The Influence of Variation of Electrical Current and Electroplating

Process Time on Coating Thickness, Glossiness and Adhesion of

Copper on Low Carbon Steel

Deny Hendra Cipta and Ismail Ramli

Heavy Equipment Engineering Study Program, Nunukan State Polytechnic, Nunukan, Indonesia

Keywords: Copper, Electroplating, Thickness, Glossiness, Adhesion.

Abstract: The electroplating process is widely used for various purposes, such as; decorative applications, improving

the base material properties such as wear resistance, electrical conductivity, corrosion resistance, and the

dimensions and geometry of a work piece. In this study, testing of the copper electroplating process on low

carbon steel with variations in current strength and processing time was carried out. Electric currents used are

5 Ampere, 10 Ampere, and 15 Ampere. The processing time is 20 seconds, 40 seconds, and 60 seconds. An

acidic copper solution was used as the electrolyte, with a nickel layer as the base coating layer. The plating

results were then tested for thickness, glossiness, and adhesion. Test results show the effects of electrical

current and time on coating quality. 5 Ampere current does not give a significant difference for the value of

thickness, glossiness, or adhesion. While the 15 Ampere current shows symptoms of a too-large current

density, such as dark color and low adhesion. The study shows that paired variations of 10 Ampere current

strength with 40 seconds process time gives the best results, with a thickness of 0.78 microns, a gloss value

of 46 percent, and a coating adhesion of 71.6 percent.

1 INTRODUCTION

The electroplating process is one of the finishing

processes that is often needed in the metalwork

process. Both in the metal industry and machinery

production. The final finishing process varies, some

are simply polished to make it smooth and shiny, can

also be coated with other metals with the aim of

improving the properties of the base metal, some are

painted or varnished or coated with ceramics.

Finishing is also preferred for metals that are easily

corroded. One common method to achieve this

purpose is throuh electroplating process (Kumar et

al., 2015; Purwanto and Huda, 2005).

Copper (Cu) is one of commonly substance used

for electroplating processing. This material is a good

electric and heat conductor. Copper is used as a base

coat because it can cover the surface of the material

being coated and has good leveling ability. A copper

base plating is required for further plating with

nickel which can then, be followed by a chrome,

brass, silver or gold plating. Its characteristic gives

the demanded final products properties. Copper

plating used on plastics, rotogravure rolls, printed

circuit board, semiconductor manufacturing and

also widely used as coating on steel wire to increase

conductivity (12%). Copper can be utilized as

leveling material in electrorefining and

electroforming. It has a decorative value if applied

on the surface and buffed. Coat of copper also can

act as an heat inhibitor in metal selective heat

treatment (Purwanto and Huda, 2005; Dini and

Snyder, 2020; Lowenheim, 1978).

To achieve the purposed uses, the electroplating

results need to have a certain level of quantity and

quality. To be used as an effective conductor

material the plated layer has to be at a certain

thickness. The surface glossiness of the end result is

highly demanded for decorative purposes and also

the layer adhesion strength to its substrate is

important when used as inhibitor in selected parts of

heat treated components. To get a good coating

quality, there are several influencing factors, such as

surface condition of coated base material, coating

anode quality, electrolyte quality, process

temperature, electrical current and process time.

These parameters must be studied to achieve

Cipta, D. and Ramli, I.

The Influence of Variation of Electrical Current and Electroplating Process Time on Coating Thickness, Glossiness and Adhesion of Copper on Low Carbon Steel.

DOI: 10.5220/0010941000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 117-124

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

117

optimum results (Fotovvati et al., 2019; Aygar,

2009).

The modelling and optimization pf copper

electroplating adhesion strength was conducted by

Suryanto et al. (2017). The base material

investigated was stainless steel which coated with

copper through elctroplating with variation in the

copper content in the electrolyte and also variation

of the current density. The adhesion strength was

tested using Teer ST-30 tester. This study finds the

highest current density gives the highest adhesion

strength.

Margen et al. (2018) studied the effect of process

time of 60 seconds, 120 seconds, and 180 seconds

on electroplating nickel layer upon AISI 304

stainless steel and copper with an enhancement from

an ultrasonic batch. The findings of this work tell

that the longest process time gave the highest

thickness number and the conclusion is that the

electroplating process time has a direct relationship

to level of thickness formed on the research test

subject.

The effect of current density on hardness and

thickness properties of copper coating on low carbon

steel has been studied (Sudarsono et al., 2020) This

study varies the current density of 6, 9, and 12

Ampere. The result shows the highest current

density variables gave the thickestcoating layer and

also resulting the hardest copper layer on the test

specimen.

This study aims to understand the effect of some

variables against different aspects and needs from

copper coating quality at the same time. The layer

thickness relates to mechanical properties such as

wear-resistance and hardness. The glossiness value

is directly related to the function of copper coating

as a decorative value enhancer. The adhesion test is

needed to understand the effect of heat and sudden

temperature changes to the durability of coated

copper layer for instance in the use of copper coating

as a barrier in selective heat treatment. Process time

and electrical current are two of the main basic

controllable variables in electroplating process, thus

having a deep understanding about this parameters

would have a great impact on producing quality

coating layer.

2 RESEARCH METHODOLOGY

2.1 Research Method Flowchart

The research flowchart is as shown in Figure 1.

Figure 1: Research method flowchart.

2.2 Preparations

In this stage, activities planning is arranged and the

materials are prepared for the testing and research

activities stage.

2.2.1 Test Design

In this test, there are two variables, the current

strength and processing time. Where for the current

strength variation used is 5 Ampere, 10 Ampere and

15 Ampere. As for the variation of processing time,

the selected time is 20 seconds, 40 seconds and 60

seconds.The material to be coated is low carbon steel

with nickel ,and copper as plating materials.

2.2.2 Equipment

In this study, several equipment and tools were used

for the implementation of activities.

a) Electroplating Process Equipment

The equipment used in this electroplating process

are plate cutting tool, polishing machine, coating tub,

compressor, Ampere meter, rectifier

b) Testing Methods and Equipment

• Layer Thickness Test

The layer thickness test aims to determine the

thickness of the copper deposit layer on the surface of

the workpiece after the electroplating process. The

thickness test here uses the Inverted Metallurgical

Microscope.

• Glossiness Test

This test aims to determine the level of surface

glossiness of the test speciments, which is related to

the decorative value of the results of the

electroplating process. The glossiness test is carried

out using a Lux meter.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

118

• Adhesion Test

This test aims to perceive the adhesiveness

property of the copper electroplated layer on the

surface of substrate material. The test, named heat

quench test [lowenheim] where the testing factor is the

high temperature obtained by heating objects in an

electric furnace and then the speciment subsequently

quenched in water at room temperature. The heat and

sudden temperature changes will affect the strength of

adhesion of the electroplated copper layer to the base

material. The layer’s adhesion strength is measured by

differentiating the percentage of the test specimens

surface area left covered with the copper layer after

the heat quench process. The surface area is calculated

using a transparent millimeter block [3].

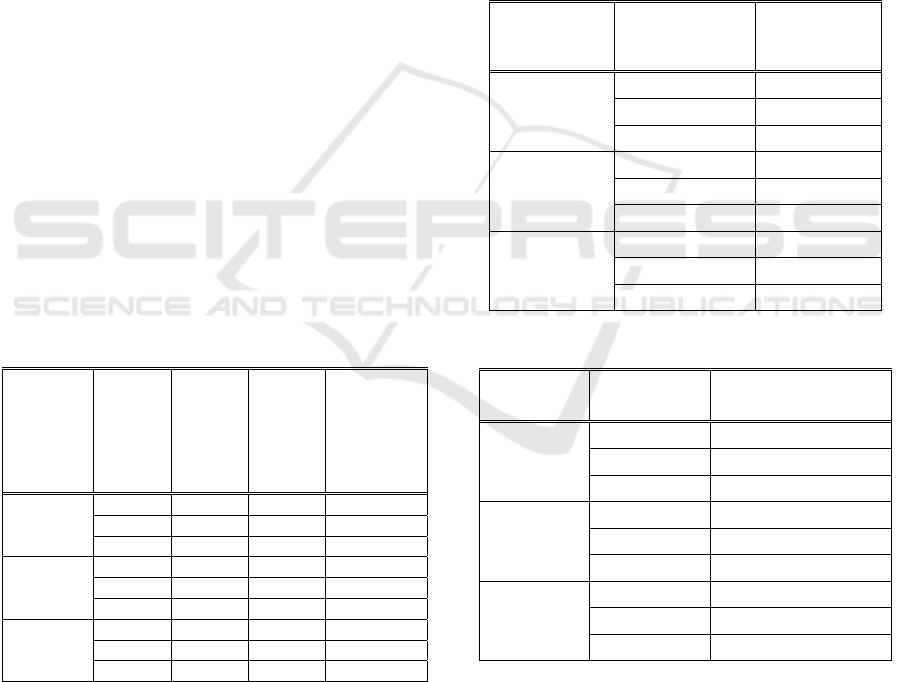

2.2.3 Materials

The coating material (anode) is copper while the

material to be coated (cathode) is a low carbon steel

plate with a size: 50 mm long, 25 mm wide and 2 mm

thick. The dimensions of the test object are shown in

Figure 2.

Figure 2: Test object dimension.

2.2.4 Electrolyte

a) Composition of Nickel Solution

The composition of the solution in 1 litre of

distilled water:

• Nickel sulfate, NiSO4.6H2O = 240 - 300

gram/litre

• Nickel chloride, NiCl2.6H2O = 40 - 60

gram/litre

• Boric acid, H3BO3 = 25 - 40 gram/litre

• Brigthener Magnum SS =2.5 cm3/litre

• Brigthener Magnum AM = 2.5 cm3/litre

• pH 1.5− 4.5

b) Copper Solution Material

The composition of the solution in 1 litre of

distilled water:

• Acid copper, CuSO4 = 195 - 250 gram/litre

• Sulfuric acid, H2SO4 = 45 - 90 gram/litre

• Hydrochloric acid, HCl = 40 – 80 mL/litre

2.3 Method of Data Collection

The data collection for this research was carried out

by conducting experiments on the copper plating

process with different parameters of electrical current

strength and processing time, with the purpose of

understanding the effect of changing these parameters

on the thickness, gloss and adhesion of the copper

layer resulting from the electroplating process. The

results of the data tests are then compiled and

documented. Then an analysis of the interconnections

between the test results and the process parameters is

performed, to obtain conclusions about the research

conducted.

2.4 Electroplating Process

The electroplating process is carried out in several

stages, namely the preparation of electroplating

equpment, the preparation of electrolyte for the nickel

and copper coating, the preparation of the test object,

the nickel and copper electroplating process and the

final finishing process. The coating process is carried

out in 2 steps. The first step is nickel plating, to form

a base layer on the surface of the test object because

acidic copper cannot applied directly over ow carbon.

In the second step, the coating process with an acidic

copper solution. Nickel plating is carried out with the

same process parameters for all test objects, process

time for 10 minutes and 10 Ampere current strength.

The copper plating is performed with variation of

current strength are 5, 10 and 15 Ampere. Variation

in processing time are 20, 40 and 60 seconds.

2.5 Testing

2.5.1 Layer Thickness Test

This thickness test is carried out to determine the

thickness of coating layer after the nickel and chrome

plating process. This test uses a Metallurgical

Microscope.

2.5.2 Glossiness Test

The glossiness test was performed using a Lux meter.

This equipment works by measuring the strength of

light reflection from a source (electric lamp) by the

surface of the test object. As a benchmark of

comparison a mirror was used, assuming that it

reflects the light received by 100 (one hundred)

percent. The power of light is measured in Lumens.

The Influence of Variation of Electrical Current and Electroplating Process Time on Coating Thickness, Glossiness and Adhesion of Copper

on Low Carbon Steel

119

2.5.3 Adhesion Testing

This adhesion test uses a qualitative test with the heat-

quench test method. Where the test object reaches a

certain temperature and then cooled with water

immersion at room temperature. The heating

temperature based on the type of base material and

coating material [3]. In this study the test object is

heated in an electric furnace to a temperature of

250°C.

3 TEST RESULTS AND

DISCUSSION

The data presented in this section are the results

obtained from the research. Consists of the results of

calculations for the electroplating process, data from

the results of thickness test, glossiness test and coating

adhesion test.

3.1 Electroplating Result Data

This research was carried out with variations in the

large current and time of the coating process. In

addition, the weight of the test object is also carried

out before and before the coating process, which

determines the weight of the object at the time it

occurs. The results of the weighing are shown in

Table 1.

Table 1: Actual deposition weight.

Current

(Ampere)

Time

(second)

Initial

weight,

W

0

(gram)

Final

weight,

W

1

(gram)

Actual

deposition

weight,

W

a

= W

1

-

W

0

(gram)

5

20 23 23.02 0.02

40 23 23.02 0.02

60 23 23.05 0.05

10

20 23 23.04 0.04

40 23 23.04 0.04

60 23 23.06 0.06

15

20 23 23.04 0.04

40 23 23.06 0.06

60 23 23.05 0.05

3.2 Calculation of Electroplating

Results

In this section, theoretical calculations are carried out

for the copper electroplating process according to the

parameters of the research carried out.

3.2.1 Calculation of Theoretical Deposit

Weight

From Faraday's Law, the weight calculation at the

beginning of the coating process variable is carried

out. The results obtained are as in Table 2.

3.2.2 Current Efficiency Calculation

By obtaining data on weight at the time of storage and

theoretical storage, it is possible to calculate the

current efficiency of each electroplating process

carried out. Then the current efficiency data obtained

for the electroplating process in this study, which is

shown in Table 3.

Table 2: Theoretical weight.

Current

(Ampere)

Time

(second)

Theoretical

weight, W

t

(gram)

5

20 0,03

40 0,07

60 0,09

10

20 0,07

40 0,13

60 0,19

15

20 0,09

40 0,19

60 0,29

Table 3: Current efficiency.

Current

(Ampere)

Time

(second)

Eficiency

(%)

5

20 66, 67

40 28,57

60 71, 43

10

20 57, 14

40 30, 77

60 31, 16

15

20 44, 44

40 31, 15

60 17, 24

3.2.3 Current Density Calculation

By using Faraday's Law, it is possible to find the large

density that occurs in each coating process variable.

Where the amount of current used is divided by the

surface area of the workpiece. So that separate results

are obtained which are shown in Table 4.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

120

Table 4: Electroplating process current density.

Current

(Ampere)

Surface area

(dm

2

)

Current density

(A/dm

2

)

5 0,28 17,81

10 0,28 35,71

15 0,28 53,57

3.3 Thickness Test Results

Observation of the layer is done visually with the aid

of a microscope. Measurements are made by

comparing the thickness with the scale lines already

on the ocular lens. Measurements are made at 3 points

on each test variables combination, then the

calculated average is taken as the thickness value of

the coresponding test object. The images from the

observations on the microscope is then photographed,

which is shown in Figure 3.

a.) 5 A and 20 seconds, (b.) 5 A and 40 seconds, (c.) 5 A

and 60 seconds, (d.) 10 A and 20 seconds, (e.) 10 A and 40

seconds, (f.) 10 A and 60, (g.) 15 A and 20 seconds, (h.) 15

A and 40 seconds, (i.) 15 A and 60 seconds

Figure 3: Thickness test result images.

Figure 4: Process time vs layer thickness graph.

The thickness value of each test object as shown

in Table 5. From the results of the tests carried out, it

can be seen from the strong influence of the current

coating process. Figure 4 showing the relationship

between current and process, where it can be seen that

the highest thickness is achieved in the 10 Ampere

process with a time of 60 seconds, although at the

same current, 10 Ampere with a time of 20 seconds

and 40 seconds the layer formed is thinner. While in

the process with a current of 5 Ampere there is no

significant difference in layer thickness. This is

because the current density that occurs is not

sufficient to move the copper electrons to move and

increase the pairing effectively.

Table 5: Layer thickness.

Current

(Ampere)

Time

(second)

Thickness

(μm)

Average

thickness

(μm)

point 1 point 2 point 3

5

20 0.63 0.31 0.31 0.42

40 0.31 0.47 0.47 0.42

60 0.63 0.16 0.47 0.42

10

20 0.16 0.63 0.16 0.32

40 0.31 0.31 0.31 0.31

60 0.31 0.31 0.16 0.26

15

20 0.31 0.63 0.63 0.52

40 0.31 0.63 0.31 0.42

60 0.31 0.31 0.31 0.31

3.4 Glossiness Test Results

The degree of glossiness relates to the decorative

function of a coating. The higher the gloss of the

coating, the better the quality of the coating will be.

This test aims to determine the effect of the current

and time of the coating process on the resulting

copper layer. So it is expected to know the best

parameters for maximum coating quality. Lux meter

scale with mirror (for comparison) is 56 lumens,

The Influence of Variation of Electrical Current and Electroplating Process Time on Coating Thickness, Glossiness and Adhesion of Copper

on Low Carbon Steel

121

which the higher the lumens number means the

surface is more bright. The comparison graph of the

glossiness test data for each coating process variable

is shown in Figure 5.

Figure 5: Process time vs glossiness graph.

From Figure 5 it can be seen that the maximum

gloss level is obtained in the coating process with a

current of 5 Ampere and a time of 40 seconds. This is

sufficient because the copper layer formed is still thin,

so the level of gloss is affected by the nickel layer

used as the base layer. Where visually the nickel layer

has a higher gloss than the copper layer. In the coating

process with a strong current of 15 Ampere, the

current density is too high which causes heat that

burns the workpiece so that the layer ages or gets

darker. This causes the level of gloss to decrease. In

addition, gloss is also influenced by several factors,

such as: the level of cleanliness and accuracy of the

initial processing, stirring of the electrolyte during the

process, the content of contaminants in the

electrolyte, the purity of the anode and the influence

of additives.

3.5 Adhesion Test Results

The adhesion strength data was obtained from the

calculation of the surface area of the copper layer that

was still left after the heat-quench test process. Where

the surface area of the object being observed is one of

the widest sides. The dimensions of the test object

are; length = 42 mm, width = 25 mm which give the

surface area = 1.050 square mm.

From the tests carried out, the area of the copper

layer that is still left on the surface of the workpiece

and the percentage of copper layer left is shown in

Table 6.

The graph of the comparison of the data from the

adhesion test results to the coating process time is

shown in Figure 6. From the test results, it is known

that the best adhesion is obtained under coating

conditions with a strong current of 10 Ampere for 40

seconds. One of the reasons for this is because the

Table 6: Remaining coating layer area.

Current

(Ampere)

Time

(second)

Remaining layer

area

(mm

2

)

Adhesion

percentage

(%)

5

20 41 3,9

40 97 9,2

60 36 3,4

10

20 120 11,4

40 750 71,6

60 49 46,7

15

20 525 50

40 90 8,6

60 40 3,9

current density at these conditions is good, resulting

in good adhesion. In the current condition of 5

Ampere and 15 Ampere there is a drastic difference

in adhesive power, both of which are related to the

process current density. It's just that at the condition

of 5 Ampere the current density meets the needs of an

ideal coating process, while at the condition of 15

Ampere the excessive current density results in

saturation of the layer, so that even though it has a

good thickness, the adhesion is low. In addition,

related to the level of glossiness, the pre-treatment

process also affects the adhesion of the coating.

Figure 6: Process time vs adhesion percentage graph.

3.6 Discussion of the Relationship

between Test Results

For the coating process with a current density of 5

Ampere, the layer formed is thin, the adhesion is low

as well as the gloss value. The test results obtained for

each process time also do not show significant

differences. From this it is known that the

electroplating process of copper with a current of 5

Ampere is less effective. Due to the low current, the

covering power of the coating anode is not good

which results in a thin layer and poor adhesion.

Layers that have not been formed properly also affect

the glossiness, so that in this test the gloss value is

lower than the process with other conditions.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

122

In the coating with a current of 10 Ampere, at the

processing time of 20 seconds and 40 seconds, the

layer formed is thinner, although then a layer of

processing time of 60 seconds occurs. If with the

value of gloss and adhesion, the coating process

carried out under these conditions gives the maximum

value, compared to the coating results under other

conditions. It can be concluded that at a current of 10

Ampere it takes longer time to increase the thickness,

the time required for the coating metal to cover the

surface of the workpiece and then develop to form a

layer of coating. With current density in this

condition, will give coating results with good

glossiness and adhesion strength.

In the coating process with a current of 15

Ampere, it can be seen the longer the time the thinner

the layer, as well as the bonding of the layer. This is

due to the large current density which forces the

electrons to move faster than needed, resulting in a

layer on the workpiece, while the growth of the layer

is not perfect which affects the adhesion of the

coating. For a time of 20 seconds, it gets bigger

because the large current affects the formation of the

layer. But as previously explained, the longer the

processing time, the less effective it will be and the

less the coating layer. Large currents also cause

excess heat which causes a decrease in aged colors

and the level of glossiness of the coating. It is very

important to consider the surface area of the

workpiece with the large current being used.

From the discussion carried out, to obtain copper

electroplating results with maximum quality under

existing constraints, 10 Ampere is used with a plating

time of 40 to 60 seconds.

4 CONCLUSIONS AND

SUGGESTIONS

In this the work the study of effect from electrical

current and process time variations in copper

electroplating were carried out. The wide application

of copper electroplating with different quality

characteristic needs, demand a deep understanding

about the process variables. In the limitation of this

study, it can be concluded that the greater current

gave the largest layer deposited. For the level of

glossiness and adhesiveness of the coating, the best

results were obtained under coating conditions with a

current of 10 Ampere for 40 seconds. This shows that

large currents and longer times does not always

provide the best coating quality. Current strength is

related to the surface area of the workpiece which

gives the value of the process current density. Where

in this study, the surface area of the test object is

relatively small so that large currents actually give a

poor final result. Therefore, it is necessary to pay

attention to the surface area of the workpiece to

determine the current strength used. To better

understand the electroplating process, especially with

copper coatings, other studies can be carried out.

Research on other process variables is encouraged,

such as about current density which relates to the

dimension of the object to plated, uses of additives in

the electrolyte, agitation and different electrolyte

bath.

ACKNOWLEDGEMENTS

There are many obstacles in completing this research,

and this work would not have been possible without

the support of several parties. Authors would like to

thank Director of the Nunukan State Polytechnic who

has provided support for completing this research.

Authors also want to thank family and colleagues

who have always supported in completing this

research.

REFERENCES

Purwanto, Huda, S. (2005). Electroplating industry

technology, Badan Penerbit Universitas Diponegoro,

Semarang. pp.7-10.

Kumar, S., Pande, S., Verma, P. (2015). Factor effecting

electro-deposition process. In International Journal of

Current Engineering and Technology, Vol.5, No.2

(April 2015), pp. 700-703. Inpressco.

Dini, J.W., Snyder D.D. Electrodeposition of copper. In

Modern Electroplating, 5

th

Edition, M. Schlesinger and

M. Paunovic, Eds. New Jersey: John Wiley & Sons, Inc,

2010, pp. 33-78.

Lowenheim, F.A. (1978) Electroplating. New York:

McGraw-Hill Book Company, pp.496.

Ivshin Y.V., Shaikhutdinova F.N., Sysoev,V.A (2018).

Electrodeposition of Copper on Mild Steel: Peculiarities

of the Process. Surface Engineering and Applied

Electrochemistry, 2018, Vol. 54, No. 5, pp. 452–458.

Allerton Press, Inc.

Fotovvati, B., Namdari, N., Dehghanghadikolaei, A. (2019)

On coating techniques for surface protection: a review.

In Journal of Manufacturing and Material Processing 3,

2019, No.1:28.

Aygar, A. M. (2009). Investigation on the factors that affect

the amount of metal coated in an electroplating process.

Retrieved from core.ac.uk: https://core.ac.uk/download/

pdf/11725439.pdf

The Influence of Variation of Electrical Current and Electroplating Process Time on Coating Thickness, Glossiness and Adhesion of Copper

on Low Carbon Steel

123

Suryanto, Haider, F. I., Ani, M. H., & Mahmood, M. (2017).

Modelling and Optimization of Copper Electroplating

Adhesion Strength. In IOP Conference Series:

Materials Science and Engineering 204 012017. IOP

Publisihing Ltd.

Margen, S. Y., Sulistyo, S., Nugroho, S., & Nugroho, Y. S.

(2018). Enhancement Surface Coating Stainless Steel

And Copper Using Ultrasonic Batch. MATEC Web of

Conferences Volume 159. EDP Sciences.

Sudarsono, Aminur, Nurjannah, I., Hidayat, & Othman, R.

(2020). Effect of Current Density on Hardness of Low

Carbon Steel Electroplated by Copper, Nickel and

Copper-Nickel. IOP Conference Series: Materials

Science and Engineering, Volume 797. IOP Publishing

Ltd.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

124