

rst

data

in the above mentioned base before a new PCA was

performed. This was iterated for the 225 possible

combinations. The result is shown in figure 10 with the

contaminated spectra marked with red squares.

Spectra corresponding to contaminated culture

were all situated in the E. coli region. This means that

the bacteria detection limit was 10

6

cells/mL (the

minimum E. coli concentration considered in this

study). Comparing with the method based on the

spectra shape analysis and considering that the

contamination is due to 1000 bacteria, the warning

signal can now be issued about 3h19 min post

contamination.

Figure 10: Principal Component Analysis. Blue circles:

lymphocytes, green crosses: E. coli, red squares:

contaminated cultures, black line: separation between pure

and contaminated cultures.

4 DISCUSSION

4.1 Technical Aspects

Figures 5, 6, 8 and 10 show that analysing the

absorption spectra of cells in culture not only allows

monitoring the expansion phase during the fabrication

of ATMPs, but also provides powerful tools to issue an

alert signal about 3 hours after a contamination with

1000 bacteria occurred. These results were obtained

using absorption spectra of various concentrations of

lymphocytes and E. coli.

Bacterial contamination spectra are artificial

spectra made by adding spectra of lymphocytes and E.

coli. This could introduce a bias in the results presented

here. Indeed, adding absorption spectra may lead to an

artificial absorption greater than 100%. However, the

method based on the estimation of the shape of the

absorption spectra will still be valid because only the

shape is considered and not the value of the maximum

absorptions. We recall that the R

2

coefficient is only

used to issue an alert signal. As long as no

contamination is detected, equation depicted in figure

4 remains valid to monitor the expansion phase. This

cell growth monitoring can also be performed

considering conventional turbidimetry as mentioned

above.

Results obtained using Principal Component

Analysis do not suffer from this because it is performed

using normalized spectra. In all cases, a more realistic

study will involve real spectra recorded with actual

mixture of lymphocytes and E. coli.

In this work, we only considered a contamination

due to E. coli. We still need to extend this study to the

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

70

case of other bacteria and other containments like

yeasts and fungi. The methods presented here will still

be valid as long as the shapes of the absorption spectra

of contaminants are different enough from the ones of

lymphocytes.

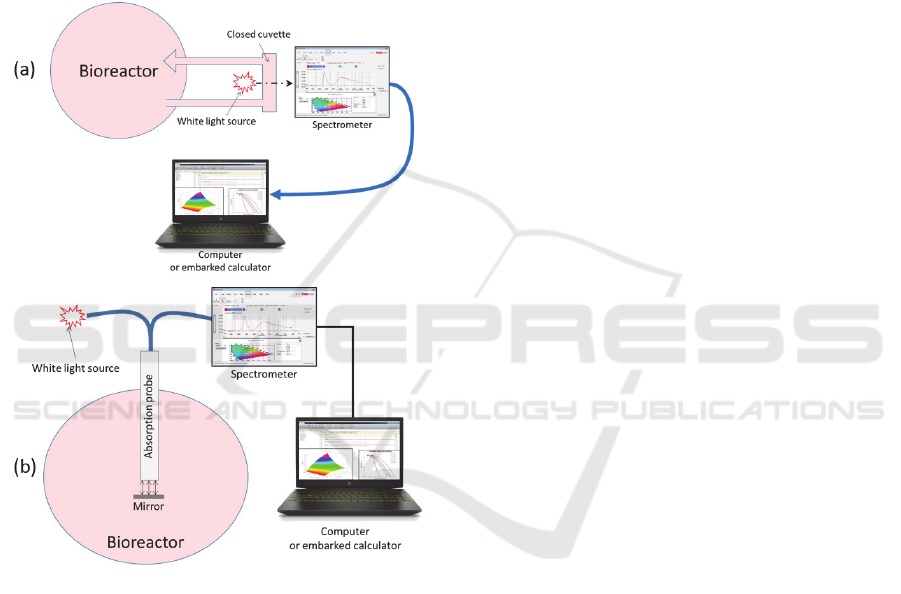

Also, the use of white light spectroscopy through

conventional cuvettes makes possible an easy

adaptation in a closed system configuration using a

derivation from the bioreactor as proposed in figure

11(a). Note that it is also possible to envision the

fabrication of a sterile absorption probe directly

included in the bioreactor as depicted in figure 11(b).

Figure 11: A possible integration of the method in a closed

system environment. (a) Using a derivation. (b) Using a

sterilized reflection probe coupled to a mirror.

4.2 Socio-economic Impacts

As mentioned above, we shortly discuss socio-

economic aspects of this work. We recall that the

duration of the expansion phase is several days. Each

day increases the price of ATMPs and the quality

control imposes regular samples, themselves risk of

contamination. The results presented above are

therefore particularly interesting since they allow

quality control without sampling and make it possible

to stop the expansion phase rapidly (and therefore the

cost associated with inefficient manufacture) about

than 3 hours post contamination if the latter is due to

1000 E. coli.

Designed to treat patients with pathologies that

are currently incurable, ATMPs are likely to create a

real therapeutic revolution in the coming years. It is

currently difficult to estimate the number of

pathologies that these medicines from the living can

address and the number of patients likely to benefit.

At the industrial level, only a few ATMPs are

available on the market and some have had their

marketing authorization cancelled (Glybera,

Sipuleucel-T, ChondoCelect) mainly because of the

enormous cost of their production. As far as we know,

only the following treatments are available (note the

price for a single treatment):

• KYMRIAH ($ 475,000)

• YESCARTA ($ 373,000)

• Strimvelis ($ 594,000)

Included in these costs are losses due to

fabrications, which are found to be contaminated

during the final conformity test, and those due to late-

stage fabrication stops due to the scheduling of

controls at precise dates.

Having a real-time and closed system monitoring

and quality control method is of great interest in terms

of research, industrial manufacturing and more

importantly in terms of benefit to the patients.

5 CONCLUSION

In this paper, we have presented methods to

continuously perform a quality control during the

expansion phase of the fabrication of ATMPs and this

in a closed system environment. These methods are

based on analysing the absorption spectra of what

happens in the bioreactor. Spectral shape analysis is

used to monitor the cells growth and to issue an alert

signal about 4h52 post contamination. Principal

Component Analysis does not allow determining the

lymphocyte concentration but it allows reducing the

time required to issue the alert signal to 3h19

(durations calculated considering that contamination

is due to 1000 E. coli). Advantages of such methods

can be summarized as follows.

It is no longer necessary to sample the content of

the bioreactor for analysis and detection of potential

pathogens. There is no longer risk of product

contamination due to sampling. The idea is no longer

to seek to identify pathogens but just reveal the fact

that the cell culture is not going as planned and stop

production. The use of planned sampling at a fixed

date and time without even knowing whether

Optical Spectroscopy for the Quality Control of ATMP Fabrication: A New Method to Monitor Cell Expansion and to Detect

Contaminations

71

contamination will be detected is avoided. The cell

growth is monitored in real time as long as the culture

is normal. Contamination is detected extremely early.

The production cost can be greatly reduced by

stopping the production as soon as a contamination is

detected.

Indeed, in order to guarantee access to the largest

number of patients, a new conception of the current

mode of production and qualification of the ATMPs

is necessary. Currently, our studies are focussed on

the validation of these above described methods

considering other types of pathogens.

ACKNOWLEDGEMENTS

This work was supported by the MiMedi project

funded by BPI France (grant No. DOS0060162/00)

and the European Union through the European

Regional Development Fund of the Region

Bourgogne-Franche-Comte (grant No. FC0013440).

REFERENCES

Cacopardo, L., et al, 2019. Real-time cellular impedance

monitoring and imaging of biological barriers in a dual-

flow membrane bioreactor, Biosensors and

Bioelectronics Vol. 140, pp. 111340

Chang, K-L., et al, 2006, Series quartz crystal sensor for

remote bacteria population monitoring in raw milk via

the Internet, Biosensors and Bioelectronics Vol. 21, pp.

1581–1590

Fong Lei, K., et al, 2014. Real-time and non-invasive

impedimetric monitoring of cell proliferation and

chemosensitivity in a perfusion 3D cell culture

microfluidic chip, Biosensors and Bioelectronics,

Vol.51, pp.16–21

Hassan, M., et al, 2016. Detecting bacteria contamination

on medical device surfaces using anintegrated fiber-

optic mid-infrared spectroscopy sensing method,

Sensors and Actuators B Vol. 231, pp. 646–654

Ikonen, J., et al, 2017. On-line detection of Escherichia coli

intrusion in a pilot-scale drinking water distribution

system », J. of Environmental Management, Vol. 198,

pp. 384-392

Janné K. et al, 2001. Hierarchical principal component

analysis (PCA) and projectionto latent structure (PLS)

technique on spectroscopic data as adata pretreatment

for calibration, J. Chemometrics, Vol. 15, pp. 203-213

Lee, S-L., et al, 2016. Real-time monitoring of 3D cell

culture using a 3D capacitance biosensor, Biosensors

and Bioelectronics, Vol. 77, pp. 56–61

Liu, Y-J, et al, 2017. Multivariate statistical process control

(MSPC) using Raman spectroscopy for in-line culture

cell monitoring considering time-varying batches

synchronized with correlation optimized warping

(COW), Analytica Chimica Acta Vol. 952, pp. 9-17

Melchor, J., et al, 2018. In-bioreactor ultrasonic monitoring

of 3D culture human engineered cartilage, Sensors and

Actuators B Vol. 266, pp. 841–852

Safavieh, M., et al, 2014. High-throughput real-time

electrochemical monitoring of LAMP for pathogenic

bacteria detection, Biosensors and Bioelectronics, Vol.

58, pp. 101–106

Teixeira, A.P., et al, 2009. Advances in on-line monitoring

and control of mammalian cell cultures: Supporting the

PAT initiative, Biotechnology Advances, Vol. 27, pp.

726–732

Thakur, B. et al, 2018. Rapid detection of single E. coli

bacteria using a graphene-based field-effect transistor

device, Biosensors and Bioelectronics, Vol. 110, pp.

16–22

Wang, X., et al, 2016. Clinical manufacturing of CAR T

cells: foundation of a promising therapy, Molecular

Therapy-Oncolytics, Vol. 3, pp. 16015

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

72