Development of Distillation Machines Incorporating Refrigeration:

Distiller for Traditional Drink “Arrack Bali” Production

I. Nyoman Suamir

a

, I. Made Rasta

b

, I. Dewa Made Susila

c

and Sudirman

d

Mechanical Engineering Department, Politeknik Negeri Bali, Campus Street Kuta Selatan, Bali, Indonesia

Keywords

:

Arrack Bali Distillation Machine, Refrigeration, Distiller, Product Quality Consistency.

Abstract: Balinese arrack, which is commonly called Arrack Bali, is a traditionally distilled alcoholic drink

made from

fermented sap of coconut flowers. Arrack Bali is a traditional Balinese drink and is also

in great demand by

guests from abroad. Those encourage arrack farmers to be more motivated in

producing arrack even though

they still use traditional production methods. To be able to provide

a good economic impact for arrack farmers,

it is very necessary to have a distillation machine based

on appropriate technology with better, cleaner and

consistent production process. This paper

presents a local genuine based distillation machine specifically

designed for Arrack Bali

production. The machine incorporates novelties which include a refrigeration

distiller, preheating

heat exchanger and smart controller for both boiler and distiller. The machines can perform

reliably

with several production characteristics. Production test results showed several variants of Arrack

Bali can be produced consistently which could be grouped into four grades: Grade-Super, Grade-

1, Grade-2

and Grade-3 with alcohol content above 40%, 30%, 20%, 10% respectively. These

variants are resulted

from production characteristics at boiler temperature 87-93 °C, distiller

temperature 15-27 °C and

corresponding production time 1.5, 2.5, 3.5, and 4.5 hours respectively.

1

INTRODUCTION

Arrack is a type of fermented liquor containing 37-

60% alcohol (ethyl alcohol) which has been known in

Bali since ancient times. Arrack is an alcoholic drink

that is used in several ceremonies for cultural and

religious activities in Bali. Arrack is generally made

from palm sap by distillation. Arrack can also be

made from fermented pineapple.

Arrack production in Bali is done traditionally, so

it is not clear the alcohol content and the consistency

of arrack quality is very difficult to maintain (Widya

Astuti et al., 2018; Suaniti et al., 2012). The simple

processing process is prone to health problems,

especially if it contains methanol, when drunk, it can

cause toxic effects on the human body. The misuse of

arrack as an alcoholic beverage has been published by

the relevant agencies as reported in Depkes RI (2014)

and Dinas Kesehatan Provinsi Bali (2014). However,

a

https://orcid.org/0000-0003-0594-7511

b

https://orcid.org/0000-0002-9610-3738

c

https://orcid.org/0000-0002-2567-9932

d

https://orcid.org/0000-0003-2816-523X

within certain limits alcoholic beverages in various

countries are permitted or halal to be consumed (Anis

Najiha and Wan Nadiah, 2014).

Karangasem is one of the places where arrack is

produced in Bali. Merita Village, in Karangasem

Regency, is a village where almost all of the people

process and produce traditional arrack drinks in a

home industry and the process is still very simple.

The use of simple tools, besides being unable to

maintain the consistency and quality of the resulting

arrack, they are also inefficient. With simple tools,

farmers are only able to produce 10 liters of arrack

per day from 60 liters of fermented palm sap.

Therefore, it is necessary to have a distillation

machine that ensures the consistency of product

quality, compliance with health standards and energy

efficient.

Arrack Bali is also in great demand by guests from

abroad. Recently, Arrack Bali has also given a good

698

Nyoman Suamir, I., Made Rasta, I., Dewa Made Susila, I. and Sudirman, .

Development of Distillation Machines Incorporating Refrigeration: Distiller for Traditional Drink “Arrack Bali” Production.

DOI: 10.5220/0010951700003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 698-703

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

economic impact for arrack farmers in Karangasem.

Moreover, the attention of the Governor of Bali is

very serious about the development of this traditional

Balinese drink. It is proven that the Governor of Bali

Regulation no. 1 of 2020 has been issued regarding

the management of Balinese fermented or distillated

drinks, including Balinese Arrack (Rhismawati,

2020). With the support of the Bali Regional

Government and the Bali Governor's belief that

Arrack Bali is very effective and useful as a basic

ingredient for Covid-19 therapy with a high healing

effect. Arrack farmers are increasingly free to

produce arrack and their economy is increasing.

Therefore, there is a need for a distillation machine

based on appropriate technology which ensures

consistency of product quality, compliance with

health standards and energy efficient. Appropriate

technology has technical characteristics, namely it is

possible and easy to manufacture, economically

affordable, in terms of safety, it is safe to use without

disturbing occupational health, is environmentally

friendly, energy efficient and in accordance with the

progress of the times (Pearce et al., 2014; Zelenika et

al., 2011; Zelenika et al., 2012; Pearce, 2012). The

applied appropriate technology is expected to have an

output with identification of effective, comfortable,

safe, healthy, efficient and productive (Shin et al.,

2012; Patnaik and Bhowmick, 2019; Boakye-Ansah

et al., 2020).

Arrack Bali is fairly high alcohol content, which

can reach 37-60% (Muliarta, 2021). While

Presidential Decree No. 74 (2013) concerning the

control and supervision of alcoholic beverages has

provided limits on alcohol content according to

group. Where class A alcoholic beverages are drinks

containing ethyl alcohol or ethanol with levels up to

5%. Class B alcoholic beverages are drinks

containing ethyl alcohol with a content of more than

5% to 20%. Class C alcoholic beverages are

beverages containing ethyl alcohol with a content of

more than 20% to 55%. On the other hand, Arrack

Bali, which is produced traditionally, is divided based

on the alcohol content into four groups, namely:

Grade-1 with more than 30% to 40% alcohol; Grade-

2 from more than 20% up to 30%; Grade-3 more than

10% to 20% alcohol (Indrayati et al., 2021).

With respect to the quality consistency of the

Arrack Bali product, one research has reported that

the increase and decrease in the temperature of the

distillation process (includes evaporation and

condensation) can occur due to poor control or caused

by a malfunction of the controller. The effect of

decreasing temperature on the quality of the

distillation product is the opposite of the effect of

increasing the temperature. Lower distillation process

temperature can result in reduction the amount or

composition of heavier components (lower water

content) or intensification the amount or composition

of lighter components (higher alcohol content). This

also means a bad temperature controller can cause

inconsistent distillation product (Sukadana and

Tenaya, 2016). Therefore, by using a traditional

distillation equipment with surely bad temperature

controller can be very difficut to produce a consistent

quality of Arrack Bali. The challenge, then, appear

“Can Arrack Bali be conventionally made with a

predetermined alcohol content and with a consistent

quality so that the quality is maintained?”. This paper

presents an alternative solution for the challenge

appearred.

2

MATERIALS AND METHODS

2.1 The Built Distillation Machines

Incorporated Refrigeration

Distiller

The appropriate technology applied on the distillation

machine combines the advantages of energy efficient

refrigeration technology using the R-600a. The

technology is also equipped with a smart control

system that is capable to control operational variables

automatically.

The three control variables include the

evaporation temperature in the boiler, the

condensation temperature in the refrigeration distiller

and the time or duration of the distillation process in

one filling of the fermented palm sap raw material in

the boiler. The evaporation temperature in the boiler

is controlled in the ethanol evaporation range of

above 78.4 °C. Then it is followed by controlling the

temperature of the refrigeration distiller to start the

process of condensing Arrack Bali. If condensation is

carried out firstly, there is a possibility that methanol

can be obtained in Arrack Bali and this is not good for

human health because its metabolic derivatives are

toxic (Kraut and Kurtz (2008). The control variable

settings can be profiled until the characteristics of the

production process are found that are suitable to get

the quality of Balinese Arrack to meet the quality of

industrial products.

The refrigeration technology applied in the

machine is optimally utilized both on the side of heat

absorption in the evaporator and heat rejection in the

condenser. The refrigeration system evaporator is

used to cool the distiller so that the arrack vapor can

condense and flow into a container or a storage bottle.

The distillation machine is shown in Figure 1.

Development of Distillation Machines Incorporating Refrigeration: Distiller for Traditional Drink “Arrack Bali” Production

699

Storage tank

for the

fermented sap

of coconut

flower

Control panel

with smart

controller

Figure 1: The established distillation machine completed with refrigeration distiller, smart controller and large storage tank

for fermented sap of coconut flower.

The condenser side of the refrigeration system is

wrapped around the storage tank for the fermented

sap to provide preheating before being filled into

boiler. So that the raw material (fermented sap) when

filled into the boiler is relatively warmer. This

concept can save energy use from LPG gas.

The automatic control system consisting of two

thermostats, one to control the evaporation

temperature in the boiler and the other to control the

temperature of the distiller. These control systems can

provide the machine flexibility to determine the

operating characteristics of the machine specifically

to produce Arrack Bali with certain predetermined

characteristics.

2.2 Methods

The method applied is an experimental study. This

research was initiated by conducting a survey with the

community of Balinese arrack farmers and potential

users of technology to obtain secondary data about

the production process, product type and quality,

including product consistency. A survey was also

conducted to obtain the characteristics of Balinese

Arrack which can be used as the basis for Covid-19

therapy.

Simulation methods with inventor and EES

(engineering equation solver) were also applied to

simulate the design of the distillation machine and its

components as well as simulation of machine

performance based on secondary data. Furthermore,

the performance calculation was performed using the

primary data from the test results. The prototype of

the distillation machine was made and carried out

function testing and testing the characteristics of the

production process with various conditions of control

variables. Primary data from testing is recorded and

processed to obtain a production process that is

consistent and in accordance with the quality target of

Arrack Bali which is appropriate of being an

industrial commodity and as a basic ingredient for

Covid-19 therapy. The content of alcohol in the

arrack Bali was measured using a handheld

refractometer with accuracy of ±0.20%. The tool is

completed with automatic temperature compensation

so that it is much easier to be used.

3

RESULTS AND DISCUSSION

3.1 Novelties Added

One of the novelties of the distillation machine is the

refrigeration distiller. This distiller can perform its

function to change the form of arrack vapor from the

boiler into arrack because it is cooled by the

refrigeration system.

In Figure 2 it can be seen that the distiller tube

made of stainless steel is wrapped around a copper

pipe which is the evaporator of the refrigeration

system. On the inside of the distiller tube is equipped

with a kind of baffle that slows down the flow of

arrack vapor. These baffles are connected to the shell

of the distiller so that they are also cooled down. So

the baffle in addition to slowing the flow also expands

Refrige-

ration

distille

r

Boiler with

gas

b

urne

r

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

700

Figure 2: Refrigeration distiller.

the contact area with the hot arrack vapor. Such

constructions increase the effectiveness of the

distiller.

The integrated distiller is also part of the

refrigeration system of the distillation machine. The

evaporator of the refrigeration system is wound on the

outer surface of the distiller. After absorbing heat

from the distiller in this case the heat from the arrack

vapor, then this heat is rejected in the condenser. The

heat from the condenser is not discharged into the

outside air but is used for preheating the raw material

of the fermented sap in the storage tank.

The novelty shown in this machine can make the

machine more compact compared to distillation

machines that use air cooling or water cooling. In

addition, the stainless steel material used, it can

ensure the cleanliness and hygiene of the arrack

product. By adjusting the cooling temperature

combined with the heating temperature setting in the

boiler, it can provide a variety of arrack products

according to market needs. The ability to maintain the

operating temperature of the distiller and boiler can

increase the novelty of the distillation machine

because it is able to maintain the consistency of the

quality of the product.

3.2 Consistency of Operation and

Controlling

Setting and maintaining the temperature level on the

two main components (distiller and boiler) of the

distillation machine is carried out by an intelligent

control system located in the electrical control panel

(Figure 3). The intelligent control system consists of:

(i) Distiller temperature controller which functions

to

maintain and regulate the condensation

temperature

of the arrack vapor in the distiller; (ii)

Boiler

temperature controller which is maintaining

and

regulating the evaporation temperature of the

raw

material of arrack (fermented sap) into vapor.

The controller for the distiller works based on a

temperature sensor mounted on the distiller body.

This sensor provides a temperature level signal from

the distiller as input. Based on this input, the

controller then responds in the form of an "On or Off"

signal to the refrigeration system. If the temperature

level is already achieved, then the compressor of the

refrigeration system is made "Off" and vice versa.

Figure 3: Smart controller.

For the boiler controller, a temperature sensor is

immersed in the fermented sap. This sensor provides

information to the controller of the temperature level

of the evaporation process that occurs in the boiler.

The controller closes the fuel supply valve to the

burner and turn off the burner (but the pilot flame

remains on) when the temperature of the evaporation

in the boiler has reached the setting temperature.

Based on the regulatory capabilities provided by the

two controllers, the Distillation Machine can perform

intelligent controls in maintaining the consistency of

operational conditions which affect the product

quality. By using the intelligent control, the machine

is able to provide various variants of the quality of the

Arrack Bali. The controller can also ensure that the

evaporation temperature in the boiler is 78.4 °C or

above. Therefore, only ethanol is produced as

reported in Kraut and Kurtz (2008).

3.3 Production Characterization

The machine incorporates novelties which include a

refrigeration distiller, preheating heat exchanger and

smart controller for both boiler and distiller. The

machines can perform reliably with several

production characteristics.

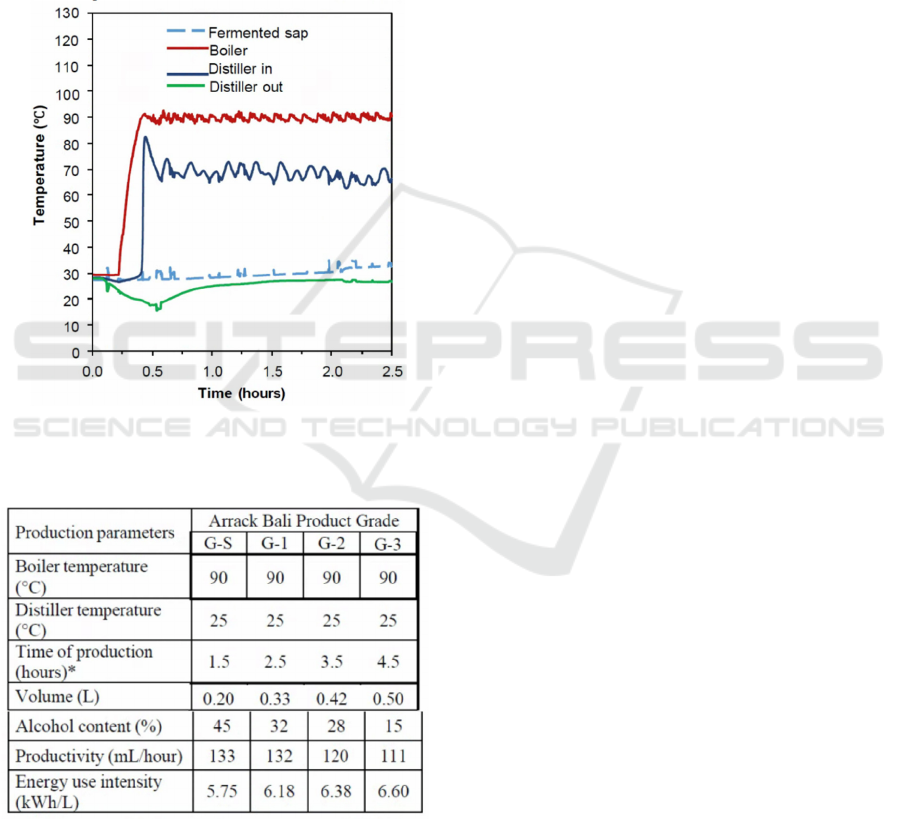

Figure 4 shows one of the characterization of the

Arrack Bali production utilizing the distillation

machine. The figure shows the operational

characteristics of the Grade-2 Arrack Bali production.

Development of Distillation Machines Incorporating Refrigeration: Distiller for Traditional Drink “Arrack Bali” Production

701

From the figure it can be seen that the machine can

maintain boiler and distiller temperature. The

temperature condensation in distiller is estimated by

using temperature at the outlet of the distiller with

ranging from 15 to 27 °C. Temperature drop occurs

along the connecting pipe from boiler to the distiller

for about 20 K. This temperature drop is not only due

to heat losses across the connecting pipe but also due

to heat absorbed by the evaporator of the refrigeration

system in the distiller. The fermented sap temperature

in the figure refers to temperature of the raw material

in the storage tank.

Figure 4: Characterization of the arrack Bali production.

Table 1: Arrack Bali product grades and characteristics.

Alcohol content of each grade: Grade Super (G-S) >40%-

50%; Grade-1 (G-1) >30%-40%; Grade-2 (G-2) >20%-

30% and Grade-3 (G-3) >10%-20%; *Time of

production including time required for initial process of

distillation about 30-40 minutes.

The machines can perform reliably with several

production characteristics. The machine is capable to

consistently produce several variants of Arrack Bali

which can be grouped into four grades: Grade-Super,

Grade-1, Grade-2 and Grade-3 with alcohol content

above 40%, 30%, 20%, 10% respectively. These

variants are resulted from production characteristics

at boiler temperature 87-93 °C, distiller temperature

15-27 °C and corresponding production time 1.5, 2.5,

3.5, and 4.5 hours respectively as shown in Table 1.

In this study, the grouping and grading of Arrack

Bali products were developed to accommodate the

grouping carried out by arrack farmers as reported in

(Muliarta, 2021) and (Indrayathi et al., 2021) and to

comply with Presidential Decree No. 74 (2013).

3.4 Energy Performance and

Productivity of the Machine

With respect to the energy performance and

productivity, test results showed the machine could

produce Arrack Bali of Grade-Super (G-S) for about

133 mL per hour with energy consumption per liter

Arrack Bali Grade-Super of about 5.75 kWh. More

detailed energy use intensity and productivity of the

machine with other variants of Arrack Bali products

can be seen in Table 1. The energy use intensity tends

to increase when the alcohol content decreases. This

means that for producing lower grade of Arrack Bali

would require higher energy. This is caused by the

more water content that must be evaporated and

condensed where water has a higher temperature and

energy of evaporation or condensation than alcohol.

4

CONCLUSIONS

A novel distillation machine specifically designed for

Arrack Bali production has been developed and

tested. The machine incorporates novelties which

include a refrigeration distiller, preheating heat

exchanger and smart controller for both boiler and

distiller. The machines can perform reliably with

several production characteristics. Production test

results showed several variants of Arrack Bali could

be produced consistently. Four grades of Arrack Bali

can be produced using the machine which include

Grade-Super, Grade-1, Grade-2 and Grade-3 with

alcohol content above 40%, 30%, 20%, 10%

respectively. The product variants are resulted from

production characteristics at boiler temperature at

boiler temperature 87-93 °C, distiller temperature 15-

27 °C and corresponding production time 1.5, 2.5,

3.5, and 4.5 hours. The machine could produce

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

702

Arrack Bali of Grade-Super for about 133 mL per

hour with energy consumption per liter Arrack Bali

Grade-Super of about 5.75 kWh. The energy use

intensity tends to increase when producing lower

grade of Arrack Bali.

ACKNOWLEDGEMENTS

Authors favorably acknowledge the Centre of

Research and Community Services (P3M) Politeknik

Negeri Bali for the technical and administrative

assistances. The authors also gratefully thank the

financial support from Politeknik Negeri Bali through

institutional funding scheme: DIPA Politeknik

Negeri Bali number: SP. DIPA-023.18.2. 677608/

2021, dated 23 November 2020.

REFERENCES

Anis Najiha, A. dan Wan Nadiah, W.A. (2014). Alkohol

(Arrack dan Etanol) dalam Makanan Halal. Jurnal

Intelek 9(1), 40-51.

Boakye-Ansah, A.S., Schwartz, K., Zwarteveen, M. (2020).

Aligning stakeholder interests: How ‘appropriate’

technologies have become the accepted water

infrastructure solutions for low-income areas. Utilities

Policy 66, 101081.

Depkes RI. (2017). Bahaya Minuman Beralkohol Bagi

Kesehatan. Available from: www.depkes.go.id

(accessed 15 August 2020).

Dinas Kesehatan Provinsi Bali. (2014). Laporan Kejadian

Keracunan Minum Arrack, Bali: Dinas Kesehatan

Provinsi Bali.

Indrayathi, P.A., Suariyani, N.L.P., Subrata, I.M.,

Noviyani, R. (2021). Persepsi produsen arrack di desa

merita, karangasem mengenai bahaya keracunan arrack

oplosan yang mengadung metanol yang dapat

mengancam kesehatan dan pariwisata di Bali. Available

at: https://simdos.unud.ac.id/uploads/file_penelitian_

1_dir/b791d1b05297a9db7aef5ae804c30153.pdf

Kraut, J.A. and Kurtz, I. (2008). Toxic alcohol ingestions:

Clinical features, diagnosis, and management. Clinical

Journal of the American Society of Nephrology, 3(1),

208-225.

Muliarta, N. (2021). Effect of Sugar Addition and Reversal

in Rice Straw Composting Aerobically to Compost

Maturity. Ilkogretim Online, 20(4).

Patnaik, J. and Bhowmick, B. (2019). Revisiting

appropriate technology with changing socio-technical

landscape in emerging countries. Technology in Society

57, 8-19.

Pearce, J.M. (2012). The case for open source appropriate

technology. Environ. Dev. Sustain. 14, 425–431.

Pearce, J.M., Albritton, S., Grant, G., Steed, G., and

Zelenika, I. (2014). A new model for enabling

innovation in appropriate technology for sustainable

development. Sustainability: Science, Practice, &

Policy 8(2), 42-53.

Presidential Decree No. 74. (2013). Presidential Regulation

of the Republic of Indonesia concerning control and

supervision of alcoholic drinks.

Rhismawati, N.L. (2020). Gubernur Bali terbitkan pergub

soal tata kelola arrack Bali. https://bali.antaranews

.com/berita/179051/gubernur-bali-terbitkan-pergub-

soal-tata-kelola-arrack-bali (accessed 21 August 2020).

Shin, H., Hwang, J., Kim, H. (2019). Appropriate

technology for grassroots innovation in developing

countries for sustainable development: The case of

Laos. Journal of Cleaner Production 232, 1167-1175.

Suaniti, N.M., Astiti Asih, I.A.R., Widya Astuti, N.P.

(2012). Deteksi Etanol setelah Konsumsi Arrack dalam

Urin dengan Gas Chromatography. Jurnal Kimia 6 (2),

112-115.

Sukadana, I.G.K. and Tenaya, I.G.N.P. (2016). Performansi

mesin berbahan bakar etanol hasil destilasi arrack Bali.

Jurnal Energi dan Manufaktur 9, 70-74.

Widya Astuti, N.P., Suaniti, N.M., dan Mustika, I.G.

(2018). Validasi metode dalam penentuan kadar etanol

pada arrack dengan menggunakan kromatografi gas

detektor ionisasi nyala. Jurnal Kimia 11(2), 128-133.

Zelenika, I., and Pearce, J.M. (2011). Barriers to

Appropriate Technology Growth in Sustainable

Development. Journal of Sustainable Development

4(6), 12-22.

Zelenika, I., and Pearce, J.M. (2012). Innovation Through

Collaboration: Scaling up Solutions for Sustainable

Development. Environ. Dev. Sustain. 16(6), 1299-

1316.

Development of Distillation Machines Incorporating Refrigeration: Distiller for Traditional Drink “Arrack Bali” Production

703