Activity Test of Temperature Variations in Cracking Process of Palm

Oil using Ni/Al2o3 to Green Diesel Viscosity

Sofiyan Adi Putra, Tiara Indah Damayanti, Faaiz Al Ghifari and Haris Puspito Buwono

Mechanical Engineering Department, State Polytechnic of Malang, Jl. Soekarno-Hatta No. 9, Malang City, Indonesia

haris.puspito@polinema.ac.id

Keywords: Green Diesel, Cracking Process, Vegetable Oil.

Abstract: Today petroleum reserves are running low along with the increasing demand of fuel transportation and

industries, therefore we are required to find alternative fuels, one of which is derived from vegetable oil,

namely Green Diesel. Green diesel is a product mixture of hydrocarbons such as diesel which is produced

through a cracking process using catalyst as reaction accelerator. The catalyst is Ni/Al

2

O

3

. Aimed to

understand the effect of temperature variations in palm oil cracking process using Ni/Al

2

O

3

catalyst to the

product viscosity. The cracking process is carried out using a batch reactor with temperature variations of

400

o

C and 460

o

C, for 10 minutes calculated from the target temperature achieved which is 400

o

C. The highest

amount of product acquired from 400

o

C which is 20.845 gram from the total of 30 grams raw material, the

product of 400

o

C is the only suitable density 0.8523 g/ml which is inside the range of green diesel standard

0.8150-0.8600 g/ml, and while the product of 400

o

C or 460

o

C does not have suitable viscosity 6,4563 cSt and

1,4305 cSt which are not inside the range of green diesel standard 2-4.5 cSt.

1

INTRODUCTION

Currently, the world's oil reserves are running low, at

the same time the human population continues to

grow and it is directly proportional to the increasing

demand for basic needs, one of which is the need for

motor vehicle fuel.

Currently, the majority of motor vehicle fuels use

petroleum derived from fossils such as pertalite,

diesel, and avtur. Petroleum is the result of the

evolution of fossils resulting from the extinction of

living things millions of years ago on earth and has

undergone a very long process to become crude oil

that is ready to be processed into fuel.

With various countries trying to turn into

industrial countries forcing fuel consumption to

increase from year to year, the average annual

increase in energy demand is 36 million barrels of oil

equivalent (BOE) from 2000 to 2014. Meanwhile,

energy reserves are not renewable energy sources,

such as oil, natural gas, and coal, are running low.

Based on the Strategic Plan (Renstra) of the Ministry

of Energy and Mineral Resources for 2015–2019,

Indonesia's oil reserves of 3.6 billion barrels are

estimated to be exhausted in the next 13 years.

(Sa'adah, et al, 2017).

Therefore, renewable fuels are required from

sources other than fossils, one of the product of

renewable source is Green diesel is a mixture of diesel

like hydrocarbons produced via catalytic reaction

involving hydroprocessing, decarbonylation, and

decarboxylation of trilicerides. (Auliastuti, et al,

2020)

Biofuel has a better characteristic than biodiesel

such as lower viscosity, better stability and produce

more energy. (Munir and Chumaidi 2019)

Green diesel does not produce any waste, very

efficient process, and all ready product can be use

directly after being produced. (Ristanti, et al, 2021)

Green diesel is produced using the

hydrodeoxygenation process of palm oil

(triglycerides) or animal fats through catalytic

treatment with hydrogen, produced a mixture of

straight and branched chain saturated hydrocarbons

which usually contain 15 to 18 carbon atoms per

molecule (C15 to C18) (Neunofa et al. 2017)

By using Ni/Al

2

O

3

catalyst as a reaction

accelerator with hydrotreating process with variations

in reaction temperature this research aimed to

determine the most suitable temperature that

produce a product with viscosity match with the

Green Diesel standard.

Putra, S., Damayanti, T., Al Ghifari, F. and Buwono, H.

Activity Test of Temperature Variations in Cracking Process of Palm Oil using Ni/Al2o3 to Green Diesel Viscosity.

DOI: 10.5220/0010940100003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 65-68

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

65

2

RESEARCH METHODOLOGY

There are five steps to produce green diesel using

batch reactor, starting

with

the Al

2

O

3

Catalyst

Preparation, the Preparation of Active Metal

Ni,Catalyst Activation, Catalytic Cracking Process,

and Viscosity Measurement.

The preparation of Al

2

O

3

catalyst begins with

mixing 470

grams of Al2(SO4)3 and 400 ml of

distilled water at a temperature of 70oC and dripping

with NH3 to pH 9, stirred until it becomes a gel and

filtered using filter paper, the filtered gel must be

dried at a temperature of 70oC for 24 hours until it

can be mashed with a mortar, after becoming a dry

powder it is calcined at a temperature of 600oC with

holding time of 3 hours and then removed when the

furnace temperature has dropped to 70oC.

The preparation for the active metal Ni begins by

lowering the commercial Ni concentration from

100% to 19% by dissolving 20 grams of Ni with 20

ml of distilled water. Then prepared 5 grams of

Al2O3 which has been calcined in a 600oC furnace

then dissolve it with 5 ml of distilled water and

dripped with 19% Ni with the desired amount of the

variable with M impregnated 2.5859 grams which is

assumed to be 10% Ni concentration if required 5%

of Ni then the M impregnated would be 1.2929

grams, dripping the Ni while stirring the catalyst

using a magnetic stirrer, then waiting for it to dry for

approximately 3 hours and mash it in a mortar and

then calcined in a furnace with a temperature of

400

o

C and holding time for 2 hours.

The calculation of M impregnated is carried out

using the following formula:

𝑀

𝑖

𝑚

𝑝

𝑟

𝑒

𝑔

𝑛

𝑎

𝑡

𝑒

𝑑

(%)=

𝑀

𝑀

𝐷

𝑒𝑠

𝑐𝑟

𝑖

𝑝

𝑡𝑖𝑜

𝑛

𝑠

∶

𝑀

= 𝑐𝑜𝑛𝑐𝑒𝑛𝑡𝑟𝑎𝑡𝑖𝑜𝑛 (%)

𝑚

=

𝑚𝑎𝑠𝑠

(

𝑔𝑟𝑎𝑚

)

𝑀

𝑖

𝑚

𝑝

𝑟

𝑒

𝑔

𝑛

𝑎

𝑡

𝑒

𝑑

=

10%

𝑀

𝑖

𝑛

𝑖

𝑡

𝑖

𝑎

𝑙

=

19%

𝑚

𝑏𝑢𝑓𝑓𝑒𝑟

= 5 𝑔𝑟𝑎𝑚

After being calcined, the catalyst powder is

formed into solid pills using a small pipe mold with

the help of a press machine, the pressure used in the

press machine is 100 kg/cm2 for a minute.

The catalyst is activated by putting it into the

reactor, then close it tightly using a wrench, then

attach helium gas hose, this process is carried out to

ensure that the oxygen in the reactor has been

removed and replaced by helium, with the method of

inputting 10 bar of helium gas into the reactor and

then slowly discharge it at a rate of 20 ml/min

repeated twice. After the drain has been completed,

input 1 atm of hydrogen gas and heated to a

temperature of 200

o

C for an hour, then the gas is

discharged when the reactor temperature has dropped

to room temperature.

The catalytic cracking reaction begins by putting

30 grams of palm oil and 1,57 grams of Ni/Al

2

O

3

catalyst into the reactor. After that, the heating

process begins with temperature settings to 400

o

C.

Wait until the temperature is reached then start

counting the time using a stopwatch for 10 minutes.

After the time is reached, the heater is turned off

and the reactor is cooled with a fan and then wait for

the temperature to drop to the room temperature then

gas is released at a flow of 20 ml/min. After the

temperature and pressure decreased the product is

saved in a container jar.

Before measuring the viscosity and density, the

product is first filtered with filter paper, and weighed

to determine the amount of product that becomes gas

and the amount of product that becomes liquid.

Then the density measurements were carried out

using a pycnometer and the density was explained as

follows.

The mass of the pycnometer was measured in an

empty state, namely 11.0546 grams. Then the

product is put into the pycnometer until it is full and

the fluid rises to the top hole, after that it is weighed

in the analytical balance, the mass of the pycnometer

with the specimen is reduced by the empty mass

with the following results.

𝜌

𝑠𝑎

𝑚

𝑝

𝑙

𝑒

=

𝜌

𝐷

𝑒𝑠

𝑐𝑟

𝑖

𝑝

𝑡𝑖𝑜

𝑛

𝑠

∶

𝜌

𝑠𝑎

𝑚

𝑝

𝑙

𝑒

=

𝑠

𝑎𝑚𝑝𝑙

𝑒

𝑑𝑒𝑛𝑠𝑖𝑡𝑦

(𝑔/𝑐𝑚

3

)

𝜌

𝑤𝑎𝑡𝑒𝑟 =

𝑤𝑎𝑡𝑒𝑟

𝑑𝑒

𝑛

𝑠

𝑖

𝑡𝑦

(

𝑔

/

𝑐

𝑚

3

)

𝑚

𝑠𝑎

𝑚

𝑝

𝑙

𝑒

=

𝑠

𝑎𝑚𝑝𝑙

𝑒

𝑚

𝑎𝑠

𝑠

(

𝑔𝑟

𝑎𝑚

)

𝑚

𝑤𝑎𝑡𝑒𝑟 =

𝑤𝑎𝑡𝑒𝑟 𝑚𝑎𝑠𝑠 (𝑔𝑟𝑎𝑚)

Furthermore, the measurement of product

viscosity is carried out by inserting the specimen into

the viscometer then the liquid is raised to the top line

on the viscometer using a suction device, then the

suction device is removed and waits for the specimen

to drop to the bottom of the viscometer with a two-

line indicator, when the specimen begins to descend

from the top line timed until the specimen reaches the

bottom line.

The results of the time calculation are entered

into the following formula:

𝜇

𝑑𝑖𝑛

𝑠𝑎𝑚𝑝𝑙𝑒

=

𝜇

𝑑𝑖𝑛

𝑤𝑎𝑡𝑒𝑟

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

66

𝐷

𝑒𝑠

𝑐𝑟

𝑖

𝑝

𝑡𝑖𝑜

𝑛

𝑠

:

𝜇

𝑑𝑖𝑛

𝑤𝑎𝑡𝑒𝑟

=

𝑠

𝑎𝑚𝑝𝑙

𝑒

𝑠

𝑑𝑦

𝑛

𝑎𝑚𝑖

𝑐

𝑣𝑖

𝑠

𝑐𝑜

𝑠

𝑖

𝑡𝑦

(

𝑚

𝑃

𝑎

.

𝑠

)

𝜌

𝑠𝑎

𝑚

𝑝

𝑙

𝑒

=

𝑠

𝑎𝑚𝑝𝑙

𝑒

𝑠

𝑑𝑒

𝑛

𝑠

𝑖

𝑡𝑦

(

𝑘

𝑔

/

𝑐

𝑚

3

)

𝜇

𝑑𝑖

𝑛

𝑤

𝑎𝑡𝑒

𝑟

=

𝑤

𝑎𝑡𝑒𝑟

𝑑𝑦

𝑛

𝑎𝑚𝑖𝑐

𝑣𝑖

𝑠

𝑐𝑜

𝑠

𝑖

𝑡𝑦

(

𝑚

𝑃

𝑎

.

𝑠

)

𝜌

𝑤𝑎𝑡𝑒𝑟

= 𝑤𝑎𝑡𝑒𝑟 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 (𝑘𝑔/𝑐𝑚

3

)

𝑡

=

𝑓𝑙𝑜𝑤

𝑡𝑖𝑚𝑒

(

𝑠

)

𝜇

𝑘𝑖𝑛𝑒

𝑚

𝑎

𝑡

𝑖𝑐

=

𝜇

𝑘𝑖

𝑛

𝑒

𝑚

𝑎

𝑡

𝑖

𝑐

=

𝑘𝑖𝑛𝑒𝑚

𝑎𝑡𝑖

𝑐

𝑣𝑖

𝑠

𝑐𝑜

𝑠

𝑖

𝑡𝑦

(

𝑚

2

/

𝑠

)

𝜇

𝑑𝑦

𝑛

𝑎

𝑚

𝑖

𝑐

=

𝑑𝑦

𝑛

𝑎𝑚𝑖

𝑐

𝑣𝑖

𝑠𝑐

𝑜𝑠

𝑖

𝑡𝑦

(

𝑁

𝑠

/

𝑚

2

)

𝜌 = 𝑑𝑒𝑛𝑠𝑖𝑡𝑦 (𝑘𝑔/𝑚

3

)

Viscosity of water is seen from the reference

table, sample flow time and water flow time are

calculated from the time the fluid passes the top line

and bottom line on the viscometer.

Measurement of the viscosity of the sample and

water must be in the same temperature conditions

and made a comparison with the table above. Then it

is calculated by the formula and the viscosity value

of the sample is known, with the principle that the

greater the viscosity value, the thicker the sample.

In this study, we tried at a temperature of 400

and 460, because we had tried it at a temperature of

300 and the result was a solid product not liquid, so

we used a higher temperature of 400 and 460, because

at this temperature we found that the result was a

liquid.

3

RESULT AND DISCUSSION

Green diesel products are said to meet the standards

if the values indicated are 0.8150 gr/ml and 0.8600

gr/ml. And the density value of the raw materials

used is 0.9112 gr/ml. While the resulting product is a

solid or solid whose density value is > 0.9112 gr/ml.

Therefore the resulting product does not meet the

standards of green diesel fuel.

Table 1: Cracking Process Parameters.

Cracking Process Parameters

Ni/Al

2

O

3

mass

5% = 1.57 gram

RBDPO weight 30 gram

Reaction time 10 minutes

Temperature 400

o

C and 460

o

C

Pressure 1 atm

In this study, the viscosity test was carried out

using an Ostwald viscometer. Green diesel products

are said to meet the standards if the kinematic

viscosity values shown are 2 cSt and 4.5 cSt. While

the dynamic viscosity of the raw materials used is

0.39 Ns/m2. The density value of the raw materials

used is 0.9112 gr/ml. Then the value of its kinematic

viscosity is 428 cSt.

3.1 Effect of Temperature Variations

Mass

21

20,5

20

19,5

19

18,5

18

17,5

400˚C 460˚C

Reaction Temperature (°C)

Figure 1: Effect of temperature variations in palm oil

cracking process using 5% mass of Ni/Al2O3 catalyst in

400oC temperature and 1 atm pressure for 10 minutes to

the product mass.

From this graph it is known that the most amount of

product is produced using 400

o

C temperature which

is 20,845 gram from the total raw material of 30

gram.

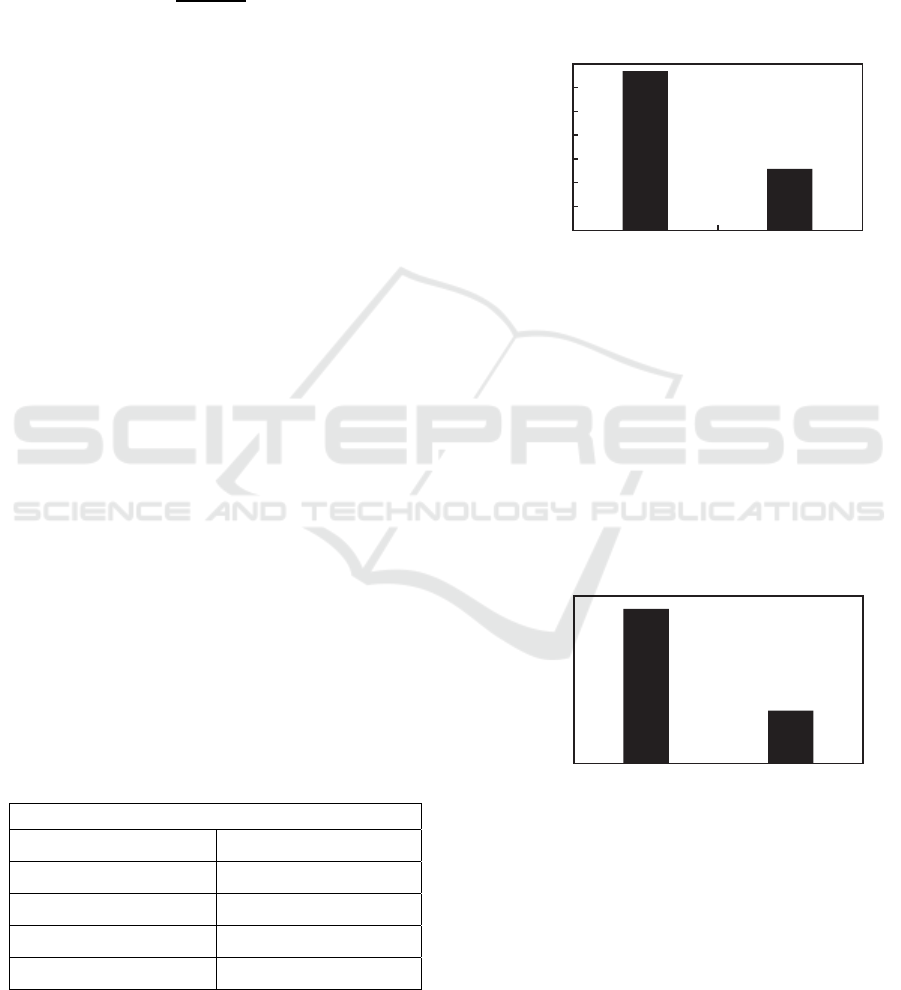

3.2 Effect of Temperature Variations

on Density

0,86

0,84

0,82

0,8

0,78

0,76

400˚C 460˚C

Reaction Temperature (˚C)

Figure 2: Effect of temperature variations in palm oil

cracking process using 5% mass of Ni/Al2O3

catalyst in 400oC temperature

and 1 atm pressure for

10 minutes to the product density.

From this graph it is known that only the 400

o

C

product has the value of density that qualify the green

diesel product standard, the 400

o

C product is 0,8523

g/ml which is between 0,8150-0,8600 g/ml.

Density (g/ml)

Product Mass (gram)

Activity Test of Temperature Variations in Cracking Process of Palm Oil using Ni/Al2o3 to Green Diesel Viscosity

67

3.3 Effect of Temperature Variations

on Viscosity

7

6

5

4

3

2

1

0

400˚C 460˚C

Reaction Temperature (˚C)

Figure 3: Effect of temperature variations in palm oil

cracking process using 5% mass of Ni/Al2O3 catalyst in

400oC temperature and 1 atm pressure for 10 minutes to

the product viscosity.

From this graph it is known that none of product has

the value of viscosity that qualify the green diesel

product standard, namely the 400

o

C product is 6,4563

cSt and the 460

o

C is 1,4305 cSt which both are not

between 2-4,5 cSt.

4

CONCLUSIONS

The effect of temperature variations in the palm oil

cracking process using Ni/Al

2

O

3

catalyst on the

response of product mass, density, and viscosity, it

was found that the higher the temperature, the lower

the value of these responses. The mass response of the

product obtained the most is 20.845 grams, and the

highest density response is 0.8523 g/ml, and the

highest viscosity response is 6.4563 cSt.

For the product that best meets the Green Diesel

standard specifications, it is analyzed from density

data, namely only the 400

o

C product of which have

met the standard, namely 0.8523 g/ml and of which is

in the standard range of 0.8150-0,8600 g/ml.

Meanwhile, the product analysis was based on

the viscosity value, none of the product met the

standard, namely the 400

o

C product 6,4563 cSt and

460

o

C 1,4305 cSt which were not in the standard

range of 2-4.5 cSt.

ACKNOWLEDGEMENTS

The author would like to thank UPT P2M Politeknik

Negeri Malang DIPA No. SP DIPA

023.18.2.677606/2021 with contract no. 5439/PL2

.1/HK/2021 for financial support.

REFERENCES

Sa’adah, A. F., Fauzi, A., & Juanda, B. (2017). Peramalan

Penyediaan dan Konsumsi Bahan Bakar Minyak

Indonesia. Jurnal Ekonomi dan Pembangunan

Indonesia Vol. 17 No. 2, 118–137.

Auliastuti, M. A., Munir, M. B., & Chumaidi, A. (2019).

PENGARUH PENAMBAHAN KATALIS Mg-Zn

Terhadap Komposisi Green Diesel Dengan Metode

Dekarboksilasi. Distilat Jurnal Teknologi Separasi, 58-

62.

Munur, M. B, & Chumaidi, M. (2019). Pengaruh Waktu

Proses Terhadap Komposisi Green Diesel Dalam

Reaksi Dekarboksilasi. Distilat Jurnal Teknologi

Separasi, 147- 151.

Ristanti, R. A., Sagara, B. P., Murti, S. S., & Redjeki, S.

(2020). Pembuatan Green Diesel dari Minyak Biji

Kapuk (ceiba pentandra) Menggunakan Katalis

NiMo/y-Al2O3 dengan Proses Hidrogenasi dan

Fraksinasi. Jurnal Teknik Kimia, Vol. 15 No. 1.

Neonufa, G. F., Soerawidjaja, T. H., & Prakoso, T. (2017).

Catalytic and Thermal Decarboxylation of Mg-Zn

Basic. J. Eng. Technol. Sci., Vol. 49, No. 5, 575-586.

Viscosity (cSt)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

68