Experimental Study of the Effect of Excitation Current on the Output

Voltage of a Self-excited Synchronous Generator

Anggara Trisna Nugraha

a

and Alwy Muhammad Ravi

Department of Marine Electrical Engineering, Shipbuilding Institute of Polytechnic Surabaya, Jl. Teknik Kimia,

Kampus ITS Sukolilo, Surabaya (60111), Indonesia

Keywords: Synchronous Generator, Excitation System, and Self-excitation.

Abstract: Energy needs continue to increase. Currently, the demand for electrical energy is growing at a higher rate than

other energies. Based on Energy Outlook 2019, coal-fired power generation still dominates. However, if no

new coal reserves are found, then medium to high-quality coal reserves are projected to be exhausted in 2038.

To meet the need for electrical energy, it is necessary to utilize the energy available in nature optimally and

stable with changes in electrical load. The potential for hydro energy that can be utilized to generate electricity

is 75,901 MW. Generators in a power plant have an important role as a converter of mechanical energy into

electrical energy to be utilized. However, to be able to use the stability of the electrical energy produced needs

to be considered. One way to stabilize the output voltage of a generator can be done by adjusting the excitation

current value. Therefore, the purpose of this study is to determine the effect of the self-amplifying excitation

system on a synchronous generator on the output voltage produced when there is no electrical load and an

electrical load. The test results show that the excitation current greatly affects the output voltage of the

synchronous generator. The hope of this research can be applied to the prototype of the vortex turbine pico

hydropower plant which is currently being researched as well.

1 INTRODUCTION

Energy has an important role in supporting human

life. Along with the times, energy needs continue to

increase (Baskoro & Adiwibowo, 2017). Currently,

the demand for electrical energy is growing at a

higher rate compared to other energies (Team

Secretary-General of the National Energy Council,

2019). Based on Energy Outlook 2019, coal-fired

power generation still dominates. However, if no new

coal reserves are found, then medium to high-quality

coal reserves are projected to be depleted in 2038

(Agency for the Assessment and Application of

Energy, 2018). To meet the needs of electrical energy,

it is necessary to utilize the energy available in nature

optimally and stable with changes in electrical loads.

Indonesia is very rich in its renewable energy

potential. One of the renewable energy that can be

used as electrical energy is hydro energy. Based on

Indonesia's clean energy status report, the potential

for hydro energy that can be utilized to generate

electricity is 75,091 MW (Tampubolon & Adiatama,

a

https://orcid.org/0000-0002-4482-2829

2019). The utilization of hydro energy into electrical

energy in a simple form is mostly obtained from the

application of hydropower plants with pico and micro

scales.

In a previous study conducted by Pambudi (2020),

he has designed a laboratory-scale micro-hydro

power generation system by utilizing an induction

generator and a permanent magnet generator

(synchronous generator) to compare the output of

electrical power generated. The results of this study

indicate that a permanent magnet generator

(synchronous generator) has an optimal efficiency

and power output of 195.3 watts with an efficiency of

89%. However, power plants can be utilized, if the

output of electrical energy is stable due to changes in

electrical load.

In another study conducted by (Syahputra, 2012),

examined the effect of a synchronous generator

voltage stabilizer system using a separate amplifier

excitation system. The test results show that the

synchronous generator output voltage is greatly

affected by the size of the excitation current.

86

Nugraha, A. and Ravi, A.

Experimental Study of the Effect of Excitation Current on the Output Voltage of a Self-excited Synchronous Generator.

DOI: 10.5220/0010940500003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 86-93

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

However, the application of an excitation system with

a separate amplifier is not possible if it is applied to a

prototype of a pico hydropower plant that utilizes

hydro energy directly in the river because the

excitation system is easy to implement, namely

utilizing a rectified generator output voltage for an

excitation source for the synchronous generator itself.

Therefore, in this study, we will utilize a self-

amplifying excitation system resulting from

rectifying the AC power output from the synchronous

generator into DC electricity, then stored in the

battery as an excitation supply to the synchronous

generator. The purpose of this study is to determine

the effect of the self-amplifying excitation system on

a synchronous generator on the output voltage

produced when there is no electrical load and an

electrical load. The hope of this research can be

applied to the prototype of the vortex turbine pico

hydropower plant which is currently being researched

as well.

2 MATERIALS AND METHODS

2.1 Excitation System

The excitation system is a system of flowing direct

current electricity supply as a reinforcement to the

electric generator so that it produces electric power

and the output voltage depends on the amount of

excitation current (Nurdin et al., 2018). The generator

excitation system is an important element to form a

stable generator terminal voltage profile. The

operating system of this generator excitation unit

functions to keep the generator voltage constant

(Fahmi & Irwanto, 2020). One of the excitation

systems in an electric generator is an excitation

system using a brush.

The excitation system uses a brush (brush

excitation), the source of electric power comes from

a power source that comes from a direct current (DC)

generator or an alternating current (AC) generator

which is rectified first using a rectifier. If you use a

power source that comes from an AC generator or

permanent magnet generator (PMG), the magnetic

field is a permanent magnet. In the rectifier cabinet,

alternating current is converted or rectified into direct

current voltage to control the main exciter field coil.

To drain the excitation current from the main exciter

to the generator rotor using slip rings and charcoal

brushes (Nurdin et al., 2018).

The use of slip rings and brushes, usually used in

small-capacity generators. This spring is made of

metal which is usually attached to the engine shaft but

is isolated from the shaft. Where the two ends of the

field winding on the rotor are connected to the slip

ring. By connecting the positive and negative

terminals of the direct current source to the slip ring

through the brush, the field winding will get a supply

of direct current electrical energy from an external

source (Fahmi & Irwanto, 2020).

2.2 Synchronous Generator

An alternating current (AC) generator or also known

as an alternator is a device that functions to convert

mechanical energy (motion) into electrical energy

(electrical) by means of magnetic field induction.

This energy change occurs due to a change in the

magnetic field in the armature coil (where the voltage

is generated in the generator). It is said to be

synchronous generator because the number of

rotations of the rotor is equal to the number of

rotations of the magnetic field on the stator (Nurdin

et al., 2018). This synchronous speed results from the

rotational speed of the rotor with the magnetic poles

rotating at the same speed as the rotating field on the

stator. The field coil in a synchronous generator is

located on the rotor while the armature coil is located

on the stator (Boldea, 2016).

Synchronous generators convert mechanical

energy into alternating electrical energy

electromagnetically. Mechanical energy comes from

the prime mover that rotates the rotor, while electrical

energy is generated from the electromagnetic

induction process that occurs in the stator coils

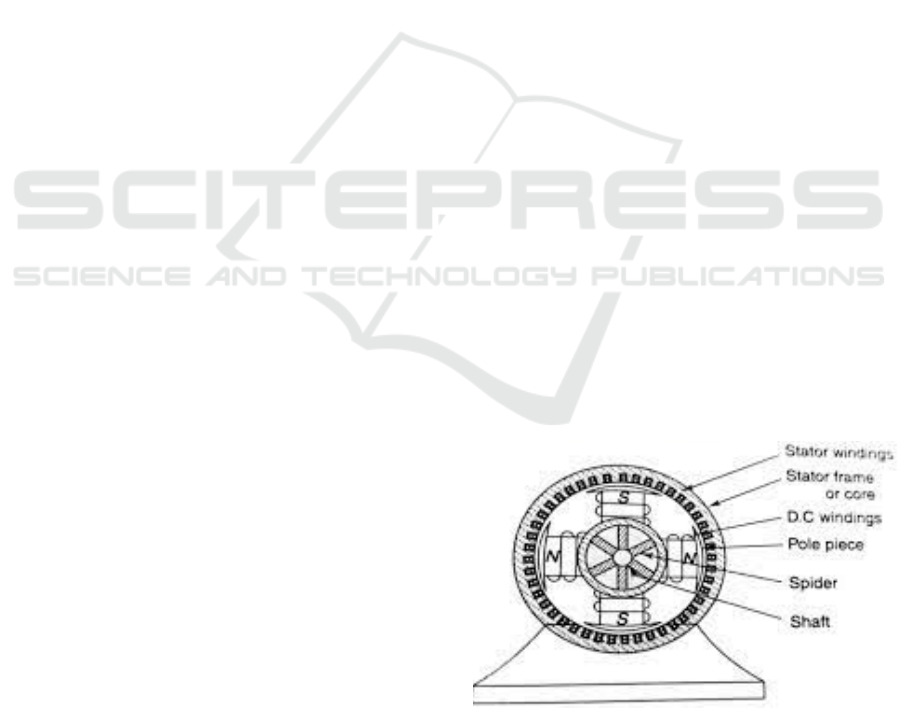

(Nurdin et al., 2018). A simple form of a synchronous

generator can be seen in Figure 1. In general, a

synchronous generator consists of a stator, a rotor,

and a rotating part of the air gap. The air gap is the

space between the stator and the rotor.

Figure 1: Synchronous Generator.

Experimental Study of the Effect of Excitation Current on the Output Voltage of a Self-excited Synchronous Generator

87

2.3 Synchronous Generator Working

Principle

Nurdin (2018) in his book describes the working

principle of a synchronous generator in general as

follows:

1. The field coil contained in the rotor is connected

to a certain excitation source that will supply

direct current to the field coil. With the direct

current flowing through the field-coil it will cause

a flux whose magnitude with time is constant.

2. The prime mover which is coupled to the rotor is

immediately operated so that the rotor will rotate

at its nominal speed.

3. The rotation of the rotor will simultaneously

rotate the magnetic field generated by the field

coil. The rotating field generated in the rotor will

be induced in the armature coil so that the

armature coil located in the stator will produce a

magnetic flux that varies in magnitude with time.

A change in the magnetic flux surrounding a coil

will cause an induced emf at the ends of the coil.

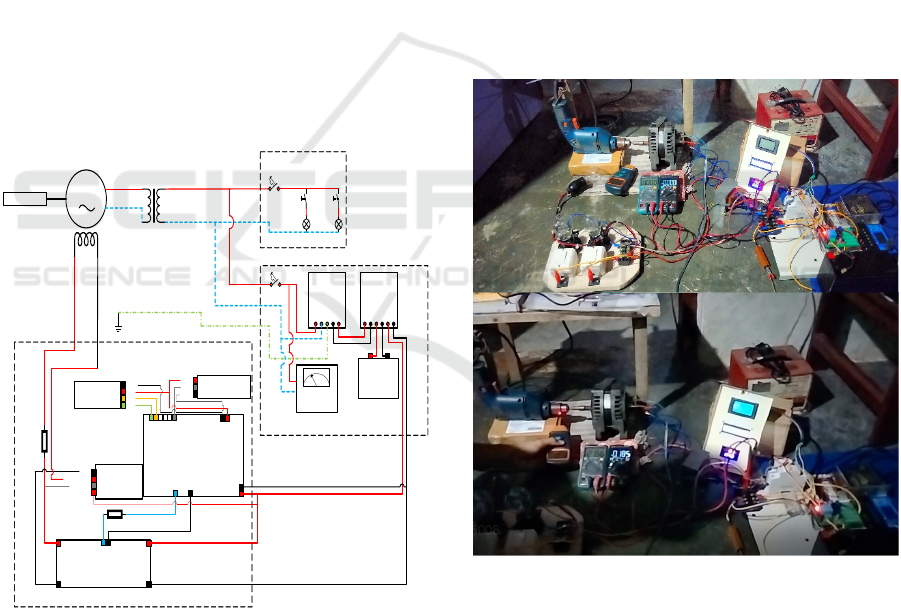

2.4 System Design

The overall system is depicted in Figure 2. The prime

mover used to rotate the synchronous generator in this

study was obtained from an electric drill set at a

rotational speed of 1000 rpm – 1300 rpm.

DC Power

Supply 12V 5A

Arduino Uno

LCD 16x2

Buck-Boost

Converter

Synchronous

Generator

Battery Charger

Controller

Battery

Load

DC Volt-

Ampere Meter

AC Voltmeter

Step-up

Transformator

Prime Mover

ADC

Potensiometer

PWM

GPIO

Power Line Control Line

Figure 2: The Experimental Setup and The Design Diagram

Block.

The rotational speed of this prime mover is made

stable so that the research discussion does not get out

of topic. The stable AC output voltage in this study

was generated from a step-up transformer with the

aim of getting a working voltage value of 110V AC.

Meanwhile, the synchronous generator used is a car

alternator that has a working voltage of 12V AC.

Start

Prime Mover

Synchronous Generator C

Lamp is

Brighter

DC Power Supply 12 Volt

5A

Charging

A

110 AC

Voltage

Is the Output Voltage

110 VAC ?

Adding Load

Yes

No

End

B

Battery

Step-up Transformator

DC Voltage

Turn

Potensiometer

Processing Data on

Arduino

A

ADC Value

PWM

Signal

Exciter (Buck-Boost

Converter)

B

C

Voltage

Excitation

Figure 3: Flow Chart Excitation System.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

88

The output voltage of this transformer will then be

used as a supply for the excitation and loading

system. The electrical load used for testing the

stability of the output voltage is a 5-watt incandescent

lamp. In accordance with the block diagram in Figure

2, the excitation system used is a self-excited

excitation system. The self-excited system in this

study was designed by changing the AC voltage

output to a stable DC voltage with the aim of

supplying the battery storage system which is used as

an excitation supply. The use of the battery here is

done with the aim of making the supply input voltage

to the exciter, namely the buck-boost converter,

stable. The buck-boost converter exciter is controlled

by a microcontroller with ADC input from a

potentiometer to adjust the duty cycle of the exciter.

This stability setting is seen from the results of the AC

voltmeter reading which then by looking at the

voltmeter it can be done by setting the excitation by

turning the potentiometer. 16 x 2 LCD is used to

display the duty cycle value. The workflow of the tool

in this study can be seen in Figure 3 below.

2.5 Wiring Diagram

G

F1 F2

L

N

0 – 12 V AC

0 – 110 V AC

L

N

PE

MCB 2 A

Lamp1

S1

MCB 6 A

Lamp2

S2

DC Power

Supply 12 V

5A

L N PE - +

Battery

Char ger

Cont ro ll er

+ - + - + -

Battery

AC

Voltmeter

Potensiometer

LCD 16x2

Vin

GND

GND

+5V

ARDUINO UNO

A0

A1

A2

A3

A4(S DA)

A5(S CL)

+5V

GND

SDA

SC L

+5V

GND

OUT

D6 PW M

BUCK-BOOST CONVERTER

Input +

Input -

Output +

Output -

PW M

Arduino

R2 20Ω

DC Volt-

Ampere Meter

Read Ampe re

GND

Re ad Volt

Vin

R1 1KΩ

GND

PWM

GND

Load System

Storage System

Control System

Prime Mover

Figure 4: Wiring Diagram of the Voltage Stabilizer.

The wiring diagram of the excitation system in this

study is shown in Figure 4. The excitation system

made has 2 systems with their respective functions

connected to each other. The two systems are storage

systems and control systems. The storage system is

used for charging the battery as an exciter supply in

the control system. The DC voltage output from the

battery will be connected to the supply with the

exciter (buck-boost converter) and at the same time

supply to the microcontroller (Arduino Uno).

The control system in the plan made uses Arduino

Uno as a regulator of the exciter output voltage value

(buck-boost converter). The excitation DC output

voltage on the exciter is controlled by setting the duty

cycle by the microcontroller with the ADC input by

the potentiometer. The DAC output value from the

microcontroller in the form of PWM is obtained from

the conversion of the potentiometer ADC value to the

duty cycle value.

3 RESULTS

In accordance with the purpose of this study, the tests

carried out were testing the synchronous generator

excitation system with no load and electrical load.

Figure 5 shows the testing of the excitation system

circuit in this study.

Figure 5: Excitation System Circuit Testing.

Excitation system testing is carried out by keeping

the AC output voltage value reaching a working

voltage of 110V AC. Table 1 contains test data on the

effect of excitation current on AC output voltage

without loading.

Experimental Study of the Effect of Excitation Current on the Output Voltage of a Self-excited Synchronous Generator

89

Table 1: Zero Load Test with If Setting.

RPM Vf

(V)

If

(A)

V Out

(V)

K (%)

1159 0,00 0,00 11,76 No Excitation

1194 2,00 0,04 21,14 99

1120 2,20 0,05 23,17 90

1297 2,40 0,06 25,60 80

1280 2,80 0,08 25,84 70

1196 3,50 0,12 28,82 60

1059 12,00 0,48 23,48 50

1005 13,10 0,53 23,83 40

1130 13,60 0,54 25,41 30

1114 13,90 0,56 25,40 20

1113 14,20 0,58 26,18 10

1110 14,50 0,58 25,82 0

1275 15,30 0,61 105,20 52

1268 15,70 0,62 107,80 51

1233 15,80 0,63 107,10 50

1291 16,20 0,65 111,10 49

This no-load test was carried out at Alwy's house

which aims to see how the effect of the excitation

current on the AC output voltage. In this no-load test,

the rpm value is maintained in the range between

1000 - 1300 rpm, because the prime mover used is an

electric drill with rpm depending on the stability of

the electric voltage at home. Based on the data in

Table 1, the output voltage will be strongly influenced

by the presence of excitation current according to the

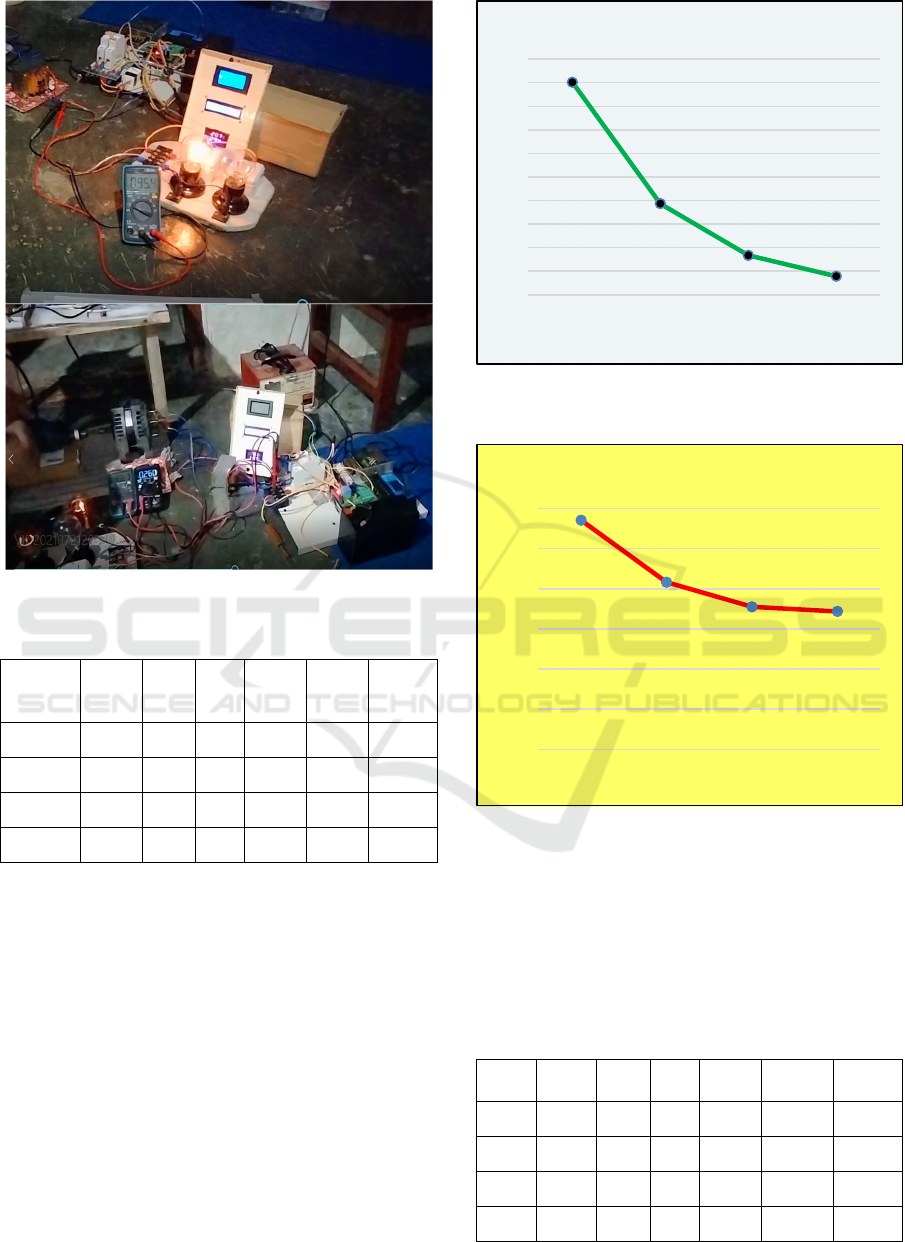

graph in Figure 6 below.

Figure 6: Characteristics of Excitation Current Change to

The Zero Load Generator Output Voltage.

The graph in Figure 6 shows that the output

voltage will increase with an increase in excitation

current. The increase in excitation current will cause

the rotating magnetic field to increase in the rotor.

The rotating field generated by this rotor will then be

induced in the armature coil in the stator which results

in greater magnetic flux. The greater the magnetic

flux changes, the greater the induced emf at the ends

of the coil.

Figure 7: Graph Effect of The Excitation Voltage on The

Excitation Current.

Figure 7 shows an increase in excitation current

caused by an increase in excitation voltage in the

exciter with the duty cycle setting as switching on the

buck-boost converter MOSFET which is regulated by

the microcontroller (Permana & Dewira, n.d.). The

buck-boost converter which acts as an exciter will

provide a DC voltage to generate an excitation current

which makes the field coil on the generator rotor

create a magnetic field. So that in this study attempts

to adjust the value of the excitation current by setting

the excitation voltage because the value of the

excitation resistance is fixed.

The reliability of the generator in producing

electrical energy is also seen from testing the stability

of the output voltage against loading. Figure 8 is a

photo of the excitation system testing with a load

using a 5watt incandescent lamp.

The following table 2 contains the test data for the

excitation system under loading if the excitation

current value is kept constant. The electrical load used

is a 5watt incandescent lamp. This incandescent lamp

is used as an electrical load because it has a good cos

phi compared to other electrical loads.

0,00

20,00

40,00

60,00

80,00

100,00

120,00

V Out (V)

If (A)

If Against V Out

0,00

2,00

4,00

6,00

8,00

10,00

12,00

14,00

16,00

18,00

Vf (V)

If (A)

Vf Against If

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

90

Figure 8: Excitation System Circuit Testing with Lamp.

Table 2: Loaded Test with Constant If.

RPM

Vf

(V)

If

(A)

K

(%)

Ia

(A)

V

Out

(V)

Load

(Watt)

1142,00 14,30 0,59 0 0 90,17 0

832,90 14,30 0,59 0 0,124 38,65 1 x 5

710,40 14,30 0,59 0 0,191 16,71 2 x 5

687,50 14,30 0,59 0 0,224 7,86 3 x 5

The value of the excitation current is kept constant

in order to see the effect of increasing the value of the

load current (Ia) on the value of the resulting output

voltage. The graph in Figure 9 describes the

characteristics of the change in load current (Ia) to the

output voltage.

Characteristics of changes in the value of the load

current (Ia) which is increasing will cause the value

of the output voltage to decrease. In addition, the

increasing value of the load current will cause the

value of the RPM to decrease. The graph in Figure 10

shows a decrease in RPM caused by an increase in

load current.

Figure 9: Load Change Characteristics (Ia) to The

Generator Output Voltage with Constant If.

Figure 10: The Effect of Increasing Load Current on RPM.

Table 3 below contains data from the experimental

results of the excitation system under load conditions

by setting the excitation current value. This experiment

was conducted with the aim of knowing the effect of

increasing the excitation current under load conditions

on the resulting output voltage.

Table 3: Loaded Test with If Setting.

RPM

Vf

(

V

)

If

(

A

)

K

(

%

)

Ia

(

A

)

V Out

(

V

)

Load

(

Watt

)

1175 16,3 0,66 50 0,000 110,40 0

1172 20,6 0,84 46 0,146 95,40 1 x 5

1178 24,7 1,06 36 0,250 90,90 2 x 5

1172 28,9 1,30 0 0,318 89,80 3 x 5

0

10

20

30

40

50

60

70

80

90

100

0 0,124 0,191 0,224

V Out (V)

Ia (A)

Ia Against V Out

0

200

400

600

800

1000

1200

0 0,124 0,191 0,224

RPM

Ia (A)

Ia Against RPM

Experimental Study of the Effect of Excitation Current on the Output Voltage of a Self-excited Synchronous Generator

91

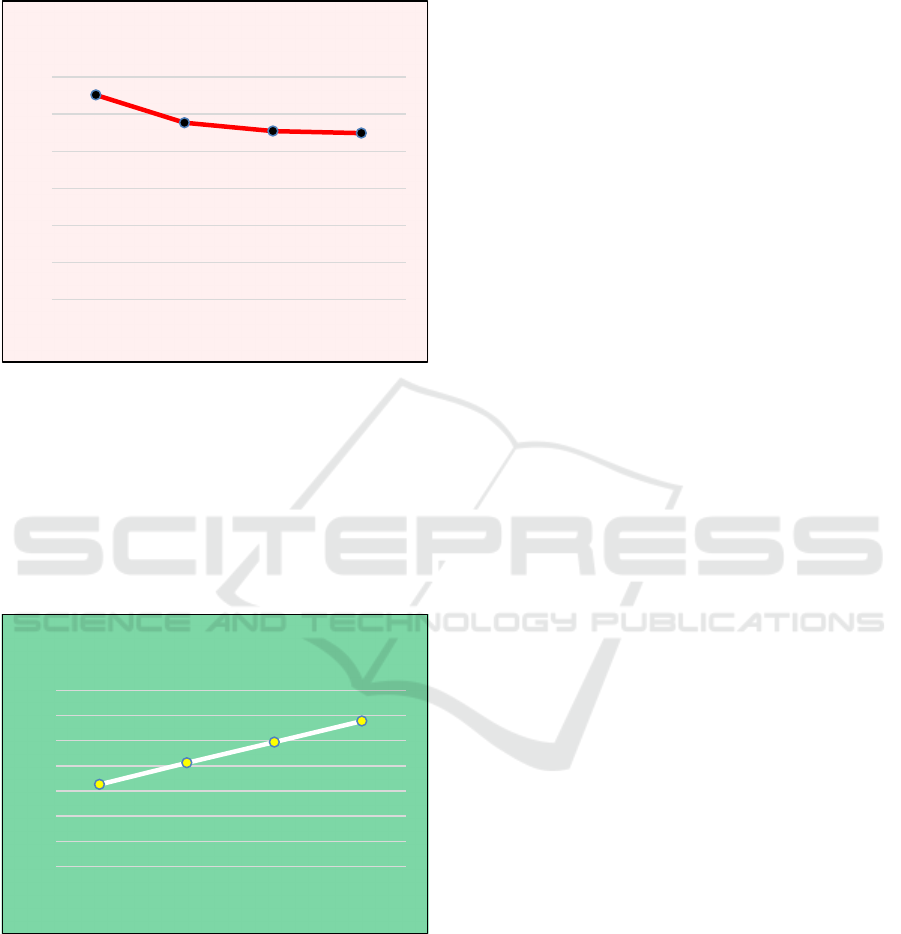

The graph in Figure 11 shows the effect of the

excitation current (If) on the output voltage under

load conditions.

Figure 11: Effect of The Excitation Current on The Output

Voltage in Loaded Condition.

From the graph, the value of the output voltage

will be relatively stable at the condition of the output

voltage value of 80 – 110 V AC when the load current

value increases. This stable output voltage is because

the value of the excitation current is increased

according to the condition of adding a load that causes

the output voltage to drop.

Figure 12: Graph Effect of The Excitation Voltage on The

Excitation Current with Load Changing Condition.

Under loaded conditions, the excitation current

value will give a stable output voltage value. An

increase in the excitation current in this study is

caused by an increase in the value of the excitation

voltage at the exciter. The graph in Figure 12 shows

the condition of an increase in excitation current

caused by an increase in excitation voltage.

4 DISCUSSIONS

Each test performed, the rotation of the synchronous

generator is treated constant ranging from 1000 -

1300 rpm, and it is seen that the increase in the value

of the excitation current in the field winding greatly

affects the generator output voltage. The greater the

excitation is given, the greater the generator output

will be (Boldea, 2016). Excitation current test results

are in line with the following equation:

𝐸𝑓𝑓 𝑛 𝑐 ∅

(1

)

Where:

Eff = ggl effective induced (Volt)

c = constant

n = rotor rotation (rpm)

∅ = magnetic flux (Weber)

If the excitation current value (If) is constant when

the load test is carried out, the voltage value will be

inversely proportional to the addition of the load

current (Ia) (Li, 2019). The higher the load current

value, the lower the output voltage value. The value

of the voltage can be stabilized by increasing the

excitation current in the field coil in the rotor of the

synchronous generator.

5 CONCLUSIONS

Based on the tests and analyzes that have been carried

out, it can be concluded that the output voltage of the

synchronous generator is strongly influenced by the

adjustment of the excitation current given. The output

voltage value of 110 VAC in the zero-load test occurs

when the excitation current is 0.65A while if an

excitation current of 0.04 the output voltage is still at

a value of 21.14 VAC. The generator output voltage

will be directly proportional to the excitation current

value. The addition of the load causes the generator

output voltage to decrease, this shows an inverse

relationship between the addition of the load current

(Ia) and the synchronous generator output voltage.

REFERENCES

Badan Pengkajian dan Penerapan Energi. (2018). Outlook

Energi Indonesia 2018: Energi Berkelanjutan untuk

Transportasi Darat Book. In Badan Pengkajian dan

Penerapan Energi (BPPT) (Issue September).

Baskoro, M. B., & Adiwibowo, P. H. (2017). Uji

Eksperimental Pengaruh Sudut Basin Cone Terhadap

0

20

40

60

80

100

120

0,66 0,84 1,06 1,3

V Out (V)

If (A)

If Against V Out

0

5

10

15

20

25

30

35

0,66 0,84 1,06 1,3

Vf (V)

If (A)

Vf Against If

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

92

Kinerja Turbin Reaksi Aliran Vortex. Jurnal Teknik

Mesin, 05(02), 81–91.

Boldea, I. (2016). The Electric Generators Handbook,

Synchronous Generators, Second Edition (CRC Press).

Fahmi, M. S., & Irwanto. (2020). SUPPLAY EKSITASI

Output Generator 300 Mw Menggunakan Metode Pola

Titik Daya Reaktif. Journal of Mechanical Engineering

and Mechatronics, 5(1), 11–20.

Li, J. (2019). Design and Application of Modern

Synchronous Generator Excitation Systems. Tsinghua

University.

Nugraha, Anggara Trisna, and Dadang Priyambodo.

"Prototype Hybrid Power Plant of Solar Panel and

Vertical Wind Turbine as a Provider of Alternative

Electrical Energy at Kenjeran Beach Surabaya."

Journal of Electronics, Electromedical Engineering,

and Medical Informatics 2.3 (2020): 108-113.

Nugraha, Anggara Trisna, and Dadang Priyambodo.

"Design of Hybrid Portable Underwater Turbine Hydro

and Solar Energy Power Plants: Innovation to Use

Underwater and Solar Current as Alternative Electricity

in Dusun Dongol Sidoarjo." Journal of Electronics,

Electromedical Engineering, and Medical Informatics

3.2 (2021): 93-98.

Nurdin, A., Azis, A., & Rozal, R. A. (2018). Peranan

Automatic Voltage Regulator Sebagai Pengendali

Tegangan Generator Sinkron. Jurnal Ampere, 3(1),

163–173. ttps://doi.org/10.31851/ampere.v3i1.2144

Pambudi, Y. D. S., Rokhmanila, S., & Septian, A. (2020).

Rancang Bangun Generator Magnet Permanen Dan

Generator Induksi Pada Sistem Pltmh. Epic (Journal of

Electrical Power, Instrumentation and Control), 3(1),

45–51. https://doi.org/10.32493/epic.v3i1.3728

Priyambodo, Dadang, and Anggara Trisna Nugraha.

"Design and Build A Photovoltaic and Vertical

Savonious Turbine Power Plant as an Alternative

Power Supply to Help Save Energy in Skyscrapers."

Journal of Electronics, Electromedical Engineering,

and Medical Informatics 3.1 (2021): 57-63.

Permana, S. I., & Dewira, R. F. (n.d.). Pembuatan Kontrol

Arus Eksitasi Pada Modul Automatic Voltage

Regulator Dengan Menggunakan Mikrokontroler. 1–4.

Syahputra, R. (2012). Pengaruh Perubahan Arus Eksitasi

Terhadap Tegangan Keluaran Generator Sinkron.

Jurnal Teknologi, 12(2), 85–88.

Tampubolon, A. P., & Adiatama, J. C. (2019). Laporan

Status Energi Bersih Indonesia. 1–28.

Tim Sekretaris Jenderal Dewan Energi Nasional. (2019).

Indonesia Energy Out Look 2019. Journal of Chemical

Information and Modeling, 53(9), 1689–1699.

Experimental Study of the Effect of Excitation Current on the Output Voltage of a Self-excited Synchronous Generator

93