Synthetic Dye Removal of Methylene Blue on Adsorption Process

using Low-rank Coal of East Kalimantan

Yuli Patmawati and Ibnu Eka Rahayu

Department of Chemical Engineering, Polytechnic State of Samarinda, East Kalimantan, Indonesia

Keywords: Adsorbent, Adsorption, Low-rank Coal, Methylene Blue, Synthetic Dye.

Abstract: Adsorption of synthetic dyes using low-rank coal as an adsorbent needs to be applied considering that

adsorption is the best technology available and low cost to remove some toxic contaminants, both organic and

inorganic contained in wastewater. In addition, the great potential of low rank coal in East Kalimantan is still

abundant and not fully utilized because so far, several studies have focused on medium and high rank coal.

This study aims to determine the dye removal of methylene blue (MB) on adsorption process using low rank

coal as an adsorbent. 100 mg low rank coal adsorbent was added to 100 mL of 100 mg/L methylene blue dye

solution at 30 °C. Initial pH effect adjusted with 0.10 mol/L of HCl or NaOH. Then the synthetic dye solution

of methylene blue was shaker at 150 rpm based on different contact times (10 - 90 min). At the end of the

period, the shaker was stopped, and the supernatants were filtered through a Whatman 40 filter paper to

separate the liquid from the solid phase. The remaining synthetic dye concentrations of methylene blue were

determined using UV-Vis Spectrophotometer at maximum wavelength (λ

max

) of adsorption. The experiment

was repeated for different initial concentrations of synthetic dye methylene blue (50 – 250 mg/L). The best

results were obtained using 100 mg low-rank coal adsorbent of East Kalimantan at optimum pH, initial

concentration, and contact time, respectively as follows 12, 150 mg/L, and 10 minutes with methylene blue

dye removal of 98.41%.

1 INTRODUCTION

Dyestuff waste generally has non-biodegradable

properties because it contains complex aromatic

compounds that are difficult to decompose by

microbes. The dye waste is harmful to human health

and biota that live around polluted water bodies.

Generally, these organic compounds are also

teratogenic (causing defects in the fetus during

pregnancy), carcinogenic and mutagenic, so that they

can pose a serious threat to human health (Irawati et

al., 2018). One of the dyes that are very dangerous for

human health is methylene blue. Methylene blue can

cause skin irritation, irritation to the digestive tract. If

inhaled, it can cause cyanosis (Fayazi et al., 2016).

To reduce environmental pollution caused by the

use of methylene blue, it is important to treat the dye

wastewater before being discharged into the

environment. One of the methods used to reduce

methylene blue dye wastewater that is easy and

economical is the adsorption process. Adsorption is an

efficient technique to remove odors and reduce the

concentration of dyes from solutions perfectly without

converting them into more dangerous compounds.

Adsorption based on carbon materials is

considered the best available and low-cost technology

for the removal of several organic and nonorganic

toxic contaminants from aqueous solutions

(Yanagisawa et al., 2010). Coal is one of the widely-

known carbonaceous raw materials that could be act

as a potentially low-cost adsorbent material for toxic

water contaminants (A. Gu¨ rses et al, 2014).

The adsorption of dyes using several ranks of coal

as adsorbent was studied by several authors. Most

research so far has focused on medium and high rank

coals, thus paid less attention to low rank coals. In this

research the dye removal of methylene blue use low-

rank coal of East Kalimantan as adsorbent.

A good adsorption performance for methylene

blue also achieved by Yu et al. (2020) in their

research “Adsorptive removal of cationic methylene

blue and anionic Congo red dyes using wet-torrefied

microalgal biochar : Equilibrium, kinetic and

mechanism modeling”. The maximum adsorption

capacities and percent removal for methylene blue

were 113.00 mg/g and 26.23% respectively.

268

Patmawati, Y. and Rahayu, I.

Synthetic Dye Removal of Methylene Blue on Adsorption Process using Low-rank Coal of East Kalimantan.

DOI: 10.5220/0010943800003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 268-271

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Research was conducted by Myneni et al. (2019)

has studied “Modelling and Optimization of

Methylene Blue (MB) Adsorption onto Magnesium

Oxide Nanoparticles loaded onto Activated Carbon

(MgONP-AC): Response Surface Methodology and

Artificial Neural Networks” obtained MB removal of

94.34% at pH 5.91, MgONP-AC dosage 0.47 g/L,

initial concentration of MB in solution 15mg/L and

temperature 313 K and 207 mg/g for MgONP-AC

adsorption capacity.

The other research has done by Shokry and

Elkady (2019) used Maghara coal which impregnates

to nano-activated carbon was inspected for the

removal of methylene blue (MB) dye from aqueous

solutions. This study obtained the adsorption

equilibrium of MB onto prepared nano-activated

carbon (NAC) was fitted well with the Langmuir

isotherm indicating monolayer coverage of dye

molecules on NAC with a maximum mono-layer

adsorption capacity of 28.09 mg/g. NAC produced

from Maghara coal is an effective adsorbent and low

cost material for removal of organic pollutants from

wastewater.

Another study related to the absorption of

methylene blue dye was carried out by Rizki et al.

(2019). By using tamarind seeds as adsorbents with

variations in contact time of 30, 60, 120, and 180 min,

the adsorbent dosage was 0.3, 0.4, 0.6, and 0.9 g. The

best sorption removal of methylene blue was

98.827% with a contact time of 120 min and pH 6 at

0.9 g biosorbent.

This article discusses the dye removal of

methylene blue on adsorption process using low rank

coal of East Kalimantan as an adsorbent.

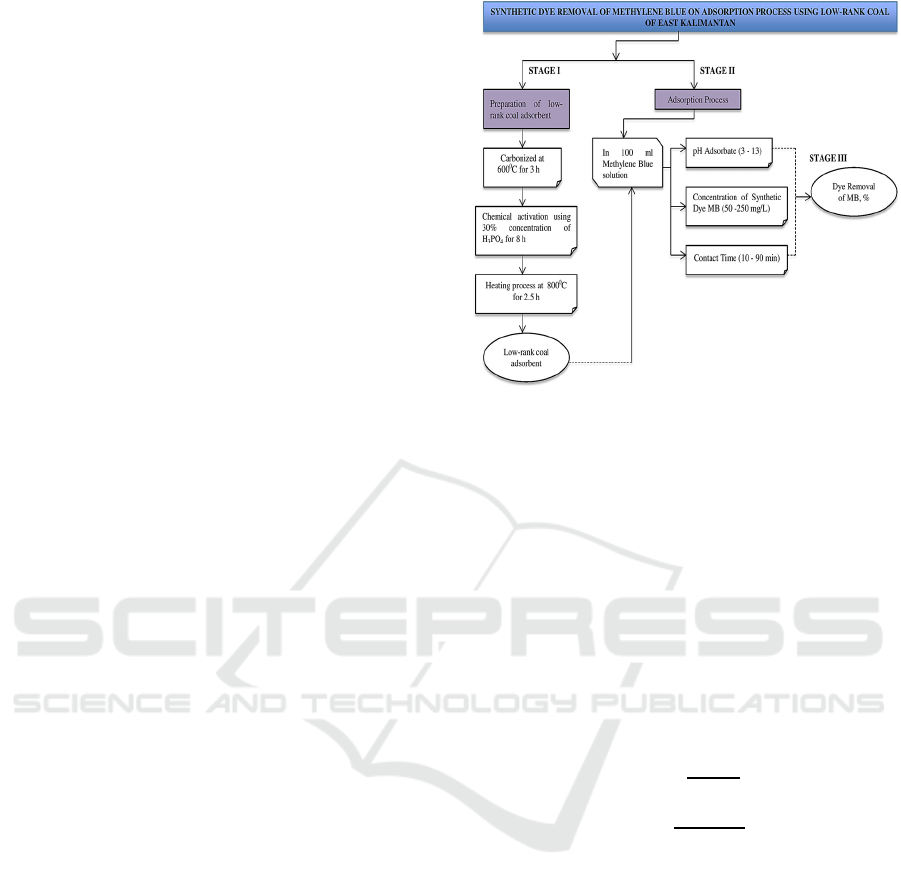

2 METHODOLOGY

Firstly, Low rank coal is carbonized at 600

0

C for 3 h,

then after cold it was activated using 30%

concentration of H

3

PO

4

for 8 h. The immersion

results were then washed to neutral pH and continued

with the heating process at 800

0

C for 2.5 h. Second,

the investigation of the dye removal of methylene

blue using the low rank coal as adsorbent runs in a

batch adsorption process at room temperature with

the adsorbent dosages 100 mg, variations in pH of

methylene blue solution (3 to 13), the initial

concentration of (50 to 250 mg/L) and the contact

time (10 to 90 min). 100 mg of low rank coal

adsorbent was added to 100 mL of methylene blue

solution at 30 °C were shaker at 150 rpm based on

different contact times and initial concentration of

methylene blue. Initial pH effect adjusted with 0.10

Figure 1: Research framework and design.

mol/L of HCl or NaOH. At the end of the period, the

shaker was stopped, and the supernatants were

filtered through a Whatman 40 filter paper to separate

the liquid from the solid phase. The remaining

synthetic dye concentrations of methylene blue were

determined using UV-Vis Spectrophotometer at 664

nm maximum wavelength (λ

max

) of adsorption.

Third, determine of dye adsorption performance

are expressed by methylene blue dye removal based

on the amount of methylene blue adsorbed per gram

of the low rank coal adsorbent at equilibrium, q

e

(mg/g), were obtained using Equation (1) and

Equation (2).

𝑅𝑒𝑚𝑜𝑣𝑎𝑙, %

𝑥 100% (1)

𝑞

(2)

Where C

0

and

C

e

(mg/L)

refer to methylene blue

concentration at initial and equilibrium,

respectively. Meanwhile,

V symbol refers to the

volume of methylene blue solution (Liter) and W

symbol refers to the adsorbent dosage used (mg).

3 RESULT AND DISCUSSION

The low-rank coal of East Kalimantan is used as an

adsorbent in the adsorption process of synthetic dye

methylene blue. The characteristics of low rank coal

to be processed into adsorbent are investigated by

proximate analysis to determine the parameters of

moisture content, ash content, volatile matter, fixed

carbon, and calorific value respectively as follows

33.66%, 3.72%, 32.53%, 33.09%, and 4208 cal/g.

Synthetic Dye Removal of Methylene Blue on Adsorption Process using Low-rank Coal of East Kalimantan

269

The characteristics of adsorbents were obtained after

the activation process consists of moisture content,

ash content, volatile matter, fixed carbon and iodine

adsorption number respectively as follows 0.45%,

1.12%, 4.2%, 84.23%, and 761 mg/g.

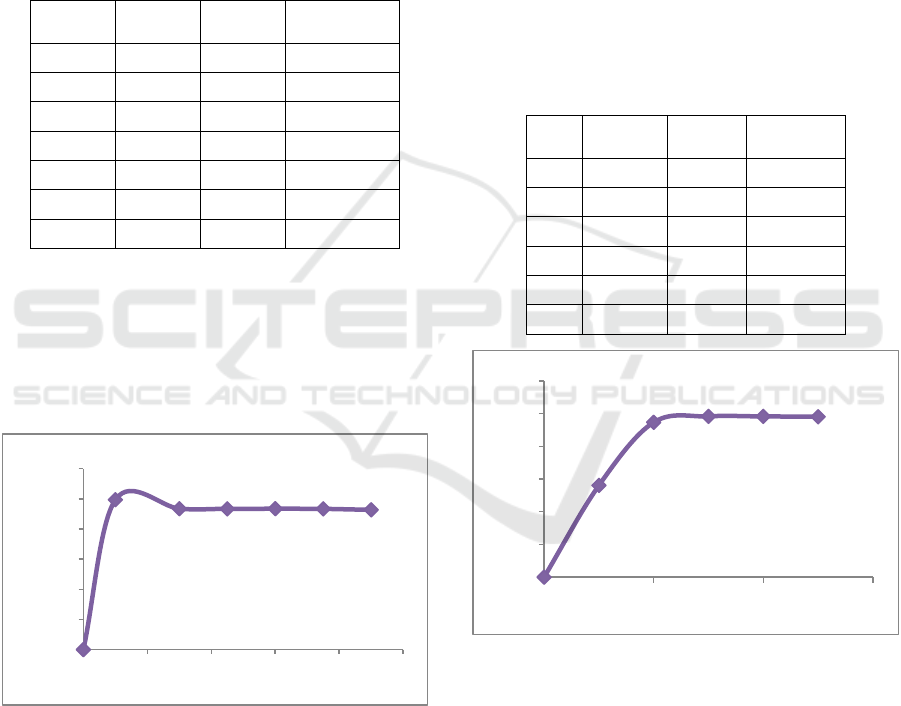

The methylene blue adsorption process results at

100 mg/L concentration of methylene blue dye

solution, pH 12, adsorbent dosage 100 mg, and

different contact times can be seen in Table 1 and

Figure 2.

Table 1: The effect of contact time on methylene blue dye

removal.

Time

(minute)

C

0

(mg/L)

C

e

(mg/L)

Removal

(%)

0 100 0 0

10 100 0.60 99.40

30 100 6.57 93.43

45 100 6.64 93.36

60 100 6.61 93.39

75 100 6.70 93.30

90 100 7.34 92.66

Contact time is one of the factors that affect the

adsorption process of methylene blue. The reaction

rate depends on the number of collisions per unit

time. The more collisions that occur, the faster the

reaction takes place until equilibrium conditions

occur. The equilibrium occurs when the rate of

adsorption is equal to the desorption rate.

Figure 2: The effect of contact time on methylene blue dye

removal.

Figure 2 shows that the methylene blue dye

removal increased with the increase of contact time

until a certain time and then tends to be constant. In

Figure 2, methylene blue dye solution adsorption

using low-rank coal as adsorbent occurs very quickly

in the first 10 minutes. After that, the methylene blue

dye removal decreased slowly and could be assumed

to be constant at 30 minutes of the adsorption process.

After the adsorption reached equilibrium at the

optimum contact time, the addition of the contact time

between the adsorbent and the adsorbate further did

not significantly affect the absorption of the dye.

Hastuti et al. (2012) said that too long physical

contact between the dye and the adsorbent causes the

dye to be released from the solution over time

(desorption). The optimum contact time was obtained

at 10 minutes of the adsorption process. Furthermore,

the adsorption process for the synthetic dye

methylene blue was carried out with variations in the

initial concentration of methylene blue at 10 minutes

of contact time. The pH of the dye solution was 12

and 100 mg adsorbent dosage.

Table 2: The effect of initial concentration on methylene

blue dye removal.

No

C

0

(

m

g

/L

)

C

e

(

m/L

)

Removal

(

%

)

1 0 0 0

2 50 21.90 56.20

3 100 5.26 94.74

4 150 2.38 98.41

5 200 3.28 98.36

6 250 4.62 98.15

Figure 3: The effect of initial concentration on methylene

blue dye removal.

Based on Figure 3, the dye removal increases as

the initial concentration of the methylene blue dye

solution increases. At 50 mg/L concentration, the

methylene blue dye removal was 56.20 %. It is due to

the large number of empty spaces on adsorbent

surfaces or pores that dyes have not occupied. At 100

mg/L concentration, the percent removal has

increased to 94.74%. It indicates that there are still

empty spaces on the surface of the adsorbent, namely

the availability of active groups from the adsorbent to

0

20

40

60

80

100

120

0 20406080100

Removal of MB, %

Contact Time, min

0

20

40

60

80

100

120

0 100 200 300

Removal of MB, %

Initial Concentration, mg/L

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

270

bind the methylene blue dye. At 150 mg/L

concentration, the increase of methylene blue dye

removal was not significant because almost all the

pores of the low-rank coal adsorbent had been filled

with methylene blue (almost saturated). Meanwhile,

at a concentration of more than 150 mg/L, the

adsorbent is already saturated, so adding the dye

concentration will decrease the adsorption ability.

The concentration of the dye is related to the active

sites on the surface of the adsorbent. If the number of

active sites is large enough compared to the amount

or concentration of dye, the dye removal will be high

until the number of active sites is the same as the dye

concentration. Therefore, when the optimum

concentration has been reached, increasing the

concentration can reduce the adsorption ability. From

this research, the optimum methylene blue dye

removal of 98,41% was obtained at 150 mg/L

concentration, 12 pH of dye solution, 100 mg

adsorbent dosage, and 10 minutes contact time of

adsorption process.

4 CONCLUSIONS

1. Characteristics of low-rank coal adsorbents used

in the methylene blue adsorption process have

moisture content, ash content, volatile matter,

fixed carbon, and iodine adsorption number

respectively as follows 0.45%, 1.12%, 4.2%,

84.23%, and 761 mg/g.

2. The optimum synthetic dye removal of methylene

blue of 98,41% was obtained at 150 mg/L

concentration, 12 pH of dye solution, 100 mg

adsorbent dosage, and 10 minutes contact time of

adsorption process.

ACKNOWLEDGEMENTS

The author would like to acknowledge the Center for

Research and Community Service at Polytechnic

State of Samarinda which has provided funding for

this research as well as to the Chemical Engineering

Laboratory of Polytechnic State of Samarinda as a

place for the research to be carried out.

REFERENCES

A. Gürses, A. Hassani, M. K. O. A. S. K. (2014). Removal

of Methylene Blue from Aqueous Solution Using by

Untreated Lignite as Potential Low-Cost Adsorbent:

Kinetic, Thermodynamic and Equilibrium Approach.

Journal of Water Process Engineering, 2, 10–21.

https://doi.org/10.1016/j.jwpe.2014.03.002.

Fayazi, M., Taher, M. A., Afzali, D., & Mostafavi, A.

(2016). Enhanced Fenton-like Degradation of

Methylene Blue by Magnetically Activated

Carbon/Hydrogen Peroxide with Hydroxylamine as

Fenton Enhancer. Journal of Molecular Liquids, 216,

781–787. https://doi.org/10.1016/j.molliq.2016.01.093

Hassan Shokry, Marwa Elkady, H. H. (2019). Nano

Activated Carbon from Industrial Mine Coal as

Adsorbents for Removal of Dye from Simulated Textile

Wastewater: Operational Parameters and Mechanism

Study. Journal of Materials Research and Technology,

8(5), 4477–4488. https://doi.org/10.1016/j.jmrt.2019.

07.061.

Heni Irawati, Nurul Hidayat Aprilita, dan E. S. (2018).

Adsorpsi Zat Warna Kristal Violet Menggunakan

Limbah Kulit Singkong (Manihot esculenta). Bimipa,

25(1), 17–31.

Hiroki Yanagisawa, Yuki Matsumoto, M. M. (2010).

Adsorption of Zn (II) and Cd (II) Ions Onto Magnesium

and Activated Carbon Composite in Aqueous Solution.

Applied Surface Science, 256(6), 1619–1623.

Kai Ling Yu, Xin Jiat Lee, Hwai Chyuan Ong, W.-H. C., &

Jo-Shu Chang, Chih-Sheng Lin, Pau Loke Show, T. C.

L. (2020). Adsorptive Removal of Cationic Methylene

Blue and Anionic Congo Red Dyes Using Wet-

Torrefied Microalgal Biochar: Equilibrium, Kinetic and

Mechanism Modeling. Environmental Pollution, xxxx,

115986. https://doi.org/10.1016/j.envpol.2020.115986.

Rizki, A., Syahputra, E., & Pandia, S. (2019). “Pengaruh

Wajtu Kontak dan Massa Adsorben Biji Asam Jawa

(Tamarindus indica) dengan Aktivator H3PO4 terhadap

Kapasitas Adsorpsi Zat Warna Methylene Blue,.” J.

Tek. Kim. USU, 8(2), 54–60.

V. R. Myneni, Thanusha Punugoti, N. Sasi Kala, N. R.

Kanidarapu, M. V. (2019). Modelling and Optimization

of Methylene Blue Adsorption onto Magnesium Oxide

Nanoparticles Loaded onto Activated Carbon

(MgONP-AC): Response Surface methodology and

artificial neural networks. Materials Today:

Proceedings, 18, 4932–4941. https://doi.org/10.1016/

j.matpr.2019.07.485.

Synthetic Dye Removal of Methylene Blue on Adsorption Process using Low-rank Coal of East Kalimantan

271