Effect of Material Type, Temperature, and Layer Thickness on PLA

and PETG from 3D Printer Products by Tensile Test

Etik Puspitasari, Syamsul Hadi and Moh. Hartono

State Polytechnic of Malang, Soekarno Hatta Street no 9, Malang City, Indonesia

Keywords: 3D Design, 3D Printer, Factorial Design, PETG, PLA, Plastic Specimen, Tensile Test.

Abstract: Many plastic products are produced from 3D printers. The problem to know the strength of the right materials,

researchers try to test the results of plastic specimens from 3D printers with the tensile test. Product size

according to ASTM D638 standard using PLA (Polylactic Acid), and Polyethylene terephthalate glycol

(PETG) filaments. The purpose is to determine the effect of material type, temperature, and thickness of PLA

and PETG filament layers from 3D printer results with tensile tests. The method used is factorial design. The

results of the maximum tensile strength on PLA material while the lowest on PETG. At the highest

temperature, the maximum tensile strength is reached at 260 °C, and the lowest is 220°C. That the higher the

temperature, the greater the effect on the tensile strength. And the highest layer thickness for maximum tensile

strength is 0.3 mm, the lowest layer is 0.1 mm and has a maximum tensile strength of 3.651 N/mm2. The

thicker the layers, the greater the effect on the tensile strength. There is an interaction effect between 3

variables. 3D designs and product prototypes for an additional hanger for a motorcycle by 3D printers have

been made.

1 INTRODUCTION

3D printers are one of the current and future

technologies that must be studied. Where the science

of reverse engineering is developing. Reverse

engineering is the process of analyzing an existing

product as a reference for designing similar products

by minimizing and increasing product advantages

(Daywin et al., 2019). Prototype product design with

the 3D printer is required. Rapid prototyping process

with emphasis on application(Davim, J. P., Kumar,

K., Zindani, 2020). Currently, many plastic products

are produced from 3D printers. 3D printers are very

practical in product development to print three-

dimensional objects such as parts for prototypes,

machine parts, robotics parts, electronic circuit parts,

and other plastic products, etc. Which are drawn from

3D software which is then transferred to 3D printer

software files and then printed on the machine 3D

printers. Preliminary design for 3D printing and

proper technique ensures the success of 3D printing

(Micallef J, 2015).

Digital manufacturing has become an intrinsic

part of the modeling profession, so the practitioner or

product designer must be skilled in traditional hand-

made techniques and digital technologies(Lansdown

H, 2019). Designer in designing a product, one of

which must take into account what material is right

for the product in terms of material strength or cost.

This has been done in previous studies related to the

strength of the PLA material on plastic specimens

produced by 3D printers with a layer thickness of 0.1-

0.5 mm. Indicating that the test results show are not

linear or the thicker the strength is not always Greater,

and the specimen increases. The strongest is in the

layer thickness of 0.35 mm.(Puspitasari et al., 2021).

The visual results of plastic test specimens with a 3D

printer are the smaller the layer used, the smoother

and more aesthetically pleasing(Puspitasari, 2020).

The types of materials or filaments in 3D printers

are Polylactic Acid (PLA), Acrylonitrile Butadiene

Styrene (ABS), Polyethylene terephthalate glycol

(PETG), Nylon (PA), Thermoplastic Elastomers

(TPE), and Polycarbonate (PC). Some filaments have

unique motifs such as wood, namely Wood filaments,

a combination of PLA and metal, and Polyvinyl

Alcohol (PVA).

PLA and PETG were chosen because researchers

wanted to prove which material had the best material

strength. Based on research that printing two types of

filaments, namely polylactic acid (PLA), and

polyethylene terephthalate glycol (PETG). the main

572

Puspitasari, E., Hadi, S. and Hartono, M.

Effect of Material Type, Temperature, and Layer Thickness on PLA and PETG from 3D Printer Products by Tensile Test.

DOI: 10.5220/0010949300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 572-580

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

objective of the study was to find, through simulation

and mechanical compression tests, the maximum

prototype deformation of the adapter and to identify

the best material regarding mechanical resistance.

The result shows that the maximum deformation for

PETG is 0.5976 mm and PLA is 0.3103 mm. From

the research results, PLA has shown a lower

deformation value, but PETG was chosen as the

impression material because no cracks or fractures

were found during the research trials (Silva &

Guilhon, 2019).

A tensile test is carried out by gripping the test

object with a known cross-sectional area on the jaws

of the testing machine and so that the test object

experiences a gradually increasing tensile force

(Higgins, 2006).

With the above background, the researcher will

design and make a tensile test plastic specimen

pattern using a 3D printer which will later be tested

with a tensile test. The purpose of this research is to

analyze the effect of material type, temperature, and

layer thickness on the tensile strength of 3D printer

products with PLA and PETG materials. Analyzing

the effect of interaction between material type,

temperature, and layers thickness on the tensile

strength of 3D printer products with PLA and PETG

materials. And able to make 3D designs and

prototypes of 3D printer products from the research

results that have been obtained.

2 RESEARCH METHODOLOGY

This research was carried out at the Department of

Mechanical Engineering, State Polytechnic of

Malang which has tensile test equipment. The

variable data that will be used are as follows :

1. Independent variables:

a. Layer thickness 0.1mm, 0.2mm, 0.3mm

b. Temperature 220°C, 240°C, 260C

c. Material Type PLA and PETG

2. Dependent Variable Tensile Test Results

3. Controlled Variables:

a. Printing speed: 70mm/s

b. Infill pattern: lines

c. Fulfill density: 100%

d. Bed Temperature: 60°C

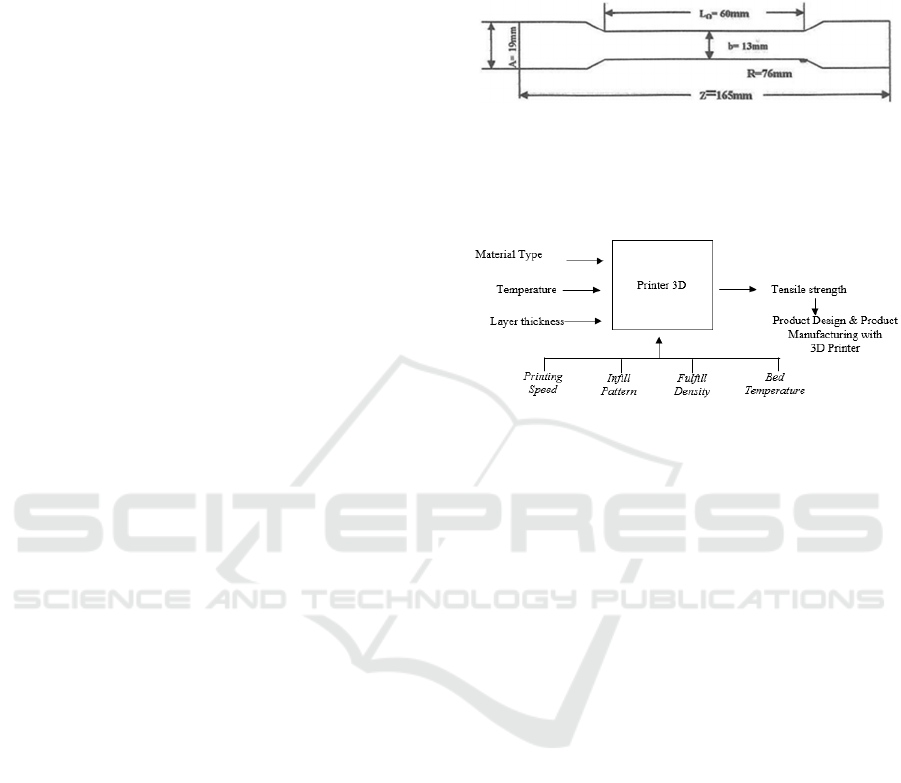

Specimens made must be based on the ASTM

D638 Type 1 standard with the following dimensions:

165 mm long, 19 mm wide, and 5 mm thick. Based

on (Materials et al., 2006) on the ASTM D638 Type

1 standard for the standard test method for tensile

testing of plastic specimens, the thickness of the

specimen is up to 7 mm and can be less than 7 mm.

Plastic specimens to be made with a 3D printer can be

seen in Figure 1 below.

Figure 1: Product Design of 3D printed plastic specimens

for Tensile Test testing.

From the variable data above, it can be seen in

Figure 2 the following research block diagram:

Figure 2: Research block diagram.

The research hypothesis is an assumption that is

not necessarily true in research, so to find the truth of

this research, the research hypothesis can be seen as

follows:

1. Research hypothesis is "There is an effect

between material type, temperature, and layer

thickness on the tensile strength of 3D printer

products made of PLA and PETG materials"

2. Hypothesis Nul (H0) is as follows:

a. There is no effect of material type on the tensile

strength of 3D printer products made of PLA

and PETG materials.

b. There is no effect of temperature on the tensile

strength of 3D printer products made of PLA

and PETG materials.

c. There is no effect of layer thickness on the tensile

strength of 3D printer products made of PLA

and PETG materials.

d. There is no interaction effect between material

type, temperature, and layer thickness on the

tensile strength of PLA and PETG 3D printer

products

3. Alternative hypothesis (H1) is as follows:

a. There is an effect of material type on the tensile

strength of 3D printer products made of PLA

and PETG materials.

Effect of Material Type, Temperature, and Layer Thickness on PLA and PETG from 3D Printer Products by Tensile Test

573

b. There is an effect of temperature on the tensile

strength of 3D printer products made of PLA

and PETG materials.

c. There is an effect of layer thickness on the tensile

strength of 3D printer products made of PLA

and PETG materials.

d. There is an interaction effect between material

type, temperature, and layer thickness on the

tensile strength of 3D printer products made

from PLA and PETG materials.

Data Processing and Analysis method

After drawing the tensile test specimen design

according to the ASTM D638 standard with drawing

software and saved in STL format, the data is entered

into CURA for data processing according to variables

and then converted into a GCODE file. Then print it

using a 3D printer. The results of the tensile test

specimens were carried out by tensile testing on PLA

and PETG specimens where specimen there were 27

specimens multiplied by 3, so the total specimen

tested was 54 specimens, in this study, there were

only 45 data because PETG at 220 C temperature

could not be printed and temperature too low. After

that, the data obtained will be recorded. Then the data

from the tensile test results will be processed by

factorial design using Minitab software. Then make

product designs and manufacture products with a 3D

printer.

3 RESULT AND DISCUSSION

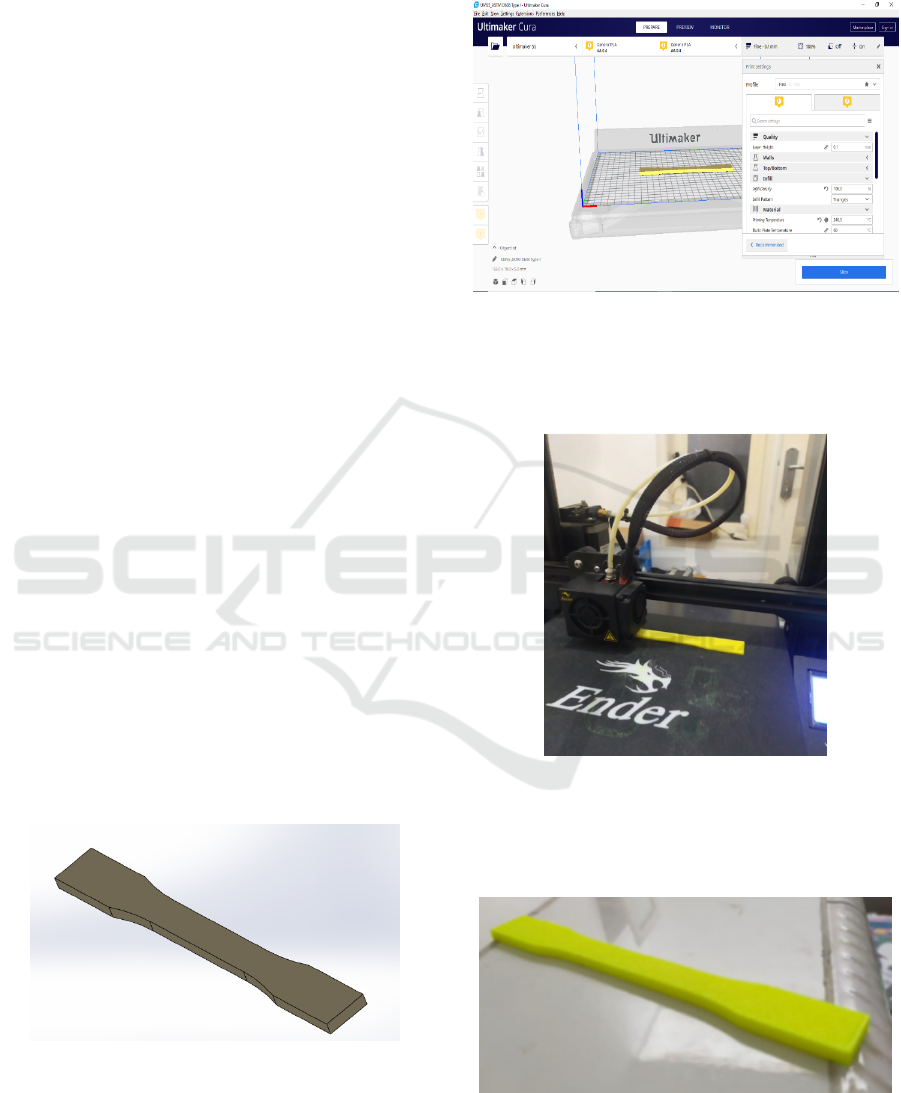

The following are the results of the 3D design of the

tensile test specimen according to the ASTM D638

standard. Save the drawing design with the STL file

format. can be seen in the following Figure 3

Figure 3: Specimen Design 3D Tensile test standard ASTM

D638.

Open the specimen drawing design file to the

CURA software for setting the independent variable

and dependent variable. can be seen in the following

Figure 4:

Figure 4: Setting specimen parameters with CURA.

After that the process of making tensile test

specimens with a 3D printer is carried out, it can be

seen in Figure 5:

Figure 5: 3D Printer Process.

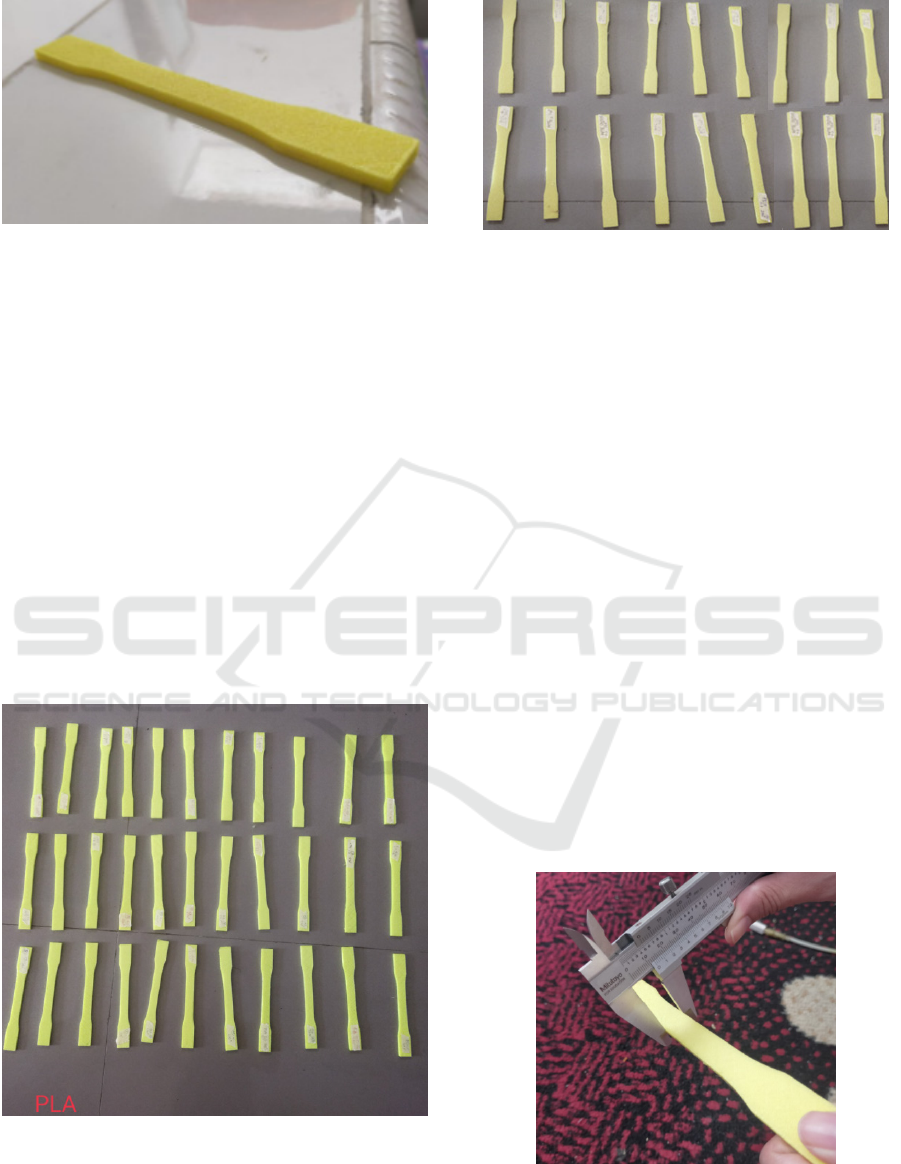

The following are the results of tensile test specimens

from PLA and PETG from 3D printers, which can be

seen in the following Figures 6 and 7

Figure 6: Results of tensile test specimens from PLA from

3D printers.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

574

Figure 7: Results of tensile test specimens PETG from 3D

printers.

The time needed to make one tensile test specimen is

as follows.

1. On a 0.1 mm thick layer with a temperature of 220

C, 240 C, 260 C, it takes an average of 3 hours 57

minutes 10 seconds per 1 specimen.

2. At 0.2 mm thick layer with a temperature of 220

C, 240 C, 260 C takes an average of 2 hours 4

minutes 40 seconds per 1 specimen.

3. Layer thickness of 0.3 mm with temperatures of

220 C, 240 C, 260 C takes an average of 1 hour 26

minutes 57 seconds per 1 specimen.

All of the results of the ASTM D638 standard tensile

test specimen can be seen in Figures 8 and 9 as

follows:

Figure 8: Tensile test specimen results with PLA filament

from a 3D printer.

Figure 9: Tensile test specimen results with PETG filament

from a 3D printer.

Before calculating the stress and strain, it is

necessary to calculate the cross-sectional area (A)

first because it greatly affects the tensile stress. The

cross-sectional area of each specimen is measured

and recorded to obtain the results of the tensile stress.

To find the cross-sectional area (A) that is Wc or the

width of the inside of the specimen multiplied by the

thickness (t).

The cross-sectional area of the design according

to the ASTM D638 standard is Wc = 13 mm and t =

5 mm, then A = 65 mm (drawing dimensions). can be

seen in the formula below:

A = Wc x t (1)

Where :

A = Specimen cross-sectional area

Wc = Width Gauge Area

t = Specimen thickness

The process of measuring tensile test objects from

PLA and PETG that have been printed with a 3D

printer using a caliper with an accuracy of 0.02 mm

to calculate the actual dimensions with the above

formula (1) so that it can calculate the actual cross-

sectional area. can be seen in Figure 10 below:

Figure 10: The process of measuring the PETG tensile test

specimen from a 3D printer.

Effect of Material Type, Temperature, and Layer Thickness on PLA and PETG from 3D Printer Products by Tensile Test

575

The following is the tensile test process which can

be seen in Figure 11 below:

Figure 11: Tensile test process of 3D printer specimen.

The results of the calculation of the cross-

sectional area (A) are used to calculate the tensile

stress (σ). So that the best tensile stress is obtained in

the material, temperature, and layer thickness which

will be tested by Factorial Design.

The tensile test is then carried out. The results of

the tensile test of 3D printer specimens from PLA in

Figure 12 are below:

Figure 12: Tensile test results of PLA specimens from 3D

printer.

The tensile test is carried out with a tensile testing

machine. The standard used in the tensile test is the

ASTM D638 standard. (Budiono, 2015).

To find the value of the tensile stress that occurs

is determined by the following formula (ASTM D

638 Standard). Based on (Hadi Syamsul, 2016) the

tensile stress formula can be seen from formula 2

below

σ = F/A (2)

Where :

σ: Tensile Stress (N/mm2)

F: Tensile Load (N)

A: Specimen cross-sectional (mm

2

)

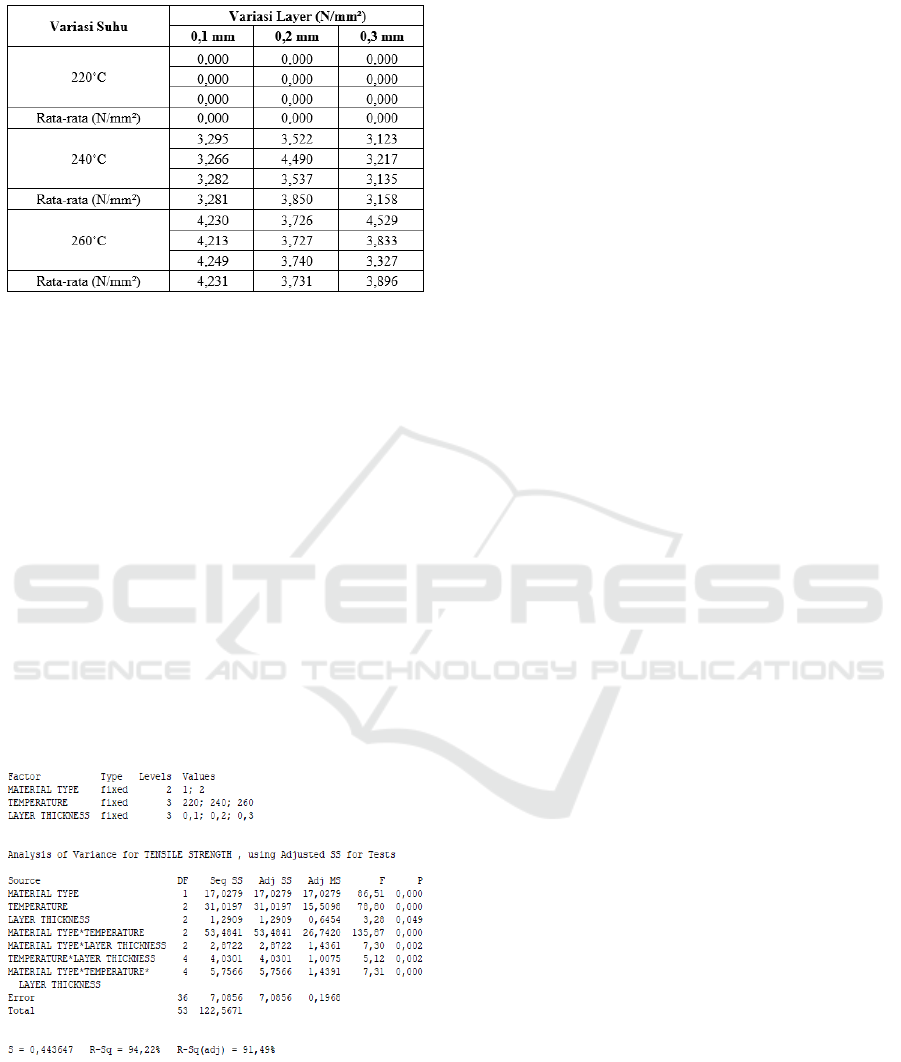

The following are the results of the tensile stress

testing of the 3D printer tensile test specimen from

the PLA filament. The data will be processed by

factorial design. which can be seen in Table 1 below:

Table 1: Tensile Stress Test Results of PLA.

The tensile test is then carried out. The results of

the tensile test of the 3D printer specimen from PETG

in Figure 13 are below:

Figure 13: Tensile Test Results of PETG Specimens from

3D printers.

The following are the results of the tensile stress

testing of the 3D printer tensile test specimen from

the PETG filament. The data will be processed by

factorial design, which can be seen in Table 1 below:

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

576

Table 2: Tensile Stress Test Results of PETG.

Table 2 shows that the temperature of 220 C is

zero because the temperature is too low for the PETG

filament so that a tensile test specimen cannot be

made.

Analysis of Tensile Test Results with Factorial

Design

After testing the tensile test on the PLA and PETG

specimens and getting the results of the tensile stress

and strain values as above. Then the data was

analyzed using Factorial Design with Minitab.

Because researchers wanted to see whether or not

there was an influence or not from 3 independent

variables, namely the type of material, namely PLA

and PETG, the temperature is 220 °C, 240 °C, 260 °C,

and the layer thickness is 0.1 mm; 0.2mm; 0.3mm.

The following results of the tensile stress analysis on

the tensile test specimen test with a 3D printer in

Figure 14 below:

Figure 14: Factorial Design Result of Tensile Strength .

From the results of the Factorial Design in Figure

4.15, the first variable, namely the type of PLA and

PETG material, has a p-value of 0.000, and the value

is less than = 0.05. can be concluded that the

hypothesis (H0a) is rejected, and the alternative

hypothesis (H1a) is accepted, namely "There is an

effect of material type on the tensile strength of 3D

printer products made of PLA and PETG materials".

For the second variable, temperature with a p-value

of 0.000, the value is less than = 0.05. can be

concluded that the hypothesis (H0b) is rejected, and

the alternative hypothesis (H1b) of the study is

accepted, namely "There is an effect of temperature

on the tensile strength of the 3D printer product, PLA

and PETG materials." The third variable is layer

thickness with a p-value of 0.049, the value is less

than = 0.05. It can be concluded that the hypothesis

(H0c) is rejected and the alternative hypothesis (H1c)

of the study is accepted, namely "There is an effect of

layer thickness on the tensile strength of 3D printer

products made of PLA and PETG materials"

In the summary model, the values are the

reference data and part of the Factorial Design

analysis. The standard deviation value (S) is the

average deviation of the data points with the average

data. can be seen in Figure 14 that the value of S in

the data processing results is 0.443647 which means

that the deviation value of the data point with the

average data is 0.443647. The coefficient of

determination (R-sq) is the percentage contribution of

the influence given by the independent variable to the

dependent variable. In Figure 14 the coefficient of

determination has a value of 94.22% which means

that the influence of the independent variables,

namely the type of material, temperature, and layer

thickness, affects 94.22% of the dependent variable,

namely tensile strength. makes the remaining 5.78%

an error in the form of other independent variables

outside the material type, temperature, and layer

thickness as well as errors in testing or other things

that affect tensile strength.

In Figure 14, it is found that the interaction

between the variables of material type and

temperature is mutually influential, this is evidenced

by the p-value of 0.000, the value is less than = 0.05.

The second interaction found that the interaction

between the material type variable and layer thickness

also had an effect, this was evidenced by the p-value

of 0.002, the value was less than = 0.05. In the third

interaction, temperature and layer thickness variables

have an effect, this is evidenced by the p-value of

0.002, the value is less than = 0.05. The fourth

interaction of the three variables. Namely, the type of

material, temperature, and layer thickness interact

and influence each other, this is evidenced by the p-

value of 0.000, the value is less than = 0.05.

Effect of Material Type, Temperature, and Layer Thickness on PLA and PETG from 3D Printer Products by Tensile Test

577

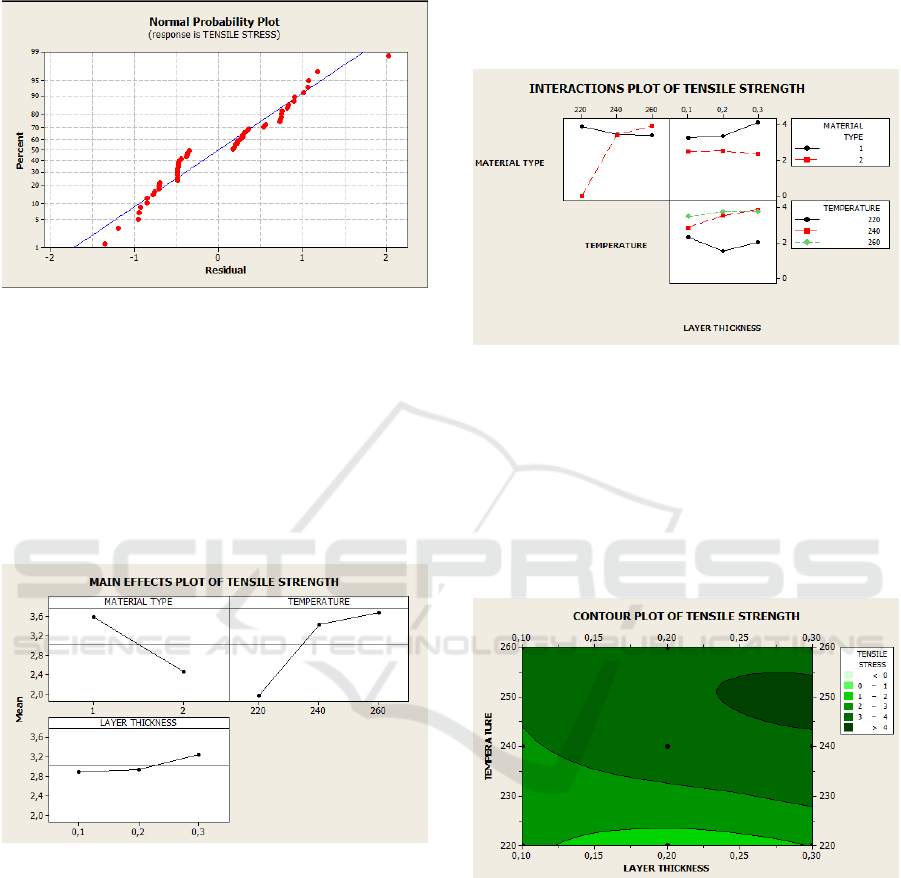

Next is the normality graph is shown in Figure 15

below:

Figure 15: Normality Probability Plot.

The normality probability plot in Figure 15 above

shows that the data is on the Normal line and

approaching the diagonal line, so it is stated that the

data is Normal.

Main effect plot for maximum tensile strength

where tensile strength is sometimes called ultimate

strength. which is the maximum stress that can be

received by a material before breaking. The results of

data processing can be seen in Figure 16 below:

Figure 16: Main Effect Plot of tensile strength for PLA and

PETG.

In Figure 16 above, the maximum tensile strength

for this type of material is at No. 1, namely PLA,

while the lowest is at No. 2, namely PETG. The

highest maximum tensile strength temperature is

achieved at a temperature of 260 °C, and the lowest is

at a temperature of 220 °C. It can be seen that the

higher the temperature, the greater the effect on

tensile strength. And the highest layer thickness for

maximum tensile strength is at layer 0.3 mm, and the

lowest is at layer 0.1 mm. It can be seen that the

thicker the layer, the greater the effect on tensile

strength.

The analysis of the interactions plot of the

tensile strength analyzes the effect of the

interaction between the type of material,

temperature, and layer thickness. And the results

are obtained as shown in Figure 17 below:

Figure 17: Interactions Plot of Tensile Strength.

From Figure 17 above, the interaction between

material type, temperature, and layer thickness shows

that the highest interaction between material type and

layer thickness is in type 1, namely PLA with a layer

thickness of 0.3 mm, the highest temperature

interaction is at a temperature of 260°C.

Furthermore, the contour plot for tensile strength

can be seen in Figure 18 below:

Figure 18: Contour Plot of tensile strength.

In Figure 18 above, it can be seen that the area

that has large tensile strength and > 4 N/mm2 is at a

layer thickness of 0.25-0.30 mm and a temperature

between 240-255 °C. Furthermore, the area that has

the smallest tensile stress of 1-2 N/mm2 is at a layer

thickness of 0.125-0.30 mm with a temperature

between 220 °C.

Designs and Prototypes of 3D Printers for an

additional hanger for a motorcycle

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

578

From the research obtained above, the best tensile

strength for PLA material with a layer thickness of

0.3 mm and a temperature of 260°C is 3.651 N/mm2,

from these results the researcher makes an additional

hanger for a motorcycle design and will then make a

prototype printed on a 3D printer. The background for

making this design is the application of the research

results obtained where the product to be made

contains elements of tensile strength because the

function of the product is as a hanger of goods where

it accepts loads and tensile forces. In addition, the

background of this design was made because the

researcher got the idea when buying a lot of items

with a lot of plastic bags that had to be hung on a

motorcycle hanger, it was not enough because there

was only one hanger so the researcher wanted to make

a hanger that had 3 branches so that when this product

placed on the original motorcycle hanger can load

more goods. This product can be used in all brands of

motorcycles because it has been pre-measured. The

following 2D and 3D designs for the additional

hanger for a motorcycle can be seen in Figures 19 and

20 below:

Figure 19: 3D design of additional hanger for a motorcycle..

Figure 20: Printer 3D result of additional hanger for a

motorcycle.

Figure 21: Application of additional hanger for a

motorcycle.

Based on Figure 21 the addition of these tools can

increase the capacity to carry goods on a motorcycle.

The time of making an additional hanger for a

motorcycle product takes 6 hours 28 minutes for 1

product. This proves that 3D printers are suitable for

making prototypes or making small quantities of

products. Not suitable for mass production. Based on

research Rapid Prototyping Techniques are for

custom-made products and not for mass manufacture

(Davim, J. P., Kumar, K., Zindani, 2020). For mass

production, it is recommended to use injection

molding but must make a mold. The advantage of 3D

printers is that there is no need to make molds or

prints and complex designs can be made on a 3D

printer. based on research (Davim, J. P., Kumar, K.,

Zindani, 2020), Rapid Prototyping Techniques are for

custom made products and not for mass manufacture.

4 CONCLUSION

1. There is an effect of material type, temperature,

and thickness on the tensile strength of 3D printer

products with PLA and PETG material. The

hypothesis (H1) is accepted. Supported by the

factorial design method where the P-value of the

three variables is less than the value of = 0.05. The

maximum stress is on the type of PLA material

while the lowest is on the PETG. The highest

maximum tensile stress temperature is achieved at

a temperature of 260 °C and the lowest is at a

temperature of 220 °C. It can be seen that the

higher the temperature, the greater the effect on

Effect of Material Type, Temperature, and Layer Thickness on PLA and PETG from 3D Printer Products by Tensile Test

579

tensile strength. And the highest layer thickness

for maximum tensile strength is at layer 0.3 mm

and the lowest layer is 0.1 mm and has a

maximum tensile strength of 3.651 N/mm2. It can

be seen that the thicker the layer, the greater the

effect on tensile strength.

2. There is an interaction effect between material

type, temperature, and layer thickness on the

tensile strength of 3D printer products with PLA

and PETG materials. Supported by the factorial

design method where the interaction value of the

three variables above the P-value is less than the

value of = 0.05.

3. 3D designs and product prototypes for an

additional hanger for a motorcycle by 3D printers

have been made according to the results of the

research.

ACKNOWLEDGMENT

The research team from Mechanical Engineering of

the State Polytechnic of Malang has carried out

research, to all parties who have helped this activity

and P2M of the State Polytechnic of Malang.

REFERENCES

Budiono. (2015). Pengujian kuat tarik terhadap produk

hasil 3d printing dengan variasi ketebalan layer 0,2 mm

dan 0,3 mm yang menggunakanan bahan abs

(acrylonitrile butadiene styrene).

Davim, J. P., Kumar, K., Zindani, D. (2020). (2020). Rapid

Prototyping, Rapid Tooling and Reverse Engineering:

From Biological Models to 3D Bioprinters. Germany:

De Gruyter.

Daywin, F. J., Utama, D. W., Kosasih, W., & Wiliam, K.

(2019). Perancangan Mesin 3d Printer Dengan Metode

Reverse Engineering (Studi Kasus di Laboratorium

Mekatronika dan Robotics Universitas Tarumanagara).

Jurnal Ilmiah Teknik Industri, 7(2), 79–89.

https://doi.org/10.24912/jitiuntar.v7i2.5929

Hadi Syamsul. (2016). Teknologi Bahan. Penerbit Andi,

Yogyakarta.

Higgins, R.. (2006). Materials for Engineers and

Technicians. 4th ed. UK: Newnes.

Lansdown H. (2019). Digital Modelmaking: Laser Cutting,

3D Printing and Reverse Engineering. The Crowood

Press.

Materials, P., Materials, E. I., Matrix, P., Materials, C., &

Specimens, P. (2006). Standard Test Method for

Tensile Properties of Plastics 1. January 2004, 1–15.

https://doi.org/10.1520/D0638-14

Micallef J. (2015). Beginning Design for 3D Printing.

Apress.

Puspitasari, E. (2020). Analisa Pola Spesimen Plastik Uji

Pukul Charpy Dengan Menggunakan Printer 3D. Jurnal

Teknik Ilmu Dan Aplikasi, 9. https://doi.org/10.33795/

jtia.v9i2.33

Puspitasari, E., Wirawan, W., & Hadi, S. (2021). Analisis

Lapisan Cetak Printer 3d Spesimen Plastik Pla

Kelipatan 0,05 mm TERHADAP ENERGI PUKUL.

Info-Teknik, 21(2), 139. https://doi.org/10.20527/

infotek.v21i2.10049

Silva, A., & Guilhon, D. (2019). Comparative analysis of

ankle prosthesis connector adapters in 3D printed using

PLA and PETG. IFMBE Proceedings, 70(1), 155–161.

https://doi.org/10.1007/978-981-13-2119-1_24

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

580