Profile of Energy Consumption on Split Air Conditioning at Various

Temperature Controls

I Nengah Ardita

a

, I Gusti Agung Bagus Wirajati

b

, Sudirman

c

and I Dewa Made Susila

d

Mechanical Engineering Departement, Bali State Polytechnic, Bali-80364, Indonesia

Keywords: Split AC, Energy Consumption, Temperature Control, and COP.

Abstract: Split air conditioning is the most widely used in the community for both commercial and domestic purposes.

Air conditioning (AC) systems that work at room temperature conditions that are too low will cause energy

consumption by the compressor to increase. This is often caused by a mistake in selecting the settings on the

Split AC. For this reason, it is important to keep the system working in good comfort conditions, to prevent

wasting energy use by the AC system. This study to investigate the effect of various temperature settings on

split air conditioners on energy consumption and performance system. Data processing is done by using

thermodynamic methods to get compressor power consumption, and coefficient of performance (COP). The

expected result is to prevent wastage of electrical energy consumption. Base on the analysis result shows that

the lower the room air temperature setting, the greater the energy consumption of the system. And that the

lower the set temperature, the greater the energy consumption of the system. Energy consumption increases

by an average of 23.3% for every 2oC decrease in temperature setting. On the other hand, the COP of the

system decreases by an average of 5%.

1 INTRODUCTION

The thermostat in Split AC is a control component to

regulate the working systems based on the desired

room temperature. The thermostat works if the

desired room temperature has been reached, the

thermostat will automatically trigger the AC

compressor to stop working. After the temperature

returns to heat, the thermostat will trigger again to

activate the AC compressor so that the cooling system

works again. Setting the room temperature will affect

how long the cooling system work, and which it will

affect the power consumption of the AC system

(Therese,2011). Several researchers have conducted

research on digital on/off control systems and fuzzy

control. The results show that the digital on/off

control system and fuzzy control provide greater

energy savings when compared to the thermostat

control system. The main results of this study indicate

that by varying the rotation of the compressor motor

and selecting the right control system, it is possible to

a

https://orcid.org/0000-0003-3391-2404

b

https://orcid.org/0000-0003-0761-071X

c

https://orcid.org/0000-0003-2816-523X

d

https://orcid.org/0000-0002-2567-9932

control the room temperature to obtain energy savings

(Henry, 2014 dan 2016).

Another researcher investigated the effect of

thermostat settings on energy consumption in a

household refrigerator. And the results show that the

energy consumption of household refrigerators

increases with higher thermostat settings. The

increase in energy consumption ranges from 17.10%

to 18.65%, depending on the thermostat setting. By

setting a lower thermostat, it can save energy

consumption and also maintain the quality of the

stored product (Edy, 2018).

Nan Wang, 2013, investigated the energy

consumption of air conditioning at different

temperature set points by modelling. To illustrate the

accuracy of this model on energy consumption

measured from the data centre is compared with the

energy consumption calculated from this model with

the coefficient of variation of the root mean square

error between the estimated data and the measured

test data is 11.5%. For air conditioners in buildings,

Nengah Ardita, I., Gusti Agung Bagus Wirajati, I., Sudirman, . and Dewa Made Susila, I.

Profile of Energy Consumption on Split Air Conditioning at Various Temperature Controls.

DOI: 10.5220/0010942300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 203-206

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

203

the thermal control strategy to adjust the temperature

set point is easy to implement and saves energy.

Marco Pritoni, 2015, researched other aspects that

also determine comfort and energy savings in air

conditioners other than the use of temperature control

using a thermostat. The result is that temperature

control determines comfort and energy savings.

Besides, comfort is also influenced by; choice of

clothing, use of windows, instructions for children,

and general perception of thermal comfort.

Aldyanto, 2014, researched an adaptive room

temperature regulation system by integrating an

"indoor positioning system" based on Wi-Fi and a

temperature sensor. The results show that by

integrating an indoor positioning system with a

temperature sensor, you can control the room

temperature butter and increase energy savings. The

positioning system can determine the load more

accurately. Thus the indoor temperature setting can

be better adjusted and can improve energy

consumption savings.

Mohamed Elhelw, 2016, has conducted energy

management analysis for heating, ventilation and air

conditioning systems. The energy saved by using the

modified bin method is higher than the

CLTD/CLF/SCL method. Using the modified bin

method will save energy by 45.57% and while the

other methods will save energy by only 33.42%. The

environmental benefits would also be realized with

energy conservation benefits in the long run.

Manjula Siriwardhana, 2017, investigated the

comparison of energy use between standard air

conditioners and inverter type air conditioners

operated in office buildings. The results show that

using inverter technology can save energy up to 35%

compared to use standard air conditioners.

Satish Parman, 2018, conducted an experimental

study of a simple VCRS cycle and a VCRS cycle with

superheating with the help of a liquid line heat

exchanger. If the evaporator temperature increases

before entering the compressor by 6 0C from (-2 0C

to 4 0C i.e. superheating refrigerant) the COP of the

cycle, and the refrigeration effect increases with the

help of superheating. In general, refrigerant R-134A

gives the best results for the same evaporator

temperature, condenser temperature, and cooling rate

compared to refrigerants R-12 and R-717

(Dharmendra, 2014).

This study will investigate the energy profile of

Split air conditioners and system performance. The

energy consumption profile can be used for energy

conservation in increasing the efficiency of energy

use.

2 METODOLOGY

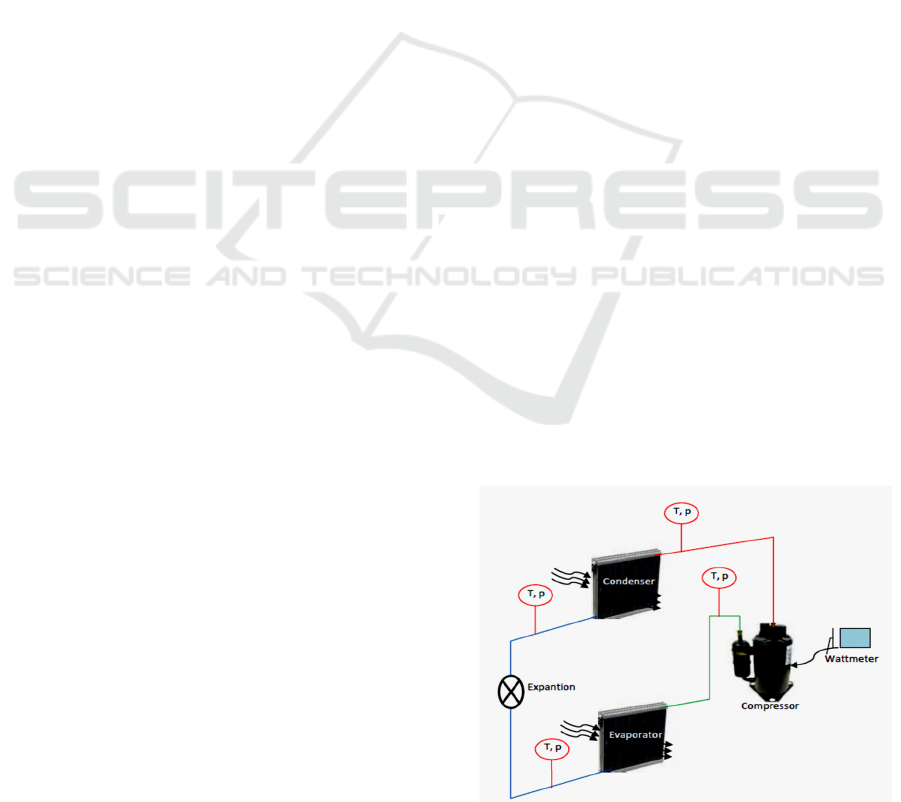

The split type of air conditioning application has a

cooling capacity of 9000 Btu / hr which is made by

Panasonic electric. The sketch of the experimental

equipment design and positioning of the measuring

instrument is shown in Figure-1. Tests are carried out

using refrigerant R32. The observed data include;

refrigeration system pressure, temperature in each

state, current and voltage used, and compressor power

consumption.

A digital AC clamp power analyzer (LT Lutron

DW-6092) use to measure the compressor power

consumption system. Bourdon tube pressure gauge

measures the refrigerant pressure of the out

evaporator which is suitable for the refrigerant system

with the 5. psi accuracy level. In this study, pressure

drops in both condenser and evaporator were ignored

due to the effect on the end of the result was not

significant. The K-type thermocouple records the

temperature in each state of the refrigerant and the air

circulation of the evaporator at predetermined

measurement points.

Based on (Arora, 2011 and Moran, 2004) , the

desired parameter is calculated by using equations (1)

to (4). Equation (1) is used to calculate the

compressor power consumption. Equations (2), (3),

and (4) are used to calculate Mass flow rate, cooling

capacity, and system performance

W

k

= V.I.Cos

ϕ

(1)

m

ref

= Wk/(h

1

-h

2

) (2)

Q

r

= m

ref

.(h

1

-h

4

) (3)

COP = Q

r

/W

k

(4)

In all equations, enthalpy of the out evaporator,

compressor, and expansion are expressed by h

1

, h

2

,

and h

4

consecutively.

Figure 1: Experimental design and instrument tool position.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

204

Experimental data include; energy consumption, low

pressure and high-pressure system, inlet and outlet

temperature of condenser and evaporator. Data

processing is done by using thermodynamic methods

to get compressor power consumption, and

coefficient of performance (COP).

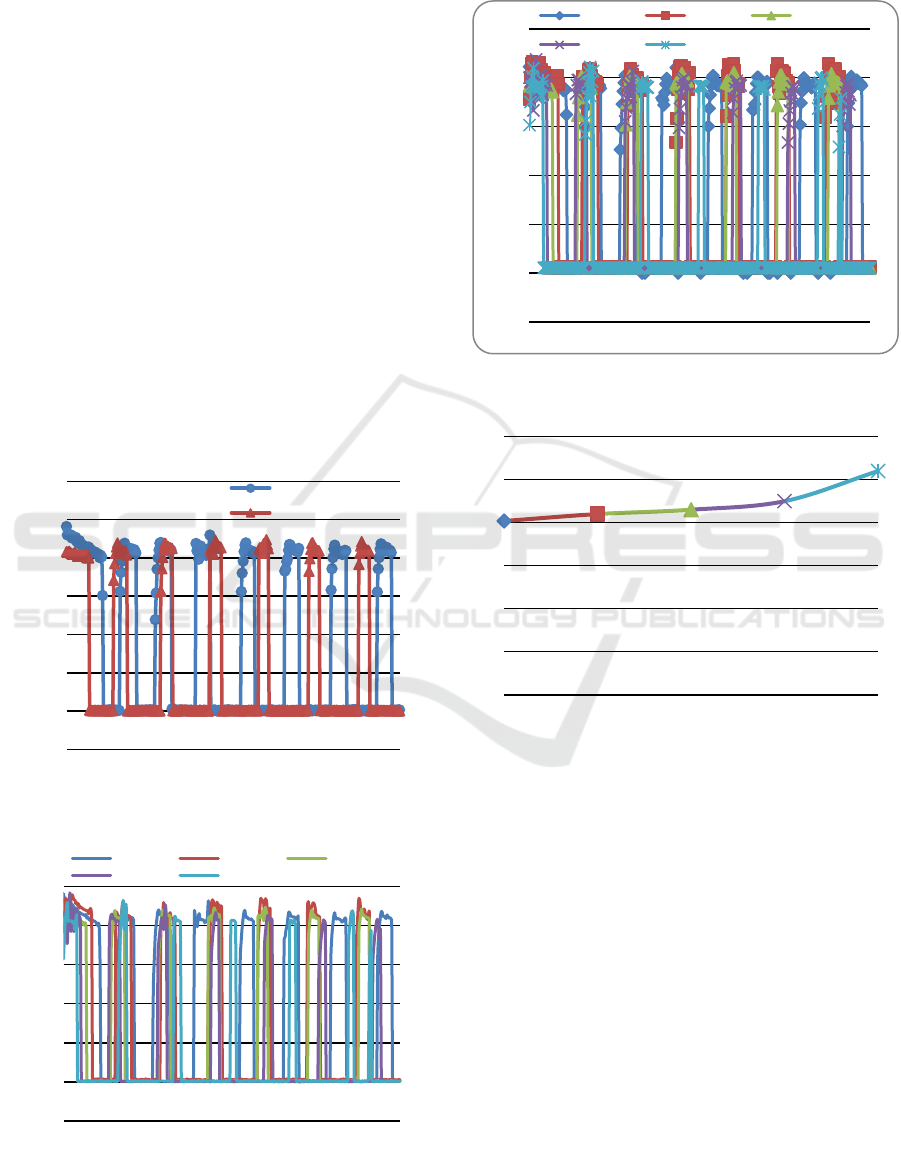

3 RESULTS AND DISCUSSION

The tests carried out have produced data on energy

consumption at various temperature settings, as well

as data on pressure and temperature in the

refrigeration system. Figure.2 and figure.3 shows the

results of floating system energy consumption data

against time. The figure shows that at a low setting

temperature, the operating period of the system is

more than that at a higher setting temperature. In

addition, at a lower set temperature, the system

operating time is longer than the operating time at a

higher setting temperature. This means that at a lower

set temperature the energy consumption is greater

than at a higher setting temperature. Based on the

Figure 2: Graph of System Power Consumption on TS20

and TS24.

Figure 3: Graph of System Power Consumption.

analysis, it was found that for every 2

o

C increase in

the setting temperature, the energy consumption of

the system will decrease by an average of 23.3%.

Figure 4: Graph of system Current on Various Temperature

Settings.

Figure 5: COP on Various Temperature Settings.

Figure 5 shows that the lower the set temperature, the

system performance slightly decreases on average 5%

for every 2

o

C decrease in the set temperature.

4 CONCLUSIONS

Based on this research, it can be concluded that the

lower the set temperature, the greater the energy

consumption of the system. Energy consumption

increases by an average of 23.3% for every 2oC

decrease in temperature setting. On the other hand,

the COP of the system decreases by an average of 5%

for every 2oC decrease in temperature setting.

Power Consumption (kW)

Time (second)

P-TS20

P-TS24

Power Consumption (kW)

Time (second)

P-TS20 P-TS22 P-TS24

P-TS26 P-TS28

Current (I) (Ampere)

Time (second)

I-TS20 I-TS22 I-TS24

I-TS26 I-TS28

COP

Temperatur seting

o

C

Profile of Energy Consumption on Split Air Conditioning at Various Temperature Controls

205

ACKNOWLEDGEMENTS

The authors would like to thank the government of

the Republic of Indonesia, especially the Bali State

Polytechnic who has funded this research. The author

also thanks the head of P3M PNB who has helped

facilitate the writing, implementation, and reporting

of the research.

REFERENCES

Aldyanto R Dicky B, Waskitho Wibisono, and Hudan

Studiawan. 2014. Sistem pengaturan suhu ruangan

yang adaptif dengan Integrasi indoor positioning

system berbasis Wi-Fi dan sensor suhu. Jurnal Teknik

POMITS, Vol 3, no2.

Arora C.P. 2001. Refrigeration And Air Conditioning.

Second edition. Singapore: McGraw-Hill,

Dharmendra Patel, Karanpal Singh, and Jagveer. 2014.

Improving The Performance of vapour compression

refrigeration system by Using Useful Superheating.

International Journal of Engineering Sciences &

Research Technology (IJESRT), pp 5053-5056.

Edy Susanto, M.Idrus Alhamid, Nasruddin, and

Budihardjo. 2018. An experimental investigation into

the effect of thermostat settings on the energy

consumpyion of household refrigerators. International

Journal of Technology, vol 2, pp 364-371.

Henry Nasution, Afiq A Dahlan, Affandi M.Nasib, Azhar

A.Aziz,and Sumeru. 2016. Indoor temperature control

and energy saving potential of split unit air

conditioning system using fuzzy logic controller.

IAENG International Journal of Computer Science,

43:4, IJCS_43_4_01.

Henry Nasution, K.Sumeru, Azhar Abdul Aziz, and

Mohd.Yusoff Senawi. 2014. Experimental study of air

conditioning control system for building energy saving.

Energy Procedia 61, pp 63-66.

Mohamed Elhelw. 2016. Analisys of Energy Management

for Heating, Ventilating and Air-Conditioning Systems.

Alexandria Engineering Journal, vol. 55, pp. 811-818.

Manjula Siriwardhana, and D.D. Ananda Namal. 2017.

Comparison of Energy Consumption Between a

Standard Air Conditioner and an Inverter-type Air

Conditioner Operating in an Office Building. SLEMA

Journal, vol. 20, no. 1&2.

Marco Pritoni, Alan K.Meier, Cecilia Aragon, Daniel Perry,

and Therese Peffer. 2015. Energy efficiency and the

misuse of programmable thermostats: The effectiveness

of crowdsourcing for understanding household

behavior. International Journal of Energy Research &

Social Science, Elsevier, pp 190-197.

Moran Sapiro. 2004. Fundamental of Engineering

Thermodynamic. 5

th

edition. New York. John Wiley &

Sons, Inc.

Nan Wang, Jiangfeng Z, and Xiaohua Xia. 2013. Energy

consumption of air conditioners at difeerent

temperature set points. International Journal of Energy

and Buildings, issue 65, pp 412-418.

Satish Parmar, and Ravindra Randa. 2018 Experimental

analysis of vapour compression refrigeration systems

with superheating by using R134a, R12, R717

refrigerant. International Research Journal of

Engineering and Technology (IRJET), Volume 05 Issue

05, pp 345-350.

Therese Peffer, Marco Pritoni, Alan Meier, Cecilia Aragon,

and Daniel Perry. 2011. How people use thermostats in

homes: A review. International Journal of Building and

Environment, Elsevier, issue 46, pp 2529-2541.

Smith, J. (1998). The book, The publishing company.

London, 2

nd

edition.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

206