Experiment Design for Manufacturing Quality Kitchen Knife

Materials using Carbon Steel with Hard Facing Technology

and Hot Forging Process

Fransiskus Sapar, Oktovianus Dharma Rerung, Roymons Jimmy Dimu

and Abdul Umar Muttaqin

Dept. of Mechanical Engineering, Kupang State Polytechnic, My Street, Kupang, Indonesia

Keywords: Forging, Hard Facing, Hardening, Analysis of Variance, Knife.

Abstract: Forging work is to form metal to produce a final product by providing a compressive force at a certainty

loading speed. Forging at high heat will soften the material when struck with a hammer or by compressive

forces. One of the forging products is a work knife in the kitchen. Production usually has corrosion resistance

and wear resistance. In addition to stainless steel, knives it also made of carbon steel, leaf plate spring steel,

and other heavy equipment steel waste. Manufacture of blades by engineering the addition of metal to parts

with hardened welding technology. The selection of electrodes considers quality by choosing electrodes with

alloy steel compositions such as Manganese (Mn), Chromium (Cr), Silicon (Si). Hard-facing data on two

types of hard-facing material and leaf plate spring steel showed an increase in the hardness of these materials.

Analysis of variance shows the effect of material factors and hardening factors by quenching on the hardness

of the test material. In addition to hardness, the analysis results show the material's resistance to rust. The

influence of the chemical composition of the alloy steel, namely chromium, causes corrosion resistance of the

test material. Another interesting fact thing is the use of control variables in testing between variables. The

variable used is a knife to analyze descriptively under binocular microscope observation.

1 INTRODUCTION

Forging work is a metal forming process by applying

a compressive force with a certain things load rate.

Forging will produce products such as hammers,

chisels, knives, and others. The main principle of

forging is hitting or pressing an object in a hot or cold

state with molds and tools (Rathi and Jakhade, 2014).

There are three type of Forging: Cold Forging, Warm

Forging & Hot Forging. This manufacturing process

of metal shaping can be done through Hammering,

Pressing & Rolling. The General concept of forging

is that the metal is deformed plastically to the desired

Shape by giving a high fatigue resistance and strength

(Ruban and Jayaprakash, 2020). One of the forging

products is a kitchen knife. The basis of knife making

is to prioritize wear resistance (Balkhaya1*, M P

Anhar1, Suwarno2, 2019). Kitchen knives are plays

with important to households, restaurants, hospitals,

and star hotels. Kitchen knives consist of various

types according to their function and quality. The

price also varies from cheap to expensive knives.

People, in general, use a knife with an anti-rust base

material, namely stainless steel. In addition to

stainless steel, it also uses friction-resistant and

impact-resistant materials. Other materials have to

make kitchen knives are: carbon steels, leaf plate

steels, waste steel from heavy pieces of equipment,

and industrial steel that is considered tough.

Considering the pricess of stainless steel and its alloys

is quite expensive, the researchers tried to engineer it

using carbon steel. Carbon steel is commercial steel,

cheap, and available in the market. Carbon steel is

engineered into more special steel by adding alloying

metals to the material side with hard-facing welding

technology. Hardfacing welding uses special

electrodes with chemical compositions of manganese

(Mn), chromium (Cr), and silicon (Si). This electrode

is an FN Mn (E7-UM-200Kp) welding electrode as a

binder in the first layer and the second layer uses a

hard FN 1000 (E-UM-60) welding electrode..

One of the interesting things about this

experimental design is work with hardfacing

technology that is not commonly used for the forging

process but the addition of a hard alloy metal that is

impact-resistant, abrasive, tough, corrosion-resistant

174

Sapar, F., Rerung, O., Dimu, R. and Muttaqin, A.

Experiment Design for Manufacturing Quality Kitchen Knife Materials using Carbon Steel with Hard Facing Technology and Hot Forging Process.

DOI: 10.5220/0010941800003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 174-180

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

(Pradeep, Ramesh and Prasad, 2010). Research is also

working on hardening treatment both in the process

and treatment at the final touch and other tests are

carried out as a measured quality.

Heat treatment is the controlled process of heating

and cooling of metal to alter their mechanical and

physical properties without changing the product

shape. The heat treatment process is defined as

heating a metal at various temperatures, holding them

for various time duration and cooling at various rates,

it helps to improve the machining, formability, restore

ductility after a cold working operation (Khera et al.,

2014).

The measure used as an experimental strength of

the engineered knife material is hardening at austenite

temperature of 900°C with water and diesel cooling.

Carrying out hardness testing after the forging

process and sharpness by observing directly the

sharpening time and the selection of the whetstone

used. The whetstone used is commonly used in the

market ranging from coarse to grit 400 (coarse),

medium grit 1000, normal sharpness with 1200-1500

grit, and fine grit ranging from 3000-10,000 grit.

Binocular microscopic photos were taken on the

sharp blade area with 500x magnification and 10x

zoom to see the shape and morphology of the sharp

blade. The main objective of the research is to

produce advanced quality kitchen knife materials by

engineering hardening, cooling media, material

hardness testing (Hardness Rockwell, HRC), and

cutting tests.

2 METHODOLOGY

2.1 Research Stages

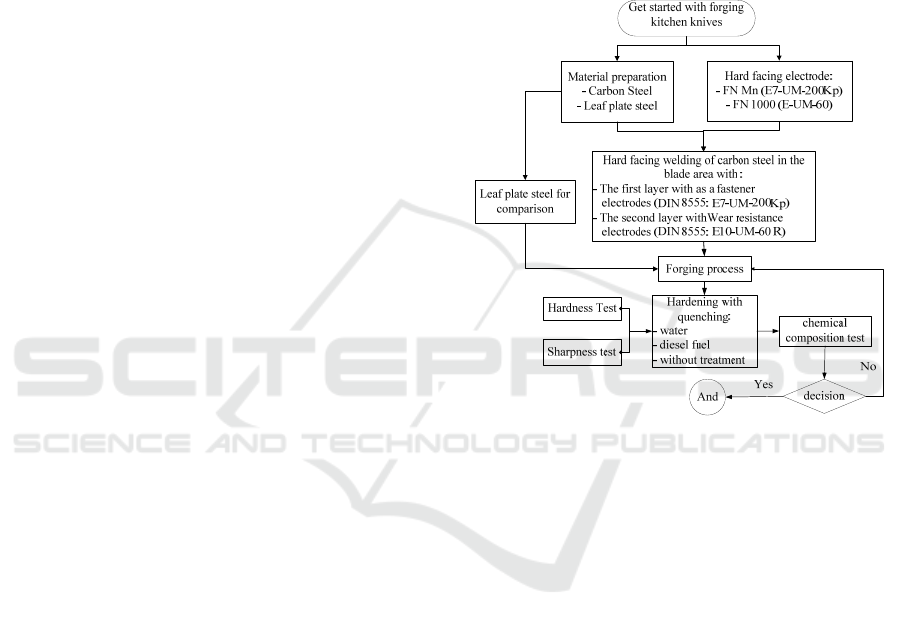

Figure 1, Starting the research by compiling a flow

chart from the beginning to reaching the final goal.

The beginning of already shows the preparation of

materials with the concept of true experimental

research and action experiments. The blade material

is carbon steel with hard-facing welding and leaf plate

steel as the reference material. Leaf plate steel is

special alloy steel whose use for automobile springs

is called leaf plate springs. In general, this type of

waste iron is suitable material for making knives,

even though the price is quite expensive.

Starting from research on how to prepare the main

ingredients for making kitchen work knives by

designing and manufacturing carbon steel coated with

metal alloys, especially those rich in Manganese

(Mn), Chromium (Cr), and Silicon (Si). It further

combines the function of manganese as a hard and

friction-resistant metal with impact-resistant and rust-

resistant Chromium. Corrosion resistant chromium in

composition equal to or greater than 16%. While the

element of silicon is needed to increase the strength

and hardness of steel. This element can stabilize the

carbide formed by the addition of other alloys. To

realize the steel design, welding uses hardfacing

technology, which forms a new metal layer coated

with a hard, strong, friction-resistant, impact-

resistant, and rust-resistant base metal surface.

Figure 1: Research flow chart.

Hard facing must be a composite, with a base

material with high hardness and a coarse

microstructure showing strength (Venkatesh, Sriker

and Prabhakar, 2015). The method used is SMAW

welding method. The first layer is a base layer that

functions as a binder using DIN 8555: E7-UM-200Kp

electrodes which are rich in Mn and Si. Then a second

layer of welding was carried out with DIN 8555: E10-

UM-60 R electrodes with 33% chromium

composition. After the main material is prepared, then

hot forging, straightening and leveling of the

workpiece surface are carried out. Carry out work

carefully and regularly, especially forging, grinding,

and sanding. The basic process is carried out in which

the workpiece is shaped by compressive forces

applied through various molds and tools.

(Engineering, no date) The sequence of work is an

important part of forming a rough knife according to

the desired design. In this process, usually simple

billets are subjected to plastic deformation between

dies during one or more operations (Design, 1995).

Before finishing touch, smooth the part of the

knife to be tested for hardness so that when the knife

Experiment Design for Manufacturing Quality Kitchen Knife Materials using Carbon Steel with Hard Facing Technology and Hot Forging

Process

175

is finished smoothing it does not interfere with the

hardening process with cooling water and diesel fuel,

which are considered as fast quenching media to get

the best hardness results.

Figure 2: Cause-and-effect relationship diagram

design.

After the finishing knife has been formed, then do a

sharpness test by sharpening it according to the grit of

the grinding stone on the market. One thing that is

important is how the quality of the steel is in the knife,

the quality will be seen at the sharp edge of the failure

or not.(Salomon, Kosasih and Angkasa, 2017). The

grit on the market ranges from coarse, medium-fine,

to very fine. The next step is a binocular microscope

with a photo magnification of 500 times and a

magnification of 10 times. The explanation of the

whole research requires a tool, namely a cause-and-

effect diagram in the form of a road map. Figure 2. A

cause-and-effect diagram also known as an Ishikawa

diagram or fishbone diagram. The aim is to identify

and categorize the causes that produce the quality

problems that make them souseful instrument in the

risk identification stage (Masoud Hekmatpanah,

2011).

2.2 Research Design

The research location was carried out at the Kupang

State Polytechnic Material Testing Laboratory.

Forging work by cooperating with a small industry in

the village of Namosain. The research method uses a

true experimental design and action method. True

experimental design research is a type of research that

explains the relationship between the observations of

the treatment group and the control group. We then

discuss three key categories of experimental design:

lab-experiments, quasi-experiments, and factorial

design experiments(Levy and Ellis, 2011).

Next, explain these comparisons closely. Material

cutting, design, and manufacture are hands-on in the

laboratory while the forging process is in

collaboration with blacksmiths at the Namosin

workshop. Scientific analysis by conducting tests,

among others, hardening testing, hardness testing,

testing with microscopic photos and sharpening knife

materials.

2.3 Research Variable

Testing the relationship between variables usually

uses a causal relationship in a sufficient number of

populations. This data uses a tool with ANOVA

analysis. This will be achieved by a statistical analysis

of experimental data using the one-way ANOVA F-

test. The approach of ANOVA test is based on the

breakdown of the total variation within an experiment

into variations due to each main factor, interacting

factors and residual (experimental) error (Joseph and

Alo, 2014). The next discussion is the independent

variables on the dependent variable. Carbon steel that

has received hard-facing welding is then heat-treated

at a temperature of 900 °C with a holding time of 60

minutes. The next step is to dip in two media, namely

water, and diesel. The dependent variable is the

hardness value on the Rockwell Hardness B (HRB)

or Rockwell C (HRC) Hardness scale. The next step

is to control the relationship between these variables.

The control variable is the sharpness of the knife by

describing it in the form of microscopic photos with

1000x magnification using a binocular microscope.

The hope is to produce quality knife material data and

can be used as an alternative to making kitchen

knives.

3 DISCUSSION

The previous discussion mentioned that the

uniqueness of the research causes the relationship

between variables not only to explain in the form of

between variables. The research also explains in the

form of descriptions and narrative descriptions. The

relationship between these variables is the material

for making knives, both untreated and heat-treated for

hardness. This happens to explain the relationship

between variables and support it with images such as

knife sharpness images. The explanation in the

introduction to the discussion above is to better

understand the next series of research.

3.1 Experiment Execution

Experimental planning describes a test that observes

and takes data directly. The results of the hardness

test are presented in table 1 and table 2. In table 1

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

176

shows the data on the material facing forward, while

table 2 is the material that uses leaf plate steel.

Table 1: Material hardness test results with hard facing

welding.

The two tables show the results of hardness tests that

relate the treatment of each material to heat treatment

at 900 C. Cooling is done after a holding time of 60

minutes in a furnace using water and diesel. Given

that the two test materials are in the same test form,

the two data tables are combined to form a factorial

causal relationship. the results of the hardness test

into two levels of material and three factors to form

2x3.

Table 2: Results of hardness test with leaf plate steel material.

Scientific explanations, both processing relationships

between variables and in the form of image

descriptions as shown in the ANOVA results.

The data table from the calculation of ANOVA

and coefficients shows that the variables that have a

significant effect are hardening with water cooling

(Q2) and then solar cooling (Q3). The variable that

also influences is the type of material itself, namely

hard facing (Hf) and Leaf Plate Steel (Lp) materials.

Interactions between factors also influence even on a

small scale. Overall, the appearance of the hardness

data table shows that the original material and the

hardening treatment have a hard material above 45

HRC. The HRC scale is a form of hardness testing

using a sharp conical indenter for hard materials.

Figure 3: Normal curve of two hardness test data.

Table 3: Analysis of variance.

Table 4: Coefficients.

Furthermore, to prove that using the type of material

is quite tough and the type of electrode is hard facing,

let's pay attention to the following table of chemical

composition.

Table 5: Chemical composition of materials and Electrodes.

Table 5 informs the types of electrodes and materials

used in the study. The hard facing electrode type uses

two types of electrodes with specifications E7-UM-

200Kp on the first layer and the second layer with

E10_Um-60 R. The basic material uses carbon steel

with a minimum tensile strength of 370 N/mm while

the comparison material uses Leaf plate spring steel.

The chemical composition of the E7-Um-200 Kp type

electrode contains a lot of Manganese (Mn) which

functions to bind and strengthen carbon steel

materials. In the second layer using hard facing

electrodes containing chromium (Cr) as much as

33%. Chromium functions to make the base material

Hard Facing 900 °C 900 °C

Material (Hf) Without Quenching : Quenching :

treatment(Q1) Water (Q2) Solar fuel (Q3)

1 46,33 60,11 58,33

2 49,86 59,60 51,77

3 45,11 62,35 60,12

4 47,99 59,23 56,25

5 51,40 63,10 52,11

6 47,88 61,11 53,44

7 45,12 62,12 56,77

8 44,89 59,44 51,85

9 47,12 58,77 50,88

10 50,77 60,55 51,35

Hardening

No

Hardness

Leaf Plate (Lp) 900 °C 900 °C

Steel Without Q uenching : Quenching :

treatment(Q1) Water (Q2) Solar fuel (Q3)

1 44,40 55,45 55,45

2 46,76 49,77 49,77

3 45,67 54,30 54,30

4 44,99 52,89 52,89

5 40,56 53,80 53,80

6 47,10 51,55 51,55

7 46,76 48,27 48,27

8 42,10 53,11 53,11

9 43,66 50,44 50,44

10 45,11 49,89 49,89

Hardening

No

Hardness

Source DF Adj SS Adj MS F-Value P-Value

Material 1,00 43,10 43,10 7,59 0,01

Hardening 2,00 843,97 421,99 74,30 -

Material*Heat Treatment 2,00 123,02 61,51 10,83 -

Error 54,00 306,69 5,68

Total

59,00 1.824,86

Term Coef SE Coef T-Value P-Value VIF

Constant 47,647 0,754 63,22 0

Lp -2,94 1,07 -2,75 0,008 3

Q2 12,99 1,07 12,19 0 2,67

Q3 6,64 1,07 6,23 0 2,67

Lp Q2 -5,75 1,51 -3,82 0 3,33

Lp Q3 0,6 1,51 0,4 0,694 3,33

Material

Hardening

Material *Hardening

N o . Ma teria ls Spesification C P S Mn Cr Si Mo

1 FN Mn electrode E7-UM-200

K

1,00 0,02 0,02 12,00 0,40 0,60 0,00

2 FN 1000 electrode E10-Um-60 R

4,30 0,02 0,02 0,40 33,00

3 Carbon Steel Plate ST 37

0,30 0,02 0,02 0,40

4 Leaf Plate Spring Steel Suzuki LJ410

0,60 0,02 0,04 1,20 0,25 0,21 0,88

Experiment Design for Manufacturing Quality Kitchen Knife Materials using Carbon Steel with Hard Facing Technology and Hot Forging

Process

177

tough, hard, friction-resistant, and the layer soft.

Hard-facing electrode hardness above 45 HRC

indicates a material that produces a special 33% Cr

steel alloy that is also corrosion-resistant. The

explanation has described the type of material for

making kitchen knives with special materials.

3.2 Blade Sharpness

The explanation of sharpness measure is still a matter

of debate and eventually becomes a consideration in

two main categories in the definition of what was

sharp. Some have tried to define it as the force

required for the substrate. Other researchers

introduced the idea that points are best measured by

measuring the radius and angle of the cutting edge at

edge under a microscope (Mulder and Scott, 2016).

Until now, there is no standard definition of

measurement or basis for measuring sharpness. The

tip towards the radius was the sharp part and, the

ratings fall into two main categories in their

measurement definition. The judgment is about what

sharpness is. Some have tried to define it as the force

required for the substrate. Other researchers

introduced the idea that the best point in measurement

is to measure the radius and angle of the cutting edge

at edge under a microscope. Multiple points on the tip

radius require measurements to make accurate

characterizations. (Janusz, 2016). To date, there is no

standard definition, measure, or protocol for

measuring knife sharpness. In response to the above,

this study will analyze sharpness level with the

concept of one of the theories that have been put

forward, namely describing the morphology of knife

sharpness descriptively under a binocular

microscope. The results showed that each knife as

shown in Figure 4 and Figure 5. Figure 4 shows the

part towards the corner radius of the knife tip showing

a very rough with a hard surface and shown a brittle

sharpness.

Figure 4: Water quenching blade under a binocular

microscope.

Figure 5: Diesel fuel quenching blade under a binocular

microscope.

Figure 6: Leaf plate steel as a comparison material.

The blade is in the process of heat treatment by

water cooling. Figure 5, The blade that received

diesel fuel quenching shows a rough but slightly

smoother surface than the first blade above. Blade

fingers with even strokes and easier to sharpen the

two-blade received hard-facing treatment but differed

in the use of quenching. The third knife in Figure 6 is

a comparison knife with leaf plate steel material. Leaf

plate steel is alloy steel on leaf plate springs, visible

part towards the spokes with a flat surface, and the

blade has a feel with a diesel cooled second blade. If

we compare the three pictures, it will be seeing that

the first knife looks rougher and toughers by

comparing it with the second knife and the third knife.

4 CONCLUSIONS

There are many interesting things from the results of

the discussion that show several important points as

conclusions, namely:

- The factors that affect the hardness are the type and

specification of the hard-facing electrode, while the

increase in hardness in the hardening test is the

cooling factor with water quenching and diesel

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

178

quenching. The interaction factor between the

material and the hardening treatment also affects the

hardnes on a small scale.How is the hardness of

each knife that has received hard facing treatment

compared to the leaf plate spring steel material.

- Engineered knives that use hard facing welding

materials when compared with leaf steel spring

plate materials have several advantages, namely

resistance of corrosion, tougher, tougher and

smoother blade material surface.

- Descriptive explanation of blade boundaries using

the radius method by observing under a binocular

microscope explains that the use of cooling with

water shows a rougher surface than the material

towards the radius with diesel fuel cooling. The

morphology of quenching with water looks rougher

and hardened, indicating a very sharp knife. If you

compare the two blades with a leaf plate steel

material, the similarity is a knife with diesel fuel

quenching. The surface is slightly smoother and

even.

ACKNOWLEDGEMENTS

I would like to thank my fellow research members

and also to one of the students who helped with this

research. Likewise, those who helped publish by

participating in the ICAST 2021 organizing

conference in Samarinda.

REFERENCES

Balkhaya1*, M P Anhar1, Suwarno2, M. S. M. S. (2019)

‘Investigation of knife quality by using forging and

flame hardening methods Investigation of knife quality

by using forging and flame hardening methods’, 1st

South Aceh International Conf. on Engineering and

Technology. doi:10.1088/1757-899X/506/1/012004.

Design, F. D. (1995) ‘Development of an Intelligent

Knowledge-Based System Mohammad BAKHSHI-

JOOYBARI’, University of Birmingham Research

Archive e-theses repository, (July).

Engineering, H. U. C. of E. D. of M. (no date) ‘Metal-

Forging Processes and Equipment Ch 14’.

Janusz, O. M. (2016) ‘An Evaluation of Modern day kitchen

knives: An ergonomic and biomechanical approach’, p.

63. Available at: http://lib.dr.iastate.edu/cgi/view

content.cgi?article=5974&context=etd.

Joseph, O. O. and Alo, F. I. (2014) ‘An Assessment of the

Microstructure and Mechanical Properties of 0.26%

Low Carbon Steel under Different Cooling Media :

Analysis by one-way ANOVA’, 4(7), pp. 39–46.

Khera, K. et al. (2014) ‘Investigation of the Effects of

Various Heat Treatment Processes on Microstructure &

Hardness with Respect to Corrosion Behavior for

Carbon Steels’, International Journal of Engineering

and Advanced Technology (IJEAT), (6), pp.2249–8958.

Levy, Y. and Ellis, T. J. (2011) ‘Interdisciplinary Journal of

Information, Knowledge, and Management A Guide for

Novice Researchers on Experimental and Quasi-

Experimental Studies in Information Systems

Research’, A Guide for Novice Researchers on Experi-

mental and Quasi-Experimental Studies in Information

Systems Research Yair, 6, pp. 1–11. Available at:

https://core.ac.uk/download/pdf/51072279.pdf.

Masoud Hekmatpanah (2011) The application of Cause and

Effect diagram in the oil industry in Iran: The case of

four liter oil canning process of Sepahan Oil Company,

African Journal of Business Management. doi:

10.5897/ajbm11.1517.

Mulder, J. and Scott, J. (2016) ‘The Measurement of Knife

Sharpness and the Impact of Sharpening Technique on

Edge Durability’, pp. 1–7. Available at: https://r

esearchcommons.waikato.ac.nz/bitstream/handle/1028

9/10004/KnifeSharpnessAndDurability-MulderScott

2016.pdf?sequence=2&isAllowed=y December, 2019.

Pradeep, G. R. C., Ramesh, A. and Prasad, B. D. (2010) ‘A

Review Paper on Hardfacing Processes and Materials’,

International Journal of Engineering Science and

Technology, 2(11), pp. 6507–6510. Available at:

http://www.ijest.info/docs/IJEST10-02-11-046.pdf.

Rathi, M. G. and Jakhade, N. A. (2014) ‘An Overview of

Forging Processes with Their Defects’, International

Journal of Scientific and Research Publications, 4(1),

pp. 2250–3153. Available at: www.ijsrp.org.

Ruban, P. and Jayaprakash, J. (2020) ‘Implementation of

design for manufacturing in hot forging’, IOP

Conference Series: Materials Science and Engineering,

992(1). doi: 10.1088/1757-899X/992/1/012011.

Salomon, L. L., Kosasih, W. and Angkasa, S. O. (2017)

‘Perancangan Eksperimen untuk Meningkatkan

Kualitas Ketangguhan Material dengan Pendekatan

Analisis General Factorial Design (Studi Kasus: Produk

Solid Surface)’, Jurnal Rekayasa Sistem Industri

, 4(1),

p. 20. doi: 10.26593/jrsi.v4i1.1386.20-26.

Venkatesh, B., Sriker, K. and Prabhakar, V. S. V. (2015)

‘Wear Characteristics of Hardfacing Alloys: State-of-

the-art’, Procedia Materials Science. Elsevier B.V.,

10(Cnt 2014), pp. 527–532. doi: 10.1016/j.mspro.2015

.06.002.

Experiment Design for Manufacturing Quality Kitchen Knife Materials using Carbon Steel with Hard Facing Technology and Hot Forging

Process

179

APPENDIX

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

180