In Situ Visual Quality Control in 3D Printing

Charalampos Kopsacheilis

a

, Paschalis Charalampous

b

,Ioannis Kostavelis

c

and Dimitrios Tzovaras

d

Centre for Research and Technology, Hellas, Information Technologies Institute (CERTH/ITI),

6th Km Charilaou-Thermi Road, Thessaloniki, 57001, Greece

Keywords: 3D Printing, Additive Manufacturing, Quality Control, Optical Monitoring, Image Processing.

Abstract: In the past decade, additive manufacturing technology has gained an immense attention in numerous research

areas and has already been adopted in a wide range of industries relevant to transportation, healthcare,

electronics and energy. However, the presence of defects and dimensional deviations that occur during the

process hinder the broad exploitation of 3D printing. In order to enhance the capabilities of this emerging

technology, online quality control methodologies and verifications of the manufacturing process are necessary

to be developed. In the present article, a low cost in-situ vision-based monitoring technique applied in Fused

Deposition Modeling (FDM) 3D printing technology is introduced. An optical scanning system was integrated

in a commercial 3D Printer in order to scan and validate the performance of the procedure. The proposed

methodology monitors the FDM process and correlates the theoretical 3D model with the manufactured one.

This technique can be utilized in various additive manufacturing technologies providing integrity and

reliability of the process, high quality standards and reduced production costs.

1 INTRODUCTION

Additive Manufacturing (AM), which is known to the

public as three-dimensional (3D) printing, is a

manufacturing process where the product is built

incrementally and vertically to the build platform of

the 3D printer, i.e. layer-by-layer (Gibson, 2014).

Industries around the world utilize AM in order to

decrease the cost of parts manufacturing and reduce

the time-to-market. Products created using AM

procedures have the potential to possess complex

geometric characteristics and lightweight structure,

challenges which are difficult be to addressed via

traditional subtractive manufacturing procedures like

turning and milling. 3D printing has undergone a

rapid growth and there are various AM processes

based on different physical principles (e.g. material

extrusion, photopolymerization, sintering, material

jetting, etc.) which are now available and allow the

manufacturing industry to reduce lead times on the

production. Depending on the applied AM

a

https://orcid.org/0000-0003-0509-618X

b

https://orcid.org/0000-0002-9399-4387

c

https://orcid.org/0000-0003-2882-2914

d

https://orcid.org/0000-0001-6915-6722

technology, there is a wide range of materials which

can be used such as plastics, ceramics and metals.

From an application perspective, polymer-based AM

methods are employed in various scientific fields like

automotive engineering, medical and bioengineering.

The most popular and rapidly-growing AM process

using polymers as feedstock material is the extrusion

based deposition process known as Fused Deposition

Modeling (FDM). FDM is an AM technology

representing the largest installed base of 3D printers

in the world and is primary used for modelling,

production and rapid prototyping. The

abovementioned process a continuous filament of a

thermoplastic material through a moving, heated

extrusion print head. Once the nozzle of the print head

has reached the desired temperature, the feedstock

material is fed to the print head where it melts locally.

The print head is connected with a computer

numerical control system that allows it to move in two

dimensions (on the horizontal plane), one layer at a

time, depositing the feedstock material in

Kopsacheilis, C., Charalampous, P., Kostavelis, I. and Tzovaras, D.

In Situ Visual Quality Control in 3D Printing.

DOI: 10.5220/0009329803170324

In Proceedings of the 15th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2020) - Volume 3: IVAPP, pages

317-324

ISBN: 978-989-758-402-2; ISSN: 2184-4321

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

317

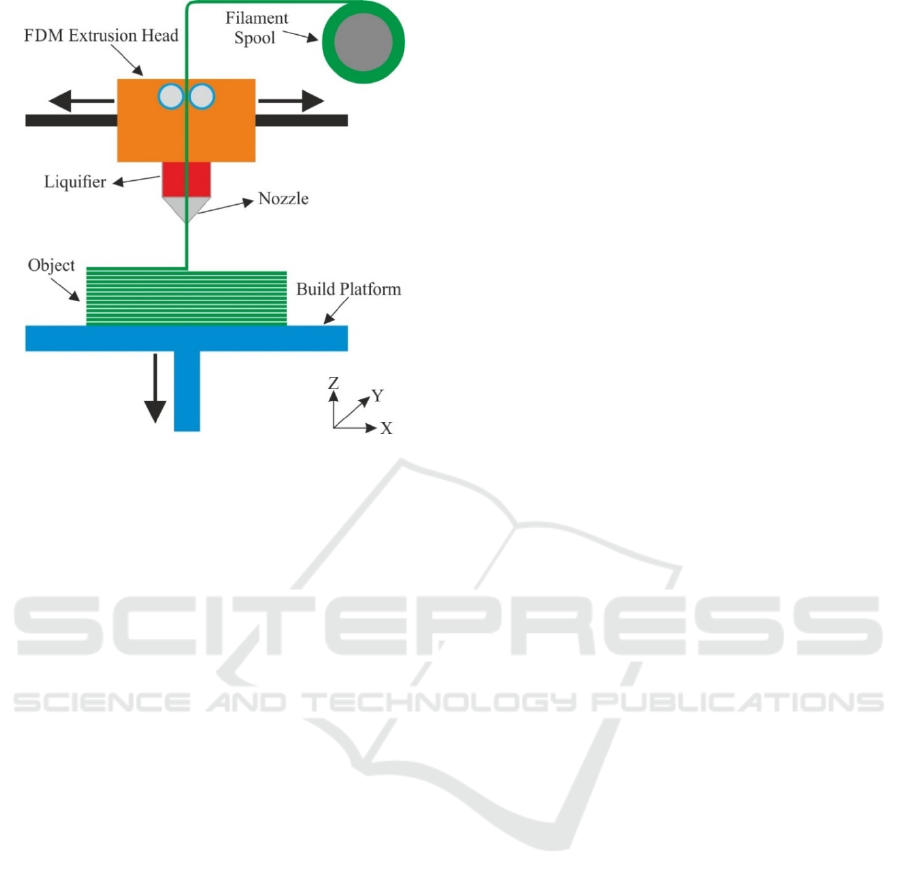

Figure 1: Principal of FDM process.

predetermined locations as illustrated schematically

in Figure

1. The deposited melted material on the

build platform cools and solidifies immediately after

its extrusion from the print head’s nozzle. When the

layer is fully created, the build platform moves

vertically down and a new layer is deposited. This

procedure is repeated until the 3D geometry of the

product has been printed.

In general, the quality of a product manufactured

via the FDM procedure can be characterized by

various aspects, such as dimensional accuracy,

surface quality, mechanical properties and

conformance to specifications. More specifically, the

geometrical accuracy of the physical printed model

consists one of the biggest concerns in AM and the

utilization of non-destructive quality control methods

constitutes a must in order to exploit the full

capabilities of this state of the art technology

(Dimitrov, 2006). In the scope of optimizing the FDM

process via the reduction of dimensional deviations

between the theoretical and the printed product,

online monitoring of the procedure is considered to

be mandatory. Real time monitoring of the AM

procedure composes an essential phase but is

frequently neglected; hence dimensional deviations

from the printed model are unknown until the end of

the process. Additionally, in situ visual monitoring of

the 3D printing process could reduce material

resources and production time, as the manufacturing

process can be aborted if an error is detected.

Therefore, semi-built parts which do not comply with

the technical standards of the product can be

interrupted prior to the prescribed process

termination. Optical methods are appropriate for low

cost, non-destructive and high resolution monitoring

of AM procedures (Nuchitprasitchai, 2017).

Moreover, monitoring of the manufacturing process

could aid in predicting the performance of the

operation and detecting possible failures beforehand.

The objective of the present work is to investigate

and develop real-time optical monitoring techniques

during the FDM process in order to perform in situ

non-destructive quality control. Hereupon, an

integration of an optical scanning system on a

commercial FDM 3D printer has been established in

order to exhibit real time monitoring of the AM

process. The rest of the paper is organized as follows:

Section 2 outlines the existing monitoring and error

detection methods utilized in AM technology and

more specifically in FDM procedures. Next in

Section 3, the applied experimental setup and the pre-

processing data of the employed methodology are

discussed, while Section 4 explicitly presents the

experimental assessment of the introduced optical

monitoring technique. Finally, conclusions and future

work are drawn in Section 5.

2 LITERATURE REVIEW

Taking into account the fact that 3D printing is a

relatively new manufacturing technology, the

research on available real time monitoring systems of

extrusion based AM processes is currently limited.

Up to now, commercial FDM 3D printers have

developed and integrated some types of sensor

solutions detecting lack of the feedstock material or

malefactions on the nozzle. However, these methods

investigate only a single form of a failure mechanism.

In order to develop a fully functional monitoring

system, which can be applied for real time error

detection, more sophisticated methodologies have to

be developed. Recent studies with applications in

online monitoring of the FDM 3D printing process

are documented in the next paragraphs.

An in situ monitoring method for evaluating the

surface quality of parts manufactured via a FDM 3D

printer was developed in (Fang, 2003). Grayscale

images of the deposited layers were captured and

analyzed during the process. Alterations in the

grayscale values on the deposited surfaces allowed

the detection of overfills and underfills of the printed

parts. The authors in (Dinwiddie, 2013) utilized an

extended range IR camera in order to measure the

developed temperatures during the process

correlating their effect on the mechanical properties

and the quality of parts manufactured through a FDM

IVAPP 2020 - 11th International Conference on Information Visualization Theory and Applications

318

3D printer. The authors in (Faes, 2014) a modular 2D

laser triangulation scanner has been utilized in order

to analyze feedback signals during the process and to

identify the source of the printing errors. Moreover,

in the work presented in (Holzmond, 2017) the

utilization of a three-dimensional digital image

correlation (3D-DIC) system as an online

measurement method has been introduced, in order to

monitor and quantify the quality of the printed part

surface. In particular, stereoscopic images were

captured and spatially correlated using 3D Digital

Image Correlation in order to extract the surface

characteristics and produce the 3D geometry of the

part during the process.

The authors in (Straub, 2015) developed a

technique to detect failure defects during the 3D

printing manufacturing procedure. In this study, the

evaluation of the product quality was accomplished

via a multi-camera system consisted of five monitor

features (each feature consisted of a Raspberry Pi

camera) and image processing analysis using Dot Net

framework and C#. Images were captured during the

process from eight predefined locations by each of the

five cameras located at five different angles in order

to compare the results with the final 3D printed part.

The correlation was performed on a pixel-wise

manner. The types of the failures which can be

detected using this experimental procedure are either

an early termination of the process resulting to an

incomplete product or a failure on the injection of the

filament into the printer’s nozzle. The proposed

technique cannot evaluate geometrical characteristics

or structural defects, which are the most common

errors in FDM process. However, in (Malik, 2019) a

3D reconstruction method was introduced requiring

only one camera integrated on the top of the build

platform avoiding the need for moving the camera

around the printed part or employing multiple static

cameras. Moreover, the isolation of the printed part

was feasible by cropping the background and the

unwanted information from the acquired images. The

3D model is reconstructed layer by layer; hence an

online monitoring and error detection technique was

developed. Finally, Augmented Reality (AR)

methods were used to evaluate the procedure utilizing

the reconstructed 3D model of the printed product.

Recently, image-sensing systems combined with

Artificial Intelligence (AI) algorithms have been

reported for the characterization and the

quantification of the geometric accuracy of 3D

printed parts. The authors in (Delli, 2018) presented

an in process quality control methodology for an

FDM 3D printer utilizing the supervised machine

learning algorithm support vector machine (SVM)

and a single camera. In this work, the state of the

printing process was classified as ‘defective’ or

‘good’ employing the machine learning model and

the image captured during the building procedure.

3 EXPERIMENTAL METHOD

3.1 3D Printer Setup

The experimental setup utilized in this work

comprises the commercial 3D Printer ‘Ultimaker 3

Extended’, an ADXL345 accelerometer and the

RGB-Depth camera ‘Asus Xtion Pro Live’. The

Ultimaker 3 Extended applies the FDM 3D printing

technology process providing a maximum build

volume of (215x215x300) mm, a layer resolution

from 20 to 200 microns and a XYZ print accuracy of

(12.5, 12.5, 2.5) micrometers respectively. Polylactic

acid (PLA) was used as an eco-friendly feedstock

material in the experimental procedures. The process

parameters were selected as documented in Table 1

and remained constant throughout the courses of the

experiments. The accelerometer has been exploited in

order to send a signal to the optical monitoring system

during the FDM process for capturing images when

the print head reaches a checkpoint, as it will be

discussed in Section 3.2.

Table 1: 3D printing process parameters during the

experimental tests.

Process Parameters Value Units

Nozzle diameter 0.4 mm

Layer height 200 μm

Printing speed 70 mm/sec

Printing temperature 205 °C

Wall thickness 1 mm

Top thickness 1 mm

Bottom thickness 1 mm

Infill density 25 %

Infill pattern triangles

Build plate temperature 70 °C

Overhang angle 45 degree

The Asus Xtion Pro Live sensor provides color

images and Per-Pixel-Depth information. Depth data

of the scene are provided from the integrated IR depth

sensor of the camera and the RGB sensor implements

the colored image on the captured scene. After the

registration of these sources of data, an RGB image

of the scene along with a Per-Pixel-Depth information

is obtained. In the present article, only the depth

sensing capabilities of the camera will be exploited.

The 3D printed objects are monitored by capturing

images during the process with the aid of the above-

In Situ Visual Quality Control in 3D Printing

319

Figure 2: Experimental setup.

mentioned laboratory equipment, as shown in Fig. 2.

It has to be noted, that the proposed experimental

setup can easily be implemented in any type of 3D

Printer and several AM technologies. The developed

software was in C++, while also Point Cloud Library

(PCL) (Rusu, 2011) has been used to for handling the

3D points; developing thus a pipeline which

automates the in situ monitoring process of the FDM

3D printing procedure. Finally, taking into account

the effect of variation in lighting conditions,

numerous experiments in different light conditions

have been performed in order to capture images using

the RGB-D camera. Since the alterations in the

lighting conditions influence the quality of the image,

a constant lighting angle throughout the course of the

experimental procedures was kept facilitating image

analysis and comparison feasibility.

3.2 Data Pre-processing

One of the major advantages of AM is the ability to

create a complex physical object utilizing only a

digital 3D CAD (Computer Aided Design) model and

a 3D printer. The executable commands of the 3D

printer are derived from the digital 3D model and by

employing a software called slicer; machine

commands are generated representing the trajectories

of the print head (Gcode). Gcode is a machine code

which is utilized in various manufacturing

procedures, like CNC milling, turning and 3D

printing. These code structures contain the

instructions for the printer in order to control and

move its actuators, the build platform and the print

head, which extrudes the semi-molten feedstock

material. However, there is no control or guarantee

that the commands of the Gcode will be accurately

executed by the 3D printer resulting to inaccuracies

of the manufactured product. Dimensional deviations

of the physical printed part compared to the 3D CAD

model is hard to be detected during the FDM process

due to the fact that the printing object does not exhibit

any obvious defects and the manufacturing process is

successfully finished. This type of errors could occur

in case of malefactions of the 3D printer during the

process or in situations where the user applies

unsuitable printing conditions. Therefore, in order to

detect dimensional deviation errors, the physical

printed part has to be monitored and compared to the

theoretical model while the process is still ongoing.

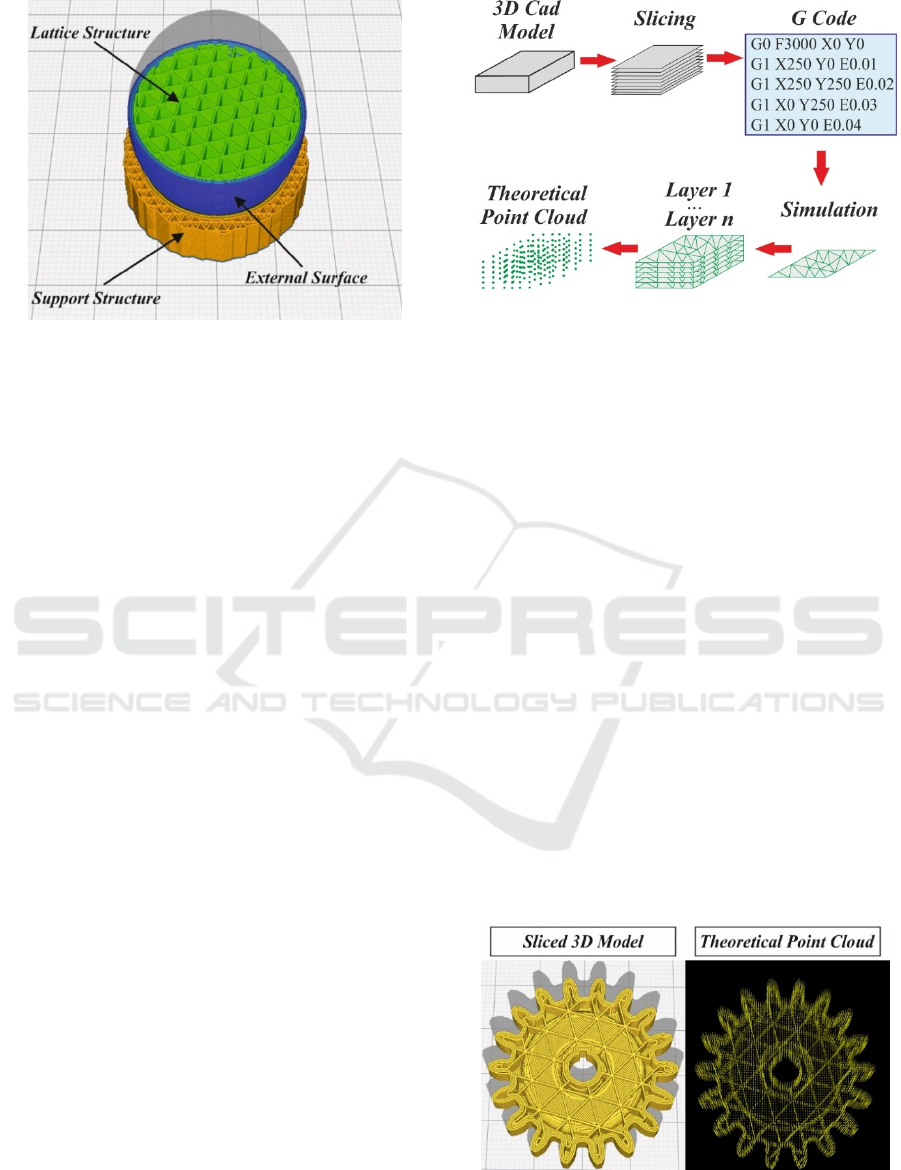

In AM technologies and especially in FDM

procedures, the conversion of a CAD model into a

Standard Triangulation Language (STL) format is

necessary in order for the slicer software to generate

the Gcode for the manufacturing of the model

(Gibson, 2014). STL format contains data that

correspond to sets of surface normal vectors and

triangle vertices, hence STL describe only the

external surface geometry of the part without any

representation of the internal structure (lattice

structure) or the necessary support structures of the

printed part. In some AM processes, like FDM, the

physical objects are not printed as solids due to the

high amount of the required feedstock material and

the total duration of the procedure. The lattice

structure (filling pattern) is the internal structure of a

part created using the FDM technology. Additionally,

as FDM 3D printing models are constructed layer by

layer, a previous layer is necessary to build upon it.

Hereupon, depending on the complexity of the 3D

model and the overhang angle of the new layer

compared to the previous one, support structures may

be required (Volpato, 2014). These types of structures

are exhibited in Fig. 3. For this reason, the

comparison between the STL data and the printed part

is not directly applicable, since the STL format does

not contain information regarding the

abovementioned structures.

In order to overcome such issues, a more holistic

approach had to be developed. The employed

methodology for the reconstruction of the digital

model taking into account the internal and the support

structures is presented schematically in Fig. 4. The

proposed method is based on the generated Gcode

IVAPP 2020 - 11th International Conference on Information Visualization Theory and Applications

320

Figure 3: Lattice and support structures in FDM process.

from the slicer software and simulates the exact

movements of the print head in order to create the

theoretical point cloud of the digital 3D model. In the

first step, the 3D CAD model is imported on the

CuraEngine, which is a fast and robust engine for

translating 3D models into 3D printing commands

(Kocisko, 2017). The outcome of this step is the

Gcode that contains certain instructions about the

X,Y and Z coordinates to which the print head and the

build platform have to move in order to build the 3D

model. In the next stage, a simulation of the 3D

printing process utilizing the Gcode takes place. The

generated Gcode has been further processed using a

modified version of gcode2vtk (Kubicek, 2011),

emulating the functionality of the 3D printer by

parsing the Gcode to extract the planar-layered

trajectories of the print head. In the next phase, a

structure containing every path of the 3D printer is

created. It has to be noted that only the Gcode

commands, which contain information about the

extruded material and the movements of the print

head (that ultimately builds the physical model) are

taken into consideration. Finally, these trajectories

are uniformly sampled generating a theoretical point

cloud of the 3D model. An example of the developed

technique is illustrated in Fig

. 5, where a 3D model

created in the slicer software and the corresponding

theoretical point cloud are displayed.

In the last step of the preprocessing data module,

some further parameters are passed to the 3D Printer.

The print head has to move to the zero position (X=0

and Y=0) of the 3D printer in order for the monitoring

system to capture a clear image of the printed part

during the FDM process. That was accomplished

through the modification of the Gcode sending the

print head in the zero position of the 3D printer every

‘n’ deposited layers and with an accelerometer placed

upon the 3D printer. In more detail, during the AM

Figure 4: Theoretical point cloud reconstruction.

process the print head commanded to move towards

the zero position and pauses for time t

w

. During t

w

, the

accelerometer sends a signal to the monitoring system

in order to capture an image of the printed part, which

is clearly visible by the RGB-D sensor, without the

printing head to occlude the visibility of the building

plate. After this operation, the printing head moves

back to its previous position and re-initializes the

printing process again. In this way, the real-time point

cloud from the printed part is captured during the

FDM process; hence the monitoring of the process

and the correlation with the theoretical point cloud is

feasible.

4 EXPERIMENTAL

ASSESSMENT

In this section, the experimental assessment of the

present work is presented. The experimental

procedure has been conducted on a 3D printed part

which has been exploited as a test specimen of basic

geometry, namely a spur gear, utilizing PLA filament

of 2.85 mm diameter (see Fig.5).

Figure 5: Sliced 3D model and the corresponding

theoretical point cloud.

In Situ Visual Quality Control in 3D Printing

321

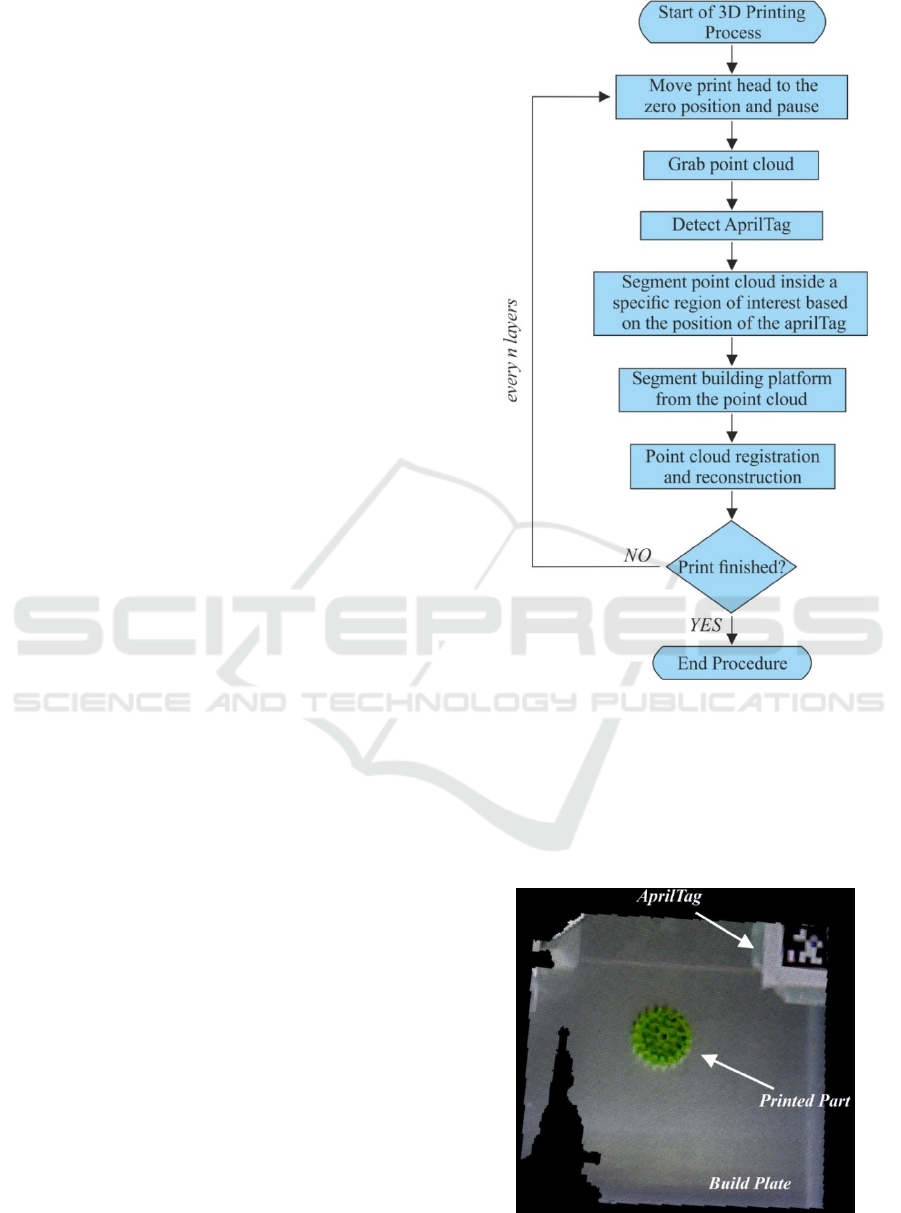

Figure 6 demonstrates a brief overview of the

applied optical monitoring process. As it was

described in the previous section, the print head

moves to the zero position of the 3D printer every ‘N’

layers, so the employed camera can capture a clear

point cloud of the printed part during the FDM

procedure. Due to the low resolution and broad field

of view of the acquired point cloud by the Asus Xtion

sensor, a fiducial marker was used to filter out the

background and determine the area of interest to crop.

The AprilTag visual fiducial system has been applied,

which is widely used for a variety of tasks including

augmented reality, robotics and camera calibration

(Olson, 2011). Targets can be printed in any size on a

simple piece of paper, thus allowing a low cost and

accessible integration of the marker with the

employed experimental setup. By placing a small

AprilTag on the build platform of the 3D printer, the

calculation of an orthogonal region of interest and

filtering out any outliers from the initial point cloud

is accomplished. The orthogonal region consists of

the build platform, the AprilTag and the 3D printed

model as shown in Fig. 7. This technique allows a fast

filtering of the noise; hence focus on a small region

of interest where the model is printed was ultimately

achieved.

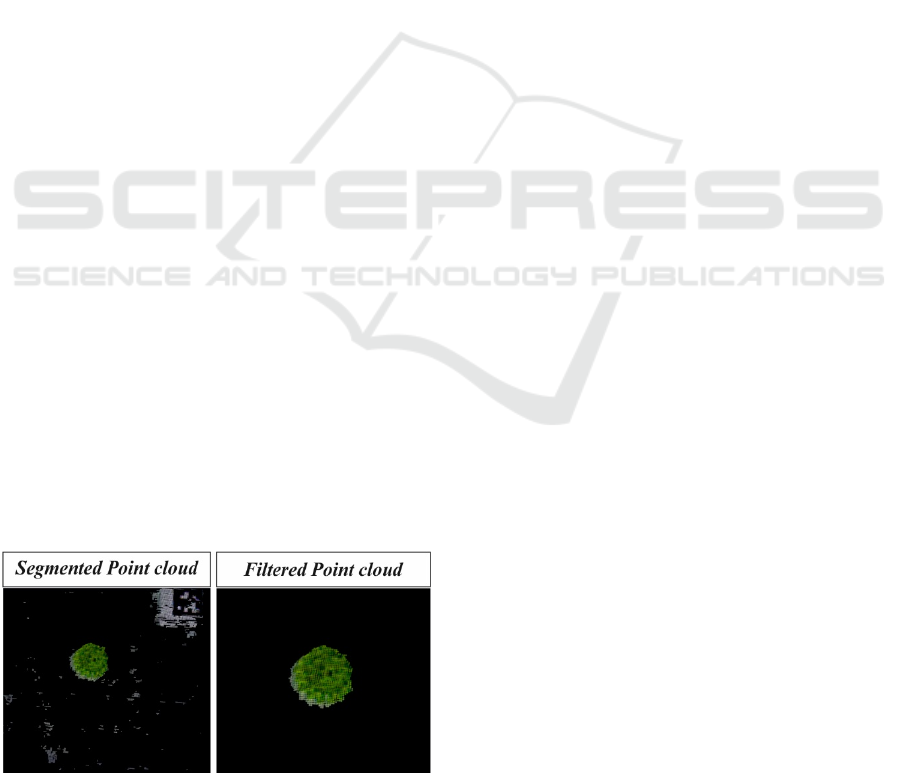

Once the original point cloud has been cropped

down to the region of interest, consisting of the

printed part, build platform and AprilTag, the next

step comprises their separation acquiring only the

printed layer in order to reconstruct the model and

evaluate its quality. This issue boils down to a plane

detection and segmentation problem. There is a

variety of methods targeting towards plane

segmentation of 3D point cloud data in literature.

Ransac algorithm has been selected and applied in the

present study, which is easily implemented in PCL

providing accurate results. Ransac is relatively slow

when provided with big data sets, however the crop

of the original point cloud reduced the overall size

heavily and thus applying it did not influence the

performance of the introduced optical monitoring

system. Using the algorithm on the cropped point

cloud resulted in a fairly accurate segmentation of the

build platform, although there were still some areas

with a small concentration of outlier points (namely

the area where the AprilTag was placed upon) as

exhibited in the left part of Fig. 8. In order to tackle

this issue, a technique has been developed in

accordance to which a point cloud representation is

obtained that retain only the inlier points belonging to

the constructed model, excluding thus the outliers.

Increasing the distance threshold, which Ransac

applies to extract the points on the detected plane,

Figure 6: Flowchart of the monitoring procedure.

resulted in segmenting away points originally

belonging on the printed model. The issue has been

solved by applying a distance–based clustering

algorithm to the remaining point cloud and

segmenting the biggest cluster, which resulted in a

point cloud consisting only from points belonging to

Figure 7: Region of interest.

IVAPP 2020 - 11th International Conference on Information Visualization Theory and Applications

322

the printed layer of the part. To this end, a Euclidean

distance clustering algorithm has been utilized which

clusters the remaining points based on the 3D

Euclidean distance from their neighbors. Due to the

sparsity of the outlier points, clustering the point

cloud using distance between points as a metric

leaded in a successfully filtering of the printed model

as exhibited in the right part of Fig. 8.

Having successfully implemented a method for

locating and segmenting each printed layer, the final

step was to reconstruct the printed model and

correlate it with the theoretical point cloud of the

3Dmodel. In situations where the build platform of

the 3D printer was stationary, the reconstruction of

the model using the methodology presented in this

work would be as simple as concatenated all the

obtained point clouds from each individual deposited

layer. However, on the employed 3D printer

(Ultimaker 3 Extended), the print head is stationary in

the vertical direction and the build platform moves

during the process. Therefore, preprocessing of the

acquired point clouds of each printed layer before

their concatenating was imperative. In the first step,

the transformation between two subsequent layers

was computed by aligning their build platforms. The

alignment was conducted utilizing the Iterative

Closest Point (ICP) algorithm (Bellekens, 2014),

which is usually deployed in order to minimize the

difference between two point clouds. Thus, the ICP

algorithm was applied between two subsequent point

clouds before the segmentation of the build platform.

Due to the high concentration of points on the build

platform, it was feasible to match the individual build

platforms of two subsequent point clouds, acquiring

ultimately their transformation. Hence, the

segmentation of the build platform as well as the

transformation of the extracted layers have been

accomplished, enabling the representation of the

physical printed object. Finally, it is a matter of

concatenating the printed layers into a single point

cloud to reconstruct the 3D model as illustrated in the

left part of Fig. 9.

Figure 8: Segmentation of the build platform using Ransac

and the filtered point cloud.

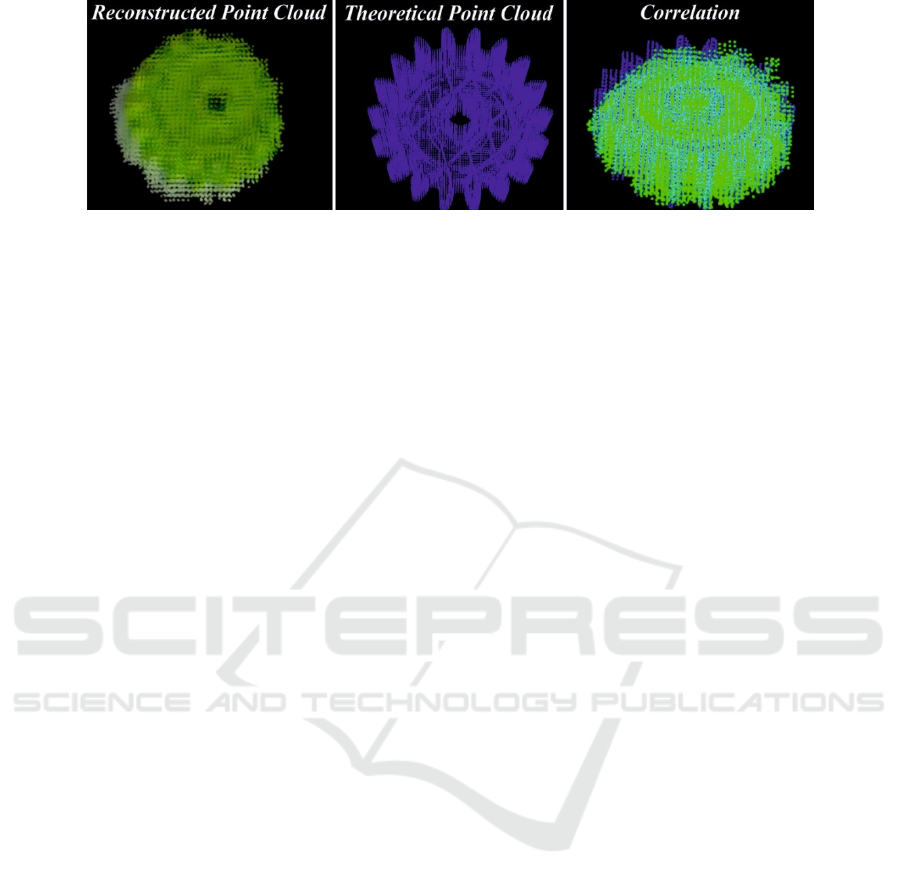

Results of the employed optical monitoring

system are displayed also in Fig. 9, where in the

middle the theoretical point cloud of the test

specimen, which was obtained through the introduced

methodology described in Section 3.2, is presented.

Additionally, in the right part of Fig. 9 the correlation

between the theoretical and the actual reconstructed

point cloud of the examined model is exhibited. As it

can be observed qualitatively, the reconstructed

model is in decent agreement with the theoretical one.

For the qualitative comparison, a point cloud spatial

change detection method based on octrees has been

employed to compare the reconstructed point cloud to

its theoretical counterpart. An octree is a tree data

structure in which each internal node has exactly

eight children and is often used to partition a 3D space

by recursively subdividing it into octants (Tang,

2016). By calculating both point clouds octrees, it

was feasible to retrieve points that are stored at voxels

of one octree structure but do not exist in the other.

Using the abovementioned method on the generated

point clouds with a voxel size of 0.5 mm, the

differential point cloud representing the spatial

change between the theoretical and reconstructed

model was calculated and amounts to 9.6%. One

reason for the deviation between the examined point

clouds is a result of poor resolution of the employed

low cost optical sensor. Nevertheless, the proposed

optical monitoring system composes an efficient

method for real time monitoring of the FDM process

and in case of utilizing a more accurate optical sensor;

the introduced methodology could be efficiently

applied for any real time error detection in AM

procedures.

5 CONCLUSIONS AND FUTURE

WORK

In the present study, a low cost solution for online

monitoring of the FDM process has been introduced

through the integration of sensors on the 3D printer

and the implementation of image analysis algorithms.

In this sense, an optical scanning system was

integrated to a commercial FDM type 3D printer

using a low cost RGB-Depth camera and performed

initial experiments. The suggested system provides an

automatic optical monitoring system with no human

oversight. Taking into account the generated Gcode

for the manufacture of the product, a theoretical point

cloud of the 3D model has been obtained. This digital

representation of the part is in the most suitable form

in order to evaluate the accuracy of the 3D printing

In Situ Visual Quality Control in 3D Printing

323

Figure 9: The reconstructed and theoretical point cloud of the test specimen and their correlation.

process, as it contains both the lattice and the support

structures of the examined model. Albeit the fact that

the resolution of the optical sensor is relatively low,

the developed algorithms by means of computer

vision and the obtained results exhibit that the

suggested method is a promising tool in real time

monitoring and detecting errors in 3D printing

technology.

ACKNOWLEDGEMENTS

«This research has been co-financed by the European

Union and Greek national funds through the

Operational Program Competitiveness,

Entrepreneurship and Innovation, under the call

RESEARCH – CREATE – INNOVATE (project

code:T1EDK- 04928)».

REFERENCES

Bellekens, B., Spruyt, V., Berkvens, R., & Weyn, M., 2014.

A survey of rigid 3D pointcloud registration algorithms.

In AMBIENT 2014: the Fourth International

Conference on Ambient Computing, Applications,

Services and Technologies, pages 8-13.

Delli, U. and Chang, S., 2018. Automated Process

Monitoring in 3D Printing Using Supervised Machine

Learning. Procedia Manufacturing, volume 26, pages

865–870.

Dimitrov, D., Van Wijck, W., Schreve, K., and De Beer, N.,

2006. Investigating the achievable accuracy of three

dimensional printing. Rapid Prototyping Journal,

volume 12, no. 1, pages 42-52.

Dinwiddie, R.B. and Love, L.J., Rowe, J.C., 2013. Real-

time process monitoring and temperature mapping of a

3D polymer printing process. In Proceedings of SPIE -

The International Society for Optical Engineering.

Faes, M., Vogeler, F., Coppens, K., Valkenaers, H.,

Abbeloos, W., Goedemé, T. and Ferraris, E., 2014.

Process Monitoring of Extrusion Based 3D Printing via

Laser Scanning. In International Conference on

Polymers and Moulds Innovations, pages 363-367.

Fang, T., Jafari, M., Danforth, S.C., and Safari, A., 2003.

Signature analysis and defect detection in layered

manufacturing of ceramic sensors and actuators.

Machine Vision and Applications, volume 15, pages

63–75.

Gibson, I., Rosen, D. and Stucker, B., 2014. Additive

Manufacturing Technologies: 3D Printing, Rapid

Prototyping, and Direct Digital Manufacturing.

Springer.

Holzmond, O. and Xiaodong, Li, 2017. In situ real time

defect detection of 3D printed parts. Additive

Manufacturing, volume 17, pages 135-142.

Kocisko, M., Teliskova M., Torok, J., and Petrus J., 2017.

Postprocess options for home 3D printers, Procedia

Engineering, volume 196, pages 1065-1071.

Kubicek, B., 2011. https://github.com/pbrier/gcode2vtk.

Malik, A., Lhachemi, H., Ploennings, J., Ba A. and Shorten,

R., 2019. An Application of 3D Model Reconstruction

and Augmented Reality for Real-Time Monitoring of

Additive Manufacturing, In Procedia CIRP, volume 81,

pages 346-351.

Nuchitprasitchai, S., Roggemann, M., and Pearce, J. M.,

2017. Factors effecting real-time optical monitoring of

fused filament 3D printing. Progress in Additive

Manufacturing, volume 2, pages 133-149.

Olson E., 2011. AprilTag: A robust and flexible visual

fiducial system. In IEEE International Conference on

Robotics and Automation, pages 3400-3407.

Rusu, R., B., and Cousins, S., 2011. 3D is here: Point Cloud

Library (PCL). In IEEE International Conference on

Robotics and Automation (ICRA).

Straub, J., 2015. Initial work on the characterization of

additive manufacturing (3D printing) using software

image analysis. Journal of Machines, volume 3, pages

55-71.

Tang, L., Fei-peng Da, and Huang, Y., 2016. Compression

algorithm of scattered point cloud based on octree

coding. In 2nd IEEE International Conference on

Computer and Communications (ICCC), pages 85-89.

Volpato, N., Aguiomar, Foggiatto J. and Coradini, Schwarz

D., 2014. The influence of support base on FDM

accuracy in Z. Rapid Prototyping Journal, volume 20,

no. 3, pages 182-191.

IVAPP 2020 - 11th International Conference on Information Visualization Theory and Applications

324