Non-invasive Recording with a New Three-channel Pneumatic Sensor

V. E. Antsiperov

1a

, G. K. Mansurov

1

, M. V. Danilychev

1

and A. S. Bugaev

2

1

Kotelnikov Institute of Radioengineering and Electronics (IRE) of RAS, Mokhovaya, Moscow, Russian Federation

2

Moscow Institute of Physics and Technology, Dolgoprudny, Russian Federation

Keywords: Arterial Blood Pressure, Non-invasive Pressure Monitoring, Hemodynamics, Pulse Wave Transition,

Three-channel Pneumatic Sensor.

Abstract: The paper presents the design features and test results of a new non-invasive blood pressure monitoring sensor

based on the local pressure compensation principle. Real-time differential processing of three-channel pulse

wave data is used to determine and maintain the optimal position of the sensor on the patient’s body. The

small size measuring unit with very small (1 mm

2

or less) sensor pads, when placed accurately on elastic

surfaces (for example, on the skin and underlying tissues), provides high-quality pulse wave recording,

continuity of measurement and minimization of external interference. The paper also gives the results of

measurement for some superficial arteries of the human body. Further development version of the sensor with

synchronous ECG measurement is also presented.

1 INTRODUCTION

Cardiovascular and cerebrovascular disorders,

referred to in the official statistics as circulatory

diseases, represent the most common death causes in

the Russian Federation (55% of deaths) (Chazova et

al., 2015). As part of diagnosis and treatment of those

disorders, specialists use the data on the state of the

circulatory system and the state of specific organs,

obtained by analysing blood pressure measurement

data (for accessible body parts). Though the invasive

blood pressure measurement method is considered

the most accurate and reliable, it is used only in a

medical institution under continuous supervision of a

competent and accredited medical staff. This method

is not suitable in everyday life due to strict staff

requirements and the risk of injury. Besides, the

invasive method is not applicable for everyday health

examination, monitoring of hemodynamics and the

state of the cardiovascular system in real-time.

Most modern non-invasive blood pressure

measurement methods are based on counter-pressure

handling in the cuff or pad applied to this artery

(usually to the whole limb). The purpose of these

manipulations is to maximally balance the excess

pressure held by the elastic walls of the artery

(Settels, 2015). For instance, the Penaz blood

a

https://orcid.org/0000-0002-6770-1317

pressure monitoring method employs the volumetric

compensation principle, which implies the dynamic

unloading of vascular walls (Peňáz, 1973). Speaking

of the bottlenecks of those methods – the limb

gripping causes blood stagnation and a physician

should periodically relax the cuff, which violates

continuous monitoring and disturbs the wave pattern.

Furthermore, it is quite difficult to arrange the

continuous recording of pulse wave signals during

numerous consecutive cardiac cycles under

dynamically changing load and at various parts on the

human body. From a technical point of view,

transmitting and processing the recorded signals by

developed or existing software cause no difficulties.

However, what remains to be a problem is capturing

high-quality blood pressure signals with no artifacts

at various points on the human body.

2 SENSOR CONCEPT / DESIGN

To address the above problem, a new continuous

blood pressure monitoring method was developed

based on the local pressure compensation technique

(Figure 1). The method became viable thanks to the

local compensation principle for pressure

measurement on small (1 mm

2

and less) surfaces,

268

Antsiperov, V., Mansurov, G., Danilychev, M. and Bugaev, A.

Non-Invasive Blood Pressure Monitoring Based on Pulse Wave Recording with a New Three-channel Pneumatic Sensor.

DOI: 10.5220/0009169902680273

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 268-273

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

worked out earlier by the authors (Antsiperov et al.,

2017).

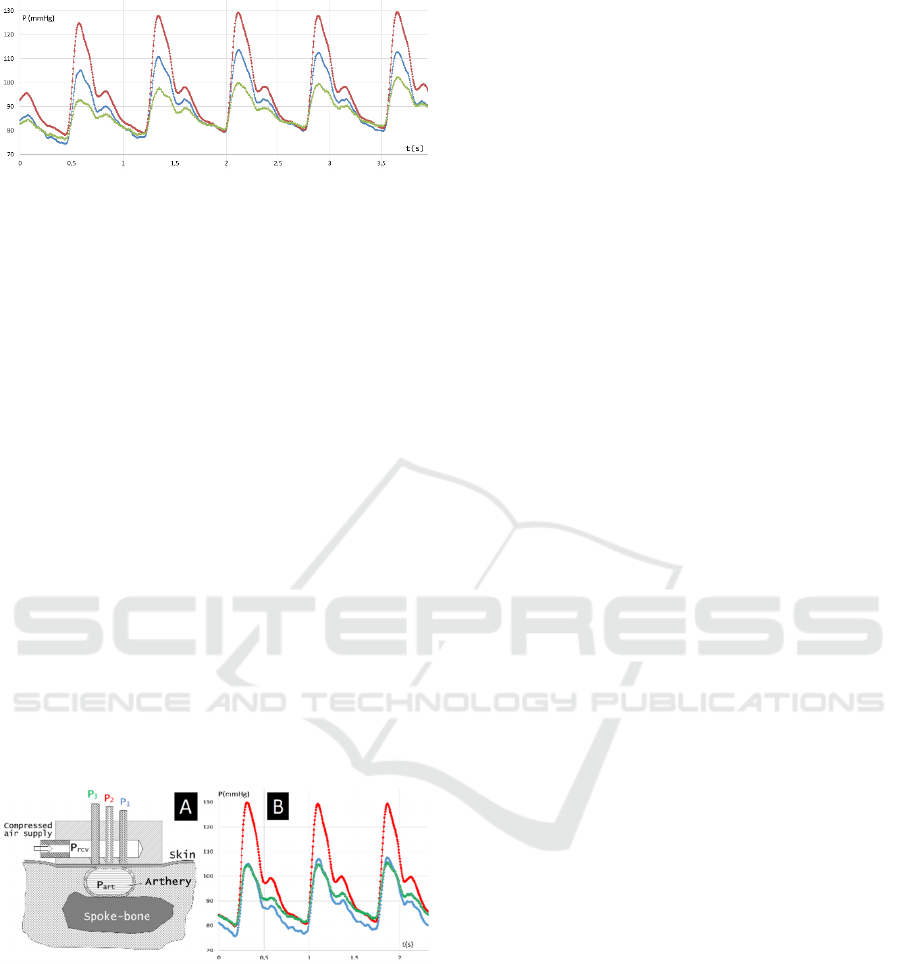

Figure 1: Blood pressure measurement through local

pressure compensation. P

rec

is compressed air receiver

pressure, P

art

is pressure in the artery, P

sen

is that in the

sensor chamber (A); and measuring assembly applied to the

patient's wrist (B).

Basically, local compensation in pressure

measurement amidst barely accessible gas/fluid

volumes is an intuitive concept. If it is possible to

make the surface enclosing the volume of an elastic

covering locally flat via the external impact, external

pressure will equalize internal pressure due to the

absence of normal tension. The principle was

implemented in the applanation tonometry method

used for measuring intraocular pressure (Goldmann et

al., 1975). After several years of hard work, the

authors found the solution and developed an

applanation tonometer that provides local pressure

compensation and has an open chamber between the

tile flat surface and the elastic surface of the skin.

With that, the chamber volume is quite small (about

1mm

3

) and mostly consists of the connection tube

hole and pressure sensor hollow. Using air as the

working agent of the sensor, we get an advantage over

the analogues sensor filled with liquid. Excess air can

be easily discharged into the atmosphere without

reversing charge ducts. Figure 1 illustrates how the

tonometer works. If at a specific moment P

sen

(pressure in the measurement unit) is lower than P

art

(arterial pressure), the tissue and skin above the artery

press against the sensor air duct, thereby shutting it.

P

sen

is growing fast due to continuous air supply from

the high-pressure receiver through the screw throttle.

When it reaches P

art

, the duct opens, and the excess

air is discharged into the area underneath the sensor

flat surface pressed against the skin. If the air inflow

to the chamber is designed correctly (by determining

P

rec

and throttle screw position), laminar airflow will

keep the skin surface flat and almost enclosed,

maintaining P

sen

≈ P

art

(even upon variable blood

pressure). In other words, the pneumatic sensor

performs local pressure compensation like a safety

valve with continuous compressed air inflow (from

the receiver) through the flow limiting throttle.

Significantly, the pressure is measured directly, and

not calculated, for example, by the normal component

of the force per area of the sensing element. Static

tests on the artery simplified the model connected to

a water column of adjustable height showed that the

measured values correspond to the water pressure in

the model from 0 to 90 mmHg with a stable offset of

about +10 mmHg. As a model was used a thin-walled

rubber tube — a piece of sausage-shaped air balloon

of a diameter of less than 1 cm at pressures up to 90

mmHg. The pressure drop on the model wall can be

explained by the properties of rubber — simple

elasticity, in contrast to the viscoelastic properties of

living tissue.

Inexpensive piezoresistive sensors by Honeywell

International Inc., used as primary pressure

converters, are mounted close to sensing pads to

minimize working volumes. Preamplified signals are

fed to analog inputs of embedded MCU (we use

STM32L151), which performs all low-level tasks,

including the micro compressor steering, data

acquisition, processing and communication with the

host computer (or smartphone).

3 POSITIONING PROBLEM

Beneficial as it may be the local pressure

compensation method entails new problems

concerning positioning the sensor. As the sensing

area of contact (duct outlet) is much smaller than the

artery cross-section, P

sen

matches P

art

(Figure 1) only

if the area of contact is located exactly above the

artery axis. Figure 2 shows in detail the uneven

distribution of pressure along the contact line of the

sensor in the transverse direction. As is seen, if the

sensor is moved left or right from the symmetry axis,

the observed value of pressure decreases while the

ratio of various curve elements distorts (Figure 2). A

detailed study showed that if the sensor is positioned

exactly above the artery axis, the pressure signal has

the largest amplitude, and local extrema points

themselves turn out to be sharper. For positions

symmetrically located against the artery, pulse wave

charts are almost identical though they may have

certain distinctions. Those distinctions are most

explicit at the diastole stage (Figure 3).

In the sensor tests the pressure appeared to be

distributed unevenly in the direction transversal to the

artery axis. That is due to the artery shape and

wavering of the artery axis position upon pulsation

under the sensor plate.

Non-Invasive Blood Pressure Monitoring Based on Pulse Wave Recording with a New Three-channel Pneumatic Sensor

269

Figure 2: Different shapes of pulse wave signal depending

on the sensor pad position: ● — pad is located accurately

above the artery axis, ■. ♦ — pad is moved left and right

from the center of the radial artery, respectively.

This leads to two important conclusions relating

to positioning the sensor. First, the central measuring

chamber must be located accurately above the artery

axis projection. Second, the artery must be pressed by

the sensor to underlying tissues in a way its axis does

not waver upon pulsation. These observations

stimulated the authors to practically realize the

"targeting" method similar to the lateral signals

equalizing approach used in radar technique.

According to that, the authors designed a blood

pressure monitoring sensor whose main part is the

measuring block with three separate chambers. Each

chamber has its own independent measuring output.

During the operation, the channel nozzles are

positioned in a row transversely against the artery.

With that, the dimensions of the area of contact must

be designed to ensure that all the three nozzles are

located above the subject artery during the operation.

Figure 3 gives the sketch of the sensor and the result

of concurrent three-channel pulse wave measurement

(the sensor located above the radial artery).

Figure 3: Three-chamber sensor enabling local-

compensation blood pressure measurement (A); and

synchronous three-channel pulse wave chart (B).

The comprehensive specification of the sensor is

provided in the patent (Mansurov et al., 2018). In

terms of the proposed design, the main task of side

channels is to ensure proper positioning of the central

measurement pad. With the correct position of the

measuring unit, the calibrated signals on the side

channels (Figure 3) coincide or slightly differ from

each other. It can be neglected that artery walls under

side channels cannot be fully unloaded, so the

pulsation response in those channels is significantly

distorted. It is only important that upon the equality

of those signals, the central chamber is positioned

accurately above the artery axis ("targeted") — in

such a position, that its signal will be a non-distorted

copy of arterial pressure (Antsiperov et al., 2018).

The methodology of measuring blood pressure by

the three-chamber pneumatic sensor is tightly related

to the described design features. At the first stage, just

before the measurement, the location of the artery is

determined by palpation. Then the sensor is applied

onto that place so that measuring chambers are

positioned in a row transversely against the artery

(Figures 2 and 3). Then, manually moving the sensor

along this direction (transversely against the artery),

the physician should find a position in which signals

of side channels are as equal as possible. After that,

the measurement unit is pressed against the skin so

that the contact area under the central pad became flat,

but without the artery occlusion (applanation

principle). For the radial artery case, the criterion of

the best position was experimentally determined.

According to it, the signal amplitude of the central

channel must be about twice as high as the equalized

amplitudes of the side channels.

The problem of positioning the sensor on the

radial artery was addressed via designing a

monolithic three-chamber sensor that reflected the

problem specifics. Three chambers are made in a rigid

flat surface (1.8 mm increment) along the line

perpendicular to the artery axis projection on the

sensor plane. The chambers are independently fed by

the air from the receiver through individual air

throttles. This way the pressure on the sensor surface

can be measured concurrently and independently at

three points (0.8 mm in diameter). To estimate the

thickness of the air cushion underneath the plane

surface, the current air consumption rate was

measured and amounted to ~ 0.5 cm

3

/s (with

accounting possible leaks). By the average pressure

difference of 100 mm Hg, the discharge flow speed in

the hole is about 140 m/s. The flow cross-section

thereby totaled 500/140,000 = 0.0036 mm

2

or 0.0012

mm

2

for each camera. Assuming that air is discharged

within the half of the chamber hole perimeter (cleft

length is ~ 1 mm), the cleft width should be ~ 1 µm.

The sensor of this type can be used for measuring

parameters of radial and other arteries (carotid,

temporal, etc.). However, such a sensor positioning

algorithm enabling adequate quantitative blood

pressure measurement is developed and empirically

confirmed only for positioning the sensor on the

radial artery.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

270

4 PRIMARY TESTING

The experiments accompanied every stage of

hardware and software development. Some of the

recent results we found to be interesting are presented

below. The comparison of the results shows that

every artery is subject to individual specifics of pulse

wave parameters recorded at a certain point on the

human body. Those specifics affect the methodology

of practical measurements and further data

interpretation. Generally, the procedure of measuring,

interpreting, and using such data requires coordinated

efforts of equipment developers and cardiologists, as

well as measurement statistics for every artery.

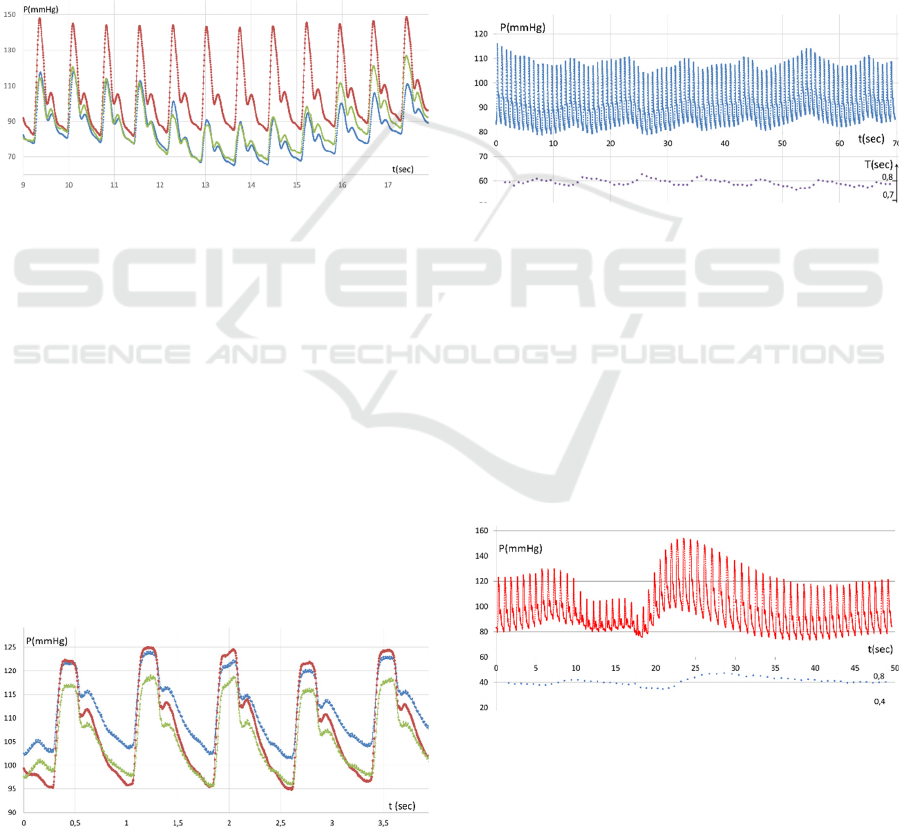

Figure 4: Radial artery pulse wave, optimal position, slight

variations of press force ● – central channel signal (right

above the radial artery axis), ■, ♦ − side channels signals.

The experiments on measuring the pressure on

various surface arteries showed that the arteries

located over rigid tissue (bone) enable to register the

pulse wave shape and current blood pressure. Besides

the radial artery (Figure 4), we managed to measure

pressure only on the temporal artery (below in text).

With that, the positioning of the present sensor on it

turned out to be a difficult procedure, probably due to

the mobility and small diameter of the artery.

Unfortunately, as for the carotid artery, we can still

register the pulse wave pattern (Figure 5), but the

shape of the pulse wave does not give us the

appropriate information about the aorta state and the

cerebral circulation activity.

Figure 5: Carotid artery pulse wave: ● − central channel

signal, ■, ♦ − side channel signals.

The charts presented in Figure 5 demonstrate that

the carotid artery’s cross-section (which is

significantly larger than that of the radial artery) and

the lack of rigid tissues underneath has explicit

impact on the central vs side signal ratio. It seems

necessary to study the correlation and find an optimal

artery diameter/channel interval ratio for every artery

type.

The pulse wave pattern and quantitative

parameters change under various external and

internal processes. For instance, this phenomenon is

reflected in the radial artery pulse wave charts for the

quiescent state with consecutive deep inhaling and

exhaling (Figure 6) and holding breath when inhaled

(Figure 7). Let us consider those situations.

Figure 6: Pulse wave (upper curve) and variability of

heartbeat intervals (bottom point row, right scale),

quiescent, deep breathing.

Figure 6 illustrates the long-term pulse wave

pattern for a calm patient. Several deep inhalations

and exhalations explicitly affect average pressure in

the radial artery and heartbeat variations. It could be

supposed that, in the quiescent state, the heartbeat rate

adapts to maintain the average pressure in the aorta

against the thorax pressure. Perhaps a well innervated

aortic arch acts as a pressure gauge that is sensitive to

pressure differences inside and outside the aorta.

Figure 7: Radial artery pulse wave transformation (upper

curve) and variability of heartbeat intervals (bottom point

row, right scale) for short breath holding after inhaling.

The next figure (Figure 7) shows the pulse wave

pattern for the radial artery for held breath after

inhaling. Here’s how we can explain the peculiar

pattern of oscillations. During the very first seconds

Non-Invasive Blood Pressure Monitoring Based on Pulse Wave Recording with a New Three-channel Pneumatic Sensor

271

of breath holding, the lung and thorax pressure

increase due to the reflective desire to exhale

suppressed by the shut pharynx. The average pressure

in the artery starts growing following the aortic

pressure. At the 6th-7th second, the pressure starts

falling. Probably due to the increasing pressure drop,

insufficient venous blood enters the chest. At the 17th

second of the recording after exhalation, we can see

how the pressure drops briefly and then, after a

smooth increase in pressure for 20-25 seconds, the

initial picture of the pulse pressure wave is restored.

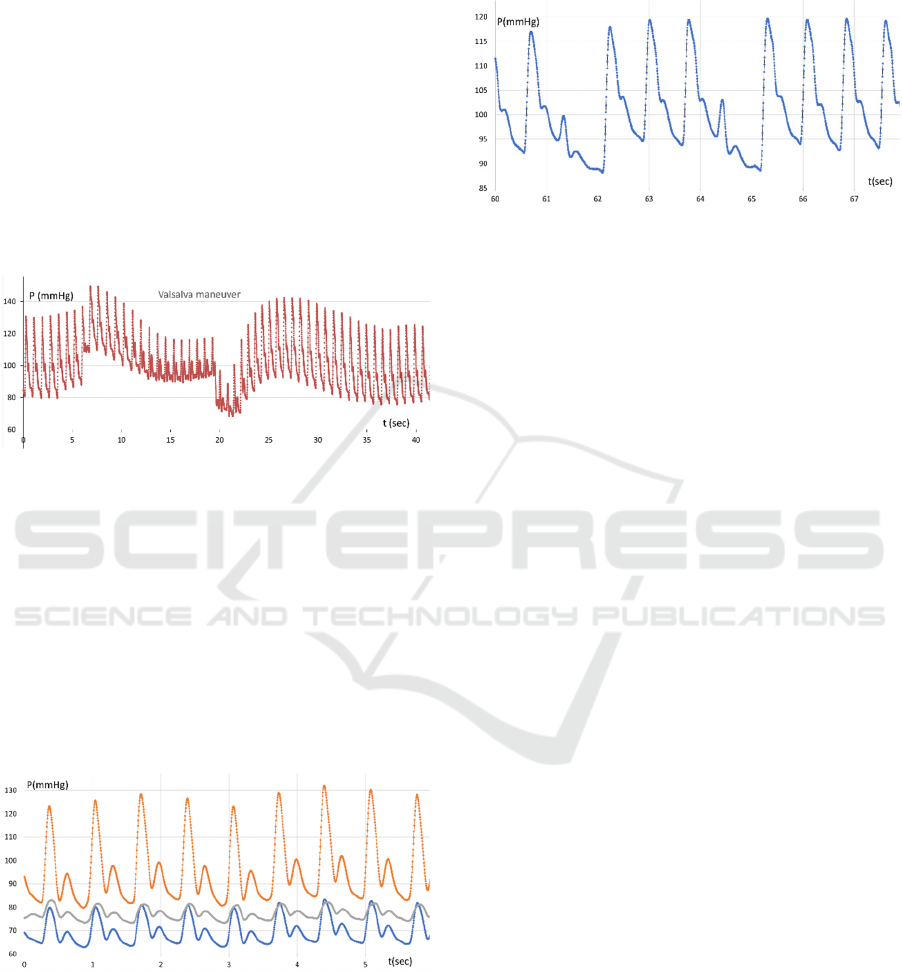

Figure 8 illustrates the pulse wave pattern under the

Valsalva maneuver. A few seconds before exhaling

the aortic walls appear to be unloaded almost

completely because of the pressure balance.

Figure 8: Radial artery pulse wave pattern under Valsalva

maneuver.

Another instance of an unusual radial artery pulse

wave pattern is shown in Figure 9. This signal was

recorded in the patient on the second day after the

injection of the EnceVir vaccine against tick-borne

encephalitis. It is known that this medicine may cause

reactions manifested in higher body temperature

(37.1° to 38.0°C), headache, fatigue, muscle and joint

pain. The reaction usually lasts for 3 days. By the end

of the second day, the above symptoms faded away

and the pulse wave pattern normalized.

Figure 9: Radial artery pulse wave pattern transformation

(central and side channels) one day after EnceVir injection.

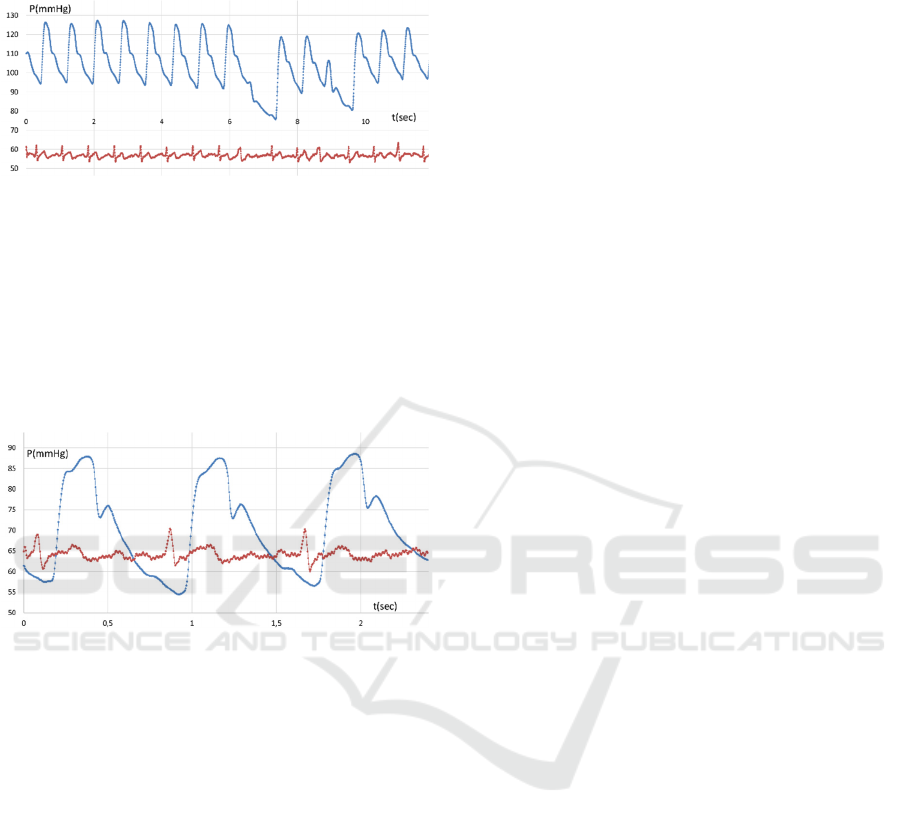

Figure 10 illustrates the pulse wave pattern of the

diseased and fatigued patient. It is seen that the

regularity of the registered systolic pressure peaks

remains, while the partial losses look like omissions

without any disturbance of time intervals. Most

probably it is arrhythmia manifested in the form of

extrasystoles. However, without a synchronous ECG,

it is difficult to assert it is arrhythmia.

Figure 10: Pulse wave pattern disturbances (possibly

arrhythmia).

Therefore, this experiment drove us to develop the

synchronous ECG channel and integrate it into the

device. Since the high-resolution ECG is not required

to locate R-peaks, we designed a simplified single-

channel cardio-signal amplifier.

5 ECG CHANNEL-INTEGRATED

CIRCUIT

In the simplified cardio-signal amplifier we

developed an original scheme for connecting ECG

electrodes. It enables the equipment to operate

without a neutral electrode and without a conductive

gel. In this case, the suppression of interference is

carried out at the circuitry level and then using digital

signal processing (filtering). The purpose of

modifying the initial design was the desire to find out

the relationship between the pulse wave dynamics

and the rhythmic activity of the heart. Figure 11

illustrates the radial artery pulse wave pattern (blue

curve) recorded synchronously with the ECG (red

curve). Introducing the ECG channel to the circuit

enables watching the cardiac contraction signal (input

signal) pattern and the pattern of the resulting pulse

wave (output signal) at one of the possible

measurement locations (e.g. wrist, Figure 11). Based

on the analysis of the relationship between the signals

at the input and output of the cardiovascular system,

a few its time-frequency characteristics can be

estimated using methods known in radio physics.

Using the subject pneumatic sensor with an ECG

channel enables non-invasive measurement of the

pulse wave transit time. This value, jointly with non-

invasive systolic pressure monitoring and continuous

analysis of the pulse wave dynamics, can be used to

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

272

estimate the current state of the cardiovascular system

and diagnosing clinical and subclinical atherosclerosis.

Figure 11: Pulse wave pattern disturbances (extrasystoles)

and synchronously recorded ECG.

As mentioned above, in our experiments we

managed to measure actual pressure (in mmHg) in the

temporal artery (likewise the radial artery). It was quite

difficult to ensure proper positioning in that case

(probably due to high motility and small diameter).

Figure 12 illustrates the results of synchronous pulse

wave measurement and ECG.

Figure 12: Temporal artery pulse wave pattern and

synchronously recorded ECG.

It goes without saying that the complex technology

of acquiring and interpreting combined data described

in this section has much room for further improvement.

However, there is feasibility in the significant growth

of the comprehensiveness and reliability of the

suggested approach in early heart and vessel disease

diagnosis compared to earlier methods not employing

pressure wave measurement with ECG timing.

6 CONCLUSIONS

The research results in the following conclusions:

1. The device designed enables real-time continuous

blood pressure measurement on several surface

arteries, displaying the pulse wave within a single cycle

and in long-time intervals.

2. The experiments on measuring pressure of

various surface arteries showed that arteries located

over rigid tissues (bones) allow to register the pulse

wave shape and current blood pressure. This was

proved for the radial and temporal arteries.

3. The device enables not only systolic/diastolic

pressure metering but also monitoring current value as

well as durable variations of arterial pressure

associated with respiration and the processes of

autonomic regulation.

4. Implementing the synchronous ECG channel

increased the amount of measurement data and enabled

monitoring of parameters of pulse wave transit along

surface arteries significant for several diseases.

5. In general, the research of the optimal methods for

measuring, interpreting, and using discussed data

demands the cooperation of cardiologists and

equipment developers, as well as the software

developers.

ACKNOWLEDGEMENTS

The authors are grateful to the Russian Foundation for

Basic Research (RFBR), grant N 18-29-02108 mk for

the financial support of this work.

REFERENCES

Antsiperov, V.E., Mansurov, G.K. et al, 2016. Pneumatic

sensor for non-invasive continuous blood pressure

measurement In Invention patent 2638712. Priority

November 7, 2017. Bulletin No. 35.

Antsiperov, V.E., Mansurov, G.K., and Danilychev, M.V.,

2018. Method of positioning a pneumatic sensor for

noninvasive blood pressure monitor according to three-

channel pulse wave detecting signal. In Proceedings of

the 11

th

International Scientific and Technical

Conference «Acousto-optic and radar methods for

information measurements and processing». P. 140-144.

Chazova I.E., Oshepkova E.V., Zhernakova Yu.V.

Diagnostics and treatment of arterial hypertension.

Clinical guidelines. In Kardiologicheskij Vestnik. No.1.

2015. Vol.10. pp.5-30.

Goldmann, H., Schmidt, T., 1975. Ueber

Applanationstonometrie In Ophthalmologica. Vol. 134.

P. 221-242.

Mansurov, G.K. et al. 2018. Monolithic three-chambered

pneumatic throttle sensor with integrated channels for

continuous non-invasive blood pressure measurement.

Patent application 2018106865.

Peňáz, J., 1973. Photoelectric measurement of blood

pressure, volume and flow in the finger. In Digest of the

10th International Conference on Medical and

Biological Engineering, Dresden, p.104.

Settels, J.J., 2014. Non-invasive Arterial Pressure

Monitoring. In Monitoring Technologies in Acute Care

Environments, ed. Ehrenfeld J.M., Cannesson M.

Springer, New York, P. 87-107.

Non-Invasive Blood Pressure Monitoring Based on Pulse Wave Recording with a New Three-channel Pneumatic Sensor

273