The Effect of Straining on the Quality Indicators of Vulcanized

Rubber Compounds for Rires of Agricultural Machinety

T. B. Smirnova

1a

, O. V. Chemisenko

1b

, I. V. Temereva

2c

and T. Yu. Stepanova

2d

1

K.G. Razumovsky Moscow State University of Technologies and Management (the First Cossak University), Omsk, Russia

2

Omsk State Agrarian University named after P.A. Stolypin, Omsk, Russia

Keywords: Vulcanizates, Straining, Raw Mix, Tire, Polymer Matrix, Press, Heavy Machinery, Characteristics of Physical

and Mechanical Properties, Breaking Machine, Electron Microscope.

Abstract: The article presents the results of the analysis of the rubber compound used in the production of tires for heavy

agricultural machinery. The research was carried out in order to increase the reliability of the machines and

increase the period of their maintenance-free operation in the field. The structure of the elastomeric matrix of

vulcanizates was studied before and after straining the rubber mixture using the electron microscopy method.

The solidity of vulcanizates and their physical and mechanical characteristics were evaluated on a

Zwick/Roell breaking machine in a climate chamber in accordance with GOST. It is noted that the use of an

additional technological operation "straining" increases the characteristics of physical and mechanical

properties, the solidity of the rubber array and the density of the elastomeric matrix, which positively affects

the quality of tires for transport vehicles used in the agro-industrial complex.

1 INTRODUCTION

The development of the agro-industrial complex is

one of the priority areas of Russia's economic

development. Mutually beneficial cooperation of the

subjects of the Russian Federation makes it possible

to increase the effectiveness of their activities, ensure

the efficient use of resources, and reduce the time

required to complete work without violating the

optimal deadlines (Kolokolov, Stepanova,

Semerkhanova and Mikhal, 2012) The management

of a modern enterprise of the agro-industrial complex

should cover all aspects of the production of the main

types of products (Myalo, Prokopov, Myalo,

Soyunov and Demchuk, 2020). The efficiency of

agricultural work is largely determined by the

conditions of their implementation, in particular, the

level of condition of heavy equipment intended for

use in the field and the level of its maintenance

(Myalo, Solomkin, Prokopov and Soyunov, 2019;

Trotsenko, 2019). Machines for agricultural

production must meet the criteria of reliability, have

a

https://orcid.org/0000-0002-3822-4873

b

https://orcid.org/0000-0003-0043-6886

c

https://orcid.org/0000-0002-1123-0472

d

https://orcid.org/0000-0003-1489-6664

high cross-country performance and speed, be easy to

maintain and replace individual components. The

route of such vehicles is characterized by the

conditions of rough terrain, the variety of the path

profile, the presence of curved sections and single

obstacles on it (Apping, 2001). In this regard,

research on the use of modern high-strength and

environmentally friendly materials for the creation of

various types of tire sizes for agricultural machinery

is relevant. Special attention is paid to improving the

physical and mechanical characteristics of tires

(Chemisenko, From and Breiter, 2016).

Work in the field of improving the quality of tires

has been carried out since the production of the first

automobile wheel and continues to this day in many

areas, and the issues of increasing the walking

capacity, increasing the grip of the tire on the road

and, as a result, the safety of the vehicle are acute for

manufacturers. They can be solved only by improving

the design of tires and improving the quality of the

ingredients used for their production (Chemisenko,

Rogachev and Filenko, 2016).

72

Smirnova, T., Chemisenko, O., Temereva, I. and Stepanova, T.

The Effect of Straining on the Quality Indicators of Vulcanized Rubber Compounds for Rires of Agricultural Machinety.

DOI: 10.5220/0010664100003223

In Proceedings of the 1st International Scientific Forum on Sustainable Development of Socio-economic Systems (WFSDS 2021), pages 72-75

ISBN: 978-989-758-597-5

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The analysis of the reasons for the loss of

performance of tires showed that an important aspect

of the issue of safety of equipment is the solidity of

the tire design, which is achieved with high-quality

performance of all technological operations-starting

from the procurement of materials and ending with

the vulcanization process. One of the frequent

problems that arise during the operation of tires is the

separation of the tread pattern with a sufficiently good

condition of the frame that can last for more than one

thousand kilometers, or the stratification of the layers

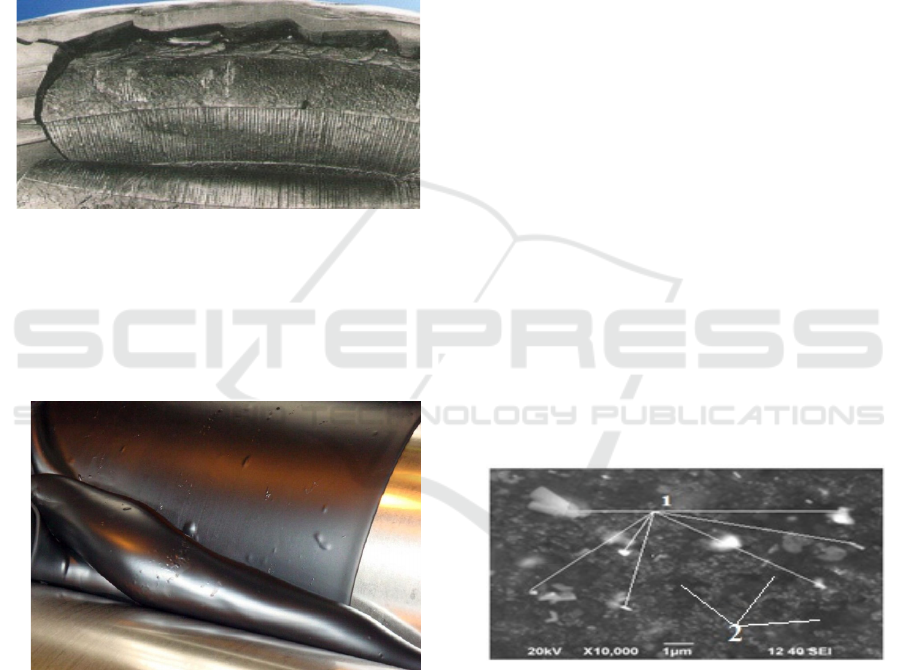

of the frame themselves (Figure 1).

Figure 1: Tire defects.

Defects can be the result of the operation of tires, as

well as the result of the conditions for the implementation

of the technological process of their manufacture. In

particular, the use of dirty carbon black leads to the

production of a rubber mixture with traces of foreign

inclusions (Figure 2).

Figure 2: Rubber compound with traces of foreign

inclusions.

The production of products made of composite

materials based on elastomers, characterized by high wear

resistance, is possible using a multi-level structural

modification (Mashkov, Chemisenko and Maliy, 2018). To

increase the uniformity of the raw material composition in

the production of treads, an additional technological

operation is used – straining, which involves passing the

rubber mixture through a filter press (Rauvendaal, 2006).

The change in the structure of the polymer matrix and the

characteristics of its physical and mechanical properties

after straining the raw material composition was the subject

of this research.

2 MANUSCRIPT PREPARATION

The research was carried out on the basis of the

research laboratories of SKITU (branch) Moscow

State Technical University named after K. G.

Razumovsky (PKU) and Omsk State Agrarian

University.

Objects of research-vulcanizates of an elastomeric

matrix from a rubber compound for manufacturing

tires of agricultural machinery:

without straining;

after straining.

Research methods:

electron microscopy (JEOL microscope);

a method for determining the elastic-strength

properties under tension according to the

indicators: tensile strength, elongation at break,

stress at a given elongation (GOST 270-75).

Experimental samples were studied in three-fold

analytical repetition. The results were processed

using standard methods of mathematical statistics.

3 RESULTS AND DISCUSSION

Vulcanizates of a rubber compound made without

straining have large particles of foreign inclusions

and voids in the elastomeric matrix (Figure 3).

Figure 3: Structure of the vulcanized.

1-foreign inclusions; 2-pores in the matrix.

The looseness of the structure has a negative

impact on the walking ability of the tire due to the

creation of many stress concentration centers. Under

dynamic loads, the area of the stress centers increases,

which contributes to the formation of cracks and, as a

result, the separation of the tread array. A

comparative analysis of the vulcanizate structures

using the electron microscopy method showed a

change in the pore size in the matrix after straining

the rubber mixture (Figure 4).

The Effect of Straining on the Quality Indicators of Vulcanized Rubber Compounds for Rires of Agricultural Machinety

73

Figure 4: Structure of the vulcanized rubber compound

after straining.

Vulcanizates subjected to an additional straining

operation had a denser elastomeric matrix. The

density of the matrix increased due to a significant

reduction in the pore size and mechanical grinding of

foreign inclusions during straining of the raw

composition when it was passed through the filter

press. The use of a filter press in the preparation of a

polymer composition for vulcanization allows the

rubber mixture to be dispersed to a more

homogeneous state than the state of the mixture after

the rubber mixing chamber. The increase in the

density of the elastomeric matrix visible under an

electron microscope causes an increase in its solidity

and the solidity of rubber products after straining.

When evaluating the quality of vulcanizates, the

characteristics of their physical and mechanical

properties are taken into account. The indicators of a

number of characteristics obtained in the studies are

shown in Table 1.

Table 1. Physical and mechanical characteristics of

vulcanizates.

Vulcanizate

Modulus,

300%,

MPa

Tensile

strength

, MPa

Elongatio

n Ԑ, %

Without

straining

6.3

2

.7

1000.2

After

straining

8.1

15.6 1113.8

NSR 05

1.4

2.1 -

The use of straining has led to a change in the

characteristics of the physical and mechanical

properties of vulcanizates. There was a significantly

significant increase in the modulus of 300 % by 1.8

MPa, the tensile strength by 2.9 MPa, and the relative

elongation by 113.6 % of the prototypes. The increase

in the physical and mechanical properties of the

rubber compound during straining occurred within

the technologically acceptable limits and is evidence

of the growth of the monolithic rubber not higher than

the quality indicators allowed by the technical

conditions for the production of tires for agricultural

machinery.

The research was carried out using the equipment

of the center for collective use of the Omsk State

Agrarian University "Additive Technologies and

Materials Processing".

4 CONCLUSIONS

An increase in the density and solidity of vulcanizates

after straining the rubber mixture for the production

of tires for agricultural machinery was established by

electron microscopy.

When straining the rubber mixture under

technologically recommended conditions, a

significantly significant increase in the characteristics

of the physical and mechanical properties of

vulcanizates was noted: the modulus of 300% by 1.8

MPa, the tensile strength by 2.9 MPa, and the relative

elongation by 113.6 %.

REFERENCES

Kolokolov A A, Stepanova T Yu, Semerkhanova E Ya,

Mikhal V. A. (2012). Development of the enterprise

interaction system using optimization models and

methods Omsk. Scientific Bulletin, 3(113): 25-29.

Myalo O. V, Prokopov S. P, Myalo V. V., Soyunov A. S.,

Demchuk E. V. (2019) Material and technical support

of the enterprises of the agro-industrial complex of the

Omsk region management and certification of the

technical component of the production processes in

crop production. Conference Series: Materials Science

and Engineering. IOP: 10.1088/1757-899X/582/1/

012028/

Myalo O. V., Solomkin A. P., Prokopov S. P. Soyunov A.

S. (2019) Mathematical Modeling and Information

Technologies in the Management of Tractor

Maintenance Operations Conference Series: Materials

Science and Engineering. IOP: 10.1088/1757-

899X/582/1/012014/

Trotsenko V. V., Trotsenko I. V. (2019) Ways to reduce

mechanical damage of barley for mechanical

processing Journal of Physics: Conference

Series.nDOI: 10.1088/1742-6596/1260/2/022003

Apping G. A. (2001). Improving the reliability of sealing

devices of hydraulic shock absorbers of multi-purpose

tracked and wheeled vehicles. OmSTU. Omsk.

Chemisenko O. V., From I. F., Breiter Yu. L. (2016).

Comparative study of physical and mechanical

WFSDS 2021 - INTERNATIONAL SCIENTIFIC FORUM ON SUSTAINABLE DEVELOPMENT OF SOCIO-ECONOMIC SYSTEMS

74

parameters of rubber compound for sealing seals.

Industrial production and use of elastomers,2:30-32.

Chemisenko O. V., Rogachev E. A., Filenko N. I. (2016)

Comparative analysis of the abrasion of rubber

vulcanizates based on various combinations of rubbers

and vulcanizing systems. Industrial production and use

of elastomers,4:7-9.

Mashkov Yu. K., Chemisenko O. V., Maliy O. V.

Development of wear-resistant nanocomposites for

extreme operating conditions in metal-polymer

tribosystems. Technical Physics, Vol. 63, 1: 41-44.

Rauvendaal K. (2006). Polymer extrusion, Profession. Saint

Petersburg.

The Effect of Straining on the Quality Indicators of Vulcanized Rubber Compounds for Rires of Agricultural Machinety

75