Effect of Waste Valve Tuning on Hydraulic Ram Pump Efficiency

Alexius Leonardo Johanis

a

, Rafael Mado and Hero Preasly Dida

State Politechnic of Kupang, Jl.Adisucipto-Penfui, Kupang-NTT, Indonesia

Keywords: Hydraulic Ram, Pump, Efficiency, Waste Valve.

Abstract: A community that lives far away from an electrical power source has a problem in moving water from lowland

water source location to higher location as their needs, one option to solving this problem is using hydraulic

ram pump whose energy is the pressure that resulted from water hammer effect caused by the sudden stop of

the water flow into the pump through its drive pipe. Some areas have a large quantity of water flow while

others must deal with a limited water source, lead to the need for optimal pump efficiency. In This paper, a

study on the effects of waste valve tuning on the efficiency of three inches sized hydraulic ram pump was

conducted by varying the weight and stroke of the waste valve. From the experiments data and statistic

correlation analysis resulting that both factors influence the efficiency as well as the interaction between them.

The optimal setting for the best efficiency is at 1 kg of valve weight and 10 millimeters of valve stroke, give

70.45 % of efficiency.

1 INTRODUCTION

In many parts of the world, villages are located above

springs: they do not allow water to flow to people's

places by gravity. For example, in the province of

East Nusa Tenggara (NTT) Indonesia, 70 percent of

the population lives upstream of the nearest water

source. A pump is needed to lift water from this

source to their compound (Jeffery et al. 2005), but

another big problem is the limited availability of

electrical energy or fuel to drive the pump motor.

Using hydraulic ram pumps placed on the banks

of rivers or springs, water can be pumped to

agricultural land or water reservoirs automatically

and without additional energy. With a good approach,

the production and use of hydraulic ram pumps in

developing countries will reduce farmers'

expenditures such as fuel and electricity, and

environmental damage can be reduced. The hydraulic

ram pump can operate for years without requiring

maintenance or control making it an ideal system

especially in areas where motor fuel is expensive and

electricity is not available to the pump system.

(Hatipoğlu et al. 2018).

a

https://orcid.org/0000-0002-4156-5505

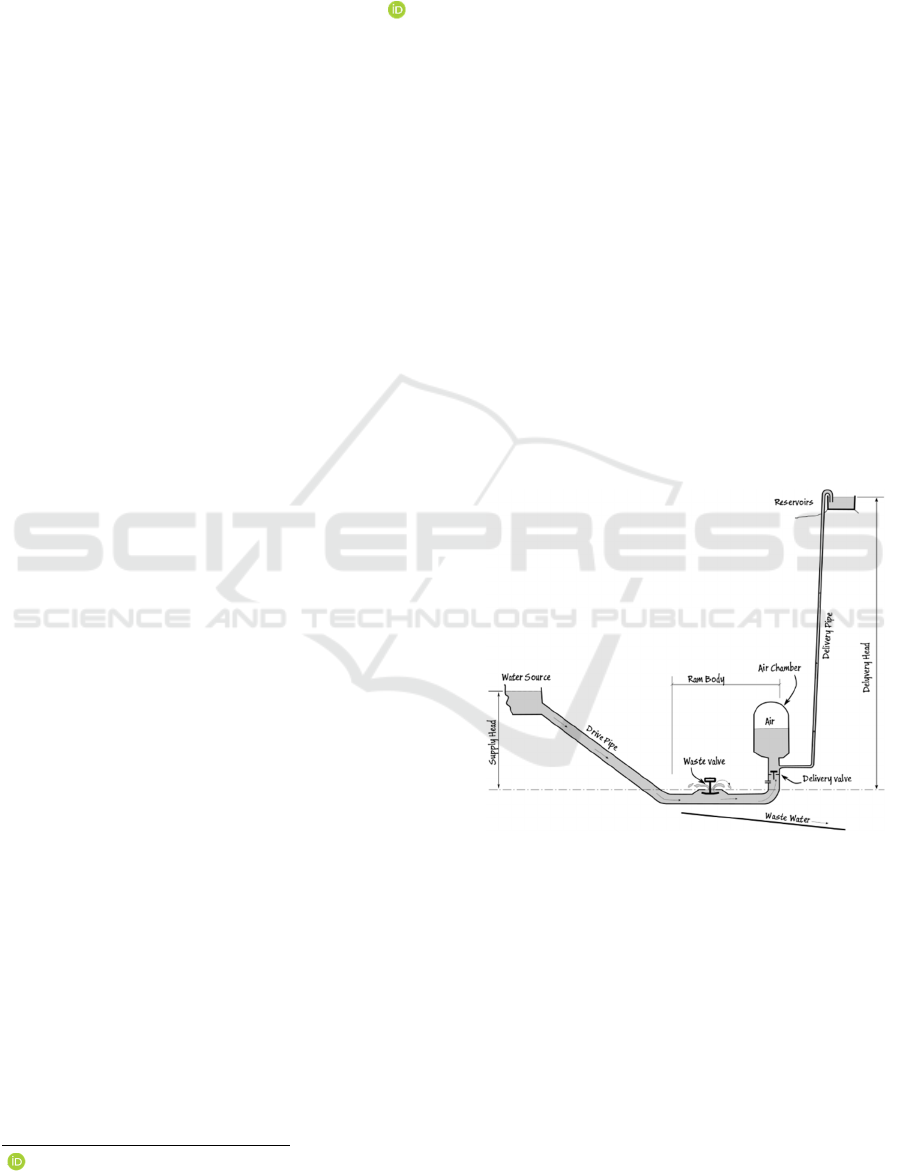

Figure 1: Typical Hydraulic Ram pump arrangement.

1.1 Hidraulic Ram Pump Instalation

As shown in figure 1, the pump works by pumping a

small fraction of water that flows through it from a

supply Source to a level that can be much higher than

the source, it only can be operated in places where

there is a steady and reliable supply of water with a

sufficient fall.

The vertical distance between two water surfaces

is known as the available water "head" and is a

Johanis, A., Mado, R. and Dida, H.

Effect of Waste Valve Tuning on Hydraulic Ram Pump Efficiency.

DOI: 10.5220/0010943000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 237-242

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

237

measure of water pressure. For instance, the Supply

head represents the pressure in the ram body when it

is full of water while not pumping; likewise, the

pressure in the air chamber with the delivery valve

closed is the delivery head. (Watt 1975)

The working cycle of the hydraulic ram pump can

be described as follows; At the start of the

acceleration phase, the flow in the drive pipe is

stationary. The waste valve opens under its weight,

and the delivery valve closes, The flow of water in the

drive pipe is accelerated under the action of the

supply head until the dynamic force that this flow

exerts on the waste valve is sufficient to cause the

waste valve to start closing at a certain critical speed.

At the end of the acceleration phase, the waste valve

closes quickly, and a water hammer phenomenon

occurs. the pumping action takes place as a shock

wave induced by the water hammer which passes

through the drive pipe up and down at the velocity of

the pressure wave and the delivery valve opens in

response to each pressure pulse and water flow is

pumped up into the reservoir. Reversal of flow in the

drive pipe, occurs at the end of the pumping phase

after the delivery valve closes, the resulting suction

from backflow causes the waste valve to open, and

the cycle is ready to start again.(Fatahi-alkouhi,

Lashkar-ara, and Keramat 2019).

1.2 Waste Valve

There are only two moving parts in the Hydraulic ram

pump mechanism, which are the delivery valve and

the waste valve or also known as the impulse valve,

these two valves work alternately and continuously

during the pump operating time.

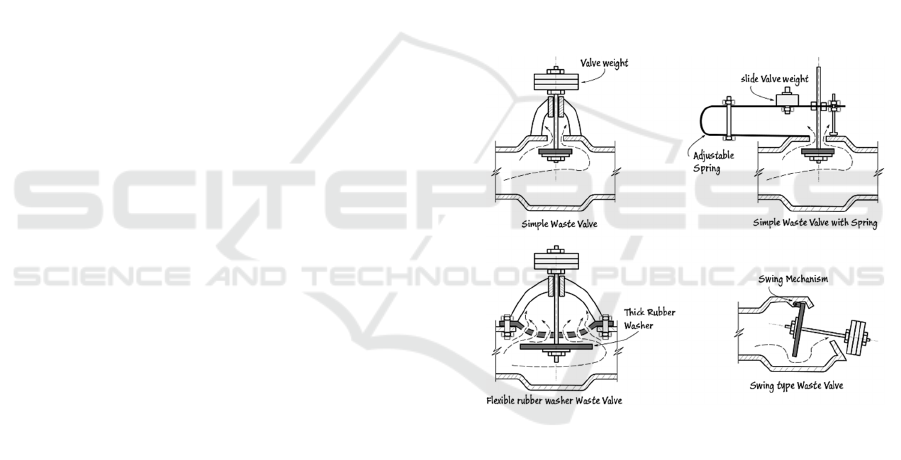

There are several developments and researches

that have been carried out on the construction of

waste valves; Some of them are Simple weighted

Waste valve, Spring type, Rubber washer type, and

Swing mechanism waste valve (Fig.2)

The Flow Pattern in the hydraulic ram pump is

significantly influenced by the diameter of the orifice

and disc of the waste valve(M. Suarda, Sucipta, and

Dwijana 2019), The increase in waste valve beat rate

per minute tends to reduce the supply flow rate,

delivery flow rate, and delivery head. But it tends to

increase the head ratio, flow rate ratio, and overall

pump efficiency(Asvapoositkul et al. 2019), pump

capacity is also affected by the weight of the waste

valve(Setyawan and Siregar 2015)(Suwandi 2015),

the effect of Waste Valve Height and Pressure

Chamber Height is found significant on both mean

and variance of the response variable (delivery flow

rate) (Sarma et al. 2016), All of the waste valve design

parameters for instance valve orifice and disc

diameter, valve mass, and valve stroke significantly

influence the performance of hydraulic ram pumps

such as delivery flowrate and total efficiency of the

hydraulic ram pump system. (Made Suarda et al.

2018).

Nowadays hydraulic ram pump technology is

starting to be promoted again in line with efforts to

utilize new renewable energy-based technology,

many people design and assemble their own simple

hydraulic ram pumps using pipe connections and

check valves as a substitute for artificial valves, on

one hand, this method is very practical and cheap but

the drawbacks are it is not possible to adjust the waste

valve to optimize pump performance.

This research aims to determine the effect of

adjusting the weight and stroke length of the waste

valve on the 3-inch hydraulic ram pump working

efficiency.

Figure 2: Types of Waste valve construction.

2 METHODS

2.1 Experimental Setup

Experiments were carried out by operating 3 inches

sized hydraulic ram pump at sufficient water as

shown in fig. 3, Simple model is used to varying the

stroke length and weight of the waste valve (fig.4)

and then measuring the wastewater flow and

delivered water flow (fig.5), hydraulic ram pump

installation as described in Tabel 1 and Table 2.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

238

Figure 3: Operating 3-inch Hydraulic Ram pump.

Figure 4: Waste valve weight and stroke length.

Table 1: Installation Arrangement.

Drive Pipe Delivery Pipe

Vertical height (head) 4.5 m 14 m

Inner Diameter 50 mm 25 mm

Length 6 m 18 m

Material GIP GIP

Figure 5: Delivered water flow measurement.

Table 2: Experiment Variables.

Variables Value

Waste Valve Stroke

5mm, 10mm, 15mm, 20mm,

25mm, 30mm, 35mm, 40mm,

45mm, 50mm, 55mm, 60mm.

Waste Valve Weight

1kg, 1.5 kg, 2kg, 2.5kg, 3kg, 3.5kg,

4kg, 4.5kg, 5kg, 5.5kg, 6kg

Waste Valve pulse

(beat)

Beat per minute (BPM)

Efficiency D’Abbusion (%)

2.2 Calculation and Analysis

The calculation of the hydraulic ram pump efficiency

(%) is taken from the ratio of the Supply head and

Supply water flow rate to the delivery head and

delivered water flow rate which is expressed in D,

Aubusson equation as follows;

()

HQQ

HQ

w

d

∗+

∗

: E

(1)

A ten liters water bucket and a stopwatch were

used to measure the wastewater flow rates by three

repetitions for each measurement, the same method

was used to measure delivered water flow rate while

using an eight liters water bucket.

Head Losses calculation in the pipe system also

included using the Hazen Williams formula, for the

friction head losses calculations the following

formula was carried out ;

L

D

C

Q

hf ×=

85,485,1

85,1

666,10

(2)

Where hf is the head losses because of friction

inside pipes (m), C is the Hazen Williams coefficient

and in this research using 120 as for galvanized iron

pipes, D is the inner diameter of pipes (m), dan L

stands for pipes length (m). Minor head losses are

also included in the considerations by using the

following formula;

g

V

Khm

2

2

2

=

(3)

Where V is the water velocity inside the pipes (m/s)

and K is the minor losses coefficients as shown in

Table 3.

Effect of Waste Valve Tuning on Hydraulic Ram Pump Efficiency

239

Table 3: Minor Head Losses Coefficients.

Pipe Accessories

K Value

Pipe Entrance 0.56

Gate Valve Fully opened 0.19

900 Pipe turn/ Elbows 1.5

Delivered water flow data was also used to calculate

the total headloss at the delivery pipe while the sum

of pumped water flow and the wastewater flow was

used to calculate the drive pipe total headloss. The

supply head is calculated by subtracting the static

supply head by the total headloss of the drive pipe,

while the delivery head was by adding the total

headloss to the static head measured.

Statistical analysis was carried out on the

experimental data to show how much influence the

waste valve tuning has on the efficiency of the

hydraulic ram pump, Statistical tests including a

simple Bivariate Correlation test and a partial

correlation test of Pearson Product moment as well as

a multiple correlation test, Microsoft Excel was used

to assist analytical calculations.

3 RESULT AND DISCUSSION

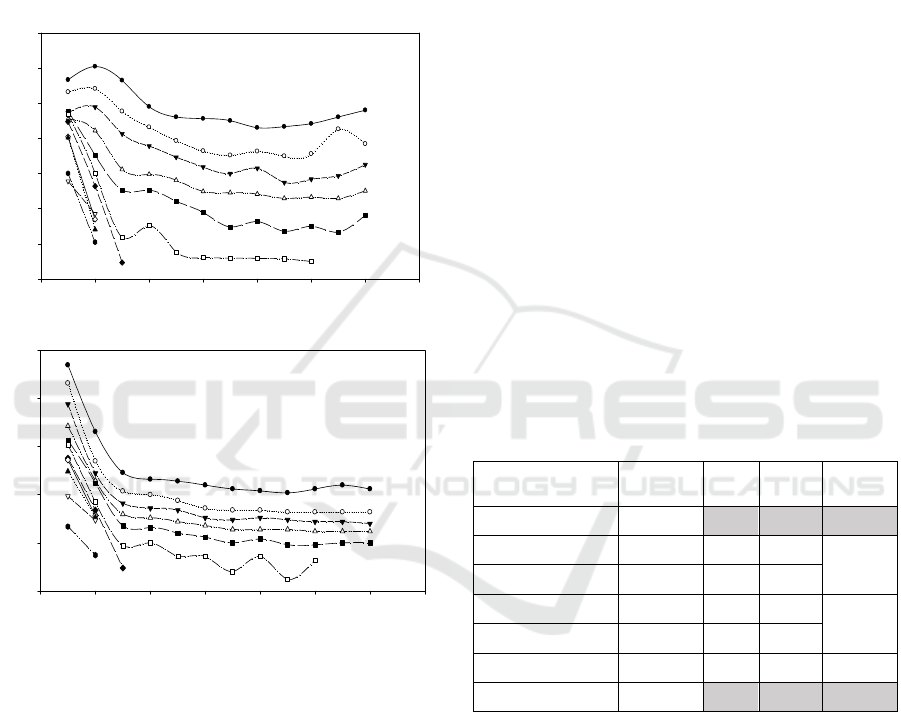

3.1 Presentation of Experimental Data

All experimental data were shorted and tabulated to

construct graphs that show the influence and

interaction between test variables as shown in fig. 6

and fig. 7.

From the experimental results, it turns out that the

pump is only able to operate on a part of the

combinations of weights and stroke lengths of the

waste valve, while in adjustments with certain

combinations the waste valve cannot close so that no

pumping step occurs, this is illustrated in Table 4. of

the pumping water flow measurement data where

empty cells are indicating the pump is not working, it

could happen when the waste valve stroke is set to be

long enough so the bottom side of the waste valve

reaches the large chamber inside the pump body as

shown in fig. 4, and then large open was created

reduce the lift force needed to push the valve upward

at waste valve shutting cycle.

Figure 6: Wastewater and delivered water flow results.

Table 4: Pumped Water flow data in liter/second.

As shown in fig.6 the wastewater flows tend to

increase when adding weight as well as adding the

length of valve stroke. For lengths longer than 25

millimeters, wastewater flows are likely to be more

constant while still highly changed under influence of

valve weight. In another hand, delivered water flow

showed more fluctuated data for most combinations

of waste valve weight and stroke length; the delivered

water flows increased until the ten-millimeter length

1kg 1.5 kg 2 kg 2.5 kg 3 kg 3.5 kg 4 kg 4.5 kg 5 kg 5.5 kg 6 kg

5mm 0,18 0,20 0,22 0,24 0,25 0,27 0,27 0,27 0,26 0,26 0,25

10mm 0,29 0,32 0,33 0,34 0,34 0,32 0,30 0,25 0,22 0,25 0,18

15mm 0,33 0,35 0,35 0,33 0,29 0,21 0,14

20mm 0,32 0,34 0,35 0,32 0,30 0,22 0,19

25mm 0,34 0,34 0,33 0,31 0,28 0,17

30mm 0,34 0,33 0,32 0,29 0,26 0,16

35mm 0,32 0,33 0,31 0,29 0,23 0,16

40mm 0,33 0,33 0,32 0,28 0,24 0,16

45mm 0,33 0,32 0,31 0,28 0,23 0,15

50mm 0,33 0,33 0,30 0,28 0,23 0,15

55mm 0,33 0,33 0,31 0,28 0,22

60mm 0,33 0,32 0,31 0,29 0,24

Waste valve stroke length

waste valve weight

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

240

of waste valve stroke adjustment and for the next

longer stroke adjustment the data is significantly

decreasing, which means more length cause mostly

reduce the pumped water flow. the most wasted water

flow was 5.2 liters per second which were obtained at

the combination of 4.5 mm valve stroke length by 3.5

kg valve weight, and for the highest delivered water

flow was 0.35 liters per second at the combination of

15 mm valve stroke length and 2 kg valve weight.

Figure 7: Pump Efficiency and Waste Valve Pulse.

Efficiency is determined by how efficiently the pump

converting resource energy in the form of supply head

and supply water flow rate to do works as presented

by a delivery head and delivery flow rate. The first

graph in fig. 7 shows that the combination of the

waste valve stroke heights and weights strongly affect

the pump efficiency, it can be seen that for each line

of valve weight variations there is a maximum

efficiency resulted from adjusting the valve stroke

length, in this experiment the effective valve stroke

length adjustment is between 5 mm to 10 mm, while

the valve stroke length more than 15 mm shows a

tendency of efficiency reduction. Maximum

efficiency reached is 70.45% at 1 kg waste valve

weight and 10 mm valve stroke adjustment. The

second graph in Fig. 7 shows the number of waste

valve pulsations which decreases with the increase of

the waste valve stroke length and weight, the less

number of pulses indicates the longer time the waste

valve is in the open position, which increases

wastewater discharge.

3.2 Statistical Analysis Results

Bivariate correlation was carried out to calculate the

respective correlation coefficient (r

x1y

) values

between the variables; the weight of waste valve (x

1

)

and the pump efficiency (y), also the value of the

correlation coefficient (r

x2y

) between the variables

stroke length (x

2

) and pump efficiency.

To find out the influence of each independent

variable if one variable is set (constant), a partial

correlation analysis is carried out by first calculating

the bivariate correlation coefficient (r

x1x2

) between

weights and stroke length then calculate the

correlation coefficient (r

p_x1y

) of the waste valve

weight on efficiency if the stroke length variable is

fixed and vice versa (r

p_x2y

).

Double correlation analysis was also conducted to

determine the correlation coefficient R

yx1x2

representing the effect of valve weight and valve

stroke length together on pump efficiency.

Table 5: Statistical Analysis Results.

Correlation

Coefficient

Value Test Value

*Tables

value

r

x1x2

-0,38

r

x1y

-0,62 t1 -7,03 1,66

r

x2y

-0,25 t2 -2,33

r

p_x1y

-0,80 t1 -11,82 1,66

r

p_x2y

-0,67 t2 -8,23

R

yx1x2

0,81 Fh 77,32 3,12

R

2

0,66

Number of data = 82, α =0.5 , test value>tables value

Statistical analysis shows a strong correlation

between the adjustment of the weight and stroke

length of the waste valve on the working efficiency of

the pump. The correlation coefficient value for the

valve weight variable is greater, indicating that the

valve weight factor has a more significant effect on

efficiency. The effect of the interaction between

weight and the stroke length of the waste valve weight

on efficiency is very significant at 66% while the

other 34% is influenced by other factors such as pump

construction factors etc, the negative value of the t-

test indicates the relationship between the variables

Waste Valve stroke length (mm)

0 10203040506070

Pump Efficiency (%)

10

20

30

40

50

60

70

80

0 10203040506070

Waste Valve Pulse (BPM)

0

50

100

150

200

250

waste valve stroke length (mm)

Effect of Waste Valve Tuning on Hydraulic Ram Pump Efficiency

241

where the addition of weight and the stroke length of

the waste valve tends to decrease the efficiency value,

this is in accordance with the graphic analysis.

4 CONCLUSIONS

From the results of the research that has been carried

out, it can be concluded that the adjustment of the

waste valve by varying the weight and length of the

waste valve stroke greatly affects the performance of

the installed hydraulic ram pump, from the results of

graphic and statistical analysis it can be seen the

following things;

The addition and reduction of the waste valve

weight has a more significant effect on the

performance of the hydraulic ram pump, both the

water flow produced and the pump work efficiency

value

In this study, we found the difference between

valve adjustment for maximum pump discharge and

waste valve adjustment for maximum efficiency. For

maximum pump discharge, the waste valve is set at a

weight of 2 kg with a valve stroke length of 15mm

while for maximum efficiency the valve is adjusted at

a weight of 1 kg and a stroke length of 10 mm. This

fact provides an option for practical waste valve

adjustment where for water sources with abundant

source flow the adjustment can be targeted for the

largest pump discharge while for sources with the

limited flow the setting with maximum efficiency is a

good choice.

increasing both the weight and the length of

the valve stroke after passing its maximum effect

value does not have any beneficial effect

ACKNOWLEDGEMENTS

We are very grateful to the Center for Research and

Community Service at the Kupang State Polytechnic

for the opportunity and support through the regular

internal research program in 2021 so that we can

complete and publish this research.

REFERENCES

Asvapoositkul, Wanchai, Jedsada Juruta, Nattapong

Tabtimhin, and Yosawat Limpongsa. 2019.

“Determination of Hydraulic Ram Pump Performance:

Experimental Results.” Advances in Civil Engineering

2019.

Fatahi-alkouhi, Reza, Babak Lashkar-ara, and Alireza

Keramat. 2019. “On the Measurement of Ram-Pump

Power by Changing in Water Hammer Pressure Wave

Energy.” Ain Shams Engineering Journal 10(4): 681–

93. https://doi.org/10.1016/j.asej.2019.05.001.

Hatipoğlu, Tuğçen, İbrahim Nakay, Erhan Köksal, and

Alpaslan Fığlalı. 2018. “Feasibility Analysis of a

Hydraulic Ram Pump Investment Project.” Arabian

Journal of Geosciences 11(9): 9–12.

Jeffery, T.D. et al. 2005. “Design, Sizing, Construction and

Maintenance of Gravity-Fed System in Rural Areas.” In

Design, Sizing,Construction and Maintenance of

Gravity-Fed System in Rural Areas, ACF, 68.

https://www.pseau.org/outils/ouvrages/acf_gravity_fe

d_system_in_rural_areas_6_hydraulic_ram_pump_sys

tems_2009.pdf.

Sarma, Dhrupad et al. 2016. “Investigation and Parameter

Optimization of a Hydraulic Ram Pump Using Taguchi

Method.” Journal of The Institution of Engineers

(India): Series C 97(4): 551–59. http://link.sprin

ger.com/10.1007/s40032-016-0295-0.

Setyawan, Aris Eko (Universitas Negeri Surabaya), and

Indra Herlamba (Universitas Negeri Surabaya) Siregar.

2015. “Pengaruh Berat Katup Limbah Dan Ketinggian

Discharge Terhadap Kinerja Pompa Hidram.” JTM

03(03): 25–31.

Suarda, M., M. Sucipta, and I. G.K. Dwijana. 2019.

“Investigation on Flow Pattern in a Hydraulic Ram

Pump at Various Design and Setting of Its Waste

Valve.” In IOP Conference Series: Materials Science

and Engineering, Institute of Physics Publishing.

Suarda, Made, Ainul Ghurri, Made Sucipta, and I. Gusti

Bagus Wijaya Kusuma. 2018. “Investigation on

Characterization of Waste Valve to Optimize the

Hydraulic Ram Pump Performance.” AIP Conference

Proceedings 1984.

Suwandi. 2015. “Pengaruh Variasi Beban Katup Di Bawah

450 Gram Menggunakan Panjang Pipa Input 6 Meter

Terhadap Kinerja Pompa Hidram.” Widya Teknika

23(2): 50–53.

Watt, S. B. 1975. A Manual on the Hydraulic Ram for

Pumping Water. 1st ( Revi. London: Intermediate

Technology Publications Ltd.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

242