Experimental Study on the Effect of Intercooler on a Compressor

Performance on Multistage Type Cold-storage Simulation

I P. S. Negara

a

and I M. Arsawan

b

Department of Mechanical Engineering, Politeknik Negeri Bali Badung Bali, Indonesia

Keywords: Intercooler, Compressor Work and Performance.

Abstract: Multistage type cold storage is a refrigeration machine required in an industry because it functions to store

food products for a long time. Bali, as a world tourist destination, will rely heavily on this cooling system in

preparing services for tourists, especially in the food and beverage sector. Multistage type cold storage is

designed to reach the evaporator temperature below -30ºC thus the used compressor performance must be

able to produce maximum refrigeration effect. Two compressors placed in succession or connected in series

complete this cold storage system, which is expected to achieve higher operating pressures. The temperature

occurring due to the pressure increase on the second compressor will be anticipated by installing an intercooler

aiming at preventing excessive heat or over heat during the compression. The extent to which the important

role of the intercooler as a stabilizer of operating temperature in this cooling cycle will be shown in its working

cycle with a Mollier diagram (P-h diagram). The data obtained during the operation of the multistage type

cold storage is then transferred to the P-h diagram of R134A to determine the cycle diagram and the enthalpy

which then determines the amount of COP, the maximum temperature achieved by the system, and its energy

requirements. The calculation results obtained using the intercooler COP is 1.83, and the maximum

temperature achieved is 67ºC. Without using the intercooler, the system’s COP is 1.80 and the maximum

temperature achieved is 89.5ºC.

1 INTRODUCTION

A cold storage is often referred to as a cold room,

which is one of the cooling machines or refrigerators

that are widely required in the industrial sector. The

ability to store products in sufficient quantities at a

fairly low temperature for a long time makes it an

alternative choice for the industrial sector in

maintaining the freshness of its products. The stored

products can vary from raw materials to processed

products, when being produced in large quantities, it

really depends on the cold storage. Bali as a world

tourist destination will highly require the existence of

cold storage. Every hotel that contributes the greatest

support on tourism with a minimum level of three

stars must have one or even more cold storages. In

addition to hotels, businesses need the existence of

cold storage as well for having essential role in

tourism too.

a

https://orcid.org/0000-0002-1028-070X

b

https://orcid.org/0000-0002-2365-9401

Cold storage generally uses a vapor compression

system, because it is more practical and simple in

operation and maintenance. The compressor is the

main feature of the latest vapor compression system

equipped with a condenser, an expansion device, and

an evaporator. Several additional components will

complete the system such as oil separator, liquid

receiver, filter dryer, sigh glass, and accumulator.

Compressors used in cold storage are mostly piston

models because the cooling system is required to be

able to achieve high working pressures, therefore a

multi-stage compressor system is made, also known

as multi-stage. Due to the high working pressure of

the system, the operating temperature will also

increase that it may cause overheating in cold storage.

The inter cooler is finally used as an alternative to

anticipate the process of the temperature increase,

especially in the second compressor. Thus, it is

necessary to have an additional system in the form of

a heat exchanger that will be placed at intermediate

Negara, I. and Arsawan, I.

Experimental Study on the Effect of Intercooler on a Compressor Performance on Multistage Type Cold-storage Simulation.

DOI: 10.5220/0010948200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 503-509

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

503

pressure. The inter cooler will function and be

positioned on the suction line of the second

compressor or the first compressor output. This

second compressor is in charge of increasing the

working pressure of the refrigerant which has also

experienced compression in the first compressor so

that with the presence of this inter cooler, it is

expected that the working temperature of the cooling

system will not continue to increase but can be

stabilized. An experimental study will be conducted

to see the effect of the presence of inter cooler in

multistage cold storage on the performance and

performance of the system during operation.

2 REFRIGERATION

2.1 The Definition of Refrigeration

Refrigeration is a process to produce and keep

something cold. This refrigerant has been widely used

in all fields along with the rapid development of

technology, including the refrigeration machines. In

general, the use of refrigeration machines is to

preserve food because room temperature causes the

food to rot or spoil faster due to quickly grown

bacteria. The utilization of refrigeration machine is

intended to freeze the food to certain temperature and

humidity based on the requirements thus it is

preserved. Whereas the utilization of food

refrigeration machine or coolant engine is for rooms

conditioning, beverage chilling, ice making and so

on. As for the household purpose this machine is used

to preserve vegetables, fruits, meat and so on.

Preservation in large quantities can be found in meat

cuts, shrimp storage, marine fish and so on. We can

even find it on meat, vegetables, and fish transporting

vehicles that carry their goods to distant places thus

the food are still fresh untill they reach their

destination.

2.2 Multistage Cold Storage with

Intercooler

A cold storage is generally a specially designed room

with certain temperature condition that will be used

to store various kinds of products to maintain their

freshness. Cold storage is usually built based on the

building area at the installation site. Cold storage

machines are widely used by industrial parties to

preserve the quality of food and beverages that are

produced or will be produced. A multistage vapor

compression refrigeration system (multistage) is an

advanced vapor compression system that has two or

more compressors as components that can pump and

increase the pressure in series. This is done to obtain

a low temperature that cannot be achieved with a

typical vapor compression refrigeration system.

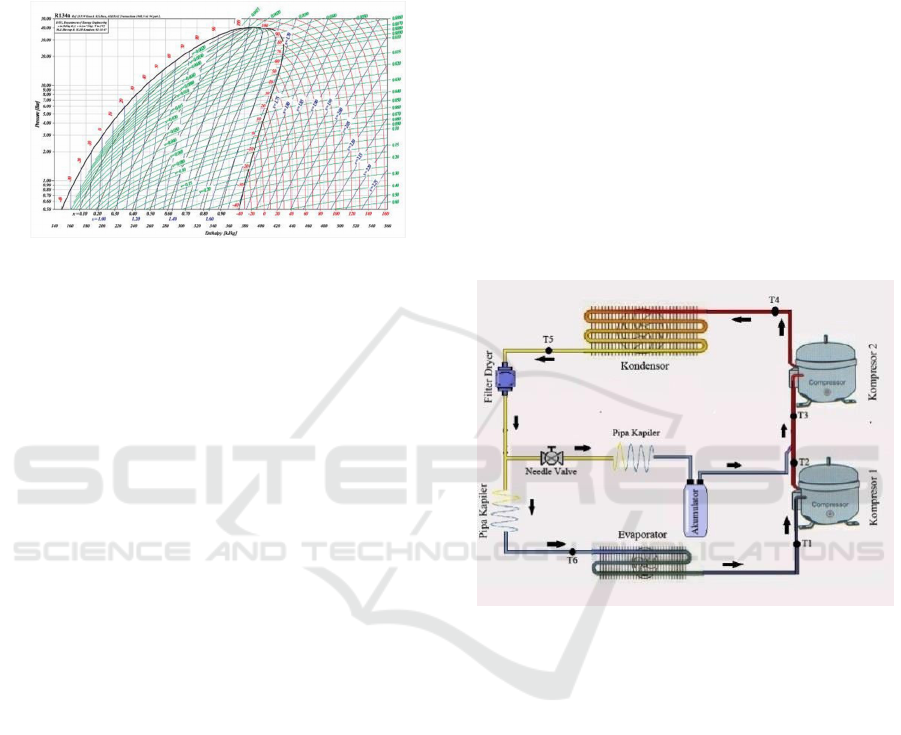

Figure 1: A Cold Storage.

Figure 2: A Multi-stage Cold Storage Piping.

The intercooler is usually placed at an

intermediate pressure

or between high pressure and

low pressure as well as between the two compression

levels which will determine the

compression work

per kg of steam. For a system with

compression

levels or multistage, it will be able to save some

work.

Intercooling in a refrigeration system can be done a

water cooled heat exchanger or by using a

refrigerant. A water-cooled intercooler may suffice

for two-stage

compressed air, but for refrigerant

compression, the water is

usually not cold enough.

Another method is to use liquid

refrigerant from

the condenser to the intercooler. The gas released

from the low-level compressor passes through the

liquid in the intercooler. The refrigerant will leave

the

incooler in the form of saturated vapor. A 2-stage

compressor with an intercooler is often an ideal way

to service a single

low-temperature evaporator.

These systems require less power than a single

compressor and these power savings will

frequently

cost extra equipment.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

504

2.3 P - h Diagram

A P – h diagram is a diagram showing the

characteristics of the refrigerant gas. The x-axis

represents the enthalpy (h) and the y-axis shows the

pressure (P) as shown by the following figure

Figure 3: A P – h Diagram.

a.

Saturated liquid line

It is a curved line from the bottom left to the

critical point. It is at this point that the refrigerant

begins to evaporate. To the left of the line is the

super-cooled liquid area. To the right of the line is

the mixed phase.

b.

Saturated vapor line

It is a curved line from the right to the critical

point. At this point the refrigerant is in the

saturated vapor phase. To the right of the line is

the area of superheated steam. To the left of the

line is the mixed area.

c.

Pressure (P, in Bar)

Pressure is expressed by the ordinate axis (x). It is

a line of constant pressure (isobar), expressed in

psia ( pound per second absolute ) or bar.

d.

Entalphy (h, in KJ/ kg)

It is a vertical line on the Y axis, and is

isoenthalpy. It is the heat energy possessed by a

substance at a certain temperature.

e.

Temperature (T, in °C)

In the liquid area, the temperature line is

constant

(isothermal). Inside the dome the temperature

line is parallel to the pressure line (isobar) and in

the area

of superheated steam, the temperature

rises do not curve

towards the lower right

f.

Specific Volume (v in m³/ kg)

The constant specific volume line (isovolumery)

connects

the state points with the specific volume

with a slightly curved top right oblique direction.

g.

Entropy (s, in KJ/kg)

It is the property of measuring the degree of

disorder or irregularity at the microscopic level

(one unit of weight). The line of constant entropy

(insentropic) connects points of the same state. It

is a right slash from the bottom.

h.

Degree of Dryness (x)

The iso-degree dryness line shows the degree of

dryness of the wet vapor. It is the dividing line

of the flat lines between the saturated liquid line

and the saturated vapor line.

3 EXPERIMENT SETUP AND

PROCEDURE

3.1 Type of Research

The type of research carried out is the analysis of inter

cooler on multi-stage type cold storage which

includes numerical and experimental studies.

Figure 4: The design of multi-stage cold storage

refrigeration simulation.

3.2 Data Source

In this study, the data were obtained by conducting

direct testing on cold storage simulations with a

multistage system with and without an intercooler.

The data can be retrieved after the system works

normally. The data were immediately collected and

carried out 10 times with a time difference of 5

minutes.

3.3 Research Resources

The testing equipment used in this study is a cold

storage simulation with a multistage system designed

at the Refrigeration Laboratory, Mechanical

Engineering, Bali State Polytechnic with the

following specifications:

Experimental Study on the Effect of Intercooler on a Compressor Performance on Multistage Type Cold-storage Simulation

505

a.

A Piston Compressor, 1/10 PK

b.

A Condenser with fan cooling

c.

An evaporator

d.

A Capillary pipe

e.

A Refrigerant R 134a

3.4 Research Instrument

To assist the research, it is essential to provide the

supporting research instrument. The instruments are

described as follows.

a. Clamp Meter

It is a measuring instrument used to measure

electric current in a conductor cable energized

by electric current using its two clamping jaws

without having to have direct contact with the

electrical terminals. In general, Clamp Meter

has two functions: as an amperemeter and a

multimeter. Thus in addition to having two

clamping jaws, the Clamp Meter also has two

probes that can be used to measure Resistance,

AC Voltage, DC Voltage and there are even

certain models that can measure Frequency, DC

Electric Current, Capacitance and Temperature

b. Manifold Gauge

The manifold gauge has very large functions

such as refrigerant filling, pressure monitoring,

and repairing which involves the cooling

medium, namely the refrigerant in the

refrigeration system. The manifold is designed

with a standard construction so that it is easy to

understand. There are two gauges for checking

the suction side and the discharge side. The low

pressure gauge has a scale - 1 bar to 8.2 bar,

meanwhile the high pressure gauge has a scale

of 0 bar s / d 34 bar.

c. Thermocouple

A thermocouple is used to detect or calculate

temperature through two different types of metal

conductors which are joined at the ends to cause

a thermo-electric effect.

d. Stop watch

A stop watch is used to set the duration when

testing the system.

3.5 Research Procedure

The data collection process in a multistage cold

storage simulation system is carried out by following

the following test procedures.

a.

Preparation Steps

1. Preparing the measuring instruments that will

be used to collect data and check high pressure

components in the system.

2. Installing the thermocouple.

3. Installing the manifold gauge.

4. Ensuring that the measuring tools are

properly installed.

5. Ensuring that all tools attached to the system

function properly.

b.

Data Collection Steps

The processes of cold storage simulation testing

with a multistage system are carried out as

follows.

1. Turn the multistage cold storage simulation

engine on and make sure the system runs

normally. Let it runs for ± 30 minutes

2. After the system is running normally, record

the

results of data collection on the high

pressure, medium pressure, and low pressure

sides

3. Perform data collection at the intervals of five

minutes, and the recording is done for twelve

times.

4. After completing data collection, turn off the

system

5. The test results are then recorded in a table

4 RESULTS AND DISCUSSION

The data oftained from the multi stage type cold

storage simulator covering the temperature, pressure,

current, and voltage are presented in Table 1 and

Table 2.

Table 1: Measurement Result Data on Multistage Cool

Storage System with Intercooler.

No T1

(

o

C)

T2

(

o

C)

T3

(

o

C)

T4

(

o

C)

T5

(

o

C)

T6

(

o

C)

LP

(Psi)

1 -6 45 19 55 30 -9 10

2 -7 48 19 56 31 -11 10

3 -10 48 19 59 31 -14 9

4 -10 49 18 69 31 -14 9

5 -10 49 18 69 32 -15 8

6 -10 49 18 70 32 -16 7

7 -12 50 18 70 32 -17 6

8 -14 50 18 70 32 -19 6

9 -16 50 18 72 32 -19 5

10 -16 51 18 72 33 -19 5

11 -17 53 18 75 33 -19 5

12 -17 55 18 75 33 -19 5

R -12 49,7 18,2 67 31,8 -15,5 7,08

1,56

(Bar)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

506

Table 1: Measurement Result Data on Multistage Cool

Storage System with Intercooler (cont.).

No MP

(Psi)

HP

(Psi)

A1

(Amp)

A2

(Amp)

V

(Volt)

1 60 200 0,81 0,91 220

2 68 200 0,82 0,90 220

3 60 210 0,82 0,90 220

4 62 210 0,82 0,90 220

5 65 210 0,82 0,90 220

6 65 215 0,82 0,90 220

7 65 215 0,82 0,90 220

8 65 215 0,82 0,90 220

9 68 220 0,82 0,90 220

10 68 220 0,82 0,90 220

11 68 220 0,82 0,90 220

12 68 220 0,82 0,90 220

R 64,7 211 0,81 0,90 220

5,46

(Bar)

15,7

(Bar)

Table 2: Measurement Result Data on Multistage Cool

Storage System without Intercooler.

No T1

(

o

C)

T2

(

o

C)

T3

(

o

C)

T4

(

o

C)

LP

(Psi)

1 -6 85 37 -11 10

2 -7 86 38 -14 10

3 -9 87 38 -14 9

4 -10 88 38 -15 9

5 -11 88 39 -16 8

6 -12 90 39 -17 7

7 -14 90 39 -19 6

8 -14 91 39 -19 6

9 -16 92 39 -19 5

10 -18 92 40 -20 5

11 -18 93 40 -20 5

12 -18 93 40 -20 5

R -12,7 89,5 39 -17 7,08

1,50

(Bar)

No MP

(Psi)

HP

(Psi)

A1

(Am

p

)

A2

(Am

p

)

V

(Volt)

1 60 200 0,81 0,91 220

2 68 200 0,82 0,90 220

3 60 210 0,82 0,90 220

4 62 210 0,82 0,90 220

5 65 210 0,82 0,90 220

6 65 215 0,82 0,90 220

7 65 215 0,82 0,90 220

8 65 215 0,82 0,90 220

9 68 220 0,82 0,90 220

10 68 220 0,82 0,90 220

11 68 220 0,82 0,90 220

12 68 220 0,82 0,90 220

R 64,7 211 0,81 0,90 220

5,46

(Bar)

15,7

(Bar)

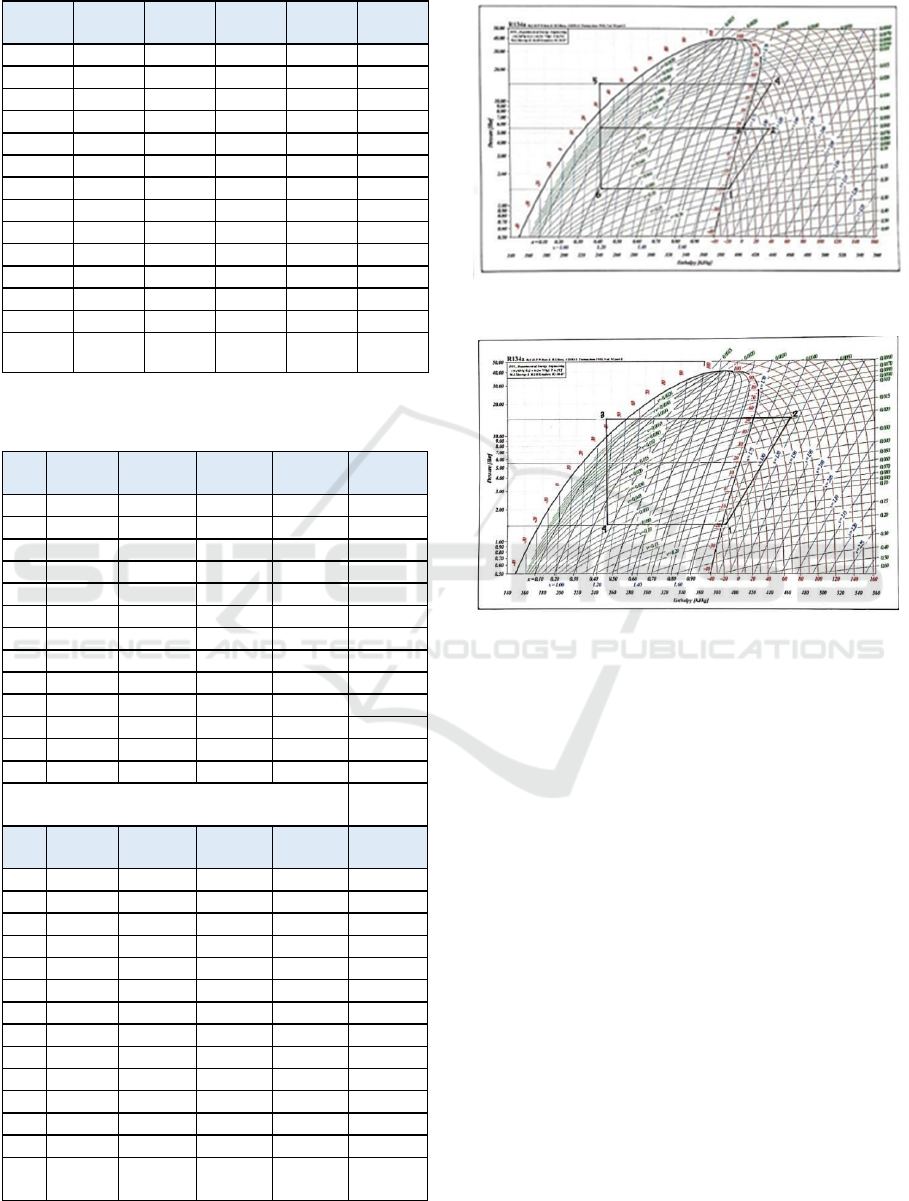

Based on table 1 and 2 a P-h diagram can be drawn as

follows.

Figure 5: P-h Diagram system with intercooler.

Figure 6: P-h Diagram system without intercooler

Based on the figure, the effect of refrigeration and

compressor work from the system with an intercooler

can be

calculated as follows:

a.

Refrigeratiom

Effect (RE) RE

= h1 - h6 (kJ/kg)

= 390 – 242(kJ/kg)

= 148kJ/kg

Where:

RE = Refrigeration Effect

h1 = The enthalpy of refrigerant leaving the

evaporator

(kJ/kg)

h6 = The enthalpy of refrigerant entering the

evaporator

(kJ/kg)

Thus the refrigeration effect of a

multistage cold

storage system with an

intercooler is 148 Kj/Kg.

b.

Compression Work (Cw)

Cw = (h4 – h3) + (h2 – h1) (kJ/kg)

= (441 – 408) + (438 – 390) (kJ/kg)

= 33 + 48 (kJ/kg)

= 81kJ/kg

Experimental Study on the Effect of Intercooler on a Compressor Performance on Multistage Type Cold-storage Simulation

507

Where:

Cw = Compression work

h4 = enthalpy of refrigerant vapor leaving

compressor 2 (kJ/kg)

h3 = enthalpy of refrigerant vapor entering

compressor 2 (kJ/kg)

h2 = enthalpy of refrigerant vapor leaving

compressor 1 (kJ/kg)

h1 = enthalpy of refrigerant vapor entering

compressor 1 (kJ/kg)

Therefore the compression work of a multistage cold

storage system with an intercooler is 81 Kj/Kg.

From the obtained results of the refrigeration effect

and compression work, it can be applied into the

following COP formula:

COP =

𝑅𝐸

𝐶𝑤

=

148

81

= 1,83

Where:

COP = Coeffision of Performance

RE =

Refrigeration

Effect

Cw =

Compression

work

Therefore the theoretical COP obtained

from a system

with an intercooler is 1.83.

For a multistage cool-storage system

without an intercooler, the following results are

obtained.

a. Refrigeration Effect (RE)

RE = h2 –

h1 (kJ/kg)

= 390 – 255(kJ/kg)

= 135kJ/kg

Where:

RE

= Refrigeration Effect

h1 = The enthalpy of refrigerant leaving the

evaporator

(kJ/kg)

h2

=

The enthalpy of refrigerant

vapor

leaving

compressor 1 (kJ/kg)

So the refrigeration effect from cold storage without

an intercooler is 135 Kj/Kg.

b. Compression

work (Wc) Wc =

(h1 – h4) (kJ/kg)

= (465 – 390)(kJ/kg)

= 75(kJ/kg)

Where:

W

= Work compression

h4

=

The enthalpy of refrigerant

vapor

leaving

compressor 2 (kJ/kg)

h1

=

The enthalpy of refrigerant vapor

entering

compressor 1 (kJ/kg)

So the compression work of a cold storage without

an intercooler is 75 Kj/Kg.

From the obtained results of the refrigeration

effect and compression work, it can be applied into

the following COP formula:

COP =

𝑅𝐸

𝐶𝑤

=

135

75

= 1,80

Where:

COP = Coeffision of Performance

RE = Refrigeration Effect

Cw = Compression work

Therefore the theoretical COP obtained from a system

without an intercooler is 1.80. The maximum

temperature of the system can also be directly seen on

the pH diagram and the energy consumption will be

obtained from the enthalpy difference in the system’s

compression work.

5 CONCLUSION

Based on the research results obtained a cool-storage

system with intercooler has a COP of 1.83 and the

maximum

temperature of the system is 67

o

C. Without

an intercooler, its COP is 1.80 and the maximum

temperature of the system is

89.5

o

C. Thus the

system’s performance by using an intercooler is better

than without an intercooler.

ACKNOWLEDGMENT

Thank you to the Bali State Polytechnic for the

financial

assistance that has been given so that this

research can be

carried out.

REFERENCES

Asep Supriatna. 2019. Keuntungan dan Kerugugian

Kompresor

Torak. tptusmkn1cimahi.blogspot.com/

2010/01/kompresor.html. Retrieved on January 25

th

2020.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

508

Calm,J.M. 2012 Options and Outloc for Chiler Frefrigernts.

International Jurnal Of Refrigeration.

Chaiwongsa, Praitoon., Wongwises, Somchai. 2007,

“Experimental study on R-134a refrigeration system

using a two-phase ejector as an expansion device”.

International Journal of Refrigeration.

Febri Amandani. 2018. Kompresor

ReciprocatingMultistage. https://id.scribd.com/doc/

179610930/Kompresor-Multi- Stage. Retrieved on

January 25th 2020.

Indartono 2015. Perkembangan Terkini Teknologi

Refrigerasi URL:http://www.beritaiptek.com

Jahar Sakar. 2010. Layout and P-H Diagram Of Two-Stage

CO 2 System. https://www.researchgate.net/

figure/Layout-and-p-h-diagram-of-two-stage-CO-2-

system- with_fig3_215549766. Retrieved on January

2nd 2020.

Michael F. Taras, Alexander Lifson 2020. Refrigeran

System with Intercooler And Liquid.Vapor Injection.

Retrieved on March 25th 2021.

Pravind D. Dhakane,M.S.Joshi, 2020. Design Of Two

Stage Vapor Compression Refigeration System With

Water Intercooler Retrieved on March 25th 2021.

Sam. 2009. Multistage Refrigeration Systems.

http://www.refrigeratordiagrams.com/refrigeration-

systems-and-applications/refrigeration-cycles-and-

systems/multistage-refrigeration-systems.html.

Retrieved on January 23rd 2021.

Stoecker F Wilbert, Jones W J, Supratman Hara. 1994.

Refrigerasi dan Pengkondisian Udara

Yohanes Johan. 2017. BAB II DASAR TEORI. 2.1 Cold

Storage. https://docplayer.info/42116751-Bab-ii-

dasar- teori-2-1-cold-storage.html. Retrieved on

January 12th 2021.

Experimental Study on the Effect of Intercooler on a Compressor Performance on Multistage Type Cold-storage Simulation

509