Evaluation of Power Consumption in Moringa Leaves Dryer

Sumartini Dana, Yohanes Suban Peli, Indranata Panggalo, Ade Manu Gah and Indah O. Laleb

Department of Electrical Engineering, State Polytechnic of Kupang, AdiSucipto St., Kupang, Indonesia

Keywords: Solar Collector, PLN Electricity, Moringa Leaves.

Abstract: Moringa leaf dryer using solar collector and PLN electricity results from developing renewable energy that

utilizes solar energy directly or indirectly and combines it with PLN electricity. The aim is to increase the

production of dried Moringa leaves with tools designed to produce quality and hygienic for consumption,

reduce dependence on weather. Another point is to minimize losses experienced by Moringa farmers at

harvest, minimize the possibility of damage caused by decay, accelerate the Moringa processing process, and

do not require a large land area. Two ways are done in the moringa leaves' drying process: 1) Direct sunlight

hits the glass collector. Heat is collected in the collector's room and distributed in the dryer room using

additional tools such as fans or blowers needed to drain the dryer air to the Moringa leaves to be dried (forced

convection) and use the temperature sensor as a temperature controller in the room. Drying process. 2). The

oven works by utilizing PLN electricity for drying done at night. And the expected dryer temperature is 37-

40

0

C for three days. The process of setting the temperature control in the room of the moringa leaf dryer using

TNZ4H control temperature connected with the RTD sensor by selecting the setpoint 35-45 ºC. If the

temperature is less than 35 ºC, the heat source (Lamp) will turn on if more than 45 ºC, then the lamp will go

out. The drying result of 20 kilos of moringa leaves only takes about 8 hours with the average temperature in

the dryer room 40ºC. While with a weight of 100 kilos takes about three days because the drying process still

requires the sun as a source of heat and backup power. The average temperature in the rack during the drying

process of Moringa leaves weighing 100 kilos is 37ºC. The maximum temperature in the moringa leaf dryer

is 61.1ºC, with a maximum outside temperature of 42ºC. So it is necessary to analyse the calculation of the

amount of power, and the cost of electricity consumption is proper and efficient for moringa leaf dryer. From

the results of this calculation, the tool can be produced and utilized by the community.

1 INTRODUCTION

The use of Moringa for the people of NTT Province

is very potential and diverse, both from food

processing businesses, medicines, etc. Moreover,

Moringa plants are easy to grow, thrive in tropical

climates such as the NTT region, and do not require

extra care, making Moringa a prima donna plant in

NTT.

The processing itself is not so tricky only requires

full accompaniment to produce Moringa with good

quality. But there are some obstacles related to the

drying process that is the drying process done by

moringa farmers by utilising direct sunlight. First, the

dry season is not an obstacle, but the rainy season,

where the sun is not shining too well and often

cloudy, will hinder the drying process to the

maximum. The second problem in marketing is that

drying Moringa leaves that are not optimal will cause

a decrease in the income of Moringa farmers because

the level of dryness of Moringa leaves is not as

desired by the market. The third problem is that it is

not hygienic because Moringa leaves are dried in the

open, and the drying containers are straightforward.

Usually, Moringa farmers dry them using woven

bamboo, zinc, and tarpaulin shelves, and some even

put them directly on the ground.

Therefore, a moringa leaf dryer is made that can

solve all the problems mentioned above. Moringa leaf

dryer has a capacity of 20 kilos; heating at night takes

three incandescent lamps with 120 watts of electric

power and usage for 8 hours starting from 5 pm to 2

am. For cooling, it takes 6 fans of 20 watts each. The

required temperature in the drying process ranges

from 37 ºC to 40 ºC. So to maximise the energy

consumption in the moringa leaf dryer, evaluation of

power consumption on moringa leaf dryer is

appropriate and efficient.

604

Dana, S., Peli, Y., Panggalo, I., Gah, A. and Laleb, I.

Evaluation of Power Consumption in Moringa Leaves Dryer.

DOI: 10.5220/0010949800003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineer ing Science (iCAST-ES 2021), pages 604-612

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 LITERATURE STUDY

2.1 Energy Audit

An energy audit is the first step in recording energy

consumption data, identifying sources of energy

wastage, analysing the possibility of energy saving,

and calculating the necessary steps. In addition, the

energy audit aims to find out "Portrait of Energy Use"

and look for efforts to improve energy efficiency.

2.2 Parameters for Calculating Power

The velocity at which electricity flows at one point on

the power grid is called an electrical power. The unit

of electricity in watts or joules per second in SI.

Electric power becomes measurable when electricity

producte by the plant and the absorb by the electricity

load. Power is negative when electrical power flows

from the circuit into the electrical capacity. Electric

power is divided into power triangles: apparent

power, active/real power and reactive power.

1. Real Power

Real power is the electrical power used by consumers

for electrical machinery or other equipment after

multiplied cos φ.

With the formula:

Phase to neutral (1 phase) :

P = V × I × cosφ (1)

Phase to phase (3 phase) :

P = V × I × cosφ ×

√

3

(2)

Where:

P = real power ( Watt or J/s)

V = voltage (Volt)

I = current flowing on the delivery (Ampere)

cos φ = power factor

2. Reactive Power

Reactive power arises due to inductive/capacitive

reactive load and this power is used for mechanical

and heat. Reactive power results from the magnitude

of the voltage-current influenced by the power factor

with the Unit Volt Ampere Reactive (VAR).

With the formula:

Phase to neutral (1 phase):

Q = V × I × sin φ (3)

Phase to phase (3 phases):

Q = V × I × sin φ ×√3 (4)

Where:

Q = reactive power (VAR)

V = voltage (Volt)

I = current (Ampere)

φ = angle between current and voltage

3. Apparent Power

Apparent power is generated from a power source or

power plant and is an electrical power that flows

through the middle and currents flowing through the

transmission—the only volt-ampere (VA).

With the formula:

Phase to neutral (1 phase):

S = V × I (5)

Phase to phase (3 phase):

S = √3 × V × I (6)

Where:

S = Apparent power (VA)

V = voltage (Volt)

I = current flowing on the transmission (Ampere)

The power triangle relationship is shown in figure 1.

Figure 1: Power Triangle.

2.3 Drying

Drying is a hydrating process, which means removing

water from a material. The drying or hydration

process occurs when the dried material loses some or

all of the water it contains. The primary technique that

occurs after the drying process is evaporation.

Evaporation occurs when the water collected by a

material evaporates when heat is given to the

material. This heat can be supplied through various

sources, such as firewood, oil and gas, new charcoal

or solar power. Drying can also take place in other

ways, namely by breaking (Handini, 2008).

Evaluation of Power Consumption in Moringa Leaves Dryer

605

The drying process is influenced by temperature,

ambient air humidity, drying air flow rate, desired

moisture content, drying energy and drying capacity.

Drying that is too fast can damage the material

because the surface of the material dries too quickly

so that it can't be balanced with the speed of

movement of water from the material to the surface.

Furthermore, fast-drying causes the hardening of the

material's surface so that the water in the material can

no longer evaporate due to obstruction. In addition,

dry conditions with temperatures that are too high can

damage the material. Setting the temperature and

drying time is done by paying attention to the contact

between the dryer and the heating device (in the form

of hot air flowing or other heating devices). However,

for the sake of considerations of nutritional standards,

heating is recommended no more than 85

0

C

(Ismawati, Pengeringan, 2012).

2.4 Energy Conversion Mechanisms

When two or more objects are in thermal contact, heat

will flow from an object with a higher temperature to

an object with a lower temperature until thermal

equilibrium is reached. This heat transfer process takes

place in 3 mechanisms, namely:

1.

Conduction

2.

Convection

3.

Radiation

The definition of the thermal efficiency of a solar

collector is the comparison between the energy used

and the amount of solar energy received at a specific

time (A. Jansen. T.J, Teknologi Rekayasa Surya,

1995), the air is heated in the collector and rises due

to natural convection. The heat is stored in the rock,

and the air is then re-entered into the collector's base.

The heat is removed from the relief drift by natural

convection or rapid air circulation through the

collector and storage. So the store must be located as

far as possible above the collector.

2.5 Fishbone Diagram

To provide an overview of research activities, the

stages of research work, outputs, and measurable

achievement indicators, can be seen through the

fishbone diagram and research chart in Figure 3

below:

Figure 2: Fishbone Diagram.

3 METHOD

The following is the methodology used in the study to

evaluate the power consumption of the moringa leaf

dryer.

Figure 3: Research Flowchart.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

606

There are three stages in this research: the design of

the tool, the manufacture, installation of the device

and the testing of the tool, and the evaluation of the

power consumption of the tool. The variable

parameters in this study are:

1.

Moringa leaf drying process time

2.

Calculation of power supply from collectors and

PLN electricity

Sub Variable:

a)

Drying evenly on moringa leaves

b)

Collector's power supply

c)

The average time used to dry the leaves perfectly

d)

Evaluation of the power used in the entire drying

process

3.1 Research Procedure

The research carried out is applied from the results of

planning, which is suitable for research to observe the

condition of the tool directly. The research procedure

includes

1. Design & Planning

2. Material selection

3. Making tools and electrical installations

4. Installation

5. Tool testing and evaluation of power usage

6. Repair,

7. Data collection,

8. Analysis and report generation.

3.2 Types and Sources of Data

The data sources and types of data in this study

consisted of primary data, namely data that were

directly measured in the field and the results of the

calculation of the information design obtained from

the measurement results, and secondary data that

supported primary data and the results of observations

and document data.

3.3 Data Collection Techniques

Data collection techniques consist of primary and

secondary data, namely: In preliminary data, the

researcher uses data collection techniques and

measurements directly in the field, the results are

recorded according to the data group and observes

and analyses the Moringa leaf dryer that has been

made, and records the phenomena that occur—being

researched. While secondary data, researchers collect

data from literature both in books and secondary data

works and perform data analysis.

3.4 Data Analysis

Data analysis, both primary data and secondary data

were analysed in the following way:

1. Analysis of quantitative research

Researchers measure the existence of a variable

using research instruments. Then analyse

looking for the relationship of one variable with

other variables.

2. Description analysis

Data is analysed according to the data group

using experimental methods and actions. Both

ways are determined by paying attention to the

cause of the occurrence.

3. Trial/Testing Prosedure

Before testing moringa leaves, ensure all

ingredients are in good condition and have gone

through the cleaning process. Ensure the shelves

in the dryer oven are in good condition and all

shelves are filled with Moringa leaves neatly and

densely. Ensures the temperature on the collector

up to 50 C and the maximum room temperature

of 40 after the Moringa leaves dry.

4. Measuring Instrument

Measuring instruments are required to obtain the

data to be analysed. In this research, Scales and

thermometer are utilized in collecting data.

Figure 4: Scales.

Evaluation of Power Consumption in Moringa Leaves Dryer

607

Scales used to measure the mass of the product before

and already dried. A thermometer used to measure the

temperature of the inside of the oven.

Figure 5: Thermometer inside the dryer.

Figure 6: Thermometer for outer measurement.

5. Testing Stages

Preparation

Preparing the equipment needed for the drying

process of moringa leaves includes the preparation of

the oven, namely the dryer shelves adjusted to the

weight of the moringa leaves to be dried. Check the

oven power plug, prepare the measuring instrument

to be used. Turn on the electric heater, observing the

oven temperature reaches the desired temperature

(47°C)

Data Retrieval

Data retrieval is done at the time difference of 1 hour

each, starting from the start of the drying process. The

measured data is Collector Temperature (°C), Dryer

Room Temperature (°C), Outer Temperature(°C),

Outer Humidity (%), Dryer Room Humidity (%),

Current (A), Voltage (V). Measurements are

performed on two conditions using and using Fan

Dryer, Fan Air Flow and heater.

Settlement

The completion stage of the drying process is done to

end the series of drying processes by turning off the

electric heater on the off button, removing the power

plug in the oven, then eliminating the shelves

containing dried moringa leaves and collecting them.

Then the rack is cleaned off the crumbs of moringa

leaves, followed by cleaning the inside of the oven

and tidying and packing the measuring instrument

used in the testing process.

4 DISCUSSION

Before drying, moringa leaves are first cleaned,

separated from the yellow leaves and dirt attached to

the leaves, then washed and queued. Moringa leaves

are placed neatly so as not to accumulate each other

so that in the drying process can be evenly distributed

on all surfaces of the leaves.

Figure 7: The process of cleaning and washing Moringa

leaves before being put into the oven for the drying.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

608

The drying process of moringa leaves is carried

out approximately for 24 hours. Moringa leaves are

evenly styled on each shelf consisting of 5 parts with

a total of testing that is 10,000 grams, 6000 grams,

4000 grams and 2000 grams.

Figure 8: Fresh Moringa leaves that have been leaned are

put into the oven for the drying process.

Figure 9: The drying process of Moringa leaves with the

half-dry result.

Figure 10: Drying moringa leaves with the result of an even

drought.

Figure 11: Drying moringa leaves one rack.

A. Moringa Testing Data

In table 1, measurement is done to 10,000 grams

moringa leaves with a difference of drying time of 1

hour. The Dryer Fan is on while Fan Air Flow inputs

and outputs is set to on and off state at certain

intervals of time. The heating process is done from

morning to night. In the afternoon the heater was left

in a state of off, while at night and dawn, the heater is

on. Some parameters considered in data collection are

:collector Temperature (°C), Dryer Room

Temperature (°C) Outside Temperature (°C ) Outdoor

Humidity (%), and Dryer Room Inertia (%).

Evaluation of Power Consumption in Moringa Leaves Dryer

609

Table 1: Measurement of 10,000 grams of moringa leaves.

A. Calculation Analysis

1. Power Calculation (W) Formula:

P = Vx I x cos φ

I = 0.1 A

V= 214 V

Cos φ =0.9

P = 214 x 0.1 x 0.9

P = 19.26 watts

2. Energy Calculation (kWh)

Formula: E ; t = 1 hour

E = Pxt/1000

E = (19.26 x 1)/1000

E = 0.019 kWh

3. Calculation of Energy in Rupiah (basic electricity

tariff = Rp. 1444.70

E

Rp

= E

kwh x Tdl

E = 0.0193 x Tdl

E = 0.0193 x (1444.70)

E = Rp. 27,82

4. Average Energy Consumption Hourly (in Kwh

and Rupiahs)

Eave = Total Energy/ Drying Duration

Eave = 2.3008/22

Eave = 0.1046 Kwh/Hour

Eave (Rp) = 0.1046 x Rp. 1444.70

Eave = Rp. 151.11/ Hour

For Table 2, the price of electricity per kWh for

the period April-June 2021 for 1300 VA and 2200 VA

loads is Rp.1444.70. During measurement, the

conditions are divided into three conditions, namely

condition 1, condition 2 and condition 3. The time for

condition 1 is 15.00-16.00, time for condition 2 is

17.00-08.00, and time for condition 3 is 09.00-12.00.

Input Output

1 15:00 On On On Off 45 32 33 40 80 0.1 214 19.26 0.0193 27.82492

2 16:00 On On On Off 42 35 32 40 75 0.37 214 71.26 0.0713 102.9522

3 17:00 On Off On On 37 34 31 40 73 0.37 210 69.93 0.0699 101.0279

4 18:00 On Off On On 30 32 30 45 70 0.8 208 149.76 0.1498 216.3583

5 19:00 On Off On On 28 33 29 45 65 0.8 208 149.76 0.1498 216.3583

6 20:00 On Off On On 29 34 28 50 65 0.8 209 150.48 0.1505 217.3985

7 21:00 On Off On On 26.5 35 26 50 60 0.8 209 150.48 0.1505 217.3985

8 22:00 On Off On On 26 35.2 25.8 52 60 0.8 204 146.88 0.1469 212.1975

9 23:00 On Off On On 25 35 25.5 52 60 0.8 204 146.88 0.1469 212.1975

10 00:00 On Off On On 25 35 25.2 52 59 0.8 204 146.88 0.1469 212.1975

11 01:00 On Off On On 25 35 25 52 57 0.78 203 142.51 0.1425 205.8784

12 02:00 On Off On On 25 35 25 52 55 0.78 203 142.51 0.1425 205.8784

13 03:00 On Off On On 25 35 24 52 50 0.75 203 137.03 0.1370 197.96

14 04:00 On Off On On 25 35 24 52 50 0.75 203 137.03 0.1370 197.96

15 05:00 On Off On On 25 35 24 40 45 0.73 202 132.71 0.1327 191.7319

16 06:00 On Off On On 26 35 25 35 42 0.73 202 132.71 0.1327 191.7319

17 07;00 On Off On On 28 36 27 30 38 0.73 202 132.71 0.1327 191.7319

18 08:00 On Off On On 35 36 29 30 35 0.37 205 68.27 0.0683 98.62245

19 09:00 On Off On Off 43 36 32 25 33 0.1 205 18.45 0.0185 26.65472

20 10:00 On Off On Off 45 38 35 20 30 0.1 205 18.45 0.0185 26.65472

21 11:00 On Off On Off 49 39 35 25 30 0.1 205 18.45 0.0185 26.65472

22 12:00 On Off On Off 52 39 35 25 30 0.1 205 18.45 0.0185 26.65472

2.3008 3324.025

0.1046 151.092

Total

Energy

Consumption/ hour

Power

(W), Cos

Phi 0.9

Energi

(KWh) ,1

hour

duration

Energy in

Rupiahs

(Rp)

Voltage

(V)

Fan Air Flow

Drying

Room

Temper

ature

(°C)

Outdoo

r

Temper

ature(°C

)

Humidity

(%)

Drying

Room

Humidity

(%)

Current

(A)

No Time

Dryer

Fan

Heater

Collecto

r

Temper

ature

(°C)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

610

Some calculation:

Condition 1. Fan air flow for both input and output is

on, while the heater is in the Off state.

Energy consumption for 2 hours

= 0.0193 + 0.0713 = 0.905 Kwh

Energy Consumption in Rp, for 2 hours

= 0.905 x Rp. 1444.70 =Rp. 130.78

Average energy in Kwh

= 0.905/2 Kwh

= 0.0452 Kwh

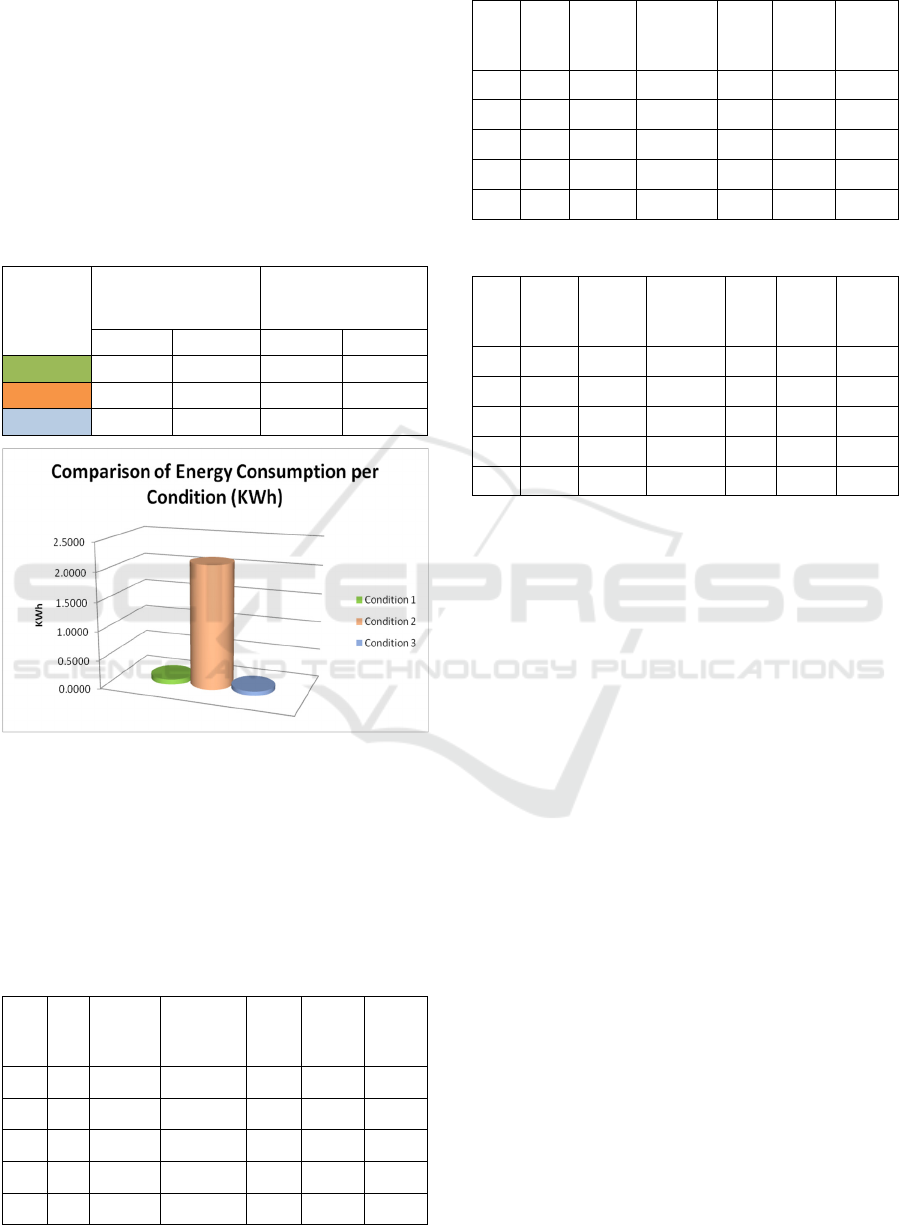

Table 2: Energy Consumption Per Condition (Watt).

Condition

Total Energy

Average Energy

consumption/

condition/Hour

Watt Rupiah Watt Rupiah

1

0,0905 130,7771 0,045261 65,38857

2

2,1365 3086,629 0,133532 192,9143

3

0,0738 106,6189 0,01845 26,65472

Figure 12: Energy graph per condition (watts).

The graph shows three conditions for energy

consumptions and the highest average energy

consumption is in condition 2, where the energy

consumed is around 2,1365 Kwh or Rp.3086,629

Experiment with product capacity 6000 grams

(Variation Oven Room Temperature)

Table 3: Moringa leaf measurement 6000 grams.

Time Heater

Collector

Temp. (°C)

Dryer Room

Temp.

(°C)

Outside

temp

(°C)

Outdoor

Humidity

(%)

Drying

Room

Humidity

(%)

15.00 Off 45 32 33 40 85

18.00 On 30 32 30 45 80

23.00 On 25 35 25,5 52 65

09.00 Off 43 36 32 25 36

12.00 Off 52 39 35 25 36

Table 4: Moringa leaf measurement 4000 grams.

Time Heater

Collector

Temp (°C)

Dryer Room

Temp

(°C)

Outside

temp

(°C)

Outdoor

Humidity

(%)

Drying

Room

Humidity

(%)

15.00 Off 45 32 33 40 90.2

18.00 On 30 32 30 45 88

23.00 On 25 35 25,5 52 70

09.00 Off 43 36 32 25 42

12.00 Off 52 39 35 25 42

Table 5: Moringa leaf measurement 2000 grams.

Time Heater

Collector

Temp (°C)

Dryer Room

Temp

(°C)

Outside

temp

(°C)

Outdoor

Humidity

(%)

Drying

Room

Humidity

(%)

15.00 Off 45 32 33 40 97

18.00 On 30 32 30 45 90

23.00 On 25 35 25,5 52 79

09.00 Off 43 36 32 25 48,7

12.00 Off 52 39 35 25 50

5 CONCLUSIONS AND

SUGGESTIONS

From the results of the dryness test of Moringa leaves

starting at 15.00 until 12.00 the next day, the effects

of Moringa drying are perfect, with even dryness on

all Moringa leaf surfaces. Some parameters obtained

from the measurement at 15.00 are Collector

Temperature is at 45°C, Dryer Room Temperature is

32°C, Outside Temperature is 33°C, External

Humidity is 40%, Drying Chamber Humidity is 80%,

Current is 0.1 A and Voltage is 214 Volt.

For drying process of 10000 grams of Moringa,

the Power (W) consumption with assumed power

factor/ Cos Phi 0.9 is 19.26 Watts. The energy (KWh)

for 1 hour is 0.0193 while the Energy in Rupiah (Rp)

is Rp. 27.8249. As for the calculation of energy

consumption per condition (wattage), in condition

two, the average energy of 0.133532 watts is Rp.

192.9143

Suggestion:

Further development can increase the load capacity of

Moringa; therefore, it can increase the amount of

production. It is necessary to optimise the automatic

control system for the drying temperature to be more

optimal. And testing in full load needs to be done

continuously to get more valid data.

Evaluation of Power Consumption in Moringa Leaves Dryer

611

REFERENCES

Zulfri, Syuhada, Hamdani., Kaji Eksperimental Sistem

pengeringan Hibrid Energi Surya Biomassa untuk

Pengering, Malaysia: Unversitas Syiah Kuala, 2012.

Y. Santosa, Pemanfaatan Energi Surya Dengan Efek

Rumah Kaca Dalam Perancangan Sistem Pengering

Kerupuk Ikan di Daerah Kenjeran., Surabaya:

Universitas Katalik Mandala Surabaya, 2012.

Ismawati, Pengeringan, Surabaya, 2012.

S. H. Zulfri, Kaji Experimental Sistem Pengering Hibrid

Energu Surya Biomassa Untuk Pengering Ikan,

Surabaya, 2012.

K. Thamrin, Rancangan Bangun Alat Pengering Ubi Kayu

Tipe Rak Dengan Memanfaatkan Energi Surya,

Sumatra: Fakultas Teknik Universitas Sriwijaya, 2011.

F. L. G. Cao, Simulasi Of A Sloped Solar Chimney Power

Plant In Lanzhou, Taiwan: Elvesier, 2011.

Bahari, Model Penyimpanan Energi Matahari Proses

Pembuatan Garam Laut, Kupang: Politeknik Negeri

Kupang, 2010.

Handini, Performa Sel Surya, Jakarta: Fakultasi Teknik

Universitas Indonesia, 2008.

Daryanto, Energi Masalah dan Pemanfaatannya Bagi

Kehidupan Manusia, Yogyakarta: Pusaka Widyatama,

2007.

H. Rosdaneli, Proses Pengeringan, Surabaya: Program

Studi Teknik Kimia, 2005.

K. Abdullah, Fish Drying Using Solar Energy, Jakarta:

Regional Workshops On Drying Technology, 2003.

A. Jansen. T.J, Teknologi Rekayasa Surya, Jakarta: Pradya

Paramita Jakarta, 1995.

P. Kreith. F, Prinsip-Prinsip Perindahan Panas, Jakarta:

Erlangga, 1986.

W. Arismunandar, Teknologi Rekayasa Surya, Jakarta:

Pradya paramita Jakarta, 1985.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

612