Similarity Measures for Visual Comparison and Retrieval of Test Data in

Aluminum Production

Nikolina Jekic

1 a

, Belgin Mutlu

1,4

, Manuela Schreyer

2

, Steffen Neubert

2

and Tobias Schreck

3

1

Pro2Future GmbH, Inffeldgasse 25f, 8010 Graz, Austria

2

AMAG Austria Metall AG, Lamprechtshausener Strasse 61, 5282 Ranshofen, Austria

3

Graz University of Technology, Institut of Computer Graphics and Knowledge Visualisation,

Inffeldgasse 16c , 8010 Graz, Austria

4

Graz University of Technology, Institut of Interactive Systems and Data Science, Inffeldgasse 16c, 8010 Graz, Austria

Keywords:

Similarity Measures, Visual Analysis, Aluminum Casting.

Abstract:

Monitoring, analyzing and determining the production quality in a complex and long-running process such as

in the aluminum production is a challenging task. The domain experts are often overwhelmed by the flood

of data being generated and collected and have difficulties to analyze and interpret the results. Likewise,

experts find it difficult to identify patterns in their data that may indicate deviations and anomalies that lead

to unstable processes and lower product quality. We aim to support domain experts in the production data

exploration and identifying meaningful patterns. The existing research covers a broad spectrum of pattern

recognition methodologies that can be potentially applied to elicit patterns in data collected from industrial

production. Hence, in this paper, we further analyze the applicability of different similarity measures to

effectively recognize specific ultrasonic patterns which may indicate critical process deviations in aluminum

production.

1 INTRODUCTION

The goal of an optimal manufacturing process is to

increase productivity and customer satisfaction while

minimizing cost, time, and waste. Achieving a high

quality of products while remaining competitive, re-

quires companies to continuously improve the per-

formance of their production process. Process data

may contain important information such as meaning-

ful relationships and patterns, which could help to im-

prove the quality of the production process (Yin and

Kaynak, 2015) (Thalmann et al., 2018). Yet, human

beings are overwhelmed by the amount of data be-

ing generated in such complex production processes.

Visual data analysis has proven to be one of the ef-

fective ways to tackle this problem (Soban et al.,

2016). The existing research does not only support

the exploration of the data and detect hidden pat-

terns/correlations, but they also pave the way to define

new methods for improving the production process

and increasing production number (Suschnigg et al.,

2020) (Sun et al., 2019).

The production process in the aluminum industry

is complex and time-consuming. A simplified alu-

a

https://orcid.org/0000-0001-9884-0929

minum production process from the recycled raw ma-

terial up to the final products includes melting, al-

loying and further treatment, casting, homogeniza-

tion, rolling and quality control. In a nutshell, during

the cast, each batch results in several ingots. Ingots

are molds cast from molten aluminum and are suit-

able for production processing using methods such as

rolling, extrusion, and forging (Vasudevan and Do-

herty, 2012). These ingots are further rolled to plates

and sheets. Finally, to assess quality, experts perform

ultrasonic tests (UT) on rolled aluminum plates. Each

part of the production process is done in accordance

with very high-quality standards. However, due to the

complex process dynamics, the final product might

not meet them and show certain degrees of indica-

tions.

Non-metallic indications that are already con-

tained in the input material or are formed in the

foundry production process, can lead to rejects in ma-

terials after ultrasonic inspection of the final plates.

This leads to reduced capacity, longer delivery times

and higher costs. Ultrasonic testing is the last step

in the complete process chain and can not be done

directly after casting. It can therefore happen that a

product goes through the entire process, but finally

210

Jekic, N., Mutlu, B., Schreyer, M., Neubert, S. and Schreck, T.

Similarity Measures for Visual Comparison and Retrieval of Test Data in Aluminum Production.

DOI: 10.5220/0010309302100218

In Proceedings of the 16th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2021) - Volume 3: IVAPP, pages

210-218

ISBN: 978-989-758-488-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

does not meet the required standard. The causes and

the influencing factors that lead to UT indications in

the casting process are not yet fully understood.

Different groups of production parameters influ-

ence the quality of batches and ingots, and this may

be an implication that only some batches and ingots

would have specific indication patterns. Influencing

parameters can be possibly found, for example, in the

input material, in process parameters of the furnace

and casting plant, where several hundred different pa-

rameters are continuously recorded during the cast-

ing, or in the chemical composition of the different

batches. By far, most of the ingots are of good quality,

with no or very few indications, which do not lead to

rejects after ultrasonic inspection. Some are of mixed

quality, which means that some parts of the ingot are

of good quality, with very few indications, and some

parts are of poor quality with many indications. In this

case, some of the plates made from the entire ingot

are rejects after the ultrasonic testing. In certain situa-

tions, the whole ingot is of poor quality, which means

that all the plates made of the entire ingot are rejects,

whereas neighboring ingots from the same batch are

of perfect quality. The number of indications in an

ingot depends also on some product-specific parame-

ters, for example, the material of the ingot, the cast-

ing format and the format of the final product, which

makes the analysis even more difficult. Additionally,

the total number of test batches is limited, especially

if one wants to concentrate on a specific alloy and/or

format. The overall small number of indications and

rejects complicates the analysis and research even fur-

ther. Thus, in the following, we restricted the analysis

to one specific material, casting- and final-product-

format in order to lay out the methodology to the in-

clined reader.

Grouping and recommending batches and ingots

with similar indication patterns, is highly desired to

support the end-users, i.e., material engineers in cast-

ing and rolling, in production data exploration and in-

spection of possible influencing parameters on prod-

uct quality. Distance or similarity measures are es-

sential to solving many pattern recognition problems

such as classification, clustering, and retrieval prob-

lems (Cha, 2007). There are many measures of sim-

ilarity and selecting the right one is one of the chal-

lenges encountered by researchers. Depending on the

application, some of the similarity measures do not

always have optimal behavior (Shirkhorshidi et al.,

2015). In this paper, we studied the capability of

different similarity measures to effectively recognize

specific indication patterns in production data. Fur-

thermore, we introduce a concept for visual analy-

sis and interactive pattern search in ultrasonic images

of aluminum ingots. To do so, we aim to help do-

main experts to identify specific patterns in produc-

tion data which may indicate critical process devia-

tions. Lastly, we evaluate the benefit of interactive

pattern search in ultrasonic images of aluminum in-

gots.

2 RELATED WORK

In this section, we analyze and discuss relevant work

conducted in the research areas of visual analysis for

industrial application and similarity measures.

2.1 Visual Analysis for Industrial

Application

The trend of digitalization in the industry (so-called

Industry 4.0, or also, smart production) generates

large amounts of production data. In this scenario,

domain experts are often overwhelmed by the amount

of data and unable to obtain useful information that

could help them to analyze their production pro-

cesses. Visual data analysis, in which users interact

with data to explore and analyze it, using visual dis-

plays, has been proven to be an effective approach

for gaining insight from production data (Lee et al.,

2014) (Wu et al., 2018).

A growing number of visualization solutions tar-

geting production scenarios have been presented in

recent years (Matkovic et al., 2002), (Jo et al., 2014),

(Xu et al., 2016). Recently, a survey on visualization

and visual analysis applications for smart manufactur-

ing has been published (Zhou et al., 2019). The sur-

vey provides an overview of several studies conducted

for industrial applications, with a few examples avail-

able for smart manufacturing applications in the iron

and steel industry. In an early study (Wu, 2001), the

problem of metal ingot casting and production plan-

ning is presented. This work reports that visualization

of the production schedule provides the basis for in-

teractive decision support. Zhou et al. (Zhou et al.,

2016) proposed the integration of advanced simula-

tion and visualization for the manufacturing process

addressing issues on energy, environment, productiv-

ity, safety, and quality in the steel industry.

The increasing amount of data becoming available

has to date triggered the use of visualization and de-

velopment of visual data analysis tools in a variety of

industrial domains (Liu et al., 2014). However, still

many manufacturing systems are not ready to allow

production specialists to efficiently and effectively an-

alyze growing amounts of production data, also due

Similarity Measures for Visual Comparison and Retrieval of Test Data in Aluminum Production

211

to a lack of analytics tools and interfaces (Lee et al.,

2013).

2.2 Similarity Measures

Manufacturing and various areas are becoming in-

creasingly more data-driven, which increases the ne-

cessity of identifying the similarity between datasets.

Datasets have several representations such as scalar

values, vectors, or matrices. Mathematically, there

are many measures of similarity or dissimilarity be-

tween the different forms of these datasets (Deza and

Deza, 2006). This work is partly inspired by simi-

larity techniques used for the comparison of distribu-

tions in image processing and computer vision. Sev-

eral works have supported the visual retrieval and ex-

ploration of large numbers of scatter plot images. In

(Scherer et al., 2011), feature vectors based on cor-

relation coefficients are proposed to rank and clus-

ter scatter plots for comparison. In (Behrisch et al.,

2014), a relevance-feedback approach was proposed

to learn to distinguish scatter plots of interest to spe-

cific users and tasks. In addition, in (Shao et al., 2016)

an approach to describe scatter plots by the set of lo-

cal patterns occurring was introduced and applied to

filter interesting scatter plots from a larger number of

plots. Recently, Bazan et al. (Bazan et al., 2019)

present research work on a qualitative analysis of the

similarity measures most used in the literature and the

Earth Mover’s Distance. In (Hern

´

andez-Rivera et al.,

2017) it is demonstrated how similarity metrics can be

used to quantify differences between sets of diffrac-

tion patterns. Although there exist many well-known

similarity metrics, still a selection of metrics to mea-

sure the similarity between two distributions is cru-

cial, because depending on the application, they do

not always have optimal behavior. In the following,

the discussion about qualitative analysis of different

similarity measures on the problem of grouping simi-

lar batches and ingots will be presented.

3 INTERACTIVE PATTERN

SEARCH

Our concept supports an interactive pattern search in

ultrasonic images of aluminum ingots. The concept

contains several steps which will be explained further

in the following sections.

3.1 Data Preprocessing

To assess the quality, experts perform ultrasonic tests

on rolled aluminum plates to meet the high-quality

standards in the final products. Ultrasonic testing

(UT) is used to locate the position and size of in-

dications on rolled aluminum plates. The explana-

tion and eventual reduction of these indications is

a key priority in production process analysis. The

dataset was obtained from ultrasonic tests conducted

on cut aluminum plates with different length, width,

and thickness from the cast and rolled ingots. One of

the biggest challenges is to match the indications, de-

tected on the final plates, to the ingot length. The data

preparation was done with Pandas, one of the main

tools used by data analysts in the programming lan-

guage Python (McKinney, 2012). In the first steps,

the tasks of data reduction, cleaning and transforma-

tion were performed, i.e., selection of relevant data;

handling incomplete data, missing values and out-

liers; removing duplicates and recalculating values

from the final plates back to the original ingot. Re-

garding the measuring unit, we note that these are the

tons of tested material as an example. A single cast

ingot with dimension 450 × 1400 × 7000 mm weighs

around 12.3 tons.

Figure 1: Interactive visual data analysis solution ADAM.

Ingot visualization is composed of scatter plots and fre-

quency histograms, showing the front and the top view of

the ingot. The figures showing the front view of the ingot

were used as UT images in the user study.

3.2 Visual Data Analysis Design ADAM

Our interactive visual data analysis solution ADAM,

an acronym for Aluminum production Data Analysis

and Monitoring, is based on the ideas presented in (Je-

kic et al., 2019). For more details, we refer the reader

to this publication.

For the analysis tool ADAM and for the proce-

dure of an interactive pattern search, which will be ex-

plained in the following section, the data preparation

was a major challenge. Data from a wide variety of

data sources had to be extracted and combined, such

IVAPP 2021 - 12th International Conference on Information Visualization Theory and Applications

212

as the process data from various melting and casting

furnaces, quality data such as the chemical composi-

tion of the batches, the input material and the UT test

results, together with the material due to technical re-

quirement that is generated in various process steps

along the production process. The UT indications,

that were detected in the individual final plates, to-

gether with the amount of the technical requirement,

then had to be calculated back to the exact ingot posi-

tion to make a comparison with, among other things,

the process data that were recorded and/or calculated

back to the casting length. The analysis tool ADAM

enables the user to view the exact position of the in-

dications in the ingot, that were detected in the final

plates. In the next development steps, an interactive

pattern search should enable the user to clearly dis-

play a part of the large amount of data recorded dur-

ing the casting process, where several hundred pa-

rameters are recorded in high resolution, for a large

number of ingots, which are produced. In the end, a

smaller, clearly visible group of similar ingots should

be proposed to the user, who can then compare the as-

sociated casting process data and thus could identify

possible influencing parameters. This aspect will be

dealt with in more detail in the following subsection.

The design of ADAM is shown in Figure 1. A

set of tightly linked views of production parameters

with cross-filtering capability supports the inspection

of factors possibly influencing the product quality.

Our approach was designed in an iterative develop-

ment cycle guided by domain requirements obtained

from a team of production experts. ADAM was devel-

oped using Bokeh, a Python software library (Bokeh

Development Team, 2018). Two scatter plots for vi-

sualization were selected, showing the front and the

top view of the ingot. Further, the figures show-

ing the front view of the ingot were used in the user

study. Color-coded circles (yellow, orange, and red)

in the scatter plots represent the values of indications

with specific diameters. ADAM is successfully in-

tegrated into the aluminum producer’s system land-

scape and used by domain experts several times a

week for data exploration and internal technical re-

porting. Our domain experts determined, using the

visual analysis tool ADAM for several months, target

use cases shown in Figure 2.

Future extension of ADAM will support auto-

mated data exploration tasks by automatically sug-

gesting to the user similar batches and ingots of inter-

est, and batches and ingots with atypical distributions.

Grouping batches and ingots with similar patterns are

important to investigate parameters that are possibly

influencing the quality.

3.3 Concept for Interactive Pattern

Search

The procedure for an interactive pattern search can be

divided into two main steps and some possible addi-

tional steps.

The first step includes a selection of reference in-

gots and batches. Ingots and batches with interest-

ing/atypical distribution of indications should be se-

lected automatically and suggested to the user. There-

fore, a standard distribution should be defined and

ingots/batches selected for which the corresponding

distribution of indications differs greatly from the

standard distribution.

The second step is the selection of similar ingots

and batches. Ingot and batches should be automat-

ically selected, where the distribution of the indica-

tions is similar compared to the selected reference in

the first step. Figure 3 shows the reference ingot and

the automatically selected ingots with a similar dis-

tribution. Furthermore, it should be possible to auto-

matically find ingots and batches with some specific

predefined patterns as in case of accumulation of indi-

cations at a specific location in the ingot (see Figure 2

the reference 431630). Different methods, which can

be used for similarity search, are described and eval-

uated in the next sections.

Figure 2: Three visual prominent patterns(from left to

right): 1) group of indications at specific location in the in-

got, 2) group of indications at the beginning of the casting,

3) group of indications at the end of the casting.

The third step includes the selection of conspicu-

ous signals in the process data. In this part, we con-

sider the process data corresponding to ingots/batches

selected in the second step and compare it to the pro-

Similarity Measures for Visual Comparison and Retrieval of Test Data in Aluminum Production

213

Figure 3: The first image is the reference image of aluminum ingot and the other five are the most similar images ranked by

distance measure.

cess data corresponding to other ingots/batches, to de-

tect patterns that are influencing the product quality.

Additionally, a further step in which the user can

label patterns would be possible. The user should be

able to add new patterns of interest to a list of pre-

defined patterns (for example accumulation of indi-

cations) and export it in a report. To implement the

three main steps, it is necessary to find good methods

for the similarity search and to construct a suitable

target value for the similarity search.

3.4 Definition of the Target Value:

Calculation of Different Quality

Criteria per Bin

In the following, only ingots with a thickness of

450 mm are taken into account, which represents

the largest quantity of all ingots produced. For the

calculation, we only consider indications between

1000 mm and 7000 mm. After recalculation of the

position of the indications in the ingot, the proportion

of the not tested area in the ingot depends on the plate

thickness of the final product. For the greater number

of ingots, the area between 0 and 1000 mm is not

tested, or only partly tested.

Non-weighted Bins. During several workshops and

with feedback from domain experts, we defined for

each bin width 1000 mm. According to that ingot was

divided into 6 parts (bin 1 to 6) and for each bin a

quality criterion was calculated, given as:

quality criteria =

indication area[mm

2

] per bin

tested material[t] per bin

(1)

The calculated area considered different plate thick-

ness groups. The result is a quality criterion for each

bin and ingot and also for each thickness group.

Weighted Bins. In many cases, it is hard to iden-

tify to which bin the indication in the ingot belongs,

e.g., if there is an accumulation of indications at the

boundary of two bins. Therefore we use a smooth-

ing procedure, which also takes into account the indi-

cations in the neighboring bin. Similar to the previ-

ous discussion, we again consider 6 bins. The po-

sition of the center of bin B

i

, i = 1, ..., 6 is at y

i

=

1000 + i ·

6000

7

and the bin-width for each bin is

6000

7

.

For each bin B

i

, i = 1, ..., 6, the indications at casting-

length l ∈ (y

i

−

6000

7

, y

i

+

6000

7

) are weighted according

to the weight-function g

i

(l) = 1 − 6 · (

7·|l−y

i

|

6000

)

2

+ 8 ∗

(

7·|l−y

i

|

6000

)

3

− 3 ∗ (

7·|l−y

i

|

6000

)

4

and the quality criterion per

bin is calculated similar to the previous calculation.

3.5 Analysis of Similarity Measures of

Distributions

There are many measures of similarity that, depend-

ing on the application, do not always have optimal be-

havior. In many different application domains, there

are several ways to define the nearness between distri-

butions. A distance is defined as a quantitative mea-

surement of how far apart two entities are. The sim-

ilarity and the dissimilarity represent, respectively,

how alike or how different two distributions are. If

distributions are close, they will have high similarity

and if distributions are far, they have a low similarity.

To consider the similarity between ingots, in our case

represented as scatter plots, we calculated 1-d his-

tograms of the indications the length of the ingot and

then compared histograms based on their distance.

The smaller the distance between the histograms, the

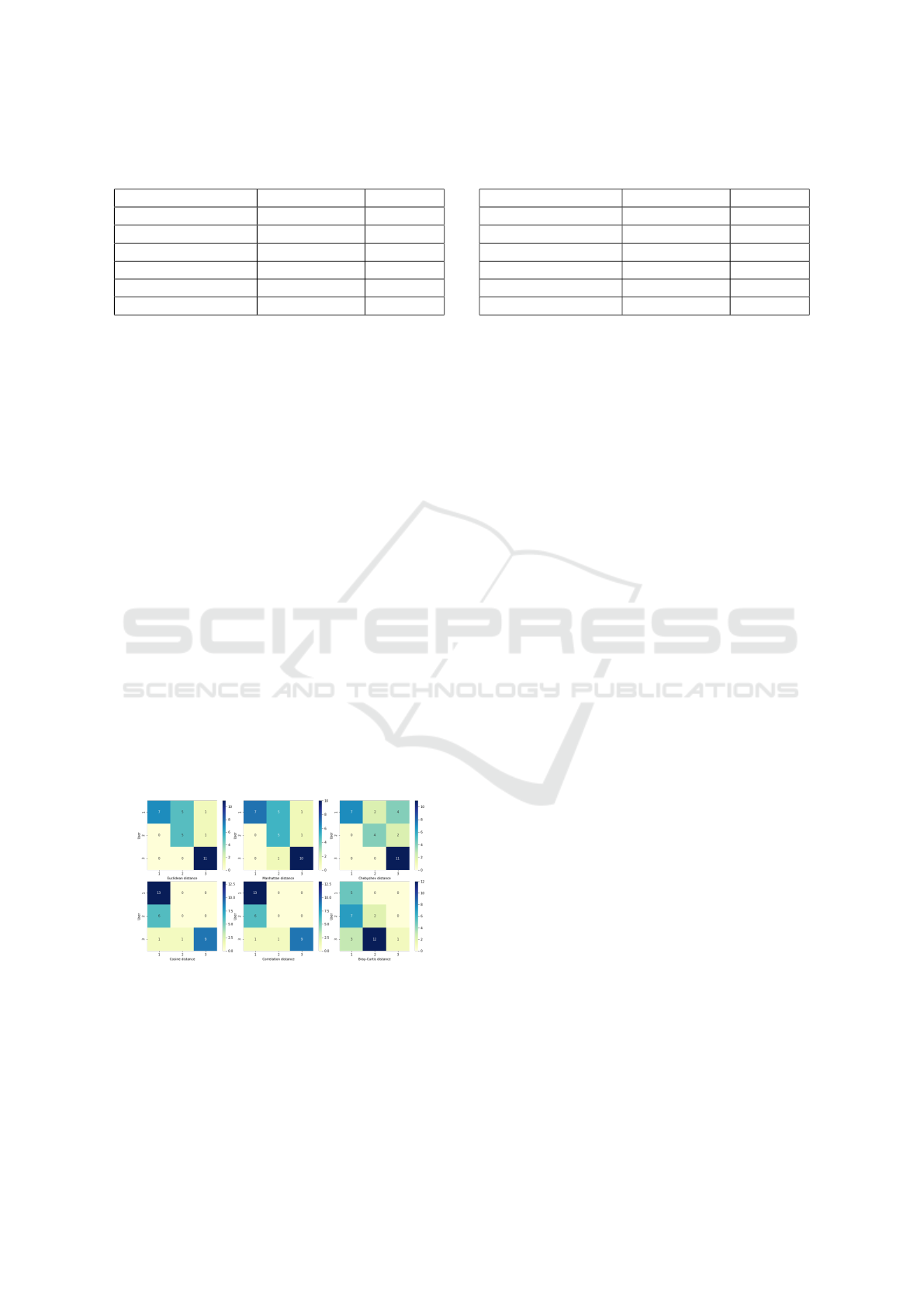

higher the similarity of the scatterplots. There are

quite a few ways to apply distance metrics to com-

pare histograms. We tested six different and popu-

lar distance measures: Euclidean distance, Manhat-

tan distance, Chebyshev distance, Cosine similarity,

Correlation distance and Bray-Curtis distance (Cha,

2007) (Deza and Deza, 2006). To assess the applica-

bility of these measures in detecting similar patterns

in ultrasonic images of aluminum ingots (in the fur-

ther text: UT images) we have performed a user study

where we have asked the domain experts to evaluate

IVAPP 2021 - 12th International Conference on Information Visualization Theory and Applications

214

the results of our method. We used the results of this

study to measure the accuracy of our approach.

4 USER STUDY AND RESULTS

In this section, we present a discussion of the first re-

sults achieved with our method, including examples

to demonstrate the value of our findings. To demon-

strate an evaluation of our approach, we conducted

a study with four domain experts who represent the

target user group. The reference result set and tar-

get use cases (see Figure 2) for our assessment were

obtained by our domain experts using the visual ana-

lytics tool ADAM. Hence, to create the ground truth

against which to evaluate, we use a set of queries cap-

turing typical analysis tasks. We are specifically inter-

ested to evaluate the applicability of similarity mea-

sures with a specific focus on domain tasks to detect

similar patterns in UT images of aluminum ingots.

4.1 Initial Results

For the pattern search in UT images of aluminum in-

gots, we consider data with the restrictions type of

material x, casting plant y, thickness 450 mm, and

width 1400 mm. Figure 2 shows visually prominent

patterns regarding the casting length. Ingots should

be automatically selected, where the distribution of

the indications is very similar compared to a selected

reference pattern. If the material is not free of indica-

tions, the standard behavior is that most of the indi-

cations appear at the beginning of the casting length

and the number of indication decreases towards the

end. During visual data exploration using ADAM, do-

main experts noticed that atypical distributions occur

in some batches. Consequently, they wanted to find

similar batches that appeared over time to analyze and

link these cases with production parameters from the

casting process. In the next section, we provide an

evaluation based on capturing ground truth from do-

main users.

4.2 Data Labeling

Data labeling is important for many practical appli-

cations. To evaluate our approach we created three

classes, established by the similarity of the figures to

the reference image from 1 to 3 (similar, partially sim-

ilar, not similar). To set the border values which are

used for data labeling we performed the first part of

the user study. As this is not a generated dataset, but

a real production dataset, the labeling borders were

verified by our domain experts. The dataset contains

Figure 4: UT ingot images used in the first part of user

study- data labeling.

1200 UT images of ingots. We calculated different

distances measures for the complete dataset. A subset

of 50 selected pairs of ingots were presented to the

domain experts. Each of the 50 images contained a

reference ingot compared against another ingot (Fig-

ure 4). Data samples were carefully selected based

on different patterns discovered during the acquired

experience in using the ADAM tool. It may happen

that for one reference ingot multiple similar ingots

exist as well as that only a few similar ingots exist.

The results were compared with the different distance

measures of the sample ingots. Finally, we managed

to define the border values between similar, partially

similar and not similar based on the results of the do-

main experts. The border values depend on the dis-

tance measure taken into account. Data labeling is a

very difficult task, where domain experts may be un-

certain about their answers. The problem with man-

ual labeling is that the labels generated are usually

subjective and can easily be biased towards the user’s

personal opinions. In our case, the accuracy between

labeling among users i.e., interrater reliability was ap-

proximately 75%. In future work, we will consider

other methods to improve labeling.

4.3 User Study

For each task, 30 figures representing UT images of

ingots are given to test users. Our domain experts

were asked to rank the similarity of the figures to the

reference image from 1 to 3 (similar, partially similar,

not similar). Results from experts are compared with

results from interactive similarity search. The dataset

containing 1200 UT images of ingots was considered

for the evaluation of our approach. To compare the

different methods (distance measures), UT images of

ingots were ranked by similarity to one specific refer-

ence ingot using different distance measures and la-

Similarity Measures for Visual Comparison and Retrieval of Test Data in Aluminum Production

215

Table 1: Accuracy of different distance measures for the

reference ingot image 9883520.

Distance measures Non-weighted Weighted

Euclidean distance 0.77 0.63

Manhattan distance 0.73 0.63

Chebyshev distance 0.73 0.57

Cosine similarity 0.73 0.73

Correlation distance 0.73 0.73

Bray-Curtis distance 0.5 0.56

beled to the three classes (explained in the previous

subsection). Additionally, for every task, we showed

to the user a selection of ingots with similar patterns

obtained from our method as in Figure 3.

In the first task, domain experts needed to rank UT

images of ingots based on similarity regarding the ref-

erence UT image. The first reference UT image was

9883520 (Figure 3). In this case, the pattern contains

indications at the beginning of casting length. The

results of comparison with different binning extrac-

tion (non-weighted and weighted bins) are presented

in Table 1. The ultimate goal of our method is the

ability to predict the target class determined by the

user. The highest accuracy in detecting similar pat-

terns is achieved with Euclidean distance using the

non-weighted quality criteria. However, we have a

certain number of UT images classified not correctly

(see Figure5). A confusion matrix was used for the

purpose of distinguishing between different classes

and see which classes actually cause confusion. What

looks promising is that for the similarity measure with

the highest accuracy i.e. euclidean distance there is

only one UT ingot image belonging to class similar,

classified as not similar class. Considering different

methods for class labeling in future work could im-

prove accuracy.

Figure 5: Confusion matrix for non-weighted bins.

Table 2 shows the accuracy of the results for the

second reference UT image of the ingot. The pattern

in reference 431630 (Figure 2) contains an accumula-

tion of indications in a small area of the ingot.

The highest accuracy in detecting similar pat-

terns is achieved with Chebyshev distance using the

Table 2: Accuracy of different distance measures for the

reference ingot image 431630.

Distance measures Non-weighted Weighted

Euclidean distance 0.6 0.63

Manhattan distance 0.63 0.63

Chebyshev distance 0.6 0.67

Cosine similarity 0.57 0.6

Correlation distance 0.6 0.57

Bray-Curtis distance 0.27 0.23

weighted quality criteria. Euclidean distance, with

the highest accuracy in the previous task, and Cheby-

shev distance come from the same family of dis-

tances(Minkowski distance family). We have earlier

discussed that if an accumulation of indications is ex-

actly between two bins, patterns may be recognized

better using the weighted quality criteria. In this case,

the accuracy is lower than the accuracy for the refer-

ence 9883520. One explanation for this is that in the

case of an accumulation of indications in a small area,

the user sometimes can not estimate the actual amount

of indications, while the distance measure calculation

highly depends on the quality criteria per bin. An-

other explanation could be that in this specific case,

the border of labeled classes should be considered fur-

ther.

In the end, we showed to our domain experts UT

images ranked by distance measure as in Figure 3.

Domain experts report the five UT images ranked by

the Minkowski distance family, showed good results

for both reference ingots. Domain experts agree that

the use of such methods could allow them to gather

information to identify specific patterns, distribution

of indication, and correlation with process data. An

important requirement for analyzing ultrasonic test

data is an extensive professional and domain-specific

knowledge of users. However, we need to be care-

ful as the similarity is subjective and is highly depen-

dent on the domain and application. The user study

showed promising results in detecting specific ultra-

sonic patterns. Regarding the similarity measures,

the Minkowski distance family provided the highest

recognition rates among the distances used in this

work.

5 SUMMARY AND FUTURE

WORK

Selecting the right distance measure is one of the chal-

lenges encountered by professionals and researchers

when attempting to apply different methods in real-

world applications. The variety of similarity mea-

sures can cause confusion and difficulties in choos-

IVAPP 2021 - 12th International Conference on Information Visualization Theory and Applications

216

ing a suitable measure. The performance of similarity

measures may vary depending on different datasets.

In this paper, we studied a quantitative comparison for

different similarity measures on UT images of ingots.

The aim of this study was to clarify which similarity

measures are more appropriate and applicable when

searching for specific ultrasonic patterns. Further, we

conducted interviews with domain experts in the anal-

ysis of UT indications images comparison and used

this feedback to define a ground truth for our eval-

uation. We provided a discussion and demonstrated

the possible insights enabled by our approach and its

potential to support production data exploration.

Future work includes investigation of process data

corresponding to groups of similar ingots and batches,

and potentially discovering key influential parameters

in the process data. As future work, we also want

to include advanced multidimensional data visualiza-

tions, to support pattern detection and parameter cor-

relation. Furthermore, automatic classification of cer-

tain quality patterns, based on interactively provided

expert examples, is considered an interesting future

extension of an existing visual analytics solution.

ACKNOWLEDGEMENTS

This research work is done by Pro2Future and AMAG

Austria Metall AG. Pro2Future is funded within the

Austrian COMET Program-Competence Centers for

Excellent Technologies under the auspices of the Aus-

trian Federal Ministry of Transport, Innovation and

Technology, the Austrian Federal Ministry for Digital

and Economic Affairs and of the Provinces of Upper

Austria and Styria. COMET is managed by the Aus-

trian Research Promotion Agency FFG.

REFERENCES

Bazan, E., Dokl

´

adal, P., and Dokladalova, E. (2019). Quan-

titative analysis of similarity measures of distribu-

tions.

Behrisch, M., Korkmaz, F., Shao, L., and Schreck, T.

(2014). Feedback-driven interactive exploration of

large multidimensional data supported by visual clas-

sifier. In 2014 IEEE Conference on Visual Analytics

Science and Technology (VAST), pages 43–52. IEEE.

Bokeh Development Team (2018). Bokeh: Python library

for interactive visualization.

Cha, S.-H. (2007). Comprehensive survey on dis-

tance/similarity measures between probability density

functions. City, 1(2):1.

Deza, M.-M. and Deza, E. (2006). Dictionary of distances.

Elsevier.

Hern

´

andez-Rivera, E., Coleman, S. P., and Tschopp, M. A.

(2017). Using similarity metrics to quantify differ-

ences in high-throughput data sets: application to x-

ray diffraction patterns. ACS combinatorial science,

19(1):25–36.

Jekic, N., Mutlu, B., Faschang, M., Neubert, S., Thalmann,

S., and Schreck, T. (2019). Visual analysis of alu-

minum production data with tightly linked views. In

EuroVis (Posters), pages 49–51.

Jo, J., Huh, J., Park, J., Kim, B., and Seo, J. (2014). Live-

gantt: Interactively visualizing a large manufactur-

ing schedule. IEEE transactions on visualization and

computer graphics, 20(12):2329–2338.

Lee, J., Kao, H.-A., Yang, S., et al. (2014). Service innova-

tion and smart analytics for industry 4.0 and big data

environment. Procedia Cirp, 16(1):3–8.

Lee, J., Lapira, E., Bagheri, B., and Kao, H.-a. (2013). Re-

cent advances and trends in predictive manufacturing

systems in big data environment. Manufacturing let-

ters, 1(1):38–41.

Liu, S., Cui, W., Wu, Y., and Liu, M. (2014). A survey on

information visualization: recent advances and chal-

lenges. The Visual Computer, 30(12):1373–1393.

Matkovic, K., Hauser, H., Sainitzer, R., and Groller, M. E.

(2002). Process visualization with levels of detail. In

IEEE Symposium on Information Visualization, 2002.

INFOVIS 2002., pages 67–70. IEEE.

McKinney, W. (2012). Python for data analysis: Data

wrangling with Pandas, NumPy, and IPython. ”

O’Reilly Media, Inc.”.

Scherer, M., Bernard, J., and Schreck, T. (2011). Retrieval

and exploratory search in multivariate research data

repositories using regressional features. In Proceed-

ings of the 11th annual international ACM/IEEE joint

conference on Digital libraries, pages 363–372.

Shao, L., Schleicher, T., Behrisch, M., Schreck, T., Sipiran,

I., and Keim, D. A. (2016). Guiding the exploration of

scatter plot data using motif-based interest measures.

Journal of Visual Languages & Computing, 36:1–12.

Shirkhorshidi, A. S., Aghabozorgi, S., and Wah, T. Y.

(2015). A comparison study on similarity and dissim-

ilarity measures in clustering continuous data. PloS

one, 10(12):e0144059.

Soban, D., Thornhill, D., Salunkhe, S., and Long, A.

(2016). Visual analytics as an enabler for manufactur-

ing process decision-making. Procedia Cirp, 56:209–

214.

Sun, D., Huang, R., Chen, Y., Wang, Y., Zeng, J., Yuan,

M., Pong, T.-C., and Qu, H. (2019). Planningvis: A

visual analytics approach to production planning in

smart factories. IEEE transactions on visualization

and computer graphics, 26(1):579–589.

Suschnigg, J., Ziessler, F., Brillinger, M., Vukovic, M.,

Mangler, J., Schreck, T., and Thalmann, S. (2020). In-

dustrial production process improvement by a process

engine visual analytics dashboard. In Proceedings of

the 53rd Hawaii International Conference on System

Sciences, pages 1320–1329.

Thalmann, S., Mangler, J., Schreck, T., Huemer, C., Streit,

M., Pauker, F., Weichhart, G., Schulte, S., Kittl, C.,

Similarity Measures for Visual Comparison and Retrieval of Test Data in Aluminum Production

217

Pollak, C., et al. (2018). Data analytics for industrial

process improvement a vision paper. In 2018 IEEE

20th Conference on Business Informatics (CBI), vol-

ume 2, pages 92–96. IEEE.

Vasudevan, A. K. and Doherty, R. D. (2012). Alu-

minum Alloys–Contemporary Research and Applica-

tions: Contemporary Research and Applications. El-

sevier.

Wu, P. Y. (2001). Visualizing capacity and load in produc-

tion planning. In Proceedings Fifth International Con-

ference on Information Visualisation, pages 357–360.

IEEE.

Wu, W., Zheng, Y., Chen, K., Wang, X., and Cao, N.

(2018). A visual analytics approach for equipment

condition monitoring in smart factories of process in-

dustry. In 2018 IEEE Pacific Visualization Symposium

(PacificVis), pages 140–149. IEEE.

Xu, P., Mei, H., Ren, L., and Chen, W. (2016). Vidx: Visual

diagnostics of assembly line performance in smart fac-

tories. IEEE transactions on visualization and com-

puter graphics, 23(1):291–300.

Yin, S. and Kaynak, O. (2015). Big data for modern indus-

try: challenges and trends [point of view]. Proceed-

ings of the IEEE, 103(2):143–146.

Zhou, C., Wang, J., Tang, G., Moreland, J., Fu, D., and

Wu, B. (2016). Integration of advanced simulation and

visualization for manufacturing process optimization.

Jom, 68(5):1363–1369.

Zhou, F., Lin, X., Liu, C., Zhao, Y., Xu, P., Ren, L., Xue,

T., and Ren, L. (2019). A survey of visualization

for smart manufacturing. Journal of Visualization,

22(2):419–435.

IVAPP 2021 - 12th International Conference on Information Visualization Theory and Applications

218