The Effect of Mahakam Sand on the Mechanical and Durability of

Porous Concrete Paving Blocks

Yudi Pranoto

1,2 a

, Nor Fazilah Hashim

1b

, Tumingan

2c

and Ashadi Putrawirawan

2d

1

Faculty of Technology and Informatics Razak, University Teknologi Malaysia, Jalan Sultan Yahya Petra 54100,

Kuala Lumpur, Malaysia

2

Civil Engineering Department, Samarinda State Polytechnic, Jl. Ciptomangunkusumo 75131, Samarinda,

East Kalimantan, Indonesia

Keywords: Mahakam Sand, Porous Paving, Compressive Strength, Permeability, Porosity.

Abstract: The high price of Palu aggregate and the reduced catchment area in East Kalimantan have encouraged the

improvisation of local materials as materials for infrastructure development. Porous Concrete Paving Block

(PCPB) is an alternative to overcome this problem. PCPB can absorb water into the soil but has a low

compressive strength. To increase the compressive strength of PCPB by adding sand. This study aims to

determine the effect of Mahakam sand on the compressive strength, flexural strength, permeability, and

porosity of porous paving. This study used the addition of 2.5%, 5%, 7.5%, 10%, 12.5%, and 15% sand. The

test results indicated that Mahakam sand has significantly affected the compressive strength and permeability

of porous paving. The compressive strength of porous paving increases with the addition of Mahakam sand.

However, the porosity value decreases with increasing sand content. The optimum sand content that can be

used is 7.5%, with compressive strength of 17.13 MPa.

1 INTRODUCTION

Porous Concrete Paving Block (PCPB) is a ground

cover using a material that can seep water flow into

the soil layer below it. PCPB are alternatives to the

traditional pervious asphalt and concrete pavement

(Hidayah et al., 2014). Porous pavers are suitable for

roads with low traffic volumes, bicycle lanes,

sidewalks, playgrounds, and terraces in front yards

(Manan et al., 2018), (Wijaya and Ekaputri, 2014). In

this porous paver, there is a space for the flow of

water and air. This space causes rainwater to enter the

paving and seep into the ground so that the porous

paver has a higher permeability than conventional

paving. Runoff water from the road will be absorbed

into the soil and can reduce water discharge in

drainage channels by being applied to the road

surface.

Porous concrete pavement is rarely used in

infrastructure development but looks at porous

a

https://orcid.org/0000-0003-2997-7475

b

https://orcid.org/0000-0002-1841-4354

c

https://orcid.org/0000-0001-9279-1521

d

https://orcid.org/0000-0001-6163-4187

concrete usefulness as multifunctional concrete,

especially to respond to green engineering issues.

Porous concrete can be considered worthy of being

one of the lightweight construction materials that will

play an essential role in the future. Therefore,

research is needed to optimize porous paving to

produce PCPB with high strength and permeability.

PCPB generally has cavities in the concrete ranging

from 15 – 35% (ACI 552R-10, 2010; Alam et al.,

2019; Huang et al., 2016).

In general, PCPB has lower strength when

compared to conventional paving because PCPB has

voids in the concrete. Increasing the strength of PCPB

can be done by using additives. In previous studies

use fly ash to improve the strength of PCPB, such as

studies conducted by (El-maaty, 2016; Gpcc et al.,

2016; Roshni J John, 2015; Jonbi and Fulazzaky,

2020; Mali and Abraham, 2016; Hossiney et al.,

2020; Aoki et al., 2012; Malliga and Moorthy, 2019).

Abd Halim et al., 2018, used different aggregate sizes

644

Pranoto, Y., Fazilah Hashim, N., Tumingan, . and Putrawirawan, A.

The Effect of Mahakam Sand on the Mechanical and Durability of Porous Concrete Paving Blocks.

DOI: 10.5220/0010950400003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 644-649

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

to determine the effect on compressive strength and

porosity. From the results of his research, PCPB with

CA 8 – 10 gave better results in permeability and was

more suitable to be applied in areas with high surface

runoff. In this study, used of Mahakam sand to

increase the strength of PCPB. The addition of sand

will certainly increase PCPB strength but will reduce

permeability.

This paper aimed to evaluate the effect of

Mahakam sand on the strength and permeability of

Porous Concrete Paving Blocks (PCPB).

2 METHODS

This research uses experimental methods in the laboratory.

PCPB mix design refers to the ACI 522R-10 to determine

the material composition. The variation of Mahakam sand

content used is 0%, 2.5%, 5%, 7.5%, and 10%. The

parameters to be tested in this research are porosity,

permeability, compressive strength, and flexural strength.

For the porosity parameters obtained using equation (1):

Porositas =

100% (1)

Where:

A: Sample weight in water (gram)

B: Sample weight SSD (gram)

C: Oven-dry sample weight (gram)

Then, the permeability parameter can be obtained

using equation (2):

.

=

(2)

Where:

: Water flow rate (m

3

/dtk)

A : Section of area (m

2

)

dh : Falling water height (m)

L : Penetration depth (m)

k : Permeability coefficient (m/dtk)

Compressive strength test was carried out

according to the SNI 03-1974-1990 (Badan

Standardisasi Nasional, 1990) standard to evaluate

the compressive strength after the desired curing

period used universal testing machine. Load at the

failure divided by area of specimen gives the

compressive strength of concrete. The compressive

strength (f’c) can be calculated from the equation (1):

Furthermore, the compressive strength parameters can

be obtained using equation (3):

f′c =

(3)

Where:

f’c : Compressive strength (MPa)

P : Maximum load (N)

A : Section area (mm

2

)

The flexural test of PCPB, according to the

Indonesian Standard SNI 03-4154-1996 to evaluates

the compressive strength. For measuring flexural

strength, the typical standard size of specimens

150×150×500 mm was used. Equal loads were

applied at the distance of one-third from both of the

beam supports. The maximum tensile stress reached

called “flexural strength” is computed from equation

(4):

=

(4)

Where:

f

lt

: flexural strength (MPa);

L : beam span between supports (mm);

d : depth of beam (mm);

b : width of the beam (mm), and

P : rupture load (N).

3 RESULT

3.1 Materials

The basic materials tested in this study were coarse

aggregate and fine aggregate, and cement. The results

of testing the material properties of fine aggregate and

coarse aggregate are shown in table 1 and table 2.

Table 1: Fine aggregate test results.

Test type Result Standard Conclusion

Bulk density 1.34 gr/cm

3

Min. 1.3 gr/cm

3

Qualify

Bulk specific gravity SSD 2,51 2.5-2.7 Qualify

Sludge content 3.9 % Max. 5 % Qualify

Absorbtion 0.76 % Max. 3 % Qualify

Water content 1.88 % Max. 2.5 % Qualify

The Effect of Mahakam Sand on the Mechanical and Durability of Porous Concrete Paving Blocks

645

Figure 1: Gradation graph of coarse aggregate.

Table 2: Coarse aggregate test results.

Test type Result Standard Conclusion

Bulk density 1.54 gr/cm

3

Min 1.3 gr/cm

3

Qualify

Bulk specific gravity SSD 2.69 2.5-2.7 Qualify

Sludge content 0.82% Max. 1% Qualify

Absorbtion 1.94% Max 3% Qualify

Abration 22.35% Max. 40% Qualify

Water content 0.45% Max. 2.5% Qualify

Figure 1 describes the fine aggregate gradation

test results that still meet the boundary requirements

of ASTM C-33. From the graph, Mahakam sand is

included in the first zone. Tests on uniform coarse

aggregate 1-2 cm in size (crushed stone) carried out

in this study included testing specific gravity,

abrasion, and coarse aggregate gradation.

Based on the results of tests carried out on fine and

coarse aggregate materials, it shows that both types of

materials meet the determined Indonesian National

Standards (SNI).

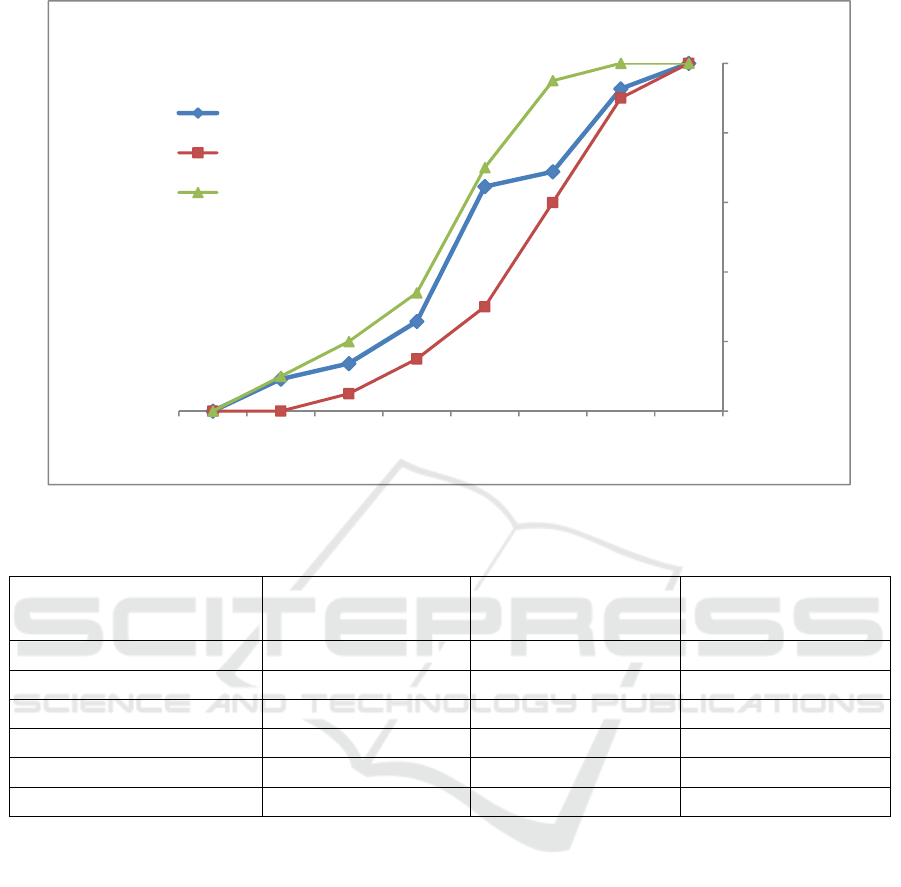

3.2 Compressive Strength

The compressive strength of concrete is the ability of

concrete to withstand compressive forces per unit

area. The compressive strength test was carried out

when the specimens were 7, 14, 21, and 28 days old

using a compression testing machine to get the

maximum load, namely the load when the concrete

was crushed when it received the load (Pmax).

Compressive strength is generally considered to be

the most important property of concrete. This usually

gives an overall picture of the quality and

performance of the concrete. From Figure 2, it can be

seen that the compressive strength of PCPB with a

sand content of 7.5% has a higher compressive

strength than PCPB with other sand content. This is

due to the lower void content in PCPB compared to

other PCPB specimens. The results also show that the

addition of 7.5% sand can increase the compressive

strength of PCPB by 36.28%.

0,0

20,0

40,0

60,0

80,0

100,0

9,64,752,361,180,600,300,150,075

%

Pass

Sieve (mm)

% Cumulative Pass

Lower limit

Upper limit

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

646

Figure 2: Compressive testing porous paving graphs.

Figure 3: Porous paving permeability testing graph.

3.3 Permeability

Permeability testing in this study used laboratory-

scale testing. The test object used for permeability

testing is pervious concrete with a length of 20, a

width of 10 cm, and a height of 8 cm. The variation

of the test object is based on the sand content. The

results of the permeability test are presented in graph 3.

Figure 3 shows that the highest permeability value

was obtained at 0% sand variation with a value of

0.55 cm/second. Meanwhile, the lowest permeability

value is found in the 10% sand variation with a value

of 0.43%. This result indicates that PCPB

permeability decreases with increasing sand content.

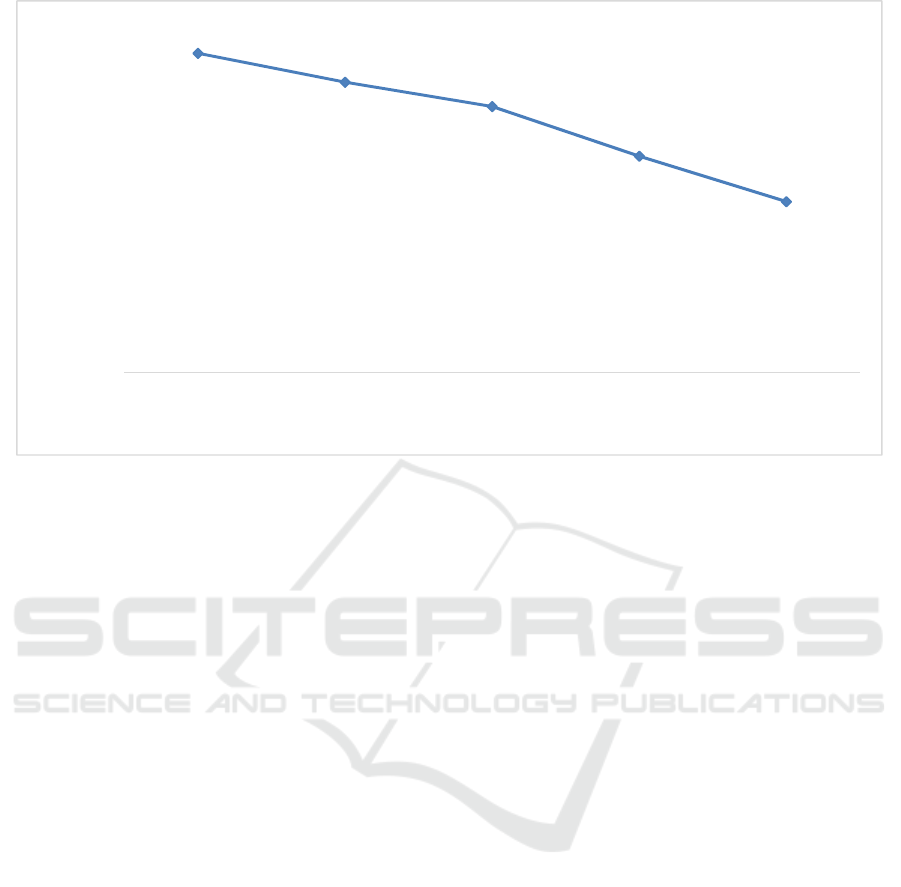

3.4 Porosity

Porosity (Void in mix) is the volume of pores in the

compacted mixture or the number of air voids in the

porous concrete mixture. The composition of the

weight of each aggregate can be seen in Table 3. In

the porous paving porosity test results, the highest

porosity value was obtained at 0% sand variation with

a value of 18.27%. Meanwhile, the lowest porosity

value is found in the sand variation of 10%, with a

porosity of 9.78%. PCPB porosity decreases with the

addition of sand. Sand fills the voids in the porous

paving, thereby reducing porosity.

5,00

7,50

10,00

12,50

15,00

17,50

20,00

71428

Compressive strength (MPa)

Age of PCPB (days)

Sand 0%

Sand 2.5%

Sand 5%

Sand 7.5%

Sand 10%

0,55

0,52

0,50

0,46

0,43

0,35

0,40

0,45

0,50

0,55

0,60

02,557,510

Permeability (cm/detik)

Sand content (%)

The Effect of Mahakam Sand on the Mechanical and Durability of Porous Concrete Paving Blocks

647

Figure 4: Porous paving porosity testing graph.

4 CONCLUSIONS

From the results of research and data analysis and

discussions that have been carried out, conclusions

can be drawn as follows:

1. The addition of Mahakam sand causes a

decrease in the porosity of the PCPB. The

highest porosity occurred in the variation of the

addition of 0% sand, which was 18.27%.

2. The highest infiltration velocity is found in the

filling of the cavity with the addition of 0% sand

content, which is 0.55 cm/second for the lowest

air infiltration speed at 10% sand content

variation, which is 0.43 cm/second.

3. The addition of Mahakam sand can increase the

compressive strength of PCPB when compared

to that without cavity filling, which is 17.3 MPa.

So that porous concrete can be used as pavement

for low traffic such as sidewalks, parks, and

gardens.

4. The addition of Mahakam sand can increase the

compressive strength but reduce the porosity

and permeability of PCPB.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the support of

the Samarinda State Polytechnic (POLNES) and

University Teknologi Malaysia (UTM) for the

support and sponsor under UTM Encouragement

Research Grants, Vot No. Q.K130000.2656.18J25,

each of which enabled this paper to be written. The

author also thanks to the permeable research group

(Bela, Dandi, and Ririn) for their dedication and

support.

REFERENCES

Abd Halim, N. H. et al. 2018. “Permeability and Strength

of Porous Concrete Paving Blocks at Different Sizes

Coarse Aggregate.” Journal of Physics: Conference

Series 1049(1).

ACI 552R-10. 2010. Report on Pervious Concrete,

American Concrete Institute.

Alam, Taufiqul et al. 2019. “A Comparison of Three Types

of Permeable Pavements for Urban Runoff Mitigation

in the Semi-Arid South Texas, U.S.A.” Water

(Switzerland) 11(10).

Aoki, Y, Sri Ravindrarajah, and H Khabbaz. 2012.

“Properties of Pervious Concrete Containing FLy Ash.”

Road Materials and Pavement Design 13(1): 1–11.

http://www.tandfonline.com/loi/trmp20%0AProperties

Badan Standardisasi Nasional. 1990. “SNI 03-1974-1990

Metode Pengujian Kuat Tekan Beton.” Badan

Standardisasi Nasional Indonesia.

El-maaty, Ahmed Ebrahim Abu. 2016. “Establishing a

Balance Between Mechanical and Durability Properties

of Pervious Concrete Pavement.” 1(2): 13–25.

Gpcc, Gsrgpc, Prof Ashok W Yerekar, Rajabhau S Londhe,

and Vikram Khajekar. 2016. “Mix Design of

18,27

16,61

15,22

12,38

9,78

,0

2,50

5,0

7,50

10,0

12,50

15,0

17,50

20,0

0 2,5 5 7,5 10

Porosity (%)

Sand content (%)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

648

Geosynthetically Reinforced Geopolymer Concrete.”

13(6): 129–38.

Hidayah, Nur A.H., Md Hasanan, and P. J. Ramadhansyah.

2014. “Effect of Coarse Aggregate Sizes on Properties

of Porous Concrete Paving Blocks.” Advanced

Materials Research 911: 433–37.

Hossiney, Nabil et al. 2020. “Geopolymer Concrete Paving

Blocks Made with Recycled Asphalt Pavement (RAP)

Aggregates towards Sustainable Urban Mobility

Development.” Cogent Engineering 7(1).

Huang, Jian, Caterina Valeo, Jianxun He, and Angus Chu.

2016. “Three Types of Permeable Pavements in Cold

Climates: Hydraulic and Environmental Performance.”

Journal of Environmental Engineering 142(6):

04016025.

Jonbi, Jonbi, and Mohamad Ali Fulazzaky. 2020.

“Modeling the Water Absorption and Compressive

Strength of Geopolymer Paving Block: An Empirical

Approach.” Measurement: Journal of the International

Measurement Confederation 158: 107695.

https://doi.org/10.1016/j.measurement.2020.107695.

Mali, Basil M, and Renjan Abraham. 2016. “Study on

Geopolymer Concrete Used for Paving Blocks.”

International Journal of Innovative Research in

Advanced Engineering 09(3): 2349–2763.

Malliga, P, and J Ashthava Moorthy. 2019. “Paver

Blocksby Using Fly Ash and GGBS ( Geopolymer

Concrete ).” International Journal of Engineering

Research & Technology (IJERT) 7(11): 1–4.

Manan, Aneel et al. 2018. “Experimental Investigation of

Compressive Strength and Infiltration Rate of Pervious

Concrete by Fully Reduction of Sand.” Civil

Engineering Journal 4(4): 724.

Roshni J John, Husain N Hamdulay,. 2015. “Effect of

Aggregate Grading and Cementitious By-Product on

Performance of Pervious Concrete.” International

Journal of Innovative Research in Science, Engineering

and Technology 4(8): 6890–97.

SNI 03-4154-1996. 1996. Badan Standar Nasional

Indonesia Metode Pengujian Kuat Lentur Beton

Dengan Balok Uji Sederhana Yang Dibebani Terpusat

Langsung. Jakarta.

Wijaya, Yulia Putri, and Januarti Jaya Ekaputri. 2014.

“Paving Geopolimer Dari Coal Ash Limbah Pabrik.”

Jurusan Teknik Sipil FTSP ITS, Surabaya (June): 33–

42.

The Effect of Mahakam Sand on the Mechanical and Durability of Porous Concrete Paving Blocks

649