The Behaviour of Neuro-2A Cells on Silicon Substrates with Various

Topographies Generated by Femtosecond Laser Micromachining

Sara Mingu

1* a

, Ihor Pavlov

2b

, Çağdaş Devrim Son

1,3 c

and Alpan Bek

1,2 d

1

Micro and Nanotechnology Graduate Program, Middle East Technical University, 06800, Ankara, Turkey

2

Department of Physics, Middle East Technical University, 06800, Ankara, Turkey

3

Department of Biological Sciences, Middle East Technical University, 06800, Ankara, Turkey

Keywords: Neuro-2A Cells, Ultrafast Laser Processing, Silicon, Live Imaging, Substrate Topography.

Abstract: The interaction of neural cells with silicon surfaces is important for basic research as well as for various

possible applications, such as silicon-based neural implants and neurochips. Laser structuring of silicon

provides a quick and versatile method for the generation of complex, hierarchical topographies on precise

locations of the substrate. The behaviour of Neuro-2A cells with laser-structured silicon substrates was studied

using a live-imaging setup with fluorescence microscopy. Neuro-2A cells were able to adhere to polished

silicon, ripples and microcolumns to different extents, depending on the substrate topography and incubation

time. Initially, cells adhere much better to structured areas, resulting in visible cell patterning on the substrates.

Time-lapse microscopy revealed cell exploration and motility behaviours on the substrates. Cell motility was

significantly decreased on structured substrates, with whole area microcolumns having the slowest cell

motility. On polished silicon, cells were found to interact with the substrates using lamellipodia and filopodia.

After 24 or 48 hours, cells were better able to adhere to polished as well as structured silicon. Neurite

alignment was observed on microcolumn and trench substrates. On the other hand, highly processed substrates

were inhibitory to cell growth and resulted in poor cell health.

1 INTRODUCTION

The interaction of cells with their physical

environment, including substrate topography, is

important in basic and applied research in tissue

engineering and regenerative medicine. Cells have

been shown to respond to substrates via alterations in

adhesion, proliferation, shape or differentiation state

(Dalby, 2014; Yang, 2015).

As a general rule, it is believed that specific parts

of the cells interact with topographical features of

similar size: small sized features (tens of nm) interact

with integrins, micron-sized features interact with

focal adhesions, while larger topographical features

(tens of microns) may interact with the cell bodies. In

particular, neurites were found to interact with

topographical features of various sizes (Yim, 2016).

The underlying biochemical mechanisms have not

been completely elucidated, and there is ongoing

a

https://orcid.org/0000-0002-7332-0764

b

https://orcid.org/0000-0001-9494-4149

c

https://orcid.org/0000-0002-4076-5441

d

https://orcid.org/0000-0002-0190-7945

research on the interaction of cells with substrates.

The parameters to consider are the choice of substrate

materials, the micromachining methods, the substrate

surface topographies, and the cell types.

Different materials such as polymers, glass,

steel, gold, platinum, titanium and silicon have been

shown to be appropriate cell substrate materials, and

various modification techniques have been

characterized (Mendes, 2013). Out of these, silicon

has extensively been studied as a cell substrate, also

due to its importance in microelectronics. It is

possible to generate different topographies on silicon

with lithographic or chemical etching techniques.

Silicon has been proposed as a base material for

implantable electronic devices and has been shown to

be biocompatible in vivo in various forms: bare,

coated with chemicals such as poly-lysine, as well as

in forms of porous silicon, quartz, and fused silica

192

Mingu, S., Pavlov, I., Son, Ç. and Bek, A.

The Behaviour of Neuro-2A Cells on Silicon Substrates with Various Topographies Generated by Femtosecond Laser Micromachining.

DOI: 10.5220/0009160001920199

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 2: BIOIMAGING, pages 192-199

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(Khan, 2010). Silicon has been previously studied as

a biomaterial with various cell types.

Direct laser writing is a fast, one-step procedure;

it does not require masks or other treatments, it can

be performed in air, and can be used to structure

silicon (Guo, 2013). Laser processing in silicon

generates complex hierarchical morphologies, which

have features in both micro- and nanoscale and thus

resemble in-vivo topographies. A wide variety of

structures is possible simply by changing the laser

fluence. These include channels/trenches, micro-

columns covered in nano-roughness, as well as laser-

induced periodic surface structures (LIPSS). In

particular, LIPSS may be of two types, high spatial

frequency (HSFL), having a period smaller than the

wavelength of the laser, or low spatial frequency

(LSFL), having a period close to the wavelength. In

our study, LSFL LIPSS is used; to the best of our

knowledge, no other study reports the interaction of

LSFL LIPSS on silicon with cells. Femtosecond-laser

induced LIPSS is interesting because it is a regular

grating-like structure covered in nano-roughness. As

such, it may resemble ordered fibres in the cells’

natural environment. Many studies try to replicate

ordered fibres by polymer electrospinning or

lithographic techniques. However, with laser, unlike

other procedures, selective processing of defined

areas on a single substrate and in a single step is

possible, allowing for simultaneous comparison of

different topographies on the same substrate without

any mask.

Neural cells are particularly important, due to

possible applications for neural prosthetics or chips.

As such, there has been extensive research on the

interaction of various primary neurons or neural stem

cell lines with topographies on different materials

(Simitzi, 2018). In the present study, the Neuro-2A

cell line was chosen, as a fast-growing, widely

available cell line which can differentiate into neural

cells spontaneously or upon induction. Neuro-2A

cells have previously been used in studies of cell-

substrate interactions. In one study, Neuro-2A cell

adhesion and localization was modulated on PDMS

chips subjected to chemical treatments, and

communicating neural networks were formed

(Yaghoub, 2005). In another study, 20 micron-width

grooves on PDMS were found to be optimal for cell

density, neurite alignment and differentiation rate for

Neuro-2A cells (Beduer, 2011). Neuro-2A cells have

also been previously studied on silicon substrates. It

was shown that Neuro-2A cells prefer porous silicon

of pore sizes 8 to 75 nm compared to flat silicon, and

that the cell clustering was changed on the porous

surfaces, possibly forming neural networks (Gentile,

2016).

In this work, Neuro-2A cells were observed

interacting with various topographies on silicon

including ablation based microcolumns and LIPSS

based nanoscale ripples using time-lapse microscopy

and confocal microscopy. To our knowledge, this is

the first study where this cell line is used on laser

structured silicon substrates, including LIPSS

topographies, using live imaging.

2 METHODS

2.1 Laser Structuring of Silicon

Substrates

Single-side polished, p-type silicon substrates were

cut into 0.5 mm or 16 mm side squares using precise

laser cutting, in order to ensure an equal number of

cells seeded onto each substrate. The surfaces were

cleaned with hydrogen fluoride for five minutes

before the laser processing. The Laser Induced

Periodic Surface Structures and other topographies

were created using our home-made ultrafast laser

system with central wavelength at 1030 nm, pulse

duration of 370 fs, repetition rate of 1 MHz, and with

up to 1 W of average power. The focused beam spot

size was 9 μm. The system was equipped with a

waveplate for controlling polarization of the laser

beam on the sample, a 3D motorized stage, as well as

precision motion stages. The laser beam was be

raster-scanned onto the substrate using various

shapes, velocities and hatch values (distance between

raster-scan lines). The laser processing was carried

out in air. On 5 mm square substrates, 3mm square

patterning was done. On the 16 mm square substrates,

12 rectangles of 3 mm x 2.5 mm were structured, of 4

different topographies with 3 replicas, each.

2.2 Substrate Cleaning and

Characterization

Laser-structured silicon substrates were cleaned

using 3 solvents (acetone, absolute ethanol and

isopropanol) for 10 minutes each in an ultrasonic

bath, dried using nitrogen air flow, and stored in a

closed container until characterization or use.

Topographies were characterized using Scanning

Electron Microscopy (Zeiss).

The Behaviour of Neuro-2A Cells on Silicon Substrates with Various Topographies Generated by Femtosecond Laser Micromachining

193

2.3 Cell Culture

Neuroblastoma cells were purchased from ATCC

(Neuro-2A line, albino mouse origin, ATCC® CCL-

131™) and maintained in complete medium

containing Dulbecco’s Modified Eagle Medium

(DMEM) and reduced serum medium (OptiMEM),

supplemented with 10% Fetal Bovine Serum (FBS)

and 1% Penicillin/Streptomycin. For differentiation

purposes, cell medium containing 1% FBS was

prepared. The cells were incubated in 37°C and 5%

CO2 in a Nüve EC 160 incubator. During routine

splitting procedures, the cells were washed using

Phosphate Buffered Saline (PBS) and detached using

TrypLE dissociation reagent. 24 hours prior to cell

seeding, the cells were transiently transfected with

fluorescent protein constructs using Lipofectamine

LTX. The DNA constructs included membrane-

bound or nucleus-localized EGFP constructs

equipped with the appropriate localization signals

(Gap-43 signal for membrane and c-myc NLS for

nucleus, respectively). The DNA constructs were

generated using standard molecular cloning

procedures. The Gap43 signal sequence was

MLCCMRRTKQVEKNDEDQKI, while the NLS

sequence was PAAKRVKLD. The amount of

transfected plasmid was 500 ng in all cases. All cell

culture experiments were carried out in a laminar

flow hood equipped with HEPA filter to ensure sterile

conditions.

2.4 Cell Seeding on the Silicon

Substrates

The silicon substrates were sterilized by immersion in

70% ethanol, and then immersed in complete cell

medium for 10 minutes prior to cell seeding in order

to enhance cell adhesion. The cell number was 4000

cells/cm

2

for long duration experiments and 20.000

cells/cm

2

for shorter duration ones. For live imaging

experiments, the substrates were placed upside down

over confocal glass bottom cell culture dishes. The

imaging was done 24 or 48 hours after seeding for

pictures; and for a duration of 3 to 24 hours after

seeding for live-imaging experiments.

2.5 Cell Imaging and Analysis

The cells were imaged with an inverted fluorescence

microscope (Leica) equipped with a confocal setup

(Andor) and the appropriate excitation and emission

filters for EGFP. The silicon substrates were washed

once with HHBS buffer and placed upside down onto

a coverslip. For live imaging, the dish containing the

silicon sample was placed into a live-imaging

chamber equipped with 37°C incubation and 5% CO

2

pump to ensure proper cell growth conditions. Images

were taken every 2 or 2.5 minutes with 10X objective

to observe cell movement on the substrate. All cell

image analyses were carried out with ImageJ or FIJI

software. Cell motility analysis was carried out using

the Manual Tracking Plugin in ImageJ. At least 7

cells were chosen at random and tracked from time-

lapse videos of cells on flat, LIPSS and microcolumn

topographies. The velocity and distance values were

compared for each topography using t-test.

3 RESULTS AND DISCUSSION

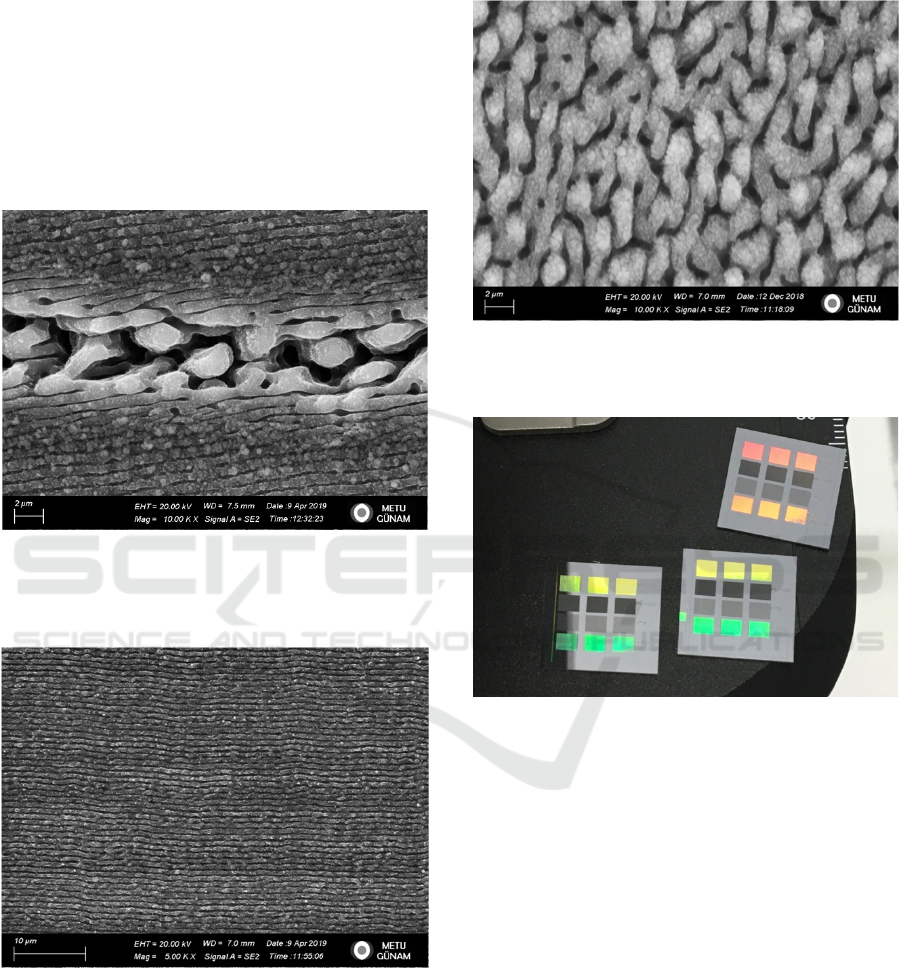

The topographies generated on silicon were

dependent on the scan velocity of the beam (which in

turn controls effective fluence) and the distance

between the raster scan lines (hatch). A velocity of 10

mm/s generated deep trench-like topographies with

depth of more than 1 μm (Figure 1). In the presented

substrate, the distance between the lines is 0.03 mm.

A velocity of 100 mm/s generated microcolumn-like

line topographies, while velocities larger than 1000

mm/s generated regular ripples (in LIPSS regime).

The ripples have depths of 300 nm, periods of 900-

1000 μm, and are covered in nano-scale roughness.

Figure 1: SEM of trench topography generated with a single

laser pass with velocity 10 mm/s, hatch = 0.03 mm, 5.000X

magnification.

Figure 2 shows a combination of the LIPSS with

microcolumn topography, generated by scanning 100

mm/s lines over LIPSS topography. LSFL type

LIPSS topography was generated by raster scanning

over the whole area with velocity 1500 mm/s and

hatch value of 0.005 mm (Figures 2 and 3). The

direction of the ripples depends on the polarization of

BIOIMAGING 2020 - 7th International Conference on Bioimaging

194

the beam. Finally, whole-area microcolumn

topographies were generated by raster-scanning the

beam at 100 mm/s using a hatch value of 0.005 mm.

The resulting topography is shown in Figure 4.

Structured silicon substrates of square shape and 1.6

cm side length are shown in Figure 5. Neuro-2A cells

showed different adhesion and motility on the various

substrates. The cell response was highly dependent on

the initial cell density, presence of clumps, serum

amount in the cell medium, and number of hours of

incubation.

Figure 2: SEM of microcolumn line topography on LIPSS,

generated with velocity 100 mm/s, hatch = 0.03 mm,

overlaid on velocity 2000 mm/s, hatch = 0.005 mm,

10.000X magnification.

Figure 3: SEM of LIPSS topography generated with

velocity 2000 mm/s and hatch = 0.005 mm, 5.000X

magnification.

In general, clumped cells were more likely to

keep adhering to each-other through cell-cell

adhesions and less likely to differentiate when

exposed to low serum media or to respond to the

underlying features. This has previously been

reported for other cell types (Menzies KL., 2010).

Figure 4: SEM of microcolumn topography generated with

velocity 100 mm/s, hatch = 0.005 mm, 10.000X

magnification.

Figure 5: 16 mm square silicon substrates used for

experiments. The three substrates are replicas. Each small

structured area is 3 mm by 2.5 mm. The first row is LIPSS,

as in Figure 3. The second row is microcolumn topography

as in figure 4. The third row is trench topography, as in

Figure 1. The fourth row is microcolumn line topography

on LIPSS, as in figure 2.

One important point is that, although the base

material is silicon, the top part of the substrate is

expected to be a native layer of silicon oxide, SiO

2

, of

depth around 10 nm (Fan, 2002). The substrates were

not treated with any agents such as HF to remove the

top oxide layer. Both Si and SiO

2

were reported to be

non-toxic to cells, but also to not support good cell

adhesion (Fan, 2002).

In the first few hours, cells showed highly

differential adhesion on the polished and structured

substrates. At 3 hours, the cell adhesion was weakest

on the flat regions, with a very low number of cells

staying attached after a single washing step. It is

The Behaviour of Neuro-2A Cells on Silicon Substrates with Various Topographies Generated by Femtosecond Laser Micromachining

195

possible that cell adhesion on structured regions

occurs faster, due to the higher surface area of the

structured parts. As a result, cell patterning could be

achieved on the first few hours of incubation. Cell

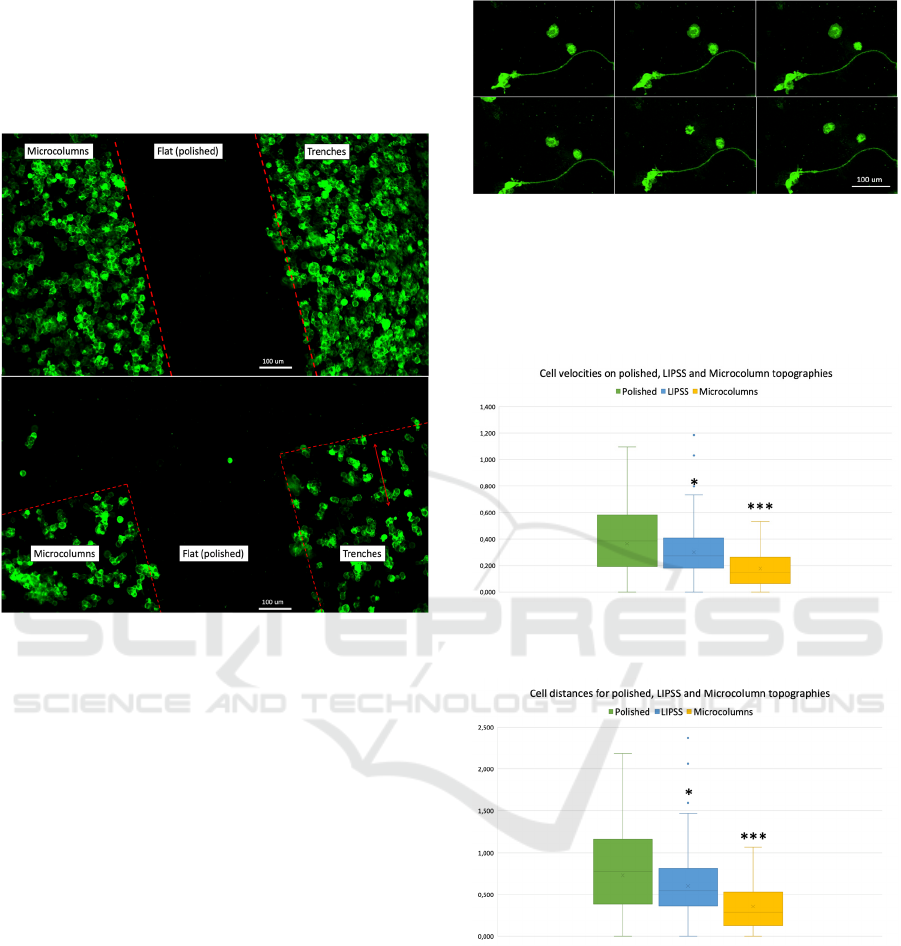

patterning is shown in Figures 6.

Figure 6: Cell patterning seen on multi-structured substrates

shown in Figure 5, after 3-hour incubation. 20.000

cells/cm

2

were seeded on the substrate. Cells were

expressing membrane localized EGFP. Top and bottom

images are representative edge and vertex regions of the

structured squares and were taken on the same substrate.

Similar cell patterning has been shown for nigral

cells on etched silicon wafers (Fan, 2002) and for

SW10 cells on laser-structured silicon (Yiannakou,

2017). In the latter study, the cells showed a similar

positive response to microcolumn-like topographies,

while being repelled by ripple topographies of very

low periodicity; on the other hand, LSFL LIPSS

regime was not considered. In the present study,

LSFL LIPSS was not found to have any negative

effect on Neuro-2A cell adhesion. The cell patterning

here was exclusively due to adhesion differences,

since cell migration out of the polished regions could

not have occurred at such a short time.

Time-lapse microscopy revealed the cell motility

and exploration patterns on the different structured

surfaces. Time-lapse recordings of cells on polished

silicon, taken 3 hours or 24 hours after seeding

showed exploratory behaviour with lamellipodia and

filopodia. Two representative cells exploring the

polished silicon are shown in Figure 7.

Figure 7: Time-lapse snapshot insets, showing cells moving

on polished silicon. The time-lapse was taken with 10X

objective. The cells had been transfected with membrane

targeted EGFP and had been growing in complete medium

for 16 hours followed by 1% FBS medium for 2 hours. Each

frame corresponds to 6 minutes.

Figure 8: Cell velocities on polished silicon, LIPSS and

microcolumn topographies.

Figure 9: The distances covered by the cells between frames

were significantly different on polished silicon, LIPSS and

microcolumn topographies.

Cell motility, defined as velocity and distance

travelled between frames, was dependent on the

underlying topography. Both velocities and distances

were found to be significantly different among

polished, LIPSS and microcolumn topographies, with

cells moving fastest on polished silicon, significantly

slower on LIPSS (p<0.5, *) and slowest on

microcolumns (p<0.001, ***). Box and whisker plots

of velocities and distances travelled by cells on the

BIOIMAGING 2020 - 7th International Conference on Bioimaging

196

different topographies are shown in Figures 8 and 9,

respectively.

Cells are observed to move preferentially along

the lines back and forth on the topography shown in

Figure 2 and extend one or two neurites along the line

structures reversibly during movement. The width of

the line is around 10 μm (Figure 2), about half the size

of the cell soma. Cells confinement to these lines may

further reflect the cells’ preference to these structures.

However, the migration of these cells is faster than

that of the cells found in whole area microcolumns

(which is evident in live videos), pointing out that it

may be the line topography, and possibly the

interaction of the thin line of the microcolumns with

the underlying LIPSS, which elicits this effect.

Figure 10: Inset of 10X objective time-lapse recording

showing aligned cells on the microcolumn lines on the

topography.

The cell response was different after 24 or 48

hours in culture, possibly due to better adhesion on

polished silicon, or cell movement on the substrates.

More cells remained adhered to polished silicon after

24 or 48 hours, compared to 3 hours.

Figure 11: 10X objective image showing cells on LIPSS,

expressing membrane localized EGFP. The cells had been

growing in complete medium for 24 hours.

When seeded onto line topographies, cells showed

neurite alignment to trenches or microcolumns after

24 or 48 hours in culture. Neurite alignment has

previously been shown in another study, using ridge-

groove substrates generated by multi-step electronic

lithographic methods (Johansson, 2006). In the

present study, a similar effect may be achieved with a

simpler procedure.

On LIPSS, cells were able to remain adhered after

24 or 48 hours. No cell body alignment or elongation

was observed. A representative image of cells

growing on LIPSS is shown in Figure 11. Images of

cells with aligned neurites are shown in Figures 12-

15.

Figure 12: 10X objective image showing various cell

clumps as well as differentiated Neuro-2A cell expressing

membrane localized EGFP and aligned neurites. The

topography consists of trenches, such as in Figure 1. The

cells had been growing in 1% serum medium for 48 hours.

Figure 13: Confocal 63X oil immersion objective image of

the cell shown in Figure 12. The neurites are on the

trenches.

On the other hand, cell body alignment was not

observed for any of the substrates, except for during

cell movement on trenches and microcolumn lines, as

seen in time-lapse videos. Cells which were found

moving on the lines or trenches tended to have a more

elliptical shape compared to the other cells, with the

longer axis coinciding with the topography lines.

However, the shape of the cells was dynamic

throughout the time-lapse imaging.

The cells did not respond well to substrates which

were highly processed. A representative image is

The Behaviour of Neuro-2A Cells on Silicon Substrates with Various Topographies Generated by Femtosecond Laser Micromachining

197

Figure 14: 10X objective image showing various cell

clumps as well as differentiated Neuro-2A cell expressing

membrane-localized EGFP and aligned neurites. The cells

had been growing in 1% serum medium for 24 hours. The

topography consists of microcolumn lines on LIPSS, the

red arrow shows the direction of the microcolumn lines and

LIPSS.

Figure 15: 63X oil immersion objective image of the cell

shown in Figure 14. The neurite extended onto the

microcolumn line. The LIPSS topography can be seen

under the cell body.

Figure 16: 10X magnification image showing blebbing

behaviour of Neuro-2A cells on substrates on highly

processed substrates. The cells had been growing for 24

hours in complete medium and express nuclear-localized

EGFP. The substrate consists of trenches like in Figure 1,

with hatch value of 20 µm.

shown in Figure 16. In these cells, nuclear

localization fluorescent proteins were found

throughout the cell, suggesting that the nuclear

integrity was compromised. Moreover, the cells

display blebbing behaviour. This suggests that it

could be possible to make regions which are cell-

inhibitory in over longer incubation periods, simply

by excessive laser damage.

4 CONCLUSIONS AND FUTURE

WORK

The behaviour of Neuro-2A cells was observed on

different time points on polished and laser-structured

silicon, using confocal fluorescence and time-lapse

microscopy. The cells displayed different behaviours

depending on the topography and incubation time. At

short incubation times, cells were more likely to

attach to the structured areas, opening up the

possibility for easy cell patterning. At later times, the

cell adhesion on all structures was improved, and

neurite alignment effects were observed.

Similar to the cell adhesion, also motility on the

substrates was affected by the underlying

topographies. Further work may include studying the

behaviour of different proteins using live imaging

setups in silicon and other opaque materials, for

example actin dynamics and stress fibre formation on

the different topographies.

Finally, future work may include live observation

of protein-protein interactions on different substrates

with methods such as FRET, which may be valuable

to understand the biochemical mechanisms

underlying the wide variety of cell responses on

topographies.

ACKNOWLEDGEMENTS

Support from TÜBİTAK under grant number

118F375 is kindly acknowledged.

REFERENCES

Beduer, A., Vaysse, L., Flahaut, E., Seichepine, F., Vieu,

C., 2011. Multi-scale engineering for neuronal cell

growth and differentiation. Microelectron. Eng. 88,

1668-1671.

Dalby, M., Gadegaard, N., Oreffo, R., 2014. Harnessing

nanotopography and integrin-matrix interactions to

influence stem cell fate. Nat. Mater. 13, 558-569.

Fan, Y.W., Cui, F.Z., Hou, S.P., Xu, Q.Y., Chen, L.N., Lee,

I.S., 2002. Culture of neural cells on silicon wafers with

nano-scale surface topography. J. Neurosci. Meth. 120,

17-23.

BIOIMAGING 2020 - 7th International Conference on Bioimaging

198

Gentile, F., Marinaro, G., Rocca, R., Berberio, M.,

Cancedda, L., Di Fabrizio, E., Decuzzi, P., 2015.

Networks of neuroblastoma cells on porous silicon

substrates reveal a small world topology. Integr. Biol.

7(2),184–197.

Guo, C., Vorobyev, A., 2013. Direct femtosecond laser

surface nano/microstructuring and its applications.

Laser Photonics Rev. 7(3), 385-407.

Johansson, F., Carlberg, P., Danielsen, N., Montelius, L.,

Kanje, M., 2006. Axonal outgrowth on nano-imprinted

patterns. Biomaterials 27, 1251-1258.

Khan, S., Newaz, G., 2010. A comprehensive review of

surface modification for neural cell adhesion and

patterning. J. Biomed. Mater. Res. 93A(3) 1209-1224.

Mendes, P.M., 2013. Cellular nanotechnology: making

biological interfaces smarter. Chem. Soc. Rev. 42, 9270.

Menzies, K.L., Jones, L., 2010. The impact of contact angle

on the biocompatibility of biomaterials. Optom. Vis.

Sci. 87, 387.

Simitzi, C., Stratakis, E., Karali, K., Ranella, A. 2018.

Controlling the outgrowth and functions of neural stem

cells: the effect of surface topography. ChemPhysChem

19(10), 1143-1163.

Yaghoub, M., Tremblay, R., Voicu, R., Mealing, G.,

Monette, R., Py, C., Faid, K., Sikorska, M. 2005.

Neurogenesis and neuronal communication on

micropatterned neurochips. Biotechnol. Bioeng. 92(3),

336-345.

Yang, L., Liu, H., Yin, Y. 2015. Biomaterial

nanotopography-mediated cell responses: experiment

and modeling. International Journal of Smart and Nano

Materials 5(4), 227-256.

Yiannakou, C., Simitzi, C., Manousaki A., Fotakis C.,

Ranella A., Stratakis E. 2017. Cell patterning via laser

micro/nano structured silicon surfaces. Biofabrication

9, 025024.

Yim, E.N., 2016. From nano to micro: topographical scale

and its impact on cell adhesion, morphology and

contact guidance. J. Phys.: Condens. Matter. 28,

183001.

The Behaviour of Neuro-2A Cells on Silicon Substrates with Various Topographies Generated by Femtosecond Laser Micromachining

199