Thermal Performance of Bio-Nano-PCM based Passive Cooling for

Vaccine Carriers

I Nyoman Suamir

a

, I Wayan Adi Subagia

b

, Luh Putu Ike Midiani

c

,

I Dewa Gede Agus Tri Putra

d

and I Made Rasta

e

Mechanical Engineering Department, Politeknik Negeri Bali, Campus Street, Kuta Selatan, Badung, Bali 80364, Indonesia

Keywords: Temperature Performance, Bio-Nano-PCM, Passive Cooling, Vaccine Carrier.

Abstract: Vaccine storage requires special attention because vaccines are biological supplies that are susceptible to

changes in environmental temperature. Vaccines are also biological products that are easily damaged so they

must be stored at temperature of 2 to 8 ºC. The vaccine can be damaged if exposed to direct sunlight. The

vaccine distribution box (vaccine carrier) presented in this paper was developed with considerations the box

is easy to carry, have aesthetics, light weight, practical use and save energy while still having good cooling

capabilities of 2-8 ºC. The vaccine box incorporates 3.2 kg Bio-Nano PCM as cold thermal storage material.

The box has a capacity of 2.8 liters or capable of loading 20 bottles of vaccine. Total weight of vaccine carrier

is approximately 7 kg. Test results showed that Bio-Nano PCM technology integrated in the vaccine carrier

box could cool and kept the vaccine at temperature range of 2-8 ºC for more than 24 hours.

1 INTRODUCTION

In the current situation of the Covid-19 pandemic, the

distribution of vaccines is very important and vital for

the people of Indonesia. The Indonesian government

is currently preparing various types of vaccines for all

Indonesian people. Considering that Indonesia is an

archipelagic country consisting of 34 provinces, the

distribution of vaccines is very important for the

community so that when the vaccine arrives it is still

in good and safe conditions.

In general, vaccine distribution boxes (vaccine

carriers) are indeed needed in the national vaccine

program for eradicating infectious diseases and

infections. More specifically, the national Covid-19

vaccination program is urgently needed to protect and

prevent the spread of the Covid-19 pandemic in

Indonesia (World Health Organization, 2020).

Vaccination or immunization is very important for

both children and adults. Therefore, immunization

can prevent the transmission of various diseases and

infections by increasing the body's immunity. The

a

https://orcid.org/0000-0003-0594-7511

b

https://orcid.org/0000-0001-9261-3549

c

https://orcid.org/0000-0002-2256-6035

d

https://orcid.org/0000-0002-9422-7876

e

https://orcid.org/0000-0002-9610-3738

obstacle encountered in immunization activities in

Indonesia is maintaining the cold chain from the

vaccine manufacturer until the immunization activity

is carried out. Cold chain is a procedure and devices

used in the delivery or storage of vaccines starting

from the manufacturer until the vaccines are given to

the community.

Vaccine storage requires special attention because

vaccines are biological supplies that are susceptible to

change in environmental temperature. According to

the Minister of Health Regulation number 12 (2017)

concerning the implementation of immunization, it is

stated that vaccines are biological products that are

easily damaged so they must be stored at a certain

temperature, namely at a temperature of 2 to 8ºC for

freeze sensitive vaccines (not frozen), and at a

temperature of -15 to -25ºC. for heat sensitive

vaccines. Currently, only polio vaccine still requires

storage at temperatures below 0 °C. A number of

vaccines can potentially be damaged if they exposed

to freezing temperatures. Meanwhile, other vaccines

can potentially be damaged if they exposed to hot

Suamir, I., Subagia, I., Midiani, L., Putra, I. and Rasta, I.

Thermal Performance of Bio-Nano-PCM based Passive Cooling for Vaccine Carriers.

DOI: 10.5220/0010944900003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 329-334

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

329

temperatures. In general, the vaccines, however, can

be damaged if they exposed to direct sunlight

(Primadi, 2017).

The toughest obstacle arises when it comes to

bringing vaccines to remote areas that do not yet have

major infrastructure such as motorized driveways and

electricity networks to run refrigerators. The tools

commonly used in the distribution of vaccines for

long distances are cold boxes that use icepacks as a

cooling medium. The tools have disadvantage of not

being able to maintain the temperature of the vaccine

in the proper range from 2-8 °C, as well as they have

a limited cooling time. Efforts have been made to help

overcome this problem, prototype vaccine carriers

have been developed using a Peltier element (Putra et

al., 2005; Putra et al., 2006; Putra, 2006). The vaccine

boxes developed with Peltier elements is able to

maintain the vaccine temperature from 2-8 °C, but

they still have disadvantages in terms of prototypes

compactness and they also still require other

supporting equipment which makes the products are

less practical.

The concepts of the vaccine carrier have also been

developed in Indonesia. The concepts are based on

thermo-electric refrigeration and are also combined

with ice-packs. The first concept was developed at the

University of Indonesia. This vaccine carrier looks

less practical when carried by health workers as a

carrier. The second concept was developed by ITS

Surabaya. This vaccine carrier concept uses

thermoelectric refrigeration with power supply from

solar panels and is combined with ice-pack or blue-

ice.

The technology concept applied to the vaccine

carrier developed in this study is the concept of

passive cooling (passive refrigeration) using a cold

storage material based on natural materials, namely

Bio-Nano PCM with a phase change temperature in

the range of 0 °C as an application. sustainable

technology. The Bio-Nano PCM is housed in an

encapsulation and integrated with a specially

designed heat transfer wall so that it is able to

maintain the vaccine chamber temperature in the

range of 2-8 °C. The volume of Bio-Nano-PCM was

designed so that the vaccine carrier is able to maintain

a minimum time storage for 24 hours.

For comparison purposes, the paper also presents

the most famous PCM that is water because it has

good thermal properties, but has the disadvantage of

high super-cooling when applied as thermal storage

at below 0 °C. Bio-PCM using ester oil in water

mixture is also presented as an alternative use of the

bio-thermal energy storage. The Bio-PCM has a good

advantage with lower super cooling than pure water

but it can maintain the advantage of high phase

change enthalpy of the water as reported in Rasta and

Suamir (2018), Rasta and Suamir (2019), and Suamir

et al. (2019).

The bio-Nano PCM vaccine carrier developed in

this study was also designed through a concept of

applying appropriate technology which was made to

meet the right needs according to its use. The use of

technology is in accordance with local natural, social,

economic and cultural conditions and can help

improve the economic standard and quality of life of

the community. Therefore, the technology has to have

technical characteristics, such as easy to manufacture,

safe to use, economically inexpensive, low impact to

the environment and energy efficient (Putra et al.,

2006; ITSmis, 2020; Pearce et al., 2014; Zelenika and

Pearce, 2011). The technology is also projected to be

applicable, comfortable, healthful, practical and

efficient (Zelenika and Pearce, 2012; Pearce, 2012;

Shin et al., 2019; Patnaik and Bhowmick, 2019,

Boakye-Ansah, 2020).

2 MATERIALS AND METHODS

2.1 Vaccine Carrier Box

The development of the vaccine carrier with Bio-

Nano PCM involved several stages such as design,

assembly, installation of instrumentation and

performance testing. For the carrier box material, a

cool box that is already on the market is used with an

outer size of 32 cm x 22 cm x 25 cm as shown in

Figure 1.

Figure 1: The cool box used as the base container of the

vaccine carrier.

The Bio-Nano PCM used in this carrier is liquid

at room temperature. Therefore, in its integration into

the vaccine carrier, the Bio-Nano PCM has to be

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

330

contained in an enclosure. In this study acrylic

enclosure are applied.

There are two types of containers used which

include: ice-pack boxes (available in the market) and

acrylic enclosures (designed and made specifically to

fit in the box and the vaccine bottle holder. The ice-

pack bio-Nano PCM enclosures used are 14 with

similar size 11 cm x 9 cm x 3 cm and each enclosure

can contains 195 g of Bio-Nano PCM. So the total

weight of bio-Nano PCM reaches 2.7 kg.

Figure 2: The bio-Nano PCM containers and vaccine bottle

holder.

The acrylic PCM box is made of 5 boxes. With 3

boxes of size 250 mm x 160 mm x 30 mm. Each

acrylic box can contain 0.865 kg. Two other smaller

boxes size 90 mm x 160 mm x 30 mm which can

contain 0.3 kg bio-Nano PCM each. Therefore, total

mass of bio-Nano PCM for acrylic boxes is 3.2 kg.

The acrylic box construction and the vaccine bottles

holder are presented in Figure 2.

Figure 3: The cooler box completed with bio-Nano PCM

containers and vaccine bottle holder.

The bio-Nano PCM vaccine carrier used in this

study can be detailed: (i) Vaccine carrier with ice-

pack PCM enclosure; (ii) Vaccine carrier with acrylic

PCM enclosure. Furthermore, to place the vaccine

safely in the carrier, both carriers are equipped with

vaccine holders as shown in Figure 2 and Figure 3.

Each vaccine carrier can accommodate 2 vaccine

holders arranged in two layers: top and bottom. Each

holder can accommodate 10 bottles of vaccine, so that

each vaccine carrier can accommodate 20 vaccine

bottles.

Between the vaccine holders and the PCM

enclosures, an acrylic wall partition is installed to

avoid direct contact between the vaccine holder and

the PCM enclosure. The complete assembly of the

bio-Nano PCM vaccine carrier is shown in Figure 3.

2.2 Methods

The type of research is an experimental study. This

research was initiated by conducting surveys and

literature studies to obtain secondary data about

vaccines and vaccine carriers including storage

conditions. A survey was also conducted to obtain the

characteristics of the Bio-Nano PCM that can be used

so that it is able to maintain the temperature of the

vaccine storage room.

Simulation methods with inventor and EES

(engineering equation solver) were also applied to

simulate the design of the Bio-Nano PCM vaccine

carrier and components as well as simulation of

vaccine room temperature based on secondary data.

Furthermore, the simulation was developed using the

primary data from the test results. The prototype of

the Bio-Nano PCM vaccine carrier was made and

function tests were carried out as well as testing the

characteristics of the vaccine room conditioning

process with various conditions of control variables.

Testing is carried out at the laboratory level. Primary

data from the test is recorded and processed to obtain

a consistent conditioning process and in accordance

with the target temperature in the range of 2-8 °C.

3 RESULTS AND DISCUSSION

3.1 Bio-Nano PCM Cooling and

Heating Characterization

An effective alternative PCM material can be used as

a passive cooling material. A vaccine carrier has been

tested for the characteristics of charging or cooling

and discharging or heating. The test results for tap

water, bio-Nano PCM and bio-PCM are presented in

Figure 4.

From Figure 4, it can be seen that the 10% bio-

PCM has a phase change temperature, especially

during discharging, which is relatively less stable

than the other two materials, namely tap water and

bio-Nano PCM. In addition, the phase change time is

very short, although the temperature change rate is

relatively slow and the phase change temperature

(PCT) of -5 °C is quite far from the vaccine

Thermal Performance of Bio-Nano-PCM based Passive Cooling for Vaccine Carriers

331

temperature requirement between 0 °C and 10 °C

precisely in the range from 2 °C up to 8 °C. The 10%

bio-PCM is a PCM made from the mixture of 10% of

corn oil ester and 90% tap water by volume as

reported in Rasta and Suamir (2018).

This result shows that if the Bio-PCM 10% is

used, the vaccine holder and the Bio-PCM must be

equipped with a thermal wall capable of maintaining

the temperature difference in such a way that the

temperature of the vaccine is in the storage range.

Otherwise, the temperature of the vaccine can be drop

down below 0 °C then increase sharply to follow the

discharging (heating) characteristic as shown in

Figure 4. This can also make the vaccine temperature

exceed 8 °C in far less than 24 hours.

Figure 4: Charging and discharging test results of PCM

alternatives.

From the figure, it can also be seen that tap water

and bio-Nano PCM are two materials that are very

suitable to be used for vaccine carrier applications.

These two PCM materials have a PCT at 0 °C.

However, the bio-Nano PCM can provide better

higher enthalpy difference of phase change.

Therefore, the vaccine carrier utilizing Bio-Nano

PCM as the passive cooling materials is chosen and

discussed in this paper.

3.2 Temperature Performance of the

Bio-Nano PCM Vaccine Carrier

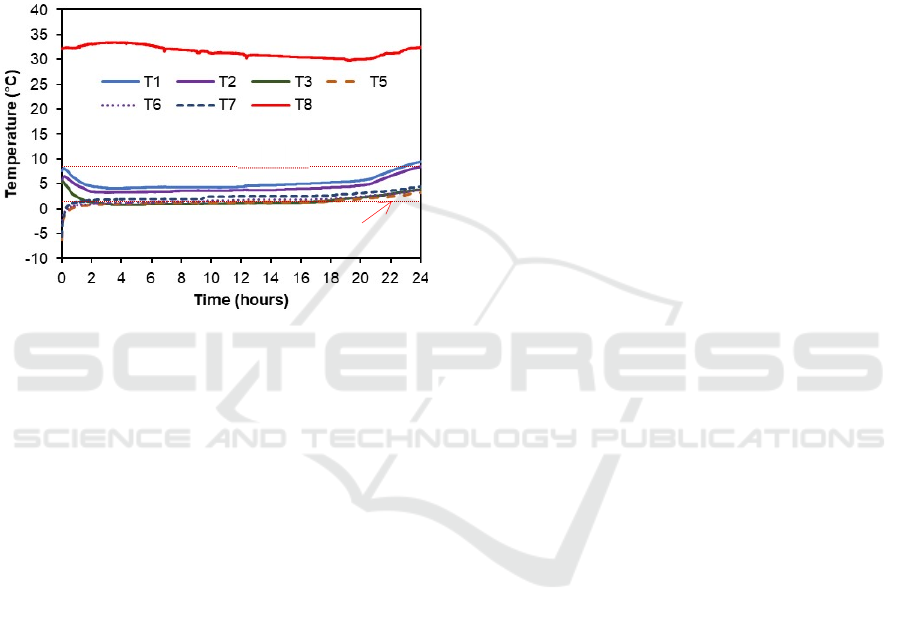

The test results on the temperature performance of the

Bio-Nano PCM vaccine carrier with different PCM

enclosure or different PCM mass are presented in

Figures 5 and 6. Where T8 is the ambient

temperature, T1-3 is the vaccine temperatures and

T5-7 is the bio-Nano PCM temperatures. In these

tests, water is used to represent the vaccines which are

placed in the vaccine bottles.

The temperature performance tests were carried

out in two stages: (i) the first test was vaccine carrier

utilizing acrylic enclosure bio-Nano PCM with total

mass of 3.2 kg and the test results are shown in Figure

5; (ii) the second test was vaccine carrier utilizing ice-

pack enclosure bio-Nano PCM with total mass of 2.7

kg and the test results are presented in Figure 6.

Figure 5: Vaccine carrier test results utilizing bio-Nano

PCM with total mass of 3.2 kg.

Figure 5 shows the discharging test results of the

vaccine carrier utilizing acrylic enclosure bio-Nano

PCM with total mass of 3.2 kg. From the graph, it can

be clearly seen that the vaccine temperature can be

maintained within a safe range between 2 °C and 8 °C

for more than 24 hours. At the beginning of the test

shows that the vaccines have been store at correct

temperature range and then their temperature

decrease gradually for about two hours until about

2° C when the bio-Nano PCM temperature is still

below its phase change temperature (PCT) of 0°C.

Then, the vaccine temperatures very slowly increase

for more than 24 hours but still far below 8 °C when

bio-Nano PCM temperature reaching its PCT. These

show that vaccine carrier with 3.2 kg bio-Nano PCM

can keep the vaccines safely for more than 24 hours,

precisely 28 hours in total.

While Figure 6 shows the test results of the

vaccine carrier utilizing ice-pack enclosure bio-Nano

PCM with total mass of 2.7 kg. It can be seen that the

vaccine temperatures can be maintained within a safe

range for only 22 hours. It also shows at the beginning

of the test that the vaccines have been store at correct

temperature range and then their temperature

decrease gradually for about two hours until about 2

°C when the bio-Nano PCM temperature is still below

its phase change temperature (PCT) of 0°C. Then, the

vaccine temperatures steadily increase for more than

18 hours but still below 8 °C when bio-Nano PCM

PCT-1 (0°C)

PCT-2 (-5°C)

8°C

2°C

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

332

temperature at its PCT. The vaccine temperatures

then gradually increase after the bio-Nano PCM

temperatures leaving its PCT and the vaccine

temperatures exceeding 8 °C after 22 hours.

Results presented in Figures 5 and 6 have shown

that the time difference of safely maintaining

temperature of the vaccines is mainly caused by the

different amounts of bio-Nano PCM mass. For the

Bio-Nano PCM ice-pack vaccine carrier, PCM mass

is 2.7 kg which is much lighter than the acrylic Bio-

Nano PCM vaccine carrier with 3.2 kg PCM mass.

Figure 6: Vaccine box test results using bio-Nano PCM

with total mass of 2.7 kg.

4 CONCLUSIONS

The vaccine carrier with novel bio-Nano PCM

passive cooling has been developed and tested. It is

found that vaccine carrier utilized with 3.2 kg bio-

Nano PCM can safely maintain the vaccine for more

than 24 hours. The vaccine carrier is easy to carry,

have aesthetics, light weight, practical use and energy

efficient while still having good cooling capabilities

of 2-8 ºC. The vaccine carrier has a capacity of 2.8

litres and it is capable of loading 20 bottles of vaccine

with total weight of approximately 7 kg.

ACKNOWLEDGEMENTS

Authors appreciatively acknowledge the financial

support from the Politeknik Negeri Bali through

institutional research with funding scheme: DIPA

Politeknik Negeri Bali number: SP. DIPA-023.18.2.

677608/2021, dated 23 November 2020. The authors

also gratefully thank Centre of Research and

Community Services (P3M) Politeknik Negeri Bali

for the technical and administrative assistances.

REFERENCES

Boakye-Ansah, A.S., Schwartz, K., Zwarteveen, M. (2020).

Aligning stakeholder interests: How ‘appropriate’

technologies have become the accepted water

infrastructure solutions for low-income areas. Utilities

Policy 66, pp. 101081.

ITSmis. (2020). Gagas Kotak Distribusi Vaksin,

Mahasiswa ITS Juarai Ajang Internasional. Dapat

diaksespada: https://www.its.ac.id/news/2020/11/30/

gagas-kotak-distribusi-vaksin-mahasiswa-its-juarai-

ajang-internasional/

Patnaik, J. and Bhowmick, B. (2019). Revisiting

appropriate technology with changing socio-technical

landscape in emerging countries. Technology in Society

57, pp.8-19.

Pearce, J.M. (2012). The case for open source appropriate

technology. Environ Dev Sustain 14, pp. 425–431.

Pearce, J.M., Albritton, S., Grant, G., Steed, G., and

Zelenika, I. (2014). A new model for enabling

innovation in appropriate technology for sustainable

development. Sustainability: Science, Practice, &

Policy 8 (2), pp. 42-53.

Primadi, O. (2017). Pemerintah Serius Untuk Kualitas

Rantai Dingin (Cold Chain) Penyimpanan Vaksin,

Dapat diakses pada: https://sehatnegeriku.kemkes.go.id/

baca/ umum/20170426/2320665/ pemerintah-serius-

kualitas-rantai-dingin-cold-chain-penyimpanan-vaksin/

Putra, N., Tedjo, H., Koestoer, R.A. (2005). Pemanfaatan

Elemen Peltier Bertingkat dua pada aplikasi Kotak

Vaksin. Prosiding Seminar Nasional Tahunan Teknik

Mesin IV. Universitas Udayana, Bali, Indonesia.

Putra, N., Siregar, P.P., Koestoer, R.A. (2006).

Pengembangan “VACCINE CARRIER” dengan

memanfaatkan efek Peltier. Seminar Nasional Tahunan

Teknik Mesin III, 6-7 Desember 2004, ISBN 979-

97158-0-6, Universitas Hasannudin Makasar

Indonesia.

Putra, N. (2006). Uji Unjuk Kerja Kotak Vaksin berbasis

Elemen Peltier Ganda. Seminar Nasional

Perkembangan Riset dan Teknologi di Bidang Industri

Universitas Gajah Mada Yogyakarta.

Putra, N., Veranika, R.M., Danardono, A.S. (2006).

Perancangan dan pengembangan produk kotak vaksin

untuk daerha pedalaman. Seminar Nasional Tahunan

Teknik Mesin (SNTTM) V, Universitas Indonesia, 21-23

November 2006: MI-024/1-7.

Rasta, I.M., Suamir, I.N. (2018). The role of vegetable oil

in water based phase change materials for medium

temperature refrigeration. Journal of Energy Storage

15, 368-378.

Rasta, I.M., Suamir, I.N. (2019). Study on Thermal

Properties of Bio-PCM Candidates in Comparison with

Propylene Glycol and Salt Based PCM for sub-Zero

Energy Storage Applications. IOP Conference Series:

Materials Science and Engineering 494, 012024.

Suamir, I.N., Rasta, I.M., Sudirman, Tsamos, K.M. (2019).

Development of Corn-Oil Ester and Water Mixture

Phase Change Materials for Food Refrigeration

Applications. Energy Procedia 161, 198-206.

8°C

2°C

Thermal Performance of Bio-Nano-PCM based Passive Cooling for Vaccine Carriers

333

The Minister of Health Regulation number 12. (2017). The

Health Minister Decree of the Republic of Indonesia

concerning the implementation of immunization.

World Health Organization. (2020). Program Imunisasi

dan Pengembangan Vaksin, Jakarta, Indonesia.

Zelenika, I., and Pearce, J.M. (2011). Barriers to

Appropriate Technology Growth in Sustainable

Development. Journal of Sustainable Development 4

(6), pp. 12-22.

Zelenika, I., and Pearce, J.M. (2012). Innovation Through

Collaboration: Scaling up Solutions for Sustainable

Development. Environment, Development and

Sustainability 16 (6), pp. 1299-1316.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

334