Factorial Identification on Surface Hardness of Cut Low Carbonsteel

with Hardening Process using Manganese Minerals Powder

Oktovianus Dharma Rerung, Fransiskus Sapar and Roymons Jimmy Dimu

Dept. of Mechanical Engineering, Kupang State polytechnic, Kupang, Indonesia

Keywords: Factorial, Hardening, Steel Cleavage, Hardness.

Abstract: This study wanted to ensure the diffusion of manganese on the surface of the carbon steel cleavage into the

steel core using high heat with a hardening process and a pack carburizing approach. The purpose of the pack

carburizing process approach is the hardening of the steel surface at high temperatures using manganese rock

powder mineral as a substitute for carbon such as solid charcoal. Previous research showed that the chemical

composition test formed elemental Manganese (Mn) and several other elements on the steel surface from the

pyrometallurgical oxidation and reduction process of manganese rock powder at a temperature of 1000 °C.

The purpose of this test is to determine the factorial effect of steel cleavage surface hardness with factors,

temperature, coal composition, and holding time. Control of chemical composition by using Energy

Dispersive X-ray (EDX). The ANOVA test results show that the percentage of coal has a significant effect

on increasing the hardness of the test sample. Control of chemical composition showed that there was an

atomic diffusion process with increasing levels of carbon (C), Manganese (Mn) and other elements, Silicon

(Si), Aluminum (Al). EDX data information explains that to form a hard steel surface not only by using carbon

but also with manganese rock powder minerals.

1 INTRODUCTION

Developers and seekers of mineral alloy steel will be

interested in discussing the manganese mineral found

on the island of Timor. Not because of the abundant

minerals but also the high content of manganese

(Mn). It is known as one of the best manganese rock

minerals with an Mn content of around 20% -5%

(Panjaitan, 2011). One of these mining locations is the

Koa area and its surroundings in the Mollo Barat

District, Timor Tengah Selatan Regency (TTS) with

a total deposit of 454,123,065.8 m³ (Harjanto, 2011).

There did two types of manganese ores found in the

area, namely manganese layers and manganese

nodules (Idrus et al., 2013). Manganese minerals did

widely distributed in various forms such as oxides,

silicates, carbonates of the most common compounds.

Both types of manganese minerals can be able formed

into powder for this research. In addition to other

technical functions, the function of manganese in

steel is as a special alloy that causes steel to be

friction-resistant, impact-resistant, and has high

hardness. That is why manganese is so important in

the metal or machinery industry. Accordingly, the

manufacturing industry is very interested in

developing new types of technological equipment

that allow the application of methods to modify the

surface of parts by processing them with lower

resources (Skeeba, Ivancivsky and Martyushev,

2021). Previous studies by researchers tried to link

manganese rock powder and high heat. This research

is to ensure the presence of metal between iron and

manganese atoms on the surface of carbon steel with

the help of high-temperature heat with pack

carburizing and pyrometallurgical approaches. Pack

Carburizing is a form of hardening of steel using a

medium containing carbon at a temperature of 800 -

950 °C then quenching quickly. For example,

ordinary gears use AlNas embedding particles, whose

carburizing temperature is in the range of 930–980

°C(Liu et al., 2021). At that temperature in an

environment containing activated carbon atoms,

activated carbon atoms will diffuse to the surface of

the steel and reach a certain depth (Mirantie

Dwiharsanti, 2016). Other tests concluded that the

optimumaustenitizing temperature is about 840◦C for

the test steel(Chen et al., 2021). Pyrometallurgy is a

metal extraction process with heat energy at a general

temperature used in the range of 500 °C-1600 °C

(Wibawa, 2018).

Rerung, O., Sapar, F. and Dimu, R.

Factorial Identification on Surface Hardness of Cut Low Carbonsteel with Hardening Process using Manganese Minerals Powder.

DOI: 10.5220/0010941700003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 167-173

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

167

Previous research with Energy Dispersive X-ray

(EDX) showed the formation of Manganese (Mn) and

several other elements on the surface of steel samples

in the oxidation-reduction process at a temperature of

1000 °C (Rerung, Sapar and Dimu, 2019). Next,

identify the factors that affect the hardnessof the steel

cleavage after receiving the previous hardening

treatment. The purpose of testing steel pieces is to

analyze effect of hardness from the steel surface

towards the steel core. The control variable remains

using the chemical composition with EDX. The

results test will be important to answer industry needs

regarding surface hardening and steel resistance to

friction. The addition of Manganese (Mn) will make

the steel test sample hard, friction-resistant and high-

strength. (Bleck and Haase, 2019). The usefulness of

the processed steel is to produce steel that can work

on various special equipment such as attack-resistant

excavator bucket teeth (Winarto et al., 2019).

The development of heavy-duty manufacturing

technology such as automotive and heavy equipment

has driven the engineering of Advanced High

Strength Steels (AHSS), namely high-strength

manganese alloy steels (SimoneKaar 1,*,

DanielKrizan 2, ReinholdSchneider 1, 2019). The

description of the AHSS data starts from traditional

high-strength steels which include manganese carbon

steel (C-Mn), hardened steel, high-strength free

intergroup steel (HSS-IF), and high-strength low-

alloy steel (HSLA). . The concept of Advanced High

Strength Steel (AHSS) had divided into high strength

steel into conventional HSS and advanced high

strength steel. The strength of AHSS ranges from 500

Mpa to 1500 Mpa as and one of the techniques used

to achieve AHSS is to increase the hardness or tensile

stress using hardening in the form of heat treatment

(Herwandi, 2005).

The next research step is to make a factorial

design. The design of factorial experiments is a

procedure for placing treatments into experimental

units with the main objective of obtaining data that

meet scientific requirements. Thus research can be

measured and strict control inprocesses and methods.

2 METHODOLOGY

This research is a continuation of previous research

that focuses on the interaction of manganese and iron

on the surface of carbon steel with a hardening

approach with pack carburizing and pyrometallurgy.

Furthermore, this study will analyze the diffusion of

manganese from the steel surface into the steel core

by measuring the hardness and analyzing the

chemical

composition of each element. Measuring the hardness

of the cut part of the test sample by selecting the

position of the outermost part of the surface of the

steel shell. The type of penetration that has been used

is Rockwell B with a spherical penetration measuring

1/16". Furthermore, testing the chemical composition

at these points. This is to ensure the influence of

manganese in manganese powder on the hardness of

carbon steel.

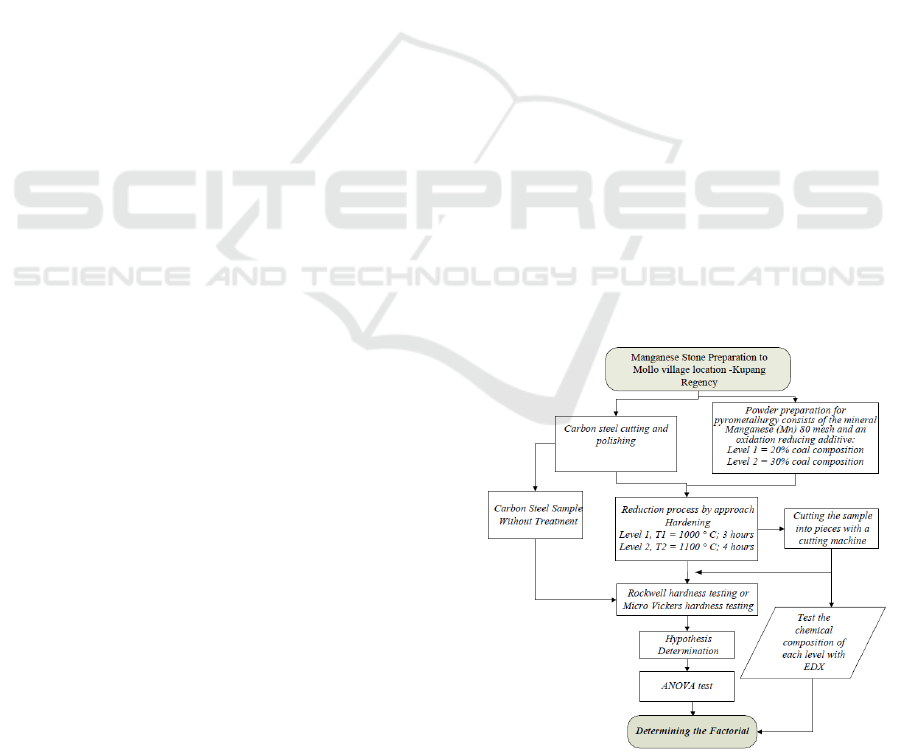

2.1 Flow Chart Diagram

Experimental research tries to explain the benefits of

manganese on the island of Timor (East Nusa

Tenggara) in this study. Another important thing is

the workflow chart from sampling, the methods, to

experimental processes. The description can be

illustrating in a research flow chart. Furthermore,

developing the research with critical thinking with

statistical rules to help find the factors that affect the

hardness of the test sample. Many experiments

involve two or more the factors. This concept creates

a factorial design in which every possible level of a

combination of all the factors will be available.

(Salomon et al., 2017). The design process will place

independent variables with two different levels

namely temperature, holding time, and percentage of

coal catalyst. The dependent variable design is the

hardness value. Factorial designs design concurrent

trials of two or more single trials with two factors

often found in multilocation trials (Lawson, 2016). To

further elaborate the research steps as shown in the

flow chart in Figure 1 below.

Figure 1: Research flow chart.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

168

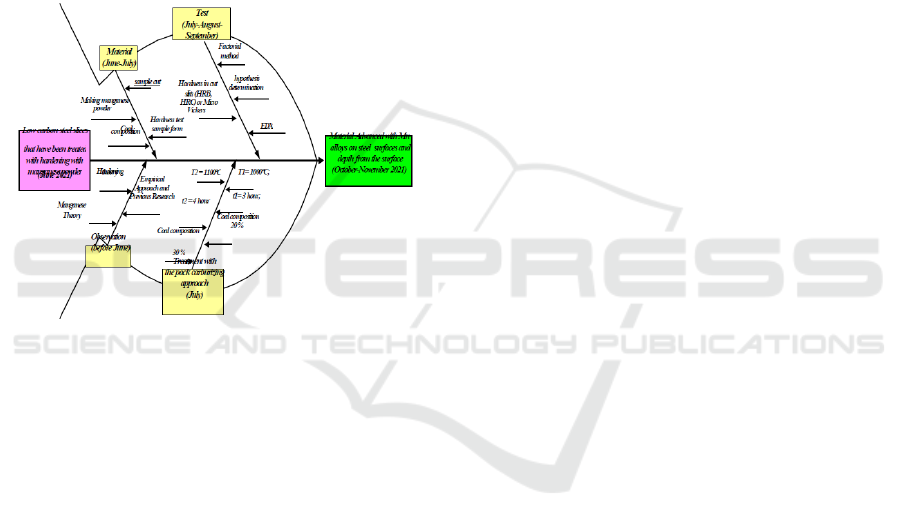

2.2 Research Roadmap

Further explanation of the research explains the

research journey from input to output with a cause-

and-effect diagram. Cause-and-Effect Diagram is a

research Road Map tool that helps identify, sort, and

display the possible causes of a certain quality or

characteristic. (Deshpande, 2008). The diagram

shows the whole concept of thinking by connecting

theory with several methods. These methods are

experimental and statistical with tentative

assumptions. The diagram picture will describe the

research journey from the beginning to the end of the

study. The information displayed is time, process,

cause and effect relationship, and achievement.

Figure 2: Road Map with Cause Effect Diagram.

2.3 Research Design

2.3.1 Research Site

The location was carried out at the Kupang State

Polytechnic Materials Testing Laboratory and testing

of chemical composition and Energy Dispersive X-

ray (EDX) was carried out at the Materials Testing

Laboratory of the Tenth Institute of Technology (ITS)

November Surabaya.

2.3.2 Research Methods

Experimental research may be of three types; Pre

experiment, Quasi experiment and True experiment.

All these types have contrastive characteristics

(Qasim, Imtiaz and Alvi, 2014). Study, experimental,

or research design is the backbone of good research.

It directs the experiment by orchestrating data

collection, defines the statistical analysis of the

resultant data, and guides the interpretation of the

results (Knight, 2010). The experimental design of

the action starts from the preparation of materials,

namely the manufacture of manganese powder, the

manufacture of coal powder, the manufacture of heat

treatment boxes, and the cutting of test samples. All

processes take place with the team by working

directly in the Kupang State Polytechnic Material

Testing Laboratory. The next step is to conduct an

experiment using the true experiment method,

namely a study of the possibility of causality between

the treated group and the untreated control group and

compare the two. The experiment in question is

hardening with pack carburizing and

pyrometallurgical processes. The last step is to carry

out hardness testing and chemical composition testing

with EDX. To explain the factors that affect the

hardness of materials and their interactions using the

factorial experimental method. Factorial

Experimental Method is an experiment that combines

or crosses all certain the factors with each other at the

factor level in the experiments. Factorial

identification will look at the influence of individual

factor and the interaction of the factors on the

measurement of the target object in the study.

Determination of significance with going test the

significant level of the influence of the factors and

their interactions using the ANOVA method. The

ANOVA test used one-way ANOVA with a

significance level (α) = 5%. If F-count < F-table, then

the null hypothesis is accepted and, the first

hypothesis was rejected and, if F-count > F-table,

then the null hypothesis is rejected and, the first

hypothesis is accepted.

2.3.3 Research Variable

Factorial design is probably the most powerful

statistical technique for research into any

manufacturing process for the purpose of quality

improvement (Teow, 2005). This article discusses the

practical aspects of using a full factorial design

optimization of heat treatment variables to increase

the cleavage hardness of carbon steel. Variables The

research variables are arranged as follows:

Independent Variables:

Level 1: Hardening temperature T1 = 1000ºC with

20% coal and holding time 3 hours Level 2:

Hardening temperature T2 = 1100ºC with 30% coal

and holding time 4 hours –

Dependent variable:

Hardness value with Rockwell Hardness on the HRC

scale.

Control variable

Chemical composition test results and Scanning

Electron Microscopy (SEM)

Factorial Identification on Surface Hardness of Cut Low Carbonsteel with Hardening Process using Manganese Minerals Powder

169

3 DISCUSSION

Researchers arrange relationships between variables

according to the concept of causal relationships in the

previous section. If one independent variable affects

the dependent variable, it is call a one-factor

experiment because there is only one modifier. This

kind of relationship is a simple relationship between

variables. The causal relationship will be more

complicated if it is a combination of several factors.

We can say that factorial is an experiment consisting

of two or more independent variables. Two

independent variables that influence is called a two-

factor factorial, and if three independent variables

affect it is called a three-factor factorial and so on. In

this study, three independent factors are considered to

have an effect on the hardness of carbon steel after

hardening treatment, namely temperature (T), holding

time (t), and coal percentage C (%). have been carried

out are as follows:

3.1 Experiment Planning

The response variable is the hardness of the low

carbon steel piece hardened by the pack carburizing

approach. The Factors using three independent

variables, namely temperature holding time and coal

composition. A process is also a form of

pyrometallurgical approach process. Each factor has

two levels with austenitizing temperatures consist of

1000 °C and 1100 °C and holding time factors of 3

hours and 4 hours, respectively. The carburizing

medium uses manganese powder with a coal

percentage of 20% and 30%.

The experimental design table format and the

table of hardness test results on treated carbon steel in

the form of a matrix are as follows:

Table 1: Experimental Design.

Independent Variables: Level

Hardening temperature (T) 1000°C 1100°C

Holding Time ( t ) 3 hour 4 hour

Coal Percentage ( C ) 20 % 30%

One of the reasons for using the table format is

because in carrying out heat treatment tests where the

temperature requires variations in holding time.

Although the format of the relationship between these

variables is quite complex and may not be common,

this study tries to answer the influence of these factors

on the sample test.

3.2 Experiment Execution

In general, pyrometallurgical and hydrometallurgical

processes are two technologies for extracting and

separating metals from minerals to produce refined

metals. Pyrometallurgy is a process that utilizes high

temperatures to chemically change minerals,

separating the desired metal from other materials and

ultimately reducing metal oxides to free metals (Sara

Yasipourtehrani, Vladimir Strezov*, Tim Evans,

2020). The experimental implementation of

hardening and pyrometallurgical processes with a

pack carburizing approach on low carbon steel is

follow the experimental design. The entire test takes

place under strict measurement controls to obtain

accurate data. If you pay attention to the table of

hardness results, it can be see that there is a

distribution of data between the hardness of 95.44

HRB - 106.12 HRB. The data shows there is an

increase in hardness from the original sample, namely

low carbon steel with a hardness ranging from 180

HB ~ 89 HRB. Support theory is the Fe - C phase

diagram at austenite temperatures above 800 C which

shows a diffusion process in carbon steel. Two

elements of the diffusion process into hope are

elements of Carbon (C) and elements of Manganese

(Mn). This provisional assumption will be

meaningful in engineering the properties of steel to

become friction-resistant steel. Friction-resistant steel

is a special steel that is rich in the element

Manganese. The hardness results from the pack

carburizing process can be seen in table 2.

Table 2: Hardness Test Results table.

Treatment

Hardness ( HRB )

Temperature ( T )

1000 °C ( T1 ) 1100 °C ( T2 )

Holding Time ( t )

3 hours (t1) 4 hours (H2) 3 hours (t1) 4 hours (t2)

Treatment Interaction

T1t1 T1t2 T2t1 T2t2

20% (C1 )

1 102,77 96,66 97,69 103,30

2 97,30 102,55 102,10 99,36

3 95,44 102,66 96,46 101,79

coal

4 100,05 99,67 100,12 99,65

composition to

5 99,80 98,93 99,80 102,89

manganese

30% ( C2 )

1 103,90 105,55 104,88 106,12

p

owde

r

2 98,77 99,01 103,44 104,90

3 105,02 103,55 105,77 98,64

4 103,11 105,77 98,99 104,25

5 102,00 100,82 104,50 105,22

3.3 Determination of Hypothesis

H01: There is no significant difference between the

temperature factors in influencing the hardness of

carbon steel

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

170

H11: There is a significant difference between the

temperature factors in influencing the hardness of

carbon steel.

H02: There is no significant difference between

holding time factors in influencing the hardness of

low carbon steel.

H12: There is a significant difference between the

holding time factors in influencing the hardness of

carbon steel.

H03: There is no significant difference between the

percentage of coal factors in influencing the hardness

of carbon steel.

H13: There is a significant difference between the

percentage of coal factors in influencing the hardness

of carbon steel.

H04: There is no significant difference between the

interaction of temperature and holding time factors in

influencing the hardness of carbon steel.

H14: There is a significant difference between the

interaction of temperature and holding time factors in

influencing the hardness of carbon steel.

H05: There is no significant difference between the

interaction of temperature factor and coal percentage

factor in influencing the hardness of carbon steel.

H15: There is a significant difference between the

interaction of temperature factor and coal percentage

factor in influencing the hardness of carbon steel.

H06: There is no significant difference between the

interaction of holding time factor and coal percentage

factor in influencing the hardness of carbon steel.

H16: There is a significant difference between the

interaction of holding time and percentage of coal in

influencing the hardness of carbon steel.

H07: There is no significant difference between the

interaction of temperature factor, holding time and

coal percentage factor in influencing the hardness of

carbon steel.

H17: There is a significant difference between the

interaction of temperature factors, holding time and

coal percentage factors in influencing the hardness of

carbon steel.

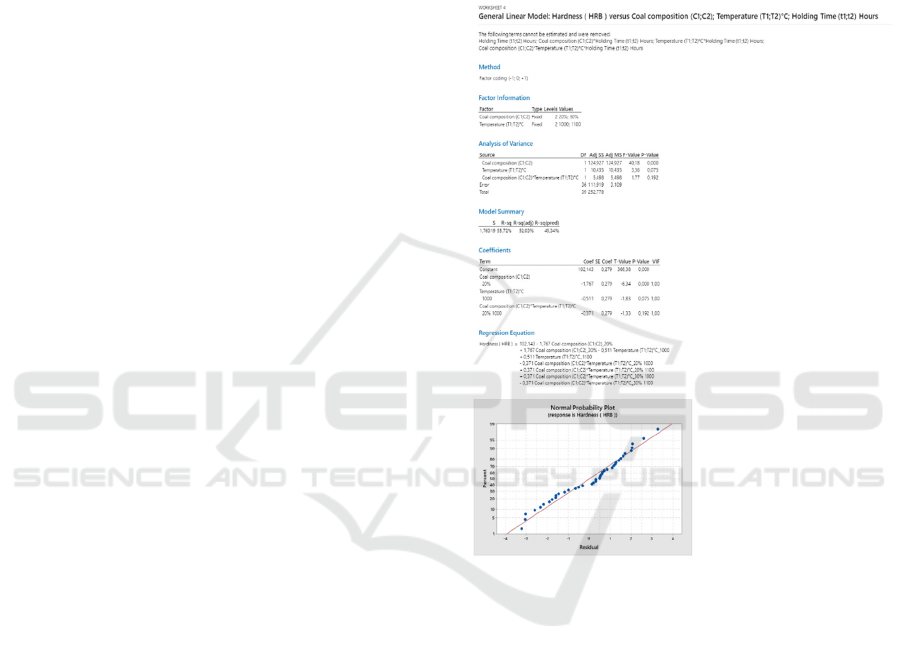

3.4 ANOVA Test

The basis of the experimental trial is a design matrix

with a factorial design. Development of a significant

regression model of process parameters to predict

quality characteristics by Design Of Experiment

(DOE) (Chauhan et al., 2017). The first step is to do

the Normality test before doing the ANOVA test. The

normality test aims to determine: "Is the data

presented is normally distributed or not?". The test

results show a p-value > 0.1 or greater than the 0.05

significance level, then the data can be the key to the

normal distribution as shown in Figure 3. Next,

perform an ANOVA test on the hardness value of the

test sample steel.

The ANOVA test results in the ANOVA table

provide information about three variables as sources

of variation and their interactions that affect steel

hardness. A more in-depth explanation with ANOVA

numbers are degrees of freedom (df), the sum of

squares (SS), mean square (MS), F-count, and F-

table.

Figure 3: Normal Probability Plot.

This test will be more interesting by integrating

experimental design and factorial testing that can

scientifically produce mathematical equations. Then

control it by displaying the results of the chemical

composition test on the hardening steel section as a

test sample.

Furthermore, it will be equipped with more

detailed and complete data and discussions.

The results of the OF Variance Analysis

(ANOVA) test show that coal has a very dominant

effect on the hardness of steel that has been treated

compared to temperature and holding time or its

interactions.

Table 3: ANOVA test.

Source DF Adj SS Adj MS F-Value F-Table P-Value

C (C1;C2) 1 106,341 106,341 17,37 4,1 0

T (T1;T2)°C 1 9,39 9,39 1,53 4,2 0,224

C (C1;C2)*T(T1;T2)°C 1 3,894 3,894 0,64 4,2 0,43

Error 36 220,398 6,122

Total 39 340,023

The effect of coal causes an increase in hardness in

the approach of the pack carburizing process because

coal contains a lot of carbon. Carbon is one of the

elements that increase the hardness of steel. The

treatment temperature above the austenite

temperature in the iron-carbon phase diagram

generally has no significant effect on the test model.

An interesting thing for the study is: "What is the role

of manganese (Mn) or manganese rock powder in the

Factorial Identification on Surface Hardness of Cut Low Carbonsteel with Hardening Process using Manganese Minerals Powder

171

process of increasing the hardness of steel?". To

explain it, let's look at the results of the following

chemical composition test: formed not only with the

elements but also with manganese rock powder in

hardening and pyrometallurgical processes.

3.5 Chemical Composition Test

Chemical Test is useful to support hardness test

results. The chemical composition will provide

information about: "How Manganese can diffuse into

the steel cleavage. It this in line with the expectations

of the research design. Besides Manganese, another b

important element is Carbon (C) for steel hardening.

Table 5 shows the hardness of the Mn diffusion

process. which occurs on a small scale of about 1%

around the point of intersection of carbon steel. In

addition to the elements Mn, there are also elements

of Carbon (C), Silicon (Si), and Aluminum (Al).

Table 4 is the chemical composition of the original

sample of carbon steel shows that no there is an

element of Mn and other additives.

Table 4: Low Carbon Steel Chemical Composition.

El

AN

Series

unn.C norm. C CAtom CError

(wt.%) (wt.%) (at.%) (%)

Fe 26 K-Series 87,36 98,47 93,27 4,1

C 6 K-Series 1,36 1,53 6,73 0,1

Total: 88,72 100,00 100,00

Table 5: Chemical composition of treated carbon steel cut

cleavage.

El

AN

Series

unn.C norm. C CAtom CError

(wt.%) (wt.%) (at.%) (%)

Mn 25 K-Series 24,19 25,30 14,25 1,04

Fe 26 K-Series 55,50 60,79 44,14 2,13

O 8 K-Series 8,30 8,55 28,80 2,88

C 6 K-Series 4,06 4,19 12,60 0,54

Si 14 K-Series 0,15 1,16 0,20 0,00

Al 13 K-Series 0,01 0,01 0,01 0,00

Total: 92,21 100,00 100,00

Observing the treatment gives a strong impression

that the hardening process is going well. The

diffusion process into the steel cleavage is not only

the C element but the Mn element. The Mn element

was importanted in the engineering of specialed steel

materials with the ability to withstand friction and

withstand impact.

Supporting data from the carbon composition test

results found that pursuing steel surfaces can be

formed not only with the elements but also with

manganese rock powder in hardening and

pyrometallurgical processes.

4 CONCLUSIONS

After conducting research and discussion resulted in

several important things as conclusions, namely:

- Hardening factorial design in hardening and

pyrometallurgical processes shows that coal

composition, temperature, and holding time

factors increase the hardness of the carbon steel

cleavage sheath.

- The most dominant factor in increasing the

hardness of steel is the percentage of coal

composition. Coal is a solid mineral that is rich in

carbon.

- Chemical composition test results show the

formation of Manganese (Mn), Carbon (C), in

small amounts of silicon (Si), and Aluminum (Al)

in the steel cleavage sheath.

- The general explanation of this research is that the

steel hardening process by pyrometallurgy shows

an increase in the hardness of carbon steel not

only because of the content ofCarbon (C) but also

the element Manganese (C) as one of the

constituents of alloy steel strength. Manganese

alloy steel is useful for spare parts for heavy work

industrial equipment such as crushers, excavator

buckets, wheel loaders, marine ship plates,

sprockets and so on.

ACKNOWLEDGEMENTS

I would like to thank my fellow research members,

including Mr. Fransiskus Sapar, Mr. Roymonds DJ

Dimu, and two students who have faithfully assisted

in the research phase. We would also like to thank the

head of the materials testing laboratory - Kupang

State Polytechnic (PNK) who helped with several

laboratory tests. Finally, thanks to ICAST and P3M

PNK who helped in the publication.

REFERENCES

Bleck, W., & Haase, C. (2019). Physical metallurgy of high

manganese steels. Metals, 9(10), 1053.

Chen, W. et al. (2021) ‘Microstructure, hardness, and

tensile properties of vacuum carburizing gear steel’,

Metals, 11(2), pp. 1–15. doi: 10.3390/met11020300.

Harjanto, A. (2011) ‘PERHITUNGAN CADANGAN

TEREKA MANGAN (Mn) DI DAERAH KOA DAN

SEKITARNYA, KECAMATAN MOLLO BARAT,

KABUPATEN SOE, NTT’, in PROCEEDING SEMINAR

NASIONAL KEBUMIAN 2011. Available at: http://

psdg.bgl.esdm.go.id/index.php?view=article&cat

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

172

id=52%3Acontent-menu-

utama&id=470%3Apenyelidikan-endapan-mangan-di-

pulau-doi-kecamatan-loloda-

kepulauan&tmpl=component&print=1&page=&option

=com_content&Itemid=475.

Herwandi (2005) ‘Analisa Perubahan Struktur Akibat Heat

Treatment’, Jurnal Teknik Mesin, 7, pp. 57–62.

Idrus, A. et al. (2013) ‘Characteristics and Origin of

Sedimentary-Related Manganese Layers in Timor

Island , Indonesia Sedimen di Pulau Timor , Indonesia’,

8(4), pp. 191–203.

Knight, K. L. (2010) ‘Study/Experimental/Research

Design: MuchMoreThanStatistics’, 45(1),pp.98–100.

Liu, H. et al. (2021) ‘Precipitation criterion for

inhibiting austenite grain coarsening during

carburization of al‐ containing 20CR gear steels’,

Metals, 11(3), pp. 1–19.doi: 10.3390/met11030504.

Lawson, J., & Erjavec, J. (2016). Basic experimental

strategies and data analysis for science and engineering.

Chapman and Hall/CRC.

Mirantie Dwiharsanti, W. S. J. dan S. V. (2016)

‘PERANCANGAN EKSPERIMEN BAJA KARBON

RENDAH HASIL PROSES PACK CARBURIZING

DENGAN METODE EKSPERIMEN DESIGN OF

EXPERIMENT OF LOW CARBON STEEL

RESULTED FROM PACK’, Jurnal Riset Industri Vol.

(2016) 10(2) 92-97, 10, pp. 92–97.

Panjaitan, R. R. (2011) ‘Kajian Pemanfaatan Batu Mangan

/ Senyawa Mangan Dalam Industri’, Berita Litbang

Industri, 48(2), pp. 45–53.

Qasim, S., Imtiaz, Z. and Alvi, U. (2014) ‘Review of True

Experimental Research Studies in Applied Linguistics’,

Research on Humanities and Social Sciences, 4(22), pp.

146–150. Available at: www.iiste.org.

Rerung, O., Sapar, F. and Dimu, R. (2019) ‘Experimental

Design Of Manganese Stone Minerals On Carbon Steel

With Pack Carburizing Approach Using Factorial

Methods’, ICESC 2019, proceeding. doi:

10.4108/eai.18-10-2019.2289977.

Salomon, L. L., Kosasih, W., & Jap, L. (2017). Peningkatan

Kualitas Benang Dty Single 150d/48f Pada Mesin Cone

Wender Menggunakan Metode Six Sigma Dan

Factorial Design Di Pt. Gemilang Texindotama. Jurnal

Ilmiah Teknik Industri, 2(2).

Sara Yasipourtehrani, Vladimir Strezov*, Tim Evans, and

H. M.A. (2020) ‘Macquarie UniversityPURE Research

Management System’, 41, pp. 933–961.

SimoneKaar 1,*, DanielKrizan 2, ReinholdSchneider 1, C.

3 andChristofSommitsch 3 (2019) ‘Effet of Manganese

on the Cavitation.Pdf’. Metals 2019, 9, 1122; doi:

10.3390/met9101122.

Skeeba, V. Y., Ivancivsky, V. V and Martyushev, N. V

(2021) ‘Peculiarities of High-Energy Induction Heating

during Surface Hardening in Hybrid Processing

Conditions’.

Teow, E. L. (2005) ‘Quality Improvement Using Factorial

Design’, Pakistan’s 9th International Convention on

Quality Improvement, pp. 1–7.

Wibawa, A. (2018) ‘TRANSFORMASI MINERAL

PIROLUSIT PADA TEMPERATUR TINGGI

Transformation of Pirolusite Mineral at High

Temperature’, 14(September), pp. 179–186. doi:

10.30556/jtmb.Vol14.No3.2018.682.

Winarto, E. W. et al. (2019) ‘The Improvement of Impact

on Manganese Steel for Bucket Tooth Product’, 2019,

pp. 78–83. doi: 10.18502/kss.v3i23.5138.

APPENDIX

Factorial Identification on Surface Hardness of Cut Low Carbonsteel with Hardening Process using Manganese Minerals Powder

173