Fuzzy Logic Control System Implementation on Solar and Gas

Energy Dryers

Ismail Ramli, Denny Hendra Cipta and Hamka Munir

Heavy Vehichle Study Program, Nunukan State Polytechnic, Jl. Ujang Dewa, Nunukan, Indonesia

Keywords: Fuzzy Logic, Drying, Moisture Content, LPG Gas, Control System.

Abstract: Savings in the use of power sources in tools receive special attention, for example by using hybrid power,

namely using two or more power sources to drive a device. The purpose of this research is to produce a

prototype control system that can be applied to a hybrid system using sunlight and LPG gas to keep it stable

and continuous with fuzzy logic method. The method used is fuzzy logic control program language using

codevision AVR program and matlab software. Parameters measured in the dryer test include air

temperature, air flow velocity, LPG gas energy consumption and material weight reduction. The

measurement results are used to calculate drying energy, dryer efficiency and moisture content. The use of

hybrid power, the dryer can save energy, small overshoot and stable temperature.

1

INTRODUCTION

Energy sources are getting depleted, energy savings

in tools or equipment receive special attention, for

example by using hybrids, namely using two or

more power sources to drive a tool. In this modern

era, energy sources are running low, saving on the

use of energy in tools or equipment needs special

attention and treatment. By using hybrid power,

namely using two or more power sources to drive a

tool. The requirement for hybridization energy for

equipment is renewable energy (water, wind, solar)

with sustain energy such as fossil energy (coal, gas

or oil). The aim of using hybridization energy is to

sustain the performance of the driven tool which it

does not decrease and in order to fossil energy can

be saved.

Combining two or more energy sources in the

system can cause the system to become

multivariable, non-linear, erratic, complex, uncertain

or fuzzy. According to (Negnevitsky 2005) a fuzzy

system can only be controlled by applying intelligent

systems such as neural network systems, experts, or

fuzzy logic.

(Azis and Sinadia, 2018) conducted studies

related to hybrid solar energy and LPG gas, namely

the design of a fuzzy-expert system on a solar and

LPG hybrid powered food control device with one

input and one output, (Satria et al., 2015) namely

designing a temperature control system on a hybrid

dryer using the fuzzy logic method, and (Arikundo

and Hazwi, 2014) designing a logic - based

temperature and humidity control system for drying

hybrid nutmeg (myristica sp.) using solar energy and

biomass.

Nowadays, on the one hand, the hybrid energy

system is unusual to implement because this kind of

technology has not fully ready yet. Moreover this

technology is quite expensive, so most of people still

using one the energy existed. On the other hand, all

existing energy are very limited. For this reason, it is

necessary to explore and to investigate the hybrid

energy system for innovate the sources energy

revolution.

2

RESEARCH METHODS

The materials used to make the dryer instrument

include U 13 mm mild steel, 0.9 mm thick aluminum

sheet, glass wool, 5 mm acrylic glass, screws, bolts,

rivets, pipes, glass glue, lighters, 3 inch Blawer, 3

inch paralon pipe, stainless steel doof plate, gas

stove, elbow iron, electronic components,

microcontroller, coax cable, electrical cable, PCB,

gas hose, 3 kg LPG gas, electronic lighter and

solenoid. The material used to test the performance

of the dryer is sago.

638

Ramli, I., Cipta, D. and Munir, H.

Fuzzy Logic Control System Implementation on Solar and Gas Energy Dryers.

DOI: 10.5220/0010950300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 638-643

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

The tools used to manufacture the dryer are

workshop equipment, solar power meter (0.1W/m²),

anemometer (0.1 m/s), digital scale (0.01g), data

logger, and software (Matlab, Codevision).

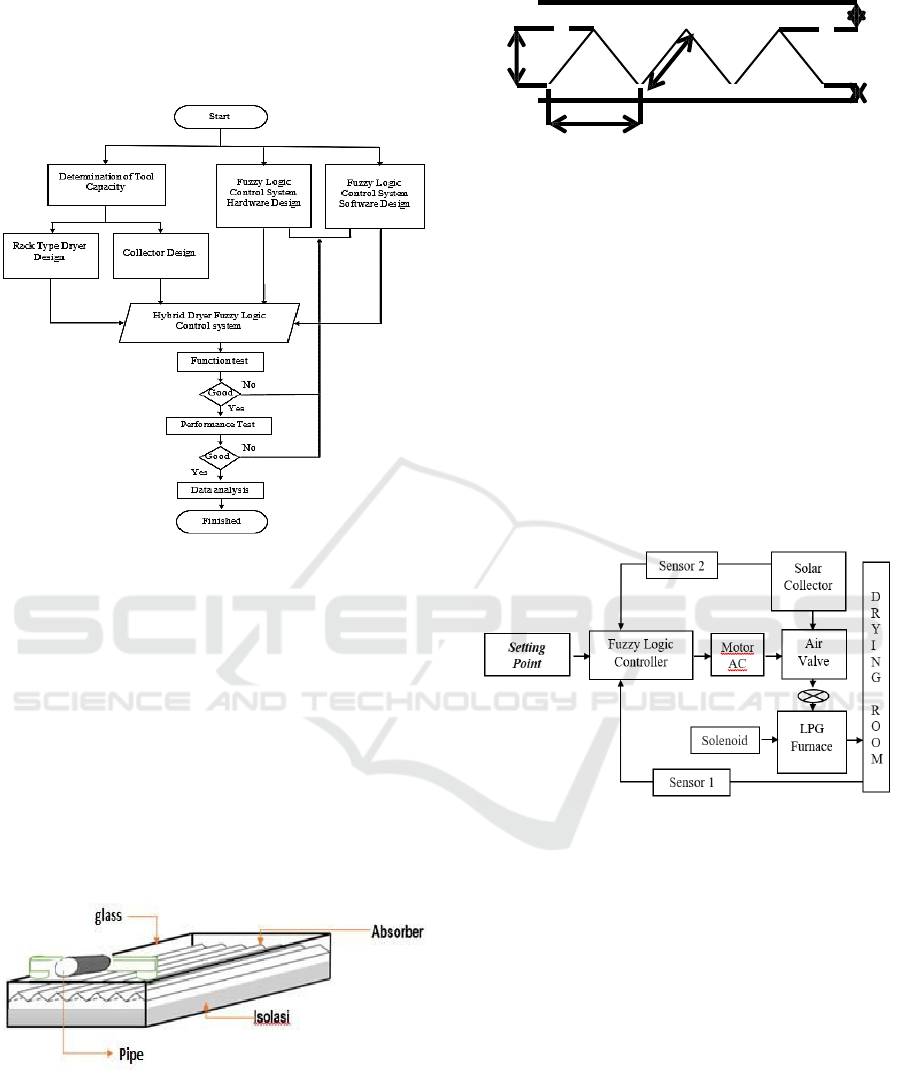

Figure 1: Research Diagram.

2.1 Determination of Tool Capacity

This tool is designed with a capacity of 40 kg. The

drying equipment in this study used an existing

drying chamber, consisting of 20 shelves with a

capacity of 2 kg per shelf. The wait is located at the

bottom of the Dryer chamber. Energy requirements

are needed to find out how much energy or power is

needed in waiting for the heater.

In this study, the type of collector used is a data

plate solar collector which has several main

components such as cover, acrylic, insulation, and

absorber.

Figure 2: Flat Plate collector design.

The corrugated type (V) on the data plate

collector is more widely used because of its higher

efficiency against the sun.

Figure 3: Flat Plate collector design.

2.2 Fuzzy Hardware Control System

Design

The design of fuzzy-based gas valve control

hardware whereas the gas valve (solenoid) is

assembled into a series and parallel circuit, so it can

supply various power for the energy needs of the

drying chamber. To produce power 0 to maximun

power, fuzzy control is used, and its use uses a

baypass on the solenoid.

Figure 4: Fuzzy Logic Control System Design.

The design of the valve control hardware is

shown in Figure 3, where the valve drive motor gets

a control signal from the microcontroller and its

action will move the air valve. The air rate of the

collector depends on the valve opening (0

0

, 45

0

,

90

0

). Motor drive used for the force acting on the

valve leaf. The driving motor used in this study is an

AC motor whose torque is caused by air in the valve.

2.3 Designing Fuzzy Control Software

2.3.1 Defining Input-Output

In developing a multivariable fuzzy logic control

system, so a fuzzy control method should be

designed, namely 2 inputs and 2 outputs. The 2-

description:

Ta = collector top surface height

Tb = collector area

Tc = width between collector cross sections

Ta = collector bottom surface height

Fuzzy Logic Control System Implementation on Solar and Gas Energy Dryers

639

input system

consists of Dryer Room Temperature

(T

1

) and Collector Temperature (T

2

). While the

output is power

(W) and valve opening (

0

).

2.3.2 Defining the Universe of Speech and

Values

In this study, the input temperature of the collector

used ranges from 25

O

C to 90

O

C, at the input of

drying room temperature 30

O

C to 60

O

C. This range

is the actual condition of the collector temperature

and drying chamber temperature. The universe talks

about fuzzy singleton output in the range of 0 – max

watt for power and 0

O

to 90

O

for opening and

closing the valve.

2.3.3 Determining the Membership Function

and Fuzzy Set

The function used for input is a triangular function

and a set of three fuzzy sets for each input variable.

For membership function. The system has two

inputs and two outputs of fuzzy sets, the drying

chamber input

temperature (T

1

) is defined as r1 =

low, s

1

= medium, t

1

= high. For the fuzzy set, the

input collector temperature (T

2

) is defined as r

2

=

low, s

2

= hot, t

2

=

high.

Figure 5: Temperature input membership function (

o

C).

Mean while, the power output fuzzy set for the

hybrid system is defined as kc=small, ak=rather

small, sd=medium, bs=large, and sb=very large. The

fuzzy set of valve open output is tt=close (0

0

),

bs=open (45

0

) and bk=open (90

0

)

Figure 6: Output membership function.

2.3.4 Formulation of Conversational Rules

In this study, the rules are arranged based on the

loop system that is in accordance with the desired

conditions. The following are the results of the

compilation of the rules for the 2 input 2 output

system proposed by (Y Wang at al., 1997) in Figure

19. The results are as follows:

The rules made from the control matrix are:

R

1

: if (T

1

is r

1

) and (T

2

is t

2

) then (K

1

is bk) (P

1

is sd)

R

2

: if (T

1

is r

1

) and (T

2

is s

2

) then (K

2

is bt) (P

2

is bs)

R

3

: if (T

1

is r

1

) and (T

2

is r

2

) then (K

3

is tt) (P

3

is sb)

R

4

: if (T

1

is s

1

) and (T

2

is t

2

) then (K

4

is bs) (P

4

is ak)

R

5

: if (T

1

is s

1

) and (T

2

is s

2

) then (K

5

is bs) (P

5

is sd)

R

6

: if (T

1

is s

1

) and (T

2

is r

2

) then (K

6

is tt) (P

6

is bs)

R

7

: if (T

1

is t

1

) and (T

2

is t

2

) then (K

7

is bk) (P

7

is kc)

R

8

: if (T

1

is t

1

) and (T

2

is s

2

) then (K

8

is bs) (P

8

is ak)

R

9

: if (T

1

is t

1

) and (T

2

is r

2

) then (K

9

is tt) (P

9

is sd)

2.4 Instrument Examining

Testing of the tool aims is to determine whether the

results of the hardware design and fuzzy rules can

run a hybrid solar and gas system simulation tool in

accordance with the expected function and it cand

produce good performance. The implementation of

this testing is carried out in two stages, namely

functional testing and performance testing

3

RESULTS AND DISCUSSION

3.1 Dryer Machine Description

The hybrid system dryer consists of a collector, an

LPG furnace, a dryer box and a control system. As

seen in the image below.

Grade

Grade

kc

ak

sd

bs

bs

t

t

b

k

k

b

s

1

0

Wat

t

0

Dera

j

ad

Da

y

a

Valve

(

o

)

r

2

s

2

t

2

30

45

Collector

Temperatur

60

r

1

s

1

t

1

25

45

Dryer Room

Temperatur

90

Figure 7: Fuzzy control matrix for hybrid systems.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

640

Figure 8: Hybrid Dryer.

Figure 9: Dryer Control Point.

The figure above is the control panel of the

drying machine which is controlled automatically

using fuzzy logic solar energy is the main source

while LPG gas is an alternative source that is used if

sunlight cannot reach room temperature.

Figure 10: LPG Gas Stove Design.

The figure above is an LPG gas stove design

which uses a selenod as an LPG flame regulator,

adjusted for use with the temperature of the drying

room.

Drying machine specifications can be seen in the

table below:

Table 1: Specification of Dryer Machine with Fuzzy Logic

Control System.

Kategori Keterangan

Tool Capacity 20 rack

Dryer Dimensions 122 cm x 57 cm x 175

Collector Dimension 122cm x 244 cm

Collector Efficiency 79,24 %

material Steinless stell

Blower 3 inci

Driving force Listrik 220 V, 2,5 A

Spower source LPG dan Surya

Control System Fuzzy Logic

3.2 Functional Test Tool

This test is carried out by heating the temperature

sensor at a temperature of 30

0

C to 60

o

C and

observing which gas solenoid is working. The

solenoid valve is used to supply energy from LPG,

there are 4 solenoids that are installed with the

markings Solenoid 1, Solenoid 2, Solenoid 3 and

Solenoid 4. Solenoid 1 will continue to provide gas

supply to keep the fire burning while solenoid 2,

solenoid 3 and solenoid 4 will lights up depending

on the energy requirements calculated by fuzzy. The

test results in table 2 show that when the temperature

is between 29

0

C and 50

0

C the power required is

large to increase the temperature in the drying

chamber, while at a temperature > 50

o

C the power

will decrease according to the energy requirement

until it reaches the desired temperature.

Table 2: Solenoid Valve Test Results Against Temperature

and Power.

Solenoid Valve

Temperature

(

O

C)

power

(Watt)

I

(300)

II

(1000)

III

(2000)

IV

(2000)

open close open open

30 -34 4300

open open close open

35-41 3300

open close open close

42-50 2300

open open close close

51-55 1300

open close close close >56 300

Fuzzy Logic Control System Implementation on Solar and Gas Energy Dryers

641

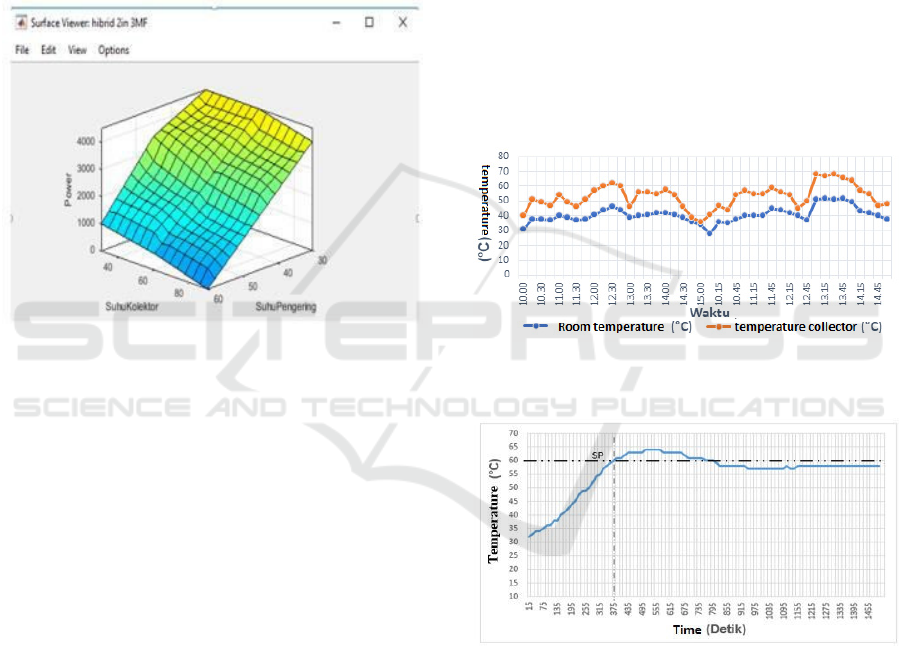

3.3 Simulation Results of Fuzzy

Control Rules 2 Inputs, 2 Outputs

in the Matlab Program

To ensure that the rules made are correct, it is

necessary to look at the surface results in Matlab as

shown in Figure 34. Figure 34 shows that the

decrease in gas power (LPG) decreases gradually so

that the rules that have been made are as desired.

The above rules are the basis for developing a fuzzy

logic control program language using the AVR

codevision program.

Figure 11: Fuzzy Surface Display in Matlab.

3.4 Tool Performance Test

Performance tests were carried out to determine the

performance of the tool when drying sago using

solar energy sources, LPG gas, and hybrids.

Parameters observed were drying chamber

temperature, drying time, moisture content and

energy use.

3.4.1 Using Solar Energy

The temperature in the drying chamber using solar

energy is strongly influenced by weather conditions.

conducted for 2 days from 10.00 AM to 15.00 PM.

The test results can be seen in Figure 12. The figure

shows that on the first day the highest air

temperature in the collector was 62

0

C (12.00 PM)

and the highest air temperature in the drying room

was 46

0

C (12.30 PM), while on the second day the

highest temperature in the collector was 68

0

C.

(13.00 PM) and the highest temperature in the

drying room is 51

0

C (13.00 PM).

The difference between the collector air

temperature and room temperature is caused by the

loss of energy in the air duct and the mixing between

the air temperature and the collector temperature. In

the picture, the temperature looks unstable, the air

temperature in the room ranges from 30

0

C to 51

0

C

on the second day of drying.

3.4.2 Using LPG

From the observations it is proved that the fuzzy

control system can control the temperature based on

the setting point, the time is quite short, the offer

shoot is 64

0

C minutes and it does not exceed 69

0

C,

and it could running well because at that temperature

gelatinization will occur (Cecil et al. 1982).

Although there is an offset of 58

0

C (3% of the

setting point) but it is smaller than 5%, according to

(Ogata et al., 1996) that the system offset occurs

between 2% - 5%.

Figure 12: Dryer Room Temperature Response to Solar

Intensity.

Figure 13: Dryer Room Temperature Response to Time

Using LPG.

While the observation of the temperature in the

drying room during the drying process can be seen

in Figure 13. It can be seen in the figure that the

temperature reaches the Setting Point (60

0

C) in 6.75

minutes and overshoot occurs at 4

0

C for 11.5

minutes after that the temperature is constant at

58

0

C.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

642

Figure 14: Dryer Room Temperature Response to Time

Using Hybrid Power.

To meet the water content of sago from the

Indonesian national standard, in this study, the water

content of 6% was taken. This aims to extend the

shelf life of sago flour, because the moisture content

is less than 7%, the microbiological damage is much

slower. According to (Winarno, 1992) the water

content of the material between 3% to 7% will

achieve optimum food stability.

4

CONCLUSIONS

Based on this research that has been done on the

hybrid powered dryer, it can be concluded that:

1.

A multivariable control system has been

successfully designed that works with the

expected results, such as relatively small

overshoot, stable temperature and relatively

small offset.

2.

The drying time using the hybrid and non-

hybrid methods (LPG gas) is same, but the use

of the solar energy method is longer.

3.

The dryer can save 50% of LPG gas with the

hybrid method in varying sunlight conditions

(cloudy).

ACKNOWLEDGEMENTS

There are many obstacles in completing this

research, and this work would not have been

possible without the support of several parties. For

that, I would like to thank all parties who have been

willing to work so far and other related writings.

Director of the Nunukan State Polytechnic who has

provided support to me in completing this research. I

also want to thank my family and friends who have

always supported me in completing this research.

REFERENCES

Ahmad A. 2012. Pengendali Cerdas Berbasis Real Time

Monitoring (RTM) pada Sistem Pengisian Tangki Air.

Jurusan Teknik Elektro Fakultas Teknik Universitas

Hasanuddin : Makasar

Azis, R., & Sinadia, B. S. (2020). Pengeringan Cabai

dengan Sistem Kontrol Fuzzy-Expert pada Alat

Bertenaga Hibrida Surya dan Gas Menggunakan

Sistem Kontrol Fuzzy Expert. Jurnal Technopreneur

(JTech), 8(2), 77-81.

Cecil, C. B., Stanton, R. W., Dulong, F. T., & Renton, J. J.

(1982). Geologic factors that control mineral matter in

coal. In Atomic and nuclear methods in fossil energy

research (pp. 323-335). Springer, Boston, MA.

Arikundo, F. R., & Hazwi, M. (2014). Rancang bangun

prototype kolektor surya tipe plat datar untuk

penghasil panas pada pengering produk pertanian dan

perkebunan. e-Dinamis, 8(4).

Fajri Zufa. 2012. Perbandingan sistem inferensi fuzzy

metode mamdani dan metode sugeno Dalam

memprediksi laju inflasi. Universitas Brawijaya :

Malang.

Hendra. 2012. Komponen Sistem Kontrol Sensor Gas

LPG Bandung. FT Elekktro-Universitas Kristen

Maranatha: Bandung

Kusumadewi Sri. Hartati Sri. 2016. Neuro-Fuzzy Integrasi

Sistem uzzy dan Jaringan Syaraf Edisi 2. Graha Ilmu :

Yogyakarta.

Negnevitsky, M., & Intelligence, A. (2005). A guide to

intelligent systems. Artificial Intelligence.

Ogata, Katsuhiko. 2016. Modern Control Engineering

(Teknik Kontrol Automatik). (Alih bahasa: Edi

Laksono). Jakarta : Erlangga.

Satria, D., Listijorini, E., & Nurghodan, M. R. (2015).

Perancangan Sistem Kendali Suhu Pada Mesin

Pengering Hybrid Menggunakan Metode Fuzzy Logic:

Design of Temperature Control System on Hybrid

Drying Machine using Fuzzy Logic Method. Jurnal

Ilmiah Rekayasa Pertanian dan Biosistem, 3(2), 179-

185.

Y Wang L X. 1997. A course In Fuzzy System and

Control. Prentice-Hall International, Inc.

Winarno, F. G. 1992. Kimia Pangan dan Gizi. PT.

Gramedia Pustaka Utama,Jakarta.

Fuzzy Logic Control System Implementation on Solar and Gas Energy Dryers

643