Performance Analysis of Monocrystalline and Polycrystalline Solar

Photovoltaic for Solar Water Pump (SWP) System in Indonesia

Rusman Sinaga

1

, Julius A. Tanesab

1

, Marthen D. Elu Beily

1

and Agusthinus S. Sampeallo

2

1

Electrical Engineering Department, State Polytechnic of Kupang, Jalan Adisucipto Penfui Kupang Indonesia

2

Electrical Engineering Department, Nusa Cendana University. Jalan Adisucipto Kupang, Indonesia

Keywords: Solar Water Pumps, Monocrystalline, Polycrystalline, Solar Panel.

Abstract: Solar Water Pumps (SWP) systems have been widely developed, especially in remote rural areas that cannot

be reached by the electricity network of the State Electricity Company. The most common obstacle is that

water supply through the SWP system is still relatively expensive, especially if solar panels are combined

with the use of batteries. This study aims to assess the performance of the water pumping system supplied by

monocrystalline and polycrystalline solar panels without using batteries. The method used in this research is

the observation method by first designing and installing the SWP system using monocrystalline and

polycrystalline solar panels. The results showed that in the use of monocrystalline and polycrystalline solar

panels in the SWP system, the average efficiency of the solar panels was 6.87% and 6.73%, the average pump

efficiency 33.85% and 32.34%, and the global efficiency 2.30%, and 2.17%.

1 INTRODUCTION

Water has a very important role in the development

of any country. It is estimated that an average of 100

liters of water is required per person per day for daily

survival (Theodolfi and Waangsir, 2014). However,

not all rural communities have sufficient water

because they cannot use water pumps sourced from

the State Electricity Company (SEC). The

electrification ratio in Kupang Regency is still 60%.

The average household with no electrical energy

supply is in remote villages that are difficult to reach

by the SEC network (Sinaga R et al, 2019); (Sinaga R

et al, 2017). On the other hand, the current SEC

electricity network mostly uses fossil fuels to

generate electricity.

The use of fossil fuels will increase greenhouse

gas (GHG) emissions so that it hurts the environment,

while the use of solar electricity can support

government programs to reduce GHG emissions. The

Indonesian government GHG emission reduction

target for 2030 is 29% with own efforts and 41% if

there is international cooperation (UURI, 2016).

Solar Water Pumps (SWP) require solar energy as

primary energy to be converted into electrical energy

through solar panels. A solar-powered water pump

system contributes to a clean environment by

reducing carbon emissions (does not use fossil fuels)

(Aliyua et al, 2018).

The intensity of solar energy is optimal in the dry

season in Kupang Regency. In the morning,

afternoon, and evening, solar radiation greatly affects

the energy output of solar panels (Sinaga R, 2011).

The average intensity of solar radiation in East Nusa

Tenggara is 5,117 Wh/m

2

/day (Rahardjo and Fitriana,

2011).

The performance of solar panels in the form of

maximum power output varies with the seasons. At

the end of the summer or dry season, the performance

of solar panels tends to increase. Solar energy is the

best choice for reducing CO2 emissions. (Sinaga R et

al. 2017).

The price of solar panels has decreased, thus

increasing the feasibility of using solar water pumps.

(Foster and Cota, 2014). The price level for installing

PV off-grid systems in Kupang also decreased to the

level of 0.29-0.31 US$/kWh (Sinaga R et al. 2019).

Solar energy is the main variable for operating a SWP

(Nogueira et al, 2015); (Sinaga R and Beily, 2019);

(Sinaga R et al, 2019).

Several aspects of solar energy for SWP have

been studied in the literature. The advantage of DC

water pumps over AC is energy efficiency, while AC

has a longer life and high speed. Belgacem (2012).

stated that the efficiency of water pumps installed in

Tunisia is 20% to 30%. Wade and Short (2012).

Sinaga, R., Tanesab, J., Beily, M. and Sampeallo, A.

Performance Analysis of Monocrystalline and Polycrystalline Solar Photovoltaic for Solar Water Pump (SWP) System in Indonesia.

DOI: 10.5220/0010942600003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 221-226

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

221

optimized the linear actuator design for use as a water

pump system. The results show that the efficiency is

7.8%, and a supply current to the actuator of 6A.

The pump head has a significant effect on the

overall efficiency of the SWP system. Benghanem et

al. (2014), studied the effect of various pump heads

on the overall performance of the SWP system. This

study tested pump heads ranging from 50 m to 80 m.

The results of the analysis show that increasing the

pump head reduces the overall efficiency of the

system.

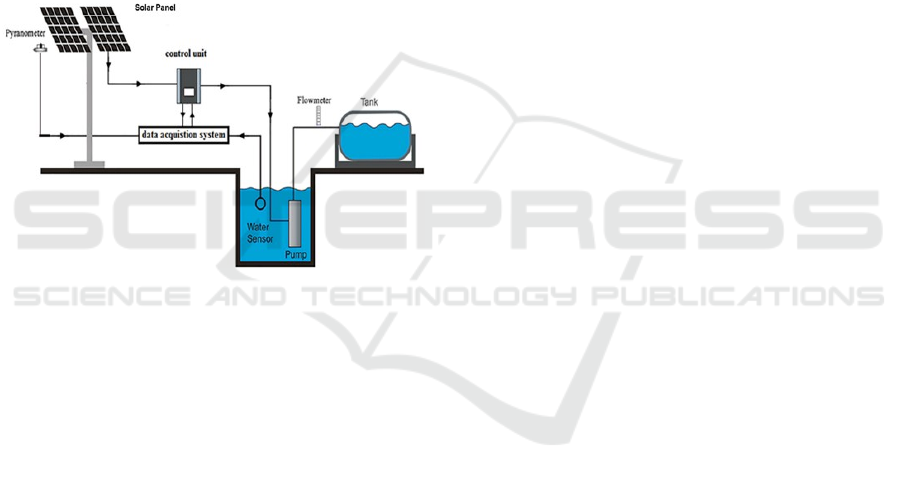

Figure 1 shows a schematic diagram of a common

SWP system consisting of a solar panel, a control

unit, a water pump and a tank. An important

parameter that also affects the performance of the

SWP system is the effective and efficient design of its

control system.

Figure 1: General schematic diagram of the SWP system

(Benghanem et al, 2014).

Campana et al. (2014), recommend a control system

that interacts between water supply and demand.

Supply the required amount of water appropriately by

managing the water supply taking into account water

and groundwater responses resulting in energy

optimization and water savings. Another control

system recommended by Salem et al. (2010) uses a

fuzzy management algorithm to control the

connection period between the solar panel, battery,

and water pump. The results of this study indicate that

by using the fuzzy management algorithm control

system, there is an increase in the use of water pumps

for more than 5 hours.

The design configuration of the SWP system has

been used, including the configuration of DC, AC,

and battery storage systems (Chandel et al, 2015);

(Susanto et al, 2018). Tukiman et al. (2013), have

tested the SWP system using a water pump 550W

220V AC. The test results show that at an altitude of

8 m, the water discharge reaches 3,000 liters/hour.

Priambodo et al. (2019), tested the SWP system using

a 45W12V DC water pump. The results show that at

the height of 4 m, the water discharge reaches 1,912

liters/hour. Sinaga R et al. (2020) have researched DC

SWP using a battery storage system supplied by

monocrystalline solar panels. This SWP system is

considered relatively expensive.

This research is a development of previous

research, especially in the design of the SWP system.

The novelty of this research is the design of the SWP

system with power supply through monocrystalline

and polycrystalline solar panels using the same

capacity to supply submersible water pumps, so that

a more efficient SWP system can be found to be

recommended to users, especially farmers in remote

villages. This SWP system is safer against electric

shock because it uses a DC system.

2 METHOD

2.1 Tools and Materials

The tools used in this study include 1) Digital

multimeter to measure voltage, 2) AC/DC digital

clamp meter to measure current, 3) Digital solar

power meter to measure solar radiation, 4)

Clinometer to measure the tilt angle of the Solar

Panel, 5) Water flow meter, to measure the volume of

water pumped.

The materials needed consist of 1) 2-units of

monocrystalline solar panels consisting of 100 Wp

and 50 Wp 2) 2-units of polycrystalline solar panels

consisting of 100 Wp and 50 Wp, 3) 1-unit DC

Submersible Water Pump 12 Volt, 4) 1-unit

Automatic Voltage Regulator (AVR) DC, 5) 1-unit

panel box with protection coponent and switching, 6)

1-unit metal structure for water tower 2.5 m, 7) 1-unit

water reservoir and 1-unit the water tank, 8) PVC

pipe, joints pipe, and pipe glue, 9) Ball valve, 10)

cables.

2.2 Data Collection Technique

The volume (V) of water pumped is measured using

a digital water flow meter. The difference between the

results of the current hour water volume measurement

and the previous hour reading is the water flow rate

(Q).

Solar radiation (SR) is measured using a solar

power meter. The solar energy produced is the

multiplication of solar radiation with the surface area

of the solar panels per hour. The solar panel energy

output is obtained by measuring the average voltage

and current of the solar panels per hour using a digital

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

222

multimeter and clamp meter. Meanwhile, the energy

consumed by the water pump is obtained by

measuring the average current and voltage per hour

on the water pump. The assembly scheme of the SWP

systems is presented in Figure 2.

1

3

4

5

6

1. Water Tank

2. Flow Meter

3. Water Pump

4. Valve

5. Panel: Switch, Fuse, and AVR

6. Photovoltaic Panel

2

1

Figure 2: Schematic assembly of the SWP systems.

2.3 Data Analysis Method

The data analysis method uses regression and

descriptive analysis to determine: 1) Curve of the

characteristics of solar radiation and the volume of

water pumped, 2) the effect of water flow rate and

energy consumed, 3) the effect of available energy

and consumed energy. Meanwhile, for the average

efficiency of each solar panel, it is obtained using

equation (1) (Nogueira et al, 2015):

ηpv =

ா

100 (1)

Where ηpv is solar panel efficiency (%), Ec is the

energy consumed, and Ae is the available energy.

Pump efficiency is calculated using equation (3):

ηp =

୕ ୦ ଷ

ହ ୍

100 (2)

Where ηp is pump efficiency (%), Q is water flow

rate (m³L

-1

); Mh i the manometric height (m), U is the

water pump voltage (V), and I is the pump current

(A). The manometric height for the reservoir

geometric height of 2.5 m has a suction loss of 0.40

m and a discharge loss of 3.93 m, which is added up

to a manometric height of 6.83 m.

The global efficiency of the SWP system is

obtained from the efficiency of the solar panels and

the efficiency of the water pump, as in equation (4):

ηg =

୮୴ ୮

ଵ

(3)

Where ηg is global efficiency (%).

3 RESULTS

Monocrystalline 100Wp and 50Wp solar panels in

parallel to get sufficient current output to run DC

water pump. Likewise for polycrystalline solar

panels. The placement of the solar Panel arrangement

is presented in Figure 3. The structure of the tower

and reservoir in the SWP test is presented in Figure 2.

Figure 3: Monocrystalline (right) and polycrystalline (left)

solar panels.

SWP testing has been carried out on 26 and 27

July 2021 in Kupang Regency Indonesia. Results

show of the test SWP system used monocrystalline

and polycrystalline that the average volume of water

produced in 3 hours reaches 4,174 liters and 3,898

liters. The water volume and solar radiation curves

are presented in Figures 4 and 5.

In the monocrystalline system, every increase in

Ec 1 Wh, Q will increase by 5.2069 L/h. Regression

equation estimation model Q = 5.2069 Ec - 9.1113

with R

2

= 94.03%, meaning that 94.03 % Q is

influenced by Ec and 5.97% is influenced by other

variables. While in the polycrystalline system, every

increase in Ec 1 Wh, Q will increase by 4.981 L/h.

Regression equation estimation model Q = 4.981Ec -

8.9075 with R

2

= 95.10%, meaning that 95.10% Q is

influenced by Ec and 4.9% is influenced by other

variables. The wter flow rate and energy consumed

by the monocrystalline and polycrystalline systems

are presented in Figures 6 and Figure 7.

Performance Analysis of Monocrystalline and Polycrystalline Solar Photovoltaic for Solar Water Pump (SWP) System in Indonesia

223

Figure 4: Volume of water and solar radiation in

monocrystalline systems.

Figure 5: Volume of water and solar radiation in

polycrystalline systems.

In the monocrystalline system, every 1Wh increase in

Ae, then Ec will increase by 0.069 Wh. Regression

equation estimation model Ec = 0.069 Ae +0.7807. R

2

= 97.82%, its mean 97.82 % Ec is influenced by Ac

and 2.18% is influenced by other variables. Whereas

in the polycrystalline system, every 1 Wh increase in

Ae, then Ec will increase by 0.0673 Wh. The

estimation model of the regression equation Ec =

0.0673Ae + 0.0132. R

2

= 99.18%, meaning that

Figure 6: Water flow rate (Q) and energy consumed (Ec) by

the monocrystalline system.

Figure 7: Water flow rate (Q) and energy consumed (Ec) by

the polycrystalline system.

99.18% Ec is influenced by Ae and 0.82% is

influenced by other variables. The available energy

and the energy consumed are presented in Figures 8

and 9.

Based on equations (1), (2), and (3),

monocrystalline and polycrystalline systems: 1) the

average efficiency of solar panels is 6.87% and

6.73%. The average efficiency of the pumps is

33.85% and 32.34%. The global efficiency is 2.30%

and 2.17%.

Table 1: Efficiency of each panels and temperature range.

Solar Panels

Temperature (

o

C)

ƞ

Pa ne l s

(%) ƞ

Pump

(%) ƞ

Global

(%)

Monocrystalline 42-62 6.87 33.85 2.30%

Polycrystalline 50-60 6.73 32.34 2.17%

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

224

Figure 8: Energy available and energy consumed for

monocrystalline system.

Figure 9: Energy available and energy consumed for

polycrystalline system.

4 CONCLUSIONS

SWP system used monocrystalline and

polycrystalline that the average volume of water

produced in 3 hours reaches 4,174 liters and 3,898

liters

There is an effect of water flow rate (Q) and

energy consumed (Ec). The regression equation

estimation models for monocrystalline and

polycrystalline systems is Q = 5.2069 Ec - 9.1113 and

Q = 4.981Ec - 8.9075. There is an influence of

available energy and energy consumed. The

regression equation estimation models for

monocrystalline and polycrystalline systems is Ec =

0.069 Ae +0.7807.and Ec = 0.0673Ae + 0.0132.

The comparison of the efficiency of the SWP

system using monocrystalline and polycrystalline

solar panels is as follows: The average efficiency of

solar panels is 6.87% and 6.73%. The average

efficiency of the pumps is 33.85% and 32.34%. The

global efficiency is 2.30% and 2.17%. Thus, the more

efficient use of solar panels in the SWP system is

monocrystalline solar panels.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support of

the State Polytechnic of Kupang for financing

through the routine research program 2021.

REFERENCES

Aliyua M, Hassana G, Saida SA, Siddiquic MU, Alawamid

AT, Elamind IM. (2018). A review of solar-powered

water pumping systems. Renewable and Sustainable

Energy Reviews. 87:61–76

Belgacem BG. (2012). Performance of submersible PV

water pumping systems in Tunisia. Energy for

Sustainable Development. 16:415–420

Benghanem M, Daffallah KO, Alamri SN, Joraid AA.

(2014). Effect of pumping head on solar water pumping

system. Energy Conversion and Management. 77:334–

339

Campana PE, Zhu Y, Brugiati E, Li H, Yan J. (2014). PV

water pumping for irrigation equipped with a novel

control system for water savings. Energy Procedia.

61:949–952

Chandel SS, Naik MN, Chandel R. (2015). Review of solar

photovoltaic water pumping system technology for

irrigation and community drinking water supplies.

Renewable and Sustainable Energy Review. 49:1084-

1099.

Foster R, Cota A. (2014). Solar water pumping advances

and comparative economics. Energy Procedia.

57:1431–1438

Nogueira CEC, Bedin J, Niedzialkoski RK, De Souza

SNM, Das Neves JCM. (2015). Performance of

monocrystalline and polycrystalline solar panels in a

water pumping system in Brazil. Renewable and

Sustainable Energy Reviews. 51:1610–1616.

Priambodo VY, Rahmawati R, Aripriharta. (2019). Studi

Perencanaan Pompa Air Tenaga Surya Sebagai

Pengadaan Air Bersih Rumah Tangga. SinarFe. 7-

2:388-392

Rahardjo I., Fitriana I. (2014). Analisis potensi pembangkit

listrik tenaga surya di Indonesia. P3TKKE, BPPT.

11:43-52.

Sallem S, Chaabene M, Kamoun MBA. (2010). Optimum

energy management of a photovoltaic water pumping

system. Energy Conversion and Management. 50:2728-

2731

Sinaga R, Beily MDE. (2019). Model Estimasi Karakteristik

Modul Photovoltaic Polycrystalline dan Monocrystalline

50 Wp. Jurnal Ilmiah Flash. 5(1):10-15

Performance Analysis of Monocrystalline and Polycrystalline Solar Photovoltaic for Solar Water Pump (SWP) System in Indonesia

225

Sinaga R, Tambunan AH, Prastowo, Simangunsong BCH.

(2017). Optimization model of electrification ratio

using solar photovoltaic: case study in Kupang

Regency. Proceeding of Annual South East Asian

International Seminar. 7:7-13

Sinaga R, Tanesab JA, Beily MDE. (2019). The impact of

snail trails and cracks to energy output of photovoltaic

modules at lotas off-grid PV system. Proceedings of the

International Conference on Engineering, Science, and

Commerce (ICESC). EAI. 1:1-8

Sinaga R., Tanesab J.A., Beily MDE. (2020). Rancang

Bangun Pompa Air Tenaga Surya Portabel 3000 Liter

per Jam (PATSP 3000 Lpj). Laporan Hasil Penelitian.

Politeknik Negeri Kupang.

Sinaga R, Tuati NF, Beily MDE, Sampeallo AS. (2019).

Modeling and analysis of the solar photovoltaic

levelized cost of electricity (LCoE) - case study in

Kupang. Journal of Physics: Conference Series. 1364

(2019) 012066: 1-10

Sinaga, R. (2011). Pengaruh parameter lingkungan dan

penempatan posisi modul terhadap luaran energi PLTS

menggunakan solar cell 50 Wp, 12 Volt. 2011. Jurnal

Studia Teknologia. SAINTEK. 4(2):178-187

Sinaga, R. Prastowo, Simangunsong, B.C.H. Leabman, A.

Tambunan, A.H. (2019). Analysis of barriers in

supplying electricity using interpretative structural

modeling. Energy Strategy Reviews. 25:11-17

Sinaga, R. Prastowo, Simangunsong, B.C.H. Tambunan

A.H. (2017). Analisis alternatif solusi penyediaan

sumber energi listrik studi kasus: Kabupaten Kupang.

JTEP. 5(3): 283-290

Susanto DA, Ayuningtyas U, Febriansyah H, Ayundyahrini

M. (2018). Evaluasi Instalasi Pompa Air Tenaga Surya

di Indonesia Dengan Menggunakan Standar IEC

62253-2011. Jurnal Standardisasi 20(2):85-94

Theodolfi R, Waangsir FWF. (2014). Analisis Kebutuhan

Air Bersih Kota Kupang Menurut Ketersediaan Sumber

Air Bersih dan Zona Pelayanan. Jurnal MKMI. 1: 90-95

Tukiman, Santoso P, Satmoko A. (2013). Perhitungan dan

pemilihan pompa pada instalasi pengolahan air bebas

mineral iradiator gamma kapasitas 200 KCI. Prosiding

Pertemuan Iimiah Perekayasaan Perangkat Nuklir

PRPN- BATAN, 14 November 2013

[UURI 16] Undang Undang Republik Indonesia Nomor 1.

(2016). Paris Agreement to the United Nation

Faramework Convention on Climate Changes

(Persetujuan Paris Atas Konvensi Kerangka Kerja

Perserikatan Bangsa Bangsa Mengenai Perubahan

Iklim. Jakarta (ID): Kementerian Hukum dan Hak

Asasi Manusia Republik Indonesia. 16:1-71

Wade NS, Short TD. (2012). Optimization of a linear

actuator for use in a solar powered water pump. Solar

Energy. 86:867–876

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

226