The Effect of Crumb Rubber Substitution and Utilization of Local

Materials Laterite on Asphalt Concrete - Binder Course

Karminto

1a

, Ashadi Putrawirawan

1b

, Ibayasid

1c

and Sakti Adji Adisasmita

2d

1

Civil Engineering, Samarinda State of Polytechnic, Jln. Ciptomangungkusumo, Samarinda, Indonesia

2

Civil Engineering, Hasanudin University, Jln. Perintis Kemerdekaan No. KM. 10, Makassar, Indonesia

Keywords: Crumb Rubber, Laterite Stone, Asphalt Concrete, Marshall, Optimum Asphalt Content.

Abstract: The opportunity to use crumb rubber for pavement layers is still minimal, while the waste generated is

increasing, one way to reduce and utilize the tire material is to add asphalt-concrete mixture - binder course

(AC-BC). To increase flexibility, one of them is by using Crumb Rubber from waste tires that pass the No.

filter. 4 (4.75 mm) as additive. This study aims to determine the effect of Crumb Rubber as a material and

the use of laterite stone as a substitute for coarse aggregate on asphalt mixtures based on the properties of

the Marshall mixture. In this study, Marshall test specimens were made with variations of laterite stone as a

substitute for coarse aggregate at a level of 50% and the addition of Crumb Rubber at a level of 1%, 2%, 3%

and the planned asphalt content was 4%, 4,5%, 5%, 5.5%, and 6% which will then determine the optimum

asphalt content, stability, flow, VIM, VMA, VFA and MQ in the Asphalt Concrete – Binder Course. Based

on the research results obtained. The best variation isthe use of Crumb Rubber as an additive to Asphalt

Concrete – Binder Course by 1% and the addition of Crumb Rubber and the value of Optimum Asphalt

Content is 5.58% with Marshall characteristics including stability values of 1082 kg, flow 2.91%, VIM

4.83%, VMA 14.82%, VFA 65.80% and MQ 438 kg/mm. The results showed that the mixture of AC-BC

with a substitute for coarse aggregate using 50% laterite stone and Crumb Rubber the requirements for the

Asphalt Concrete - Binder Course.

a

https://orcid.org/0000-0002-9373-2942

b

https://orcid.org/0000-0001-6163-4187

c

https://orcid.org/0000-0001-7805-0380

d

https://orcid.org/0000-0003-1732-4098

1 INTRODUCTION

Asphalt pavement is a large road leading through

one place to another, specifically with a prepared

roof that can be used by vehicles. Roads play a

significant role with in social and economic growth

of a nation (Alakhali, Yahya, 2021). Use of

materials for road pavement construction in East

Kalimantan is still very dependent on Palu stone and

sand, so that road construction costs in East

Kalimantan are expensive (Putrawirawan, Ibayasid,

2020). So it is necessary to makeaneffortsothat

howto utilize local natural resources in East

Kalimantan as an alternative material for making

asphalt. One of the natural resources owned by East

Kalimantan is Laterite Stone.

The purpose of this research is to find out how

much influence the use of laterite stone and Crumb

Rubber has on Masrhall characteristics in the

Asphalt Concrete - Binder Coarse (AC-BC). To

determine the optimum asphalt content (KAO) in the

Asphalt Concrete-Binder Coarse (AC-BC). Use of

laterite as a substitute for coarse aggregate on AC-

BC maximum of 50% and Optimum Asphalt

Content value of 5.48% with Marshall

characteristics including stability values 1980 kg,

flow 3.95%, VIM 4.96%, VMA 16.42%, VFA

72.07% and MQ 510.63 kg/mm. The results showed

that the mixture of AC-BC with a substitute for

coarse aggregate using laterite met the requirements

for Asphalt Concrete – Binder Course (AC-BC)

(Putrawirawan, Tristo, Ibayasid, 2019). The addition

of 0.75% of Activated Crumb Rubber (ACR)

Karminto, ., Putrawirawan, A., Ibayasid, . and Adisasmita, S.

The Effect of Crumb Rubber Substitution and Utilization of Local Materials Laterite on Asphalt Concrete - Binder Course.

DOI: 10.5220/0010940200003260

In Proceedings of the 4th Inter national Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 69-75

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

69

additive, improved the resistance to fatigue cracking

and rutting about 20% and 32% respectively but

susceptible to stripping, even though the addition of

ACR additive showed insignificant improvement

between ACR and control mixture in Marshall

properties, but based on the mechanical

performance, the ACR additive eligible to apply and

provide the same or better performance compared to

conventional and non-ACR mixtures (Kamarudin et

al, 2020). The recycled aged Crumb Rubber

Modified (CRM) mixtures (with 15%, 25%, and

35% rubberized RAP) can satisfy the current

Superpave mixture requirements, including moisture

susceptibility and rutting resistance, and in general,

there was no significant difference between the

control and the recycled CRM mixtures for the

properties evaluated (Lee J, S et al, 2008).

2 MATERIALANDMETHOD

2.1 Asphalt Concrete – Binder Course

(AC-BC)

Asphalt Concrete – Binder Course (AC – BC) is a

pavement layer located below the wear layer

(Wearing Course) and above the foundation layer

(Base Course). This layer is not directly related to

the weather, but must have sufficient thickness and

adhesiveness to reduce stress/strain due to traffic

loads which will be transmitted to the lower layers,

namely Base course and Sub grade (Subgrade).

2.2 Ingredient of Asphalt Concrete -

Binder Course (AC-BC)

Flexible pavement consists of coarse aggregate, fine

aggregate, sand, filler and additives. However, the

materials used must first be tested according to

standards and meet the specifications set by Bina

Marga. This is in order to obtain pavement that has

good quality and is in accordance with the plan.

2.3 Laterite Stone

Laterite stones is a hardened soil formed naturally

resembling rock from the deposition of substances

such as nickel and iron. Laterite itself is naturally

formed in which there are many elements and

nutrients that make up the soil layer hardened like

stone. The term Lateriteis derived from the Latin

word - later, meaning brick. It was first used in 1807

by Buchanan to describe a red iron-rich material

found in the southern parts of India. Laterites are

widely distributed throughout the world in the

regions with high rainfall, but especially in the inter-

tropical regions of Africa, Australia, India, South-

East Asia and South America, where they generally

occur just below the surface of grasslands or forest

clearings. Alexander et al., (1962) (West,

Jenbarimiema, Nyebuchi, & Azeruibe, 2020)

compiled the physical, chemical and morphological

definitions fromvarious researchers and then

redefined laterite as a highly weathered material,

rich in secondary oxides of iron, aluminum, or both,

it is nearly void of bases and primary silicates, but it

may contain large amounts of quartz and kaolinite,

and it is either hard or capable of hardening on

exposure to wetting and drying (West,

Jenbarimiema, Nyebuchi, & Azeruibe, 2020).

Figure 1: Laterite stone.

2.4 Crumb Rubber

Crumb rubber is made of tyres or vulcanized rubber.

Tyres are basically formed by combining natural and

synthetic rubber and carbon black. The tyres are

shredded into smaller particle sizes to remove wire

and fabric reinforcement. The actual chemical

composition of crumb rubber derived from tyres is

difficult to assess because of the large variation in

tyre types produced by different manufacturers.

However, crumb rubber is typically referenced by its

size together with basic compositions such as natural

and synthetic rubber, steel, fibre and carbon black

(Hassan et al, 2015). Crumb Rubber is an

environmentally friendly recycled rubber product

because it is obtained from recycling waste made

from used tire rubber. Crumb Rubber has advantages

such as good adhesion, sturdy, durable and long-

lasting, more resistant to gasoline and lubricating oil

and resistant to weather. Crumb Rubber can be

obtained by recycling ambient grinding. Ambient

grinding is a process method where used tires are

grated, ground and processed at room temperature.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

70

The main ingredients of Crumb Rubber generally

come from waste tire rubber (Julián, 2005).

Figure 2: Crumb Rubber.

Chemical content Crumb Rubber has the

constituent elements shown in Table 1.

Table 1: Chemical content Crumb Rubber.

Material Com

p

otition (%)

Rubbe

r

48

Karbon blac

k

22

Lo

g

a

m

15

Tekstil 5

Zinc Oksida 1

Sulfu

r

1

AditiveMaterial 8

Crumb rubber is produced through refining the scrap

tires of cars, trucks, busses and other transporter tires,

steel and synthetic fibers, which account for

approximately 40 percent of the structure of the tyres

are extracted via a magnetic system and an air gravity

system. Crumb rubber is an efficient material to be

used as an additive to asphalt binder since it

contributes in better performance by increasing the

strength and stiffness of pavement and can be used for

future development (Alakhali, Yahya, 2021). Crumb

rubbers (CRs) have been proposed as pavement

components because they are waste materials.

Previous studies have attempted to find alternative

material in pavement construction that act as additives

or property modifier (Hamad, S, Jaya, 2014). The hot

mix asphalt modification process in which crumb

rubber is initially mixed with mineral aggregate

before addition of a binder is known as dry process.

This process has the advantage of using conventional

blends and, at least in principle, that there is no limit

to the content of the rubber introduced (Silvrano, et al,

2005). The dimension of crumb rubber particles used

in the dry process is generally bigger than for those

used in the wet process. Besides, in the dry process,

the crumb rubber substitutes part of the aggregate

mineral (Silvrano, et al, 2005). The CRDryprocess is

the method wherethe CR particles are partially

replaced with the portion of fine aggregates in the

mix. In addition, there are several treated dry rubber

technologies where the crumb rubber particles are

pre-mixed with low viscosity petroleum-based

products or aromatic oils compatible with the lighter

fractions of asphalt binder. Treated rubber

technologies are also integrated in to mixture as a

CRDry process (Salih, K, M. Emin, K., 2017).

3 RESULTS AND DISCUSSION

3.1 Result of Testing Material

Based on the results of testing in the asphalt testing

laboratory, the values of specific gravity,

penetration, softening point and ductility meet the

requirements of asphalt, then the results of testing

the physical characteristics of aggregates that meet

the requirements of technical specifications can be

seen in the following tables.

Table 2: The result of Asphalt properties.

No. Type of testing Requirement Result

1

Penetration, 25

o

C

60-70 67.7

2

Softening point (

o

C)

Min. 48 52.25

3

Ductility 25

o

C (cm)

Min. 100 126.7

4 Spcific Ggrafity Mi. 1 1.040

Table 3: The results of testing the specific gravity and

absorption of coarse aggregate.

Type of testing Requirement Result

Dry bulk density Min. 2.5 2.63

Saturated surface dry (SSD) Min. 2.5 2.68

Apparentdensity Min. 2.5 2.75

Absorption Maks. 3% 1.58

Abration Maks. 40% 20.63

Table 4: The results of testing the specific gravity and

absorption of medium aggregate.

Type of testing Requirement Result

Dry bulk density Min. 2.5 2.55

Saturated surface dry (SSD) Min. 2.5 2.62

Apparentdensity Min. 2.5 2.74

Absorption Maks. 3% 2.69

The Effect of Crumb Rubber Substitution and Utilization of Local Materials Laterite on Asphalt Concrete - Binder Course

71

Table 5: The results of testing the specific gravity and

absorption of Filler.

Type of testing Requirement Result

Dry bulk density Min. 2.5 2.52

Saturated surface dry (SSD) Min. 2.5 2.54

Apparentdensity Min. 2.5 2.58

Absorption Maks. 3% 1.01

Table 6: The results of testing the specific gravity and

absorption of Laterite stone.

Type of testing Requirement Result

Dry bulk density Min. 2.5 2.54

Saturated surface dry (SSD) Min. 2.5 2.59

Apparentdensity Min. 2.5 2.67

Absorption Maks. 3% 2.93

Abration Maks. 40% 29.63

All material tests which include asphalt, coarse

aggregate, fine aggregate, filler and laterite stone

have met the requirements of the 2018 Bina Marga

technical specifications.

3.2 Marshall Characteristic

3.2.1 Relation of Crumb Rubber with

Stability

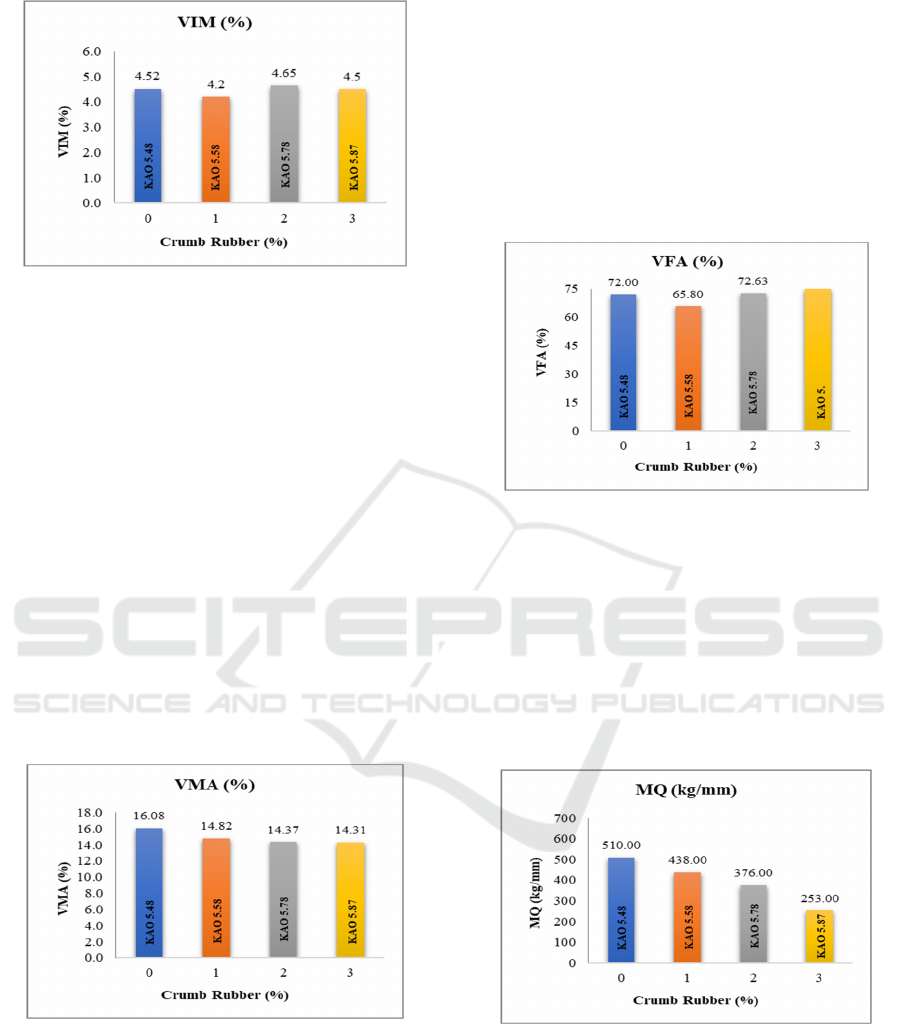

The average value of the AC-BC in the mixture with

crumb rubber content of 0%, 1%, 2%, 3%

respectively was1980kg,1082kg,1004kg,1002kg.

Figure 3: Graph of the relationship between stability and

variations in use of Crumb Rubber.

The stability value has decreased. The lowest

stability value was obtained at 1% crumb rubber,

which was 1082 kg and the highest value was

obtained at 0% crumb rubber, which was 1980 kg.

However, after that the stability value decreased at

levels of 1% to 3%. The decrease in stability was

caused by the addition of crumb rubber content in

the mixture which resulted in a lack of interlocking

between the aggregates and crumb rubber, causing

the asphalt to no longer effectively cover the

aggregates which could lead to a decrease in the

stability. Pavement layers with a stability of less

than 800 kg will easily experience rutting, because

the pavement is soft so it is less able to support the

load.

3.2.2 Relation of Crumb Rubber with Flow

The average flow value of the AC-BC mixture in the

mixture with crumb rubber content of 0%, 1%, 2%,

3%, respectively, was 3.90 mm, 2.91 mm, 3.12 mm,

3.98 mm.

Figure 4: Graph of the relationship between Flow and

variations in use of Crumb rubber.

Flow value decreased and increased. The highest

flow value was obtained at a content of 3% crumb

rubber, which was 3.98 mm, but all crumb rubber

content still meet the requirements of the 2018

General Specification, which was a minimum of 2.0

mm. The increase in the average flow value can be

caused by the increasing amount of asphalt required

so that the properties of the mixture are plastic and

easily deformed when loaded.

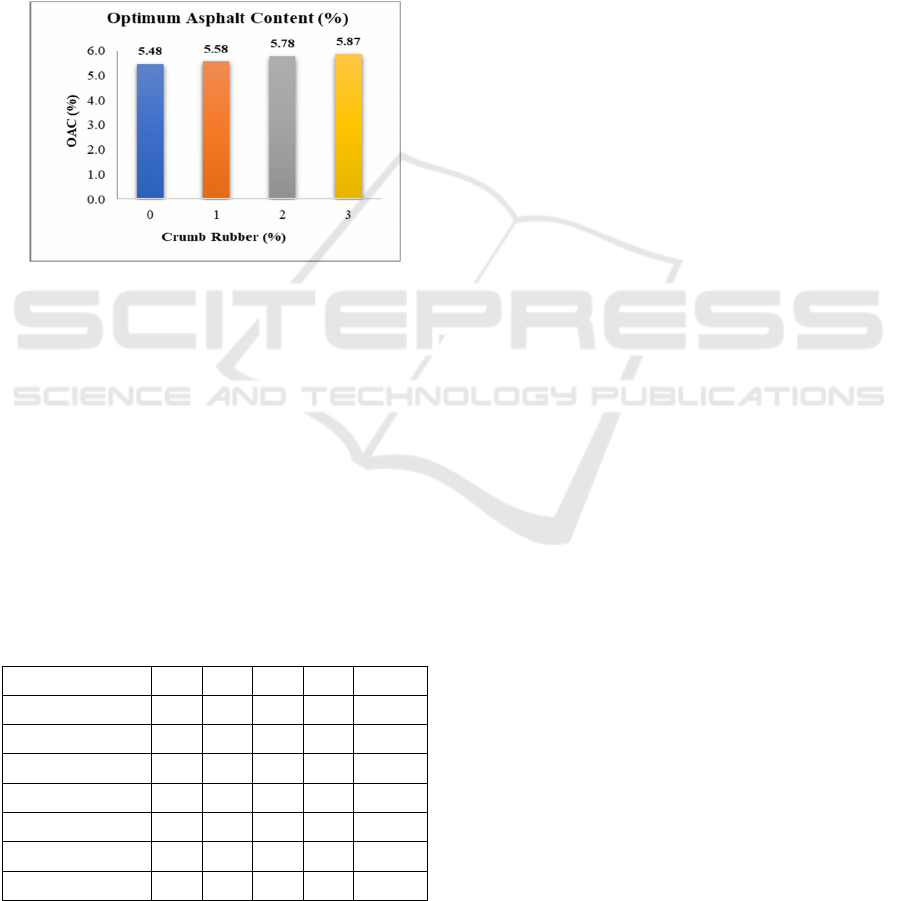

3.2.3 Relation of Crumb Rubber with Void

in Mix (VIM)

VIM value decreased or increased. This is due to the

increasing content of laterite stone causing the

asphalt to not optimally fill the voids in the

aggregate because it has larger voids and the less

asphalt content is filled, making the mixture less

dense because the aggregates are interconnected and

break due to imperfect compaction. The value of

VIM in all variations of crumb rubber content still

meets the minimum requirements of 3% and a

maximum of 5%.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

72

Figure 5: Graph of the relationship between VIM and

variations in use of Crumb rubber.

Figure 5 shows that the VIM value decreased at 4%

plastic bag content. This is because the increasing

content of plastic sacks causes asphalt to fill voids in

the aggregate because it has smaller voids and the

more asphalt content filled in the mixture can make

the mixture denser. The VIM value in all variations

of the plastic bag content still meets the minimum

requirements of 3% and a maximum of 5%

3.2.4 Relation of Crumb Rubber with Void

in Mineral Agregat (VMA)

Mixing crumb rubber as an added ingredient causes

the VMA value to decrease. The value of VMA on

the use of crumb rubber 0%, 1%, 2%, 3%, decreased

by 15.80%, 14.82%, 14.37%, 13.98%. Aggregates

form a thick blanket, as a result, the voids between

aggregates are getting smaller.

Figure 6: Graph of the relationship between VMA and

variations in use of Crumb Rubber.

The decrease in VMA value was due to the increase

in crumb rubber content so that the asphalt covering

the aggregate formed a thick blanket, as a result the

voids between the aggregates were getting smaller.

3.2.5 Relation of Crumb Rubber with Void

Filled Agregat (VFA)

Void filled with asphalt (VFA) value decreased and

increased. Values at levels of 0%, 1%, 2%, 3%

crumb rubber respectively are 72.00%, 65.80%,

72.63%, 77.80%. VFA value for each laterite stone

content still meets the general specifications for

2018 which is at least 65%. VFA value that is too

high will cause bleeding.

Figure 7: Graph of the relationship between VFA and

variations in use of Crumb rubber.

VFA value that is too small will cause the mixture to

be less water and airtight. This will cause the asphalt

film layer to become thin so that the pavement will

crack easily when it receives a load so that the

asphalt mixture is easily oxidized.

3.2.6 Relation of Crumb Rubber with

Marshall Quotient (MQ)

Figure 8: Graph of the relationship between MQ and

variations in use of plastic bags.

Along with a decrease in stability causes a decrease

in the valueof MQ and causesan increase in thevalue

of flow. As a result of the decrease in the MQ value,

the mixture will become less brittle and soft when

the mixture will be increased the amount of

compaction.

The Effect of Crumb Rubber Substitution and Utilization of Local Materials Laterite on Asphalt Concrete - Binder Course

73

The use of crumb rubber resulted in the Marshall

Quotient value decreased.

3.2.7 Relation of Crumb Rubber with

Optimum Asphalt Content (OAC)

The optimum asphalt content of each proportion of

the use of crumb rubber as an additive can be seen in

Table 4.28. From the results of the Marshall test, the

optimum asphalt content for each variation was

5.48% for 0% crumb rubber; 5.58% for 1% crumb

rubber; 5.73% for 2% crumb rubber; 5.87% for 3%

crumb rubber.

Figure 9: Graph of the relationship between Optimum

Asphalt Content (OAC) and variations in use of Crumb

rubber.

The effect of using crumb rubber as an additive in

the mixture will increase the value of the optimum

asphalt content in the AC-BC asphalt mixture.

Judging from the OAC value which continues to

show an increase in the OAC value. This means that

the use of crumb rubber greatly affects the value of

KAO, the more use of crumb rubber as an added

material, the value of the optimum asphalt content

will also be higherfor each variation of the content

of crumb rubber which can be seen in Table 7.

Table 7: Value of Characteristic Marshall Asphalt

Concrete – Binder Course.

Crumb Rubber (%)

0% 1% 2% 3% Spec.

OAC (%) 5.48 5.58 5.78 5,87 -

Stability (kg)

1980 1082 1004 1002

Min. 800

Flow (mm)

3.90 2,91 3.12 3,98 2 – 4

VIM (%) 4.52 4,83 4.92 3,74 3 – 5

VMA (%) 16,08 14,82 14,37 14,31 Min. 14

VFA (%) 72.00 65,80 72,63 75,08 Min. 60

MQ (kg/mm)

510 438 376 253

Min 250

4 CONCLUSIONS

Based on the test results of the Asphalt Concrete –

Binder Course (AC-BC) mixture using 50% laterite

stone as a substitute for coarse aggregate and crumb

rubber as an added ingredient, the maximum

addition of crumb rubber is 3% with an KAO value

of 5.58% and the value of the Marshall test

properties. namely stability = 1082 kg, flow = 2.91

mm, VIM = 4.83%, VMA = 14.82%, VFA =

65.80%, and MQ = 438 kg/mm. All variations of the

mixture meet the standards according to the

technical specifications of Bina marga 2018, the

greater the addition of crumb rubber, the lower the

stability value but still within the recommended

technical specification standards.

REFERENCES

Alakhali, A, Yahaya, M, Almalik, A, (2021), Effects of

Crumb Rubber at Different Sizes in Asphalt Mixtures

on Mechanical Properties. National Confrence on

Wind & Earthquake Engineering.

Hamad, S, Jay, P, Hassan (2014), Influences of Crumb

Rubber Sizes on Hot Mix Asphalt Mixture. Artikel in

Jurnal Teknologi Malaysia.

Hassan, N. A., Gordon D. Airey, Putra Jaya, R Mashros,

N. (2017). A Review of Crumb Rubber Modification

in Dry Mixed Rubberised Asphalt Mixtures. Article in

Jurnal Teknologi, September 2014 DOI:

10.11113/jtv70.3501.

Hendarsin, S. L. (2000). "Perencanaan Teknik Jalan

Raya". Bandung: Politeknik Negeri Bandung-Jurusan

Teknik Sipil.

Julián, B., Sanchez, C., Belleville, P., & Popall, M.

(2005). Applications of hybrid organic–inorganic

nanocomposites. Journal of Materials Chemistry,

15(35-36), 3559-3592.

Karminto, Aji, S., & Hamid, S. (2019). Pemanfaatan

material Lokal batu Laterit dan Pasir Mahakam dalam

Campuran Apal Karet Terhadap Jumlah Siklus

Pembebanan. Prosiding Konferensi Nasional

Pascasarjana Teknik Sipil (KNPTS) X 2019, (pp. 127-

137). Bandung.

Lee, J, S, Chandra K. Akisetty, Serji N. Amirkhanian,

(2008). Laboratory Characterization of recycled crumb

rubber modified asphalt mixture after extended aging.

Article in Canadian Journal of Civil Engineering ·

November 2008DOI:10.1139/L08-079.

Putrawirawan, A, Tistro R, Ibayasid, (2019) Study of The

Use of Laterite Stone From Tenggarong Seberang

District in Asphalt Concrete Mixture – Binder Course

(AC-BC). Prosiding Seminar Nasional

Penelitian &

Pengabdian Kepada Masyarakat2019 (pp.88-95).

Salih K, M. Emin, K, (2017), effect of Addition of Dry

Crumb Rubber on the Performance of Terminal Blend

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

74

Crumb Rubber Modified Asphalt Mixtures. Article in

Transportation Research Record Journal of the

Transportation Research Board DOI: 10.3141/2633-

11. January 2017.

S N N Kamarudin, M R Hainin, M N M Warid, M K I M

Satar and N A Hassan (2020). Performance of Asphalt

Mixture Incorporating Activated Crumb Rubber as

Additive. IOP Conf. Series: Materials Science and

Engineering, ISECE 2020 doi:10.1088/1757-

899X/1144/1/012081.

Silvrano, A, Dantas Neto, Márcio Muniz de Farias, Luis

Guelherme (2005) The Use of Crumb Rubber In

Asphalt Mixtures Using The Dry Process,

International Symposiumon PavementRecycling.

March 14-16.

West, T., Jenbarimiema, Nyebuchi, & Azeruibe, D.

(2020). Laterite Rock Modified Asphalt Concrete Mix

Design Properties and Swell Behaviour under Soaked

Conditions for Rural Roads. International Journal of

Constructive Research in Civil Engineering, 11-25.

Wulandari, S, Tjandra, D, (2017) Use of Crumb Rubber as

an additive in Asphalt Concrete Mixture. Sustainable

civil Engineering Structur and Construction Material,

171, p 1384-1389.

The Effect of Crumb Rubber Substitution and Utilization of Local Materials Laterite on Asphalt Concrete - Binder Course

75