A Simple Speed and Torque Meter using Arduino

Made Purbhawa, Kadek Amerta Yasa, Ketut Gede Sudiartha, Wayan Jondra

and Igna Dwijaya Saputra

a

Department of Electrical Engineering, Politeknik Negeri Bali, Jl Bukit Jimbaran, Badung, Bali, Indonesia

Keywords: Torque Meter, Speed Meter, Arduino.

Abstract: Speed and torque are crucial aspects of the operation of an electric motor. The general method to measure the

speed and torque is using a speed meter and torque meter. Unfortunately, these instruments are pricy in the

market. It is also difficult to fix those instruments because they fail in operation due to hardware problems. In

this paper, a simple device for measuring speed and torque, voltage, and current are built using an Arduino as

a central processor. This device also has a display and has a connection to a computer for storing data and

displaying these data in LabVIEW. The test results for these instruments show the average error both for

speed meter and torque meter were 0.11% and 0.81% consecutively.

1 INTRODUCTION

Induction motors are widely used in society, both in

industry and for household appliances. This motor is

cheap and easy to operate, so it is excellent as

electrical equipment. In its operation, it is necessary

to know the extent of the speed and the torque

produced as part of a study of the characteristics of

induction motors. Students must understand the

rotational speed during operation and the value of

torque generated, both at no and under load. This

torque can be controlled or reduced ripple (Alsofyani

and Idris, 2016), (Ma,2021), (Wang, 2020), (Sharma

and Pal, 019). It is usually done in the laboratory of

electrical machines using a torque meter to measure

torque and a tachometer to measure motor speed. In

general, measurement is also carried out using analog

measuring instruments as modules according to

suitable learning materials.

Nevertheless, this measuring tool is costly which

can reach tens of millions of rupiah. Experience in the

field, especially at the Electrical Machinery

Laboratory, found that the measuring instruments

used by students in carrying out practicals are easily

damaged. A good quality measuring instrument also

fails to operate due to a large number of people using

this instrument. The replacement takes a long time

because it is an imported product and must be ordered

at a high price from a distributor. For this reason, it is

a

https://orcid.org/0000-0002-1267-6222

necessary to build a torque and speed measuring

instrument that is cheap, reliable, and can be replaced

quickly in case of damage.

2 PROPOSED METHOD

This research has been conducted at the electrical

machinery laboratory, Department of Electrical

Engineering, Bali State Polytechnic. The initial

survey was conducted to determine how the

measurements were previously carried out, the

number of repetitive measures, and the tools. The

next step is to design a measuring instrument using

the Arduino microcontroller and its supporting

components. Furthermore, the finished device is

tested by comparing the measurement results with

standard tools owned by the Department of Electrical

Engineering. The stages of this research are drawn as

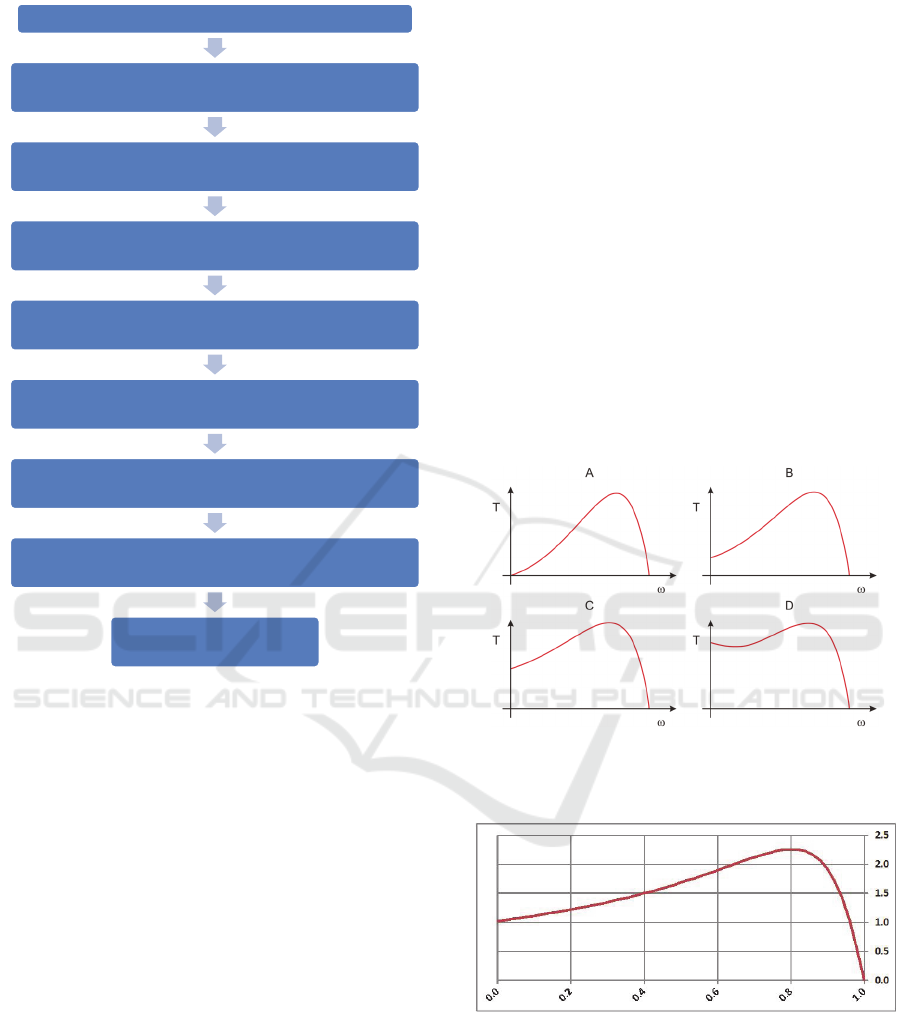

a figure that can be seen in Figure 1.

The next step is to build a system that can record

data (data logger) to a computer. This operation can

be performed using the LabVIEW software. From the

results of this data recording, the data can be plotted,

and also the necessary calculations are carried out,

such as to find power losses.

The whole system, both measuring instruments

that

use

a

microcontroller

and

programs

that

have

710

Purbhawa, M., Yasa, K., Sudiartha, K., Jondra, W. and Saputra, I.

A Simple Speed and Torque Meter using Arduino.

DOI: 10.5220/0010951900003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 710-715

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1: Research Stages.

been built using LabVIEW, will be tested to find the

specifications of the tools.

Speed and Torque

a. Speed

The synchronous speed of an AC motor, ns is the

rotational rate of the stator magnetic field with the

equation:

s = (n

s

– n

r

) / n

s

(1)

where f is the frequency of the power supply, p is

the number of magnetic poles, and with ns as a

synchronous speed of the machine with units for f in

Hertz and ns in RPM, the formula becomes (

Steinmetz,

1997) and (Alger, 1949):

n

s

= 2f/p.((60 s/min) = 120f/p. (s/min)

(2)

b. Slip

Typical curve of the torque as a function of slip

represented as "g" here. Slip, s, is defined as the

difference between synchronous speed and operating

speed, at the same frequency, expressed in rpm, or

percentage or ratio of synchronous speed. So:

s = (n

s

– n

r

) / n

s

(3)

Where ns is the electric speed of the stator, nr is

the mechanical speed of the rotor (NSW HSC, 2012)

(NEMA MG-1 2007, 2008). The value of the slip is

varied, which varies from zero at synchronous speed

and 1 when the rotor is jammed determines motor

torque. For some reason, the short-circuited rotor

windings have negligible resistance. Even a tiny slip

induces large currents in the rotor and produces

significant torque (Penton Media, 2007). When the

load reaches the highest value, the slip of small

motors varies from more than 5%, while it has only

less than 1% for large engines (Motor Formula,

1999). This speed variation can cause load sharing

problems when motors of different sizes are

mechanically connected.

c. Standard Torque

The speed-torque curves for the four types of

induction motors can be seen in Figure 2.

Figure 2: Velocity Curve - Torque A) Single phase, B)

Polyphase cage, C) Polyphase cage deep bar, D) Polyphase

double cage.

Figure 3: A typical speed-torque curve for a NEMA Design

B Motor.

Figure 3 shows the curve of the typical speed-

torque relationship of a standard NEMA Design B

polyphase induction motor. Suitable for most low-

performance loads such as pumps and centrifugal

fans, The following typical torque range limits design

B motors (Avinash and Ravi, 2013).

Start

Surveymethodandmeasurement

configuration

Designingmeasuringinstrumentsusinga

microcontroller

Makingmeasuringtools

Microcontrollermeasuringinstrument

testing

Buildasystemtoreadmeasurementresults

withLabVIEW

OverallToolTesting

Testresultsintheformoftool

specifications

end

A Simple Speed and Torque Meter using Arduino

711

Breakdown torque (peak torque),

175-300% of rated torque

Rotor-locked torque (torque at 100% slip),

75-275% of rated torque

Pull-up torque,

65-190% of rated torque.

In the normal load range of the motor, the torque

slope is approximately linear or proportional to the

slip because the value of the rotor resistance divided

by the slip, R'r/s, dominates the torque linearly

(NEMA Standard, 2007). If the load increases above

the rated load, the rotor and rotor leakage reactance

factor gradually become more significant to R'r/s. The

torque gradually curves towards breakdown torque.

When the load torque increases beyond the

breakdown torque, the motor stops.

Locked rotor torque or drive torque is the torque

developed by an electric motor when it starts at zero

speed.

High starting torque is highly used for

applications or difficult-to-start machines, such as

positive displacement pumps or cranes. Lower

starting torque is acceptable for centrifugal fans or

pumps where the starting load is low or near zero.

Pull-up Torque

Pull-up torque can be described as the minimum

torque value developed by an electric motor when

running from zero to full load speed (before reaching

the breakdown torque point). When the engine starts

and starts to accelerate, the pull-up torque value is

decreased at a certain speed to a low point. The torque

breakdown point increases its value to the highest

torque at a higher speed. The pull-up torque may be

necessary for applications that require power to pass

through some temporary barrier to reach working

conditions.

Breakdown Torque

Breakdown torque is the highest torque available

before torque is reduced as the machine accelerates to

a working state.

Full Load Torque or Brake Torque

Full Load Torque is the torque required to produce

the rated power of the electric motor at full load

speed. In imperial units, Full Load Torque can be

expressed as

T = 5252 Php/nr

(4)

where:

T = full load torque (lb ft)

Php = rated horsepower

nr = rated rotation speed (rev/min, rpm)

The rated torque in metric units, can be denoted as:

T = 9550 PkW/nr

where:

T = rated torque (Nm)

PkW = rated power (kW)

nr = rated rotational speed (rpm)

Torque measurement can be carried out in various

ways and techniques, including using a rheometer on

a permanent magnet motor (Letner et al., 2019), using

a method based on an encoder (Liu et al., 2014), and

based on Electromotive Force for Surface-Mounted

permanent magnet motors (

Simón-Sempere, 2015)

.

3 RESULT AND DISCUSSION

This speed and torque meter is built using Arduino as

the microprocessor. This measuring instrument is

made with Arduino so that the cost is not high with a

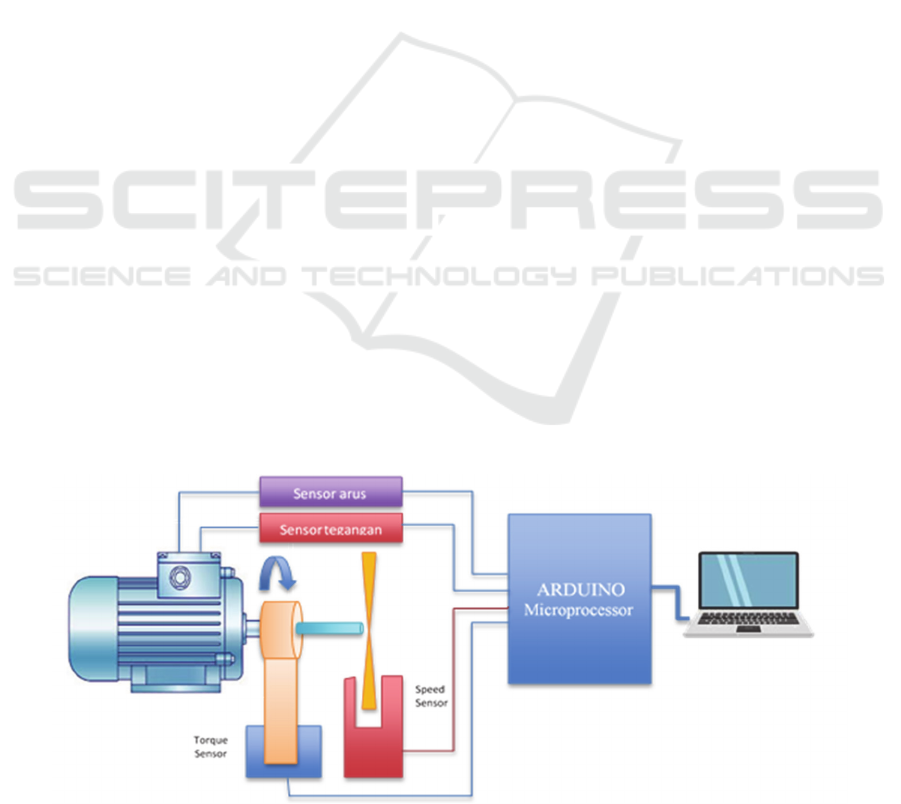

Figure 4: Speed and torque measuring circuit.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

712

level of accuracy that meets the standards. The circuit

built can be seen in Figure 4 for the schematic and

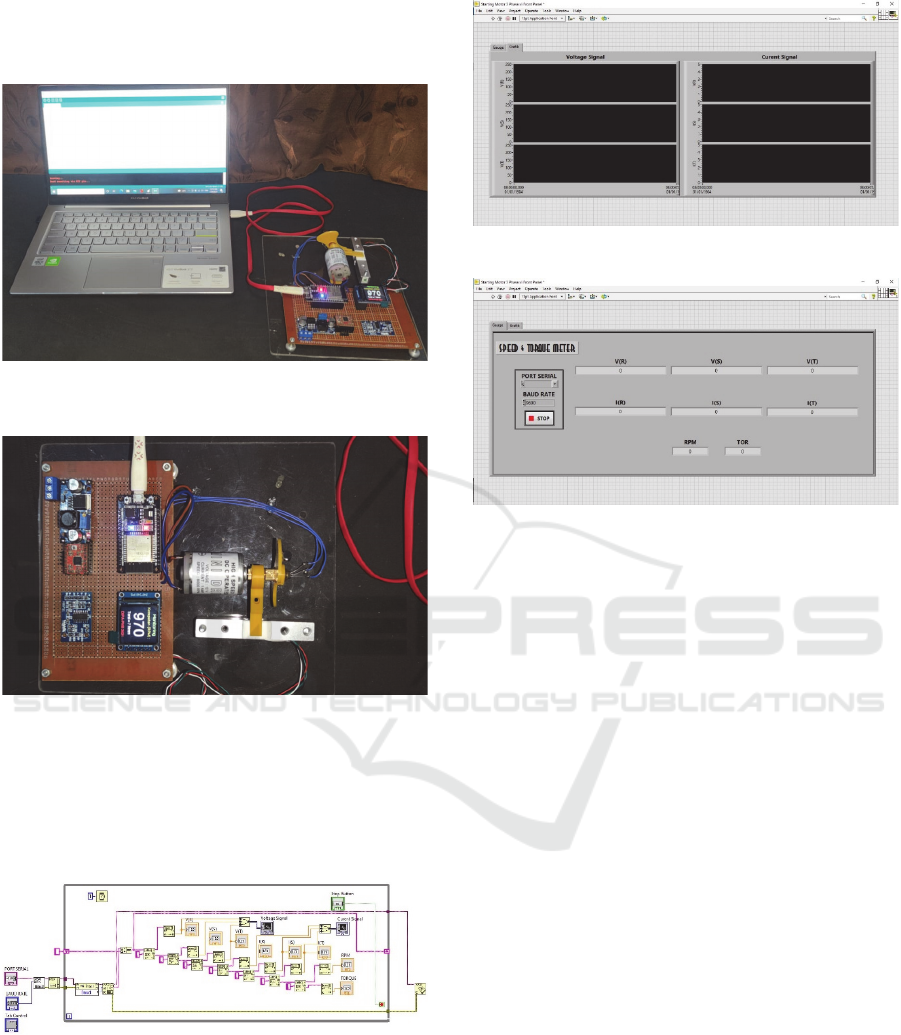

Figure 5. and 6 for its application.

Figure 5: Details of the circuit prototype connected to the

computer.

Figure 6: Circuit are made for measuring speed and torque.

The microprocessor processes the input voltage,

current, speed, and torque sensors, and the output can

be displayed on display or displayed to the computer.

One way is to use LabVIEW, as can be seen in

Figures 7, 8, and 9.

Figure 7: The Proposed system in LabVIEW.

Figure 8: Display output on LabVIEW.

Figure 9: Display output on LabVIEW.

The research on making this motor speed and

torque measuring instrument is intended for AC

motors in the electric motor lab of the Bali State

Polytechnic. Before that, the prototype was made

using a smaller engine. The measurement results of

voltage, current, speed, and torque produced can be

seen in Table 1 to Table 4, respectively.

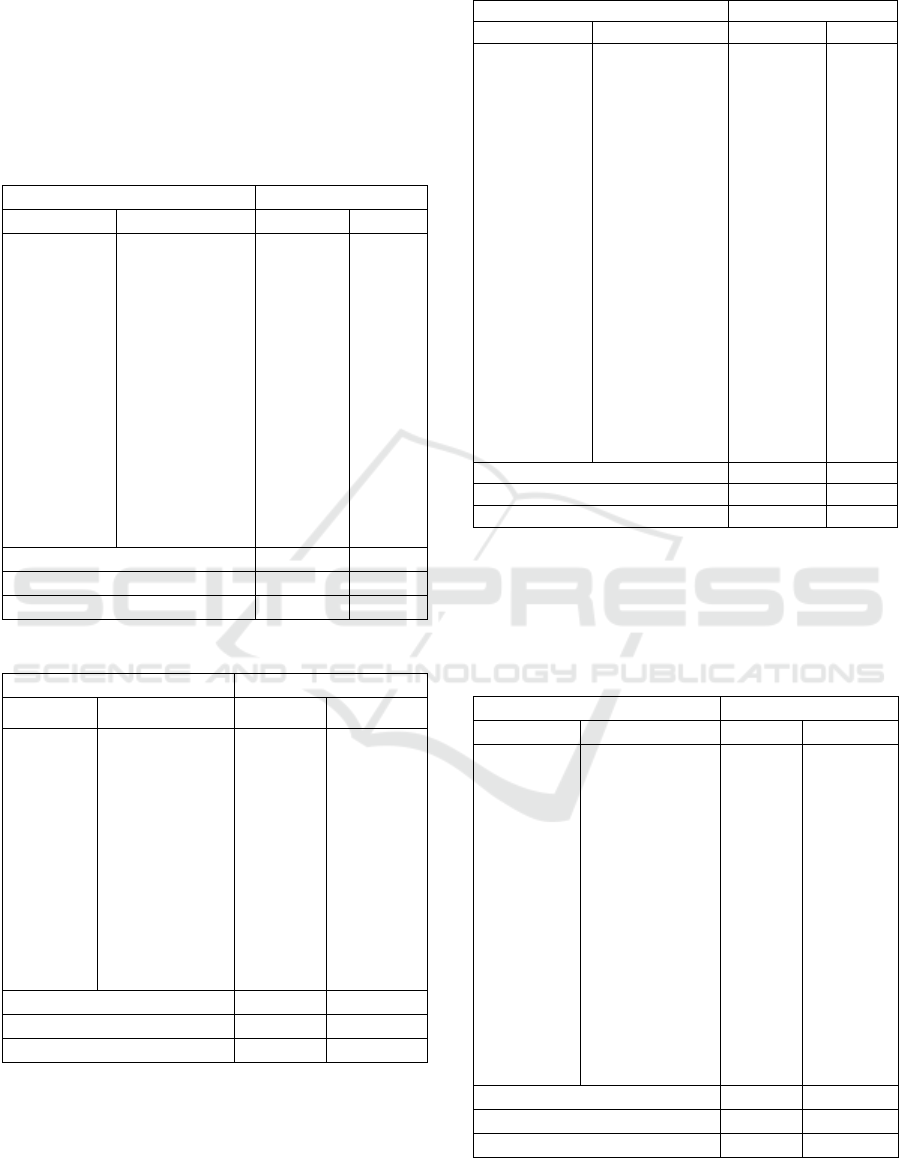

Table 1 shows results data for testing of the

measuring voltage. The error results of the voltage

measurement are between 0.001 and 0.050 volts, with

an average error is 0.020 volts or 0.42%.

For the current measurement test, the result can be

seen in Table 2. The maximum error is only 0.01A or

1.6% when this device is used for 1A measurement,

while the minimum error is zero. For the test from

0.1A to 1A, the average error is only 0.35 A.

The speed meter is tested by comparing the result

with the standard ones, and the results can be seen in

Table 3. The test is conducted for various speeds at

10 to 5500rpm. From Table 3, the error increases

gradually as the increase of speed of the motor. The

minimum error for speed testing is 0.01 rpm at the

lowest speed test of 10 rpm, while the maximum error

is 6.85 rpm at 5500 rpm, or it is only 0.22% of error.

The average error test for the speed meter is only 1.81

rpm or 1.11% of the measurement. This means that

the speed meter has a good performance with an

average error is less than 2%.

The test has also been conducted on the torque

meter, with the result shown in Table 4. The torque

A Simple Speed and Torque Meter using Arduino

713

values for the test are from 1 Nm then gradually

increased with 0.5 to get a higher value at 7 Nm. The

results show that the maximum error is found at the

maximum value of 1.87% and the minimum is only

0.08 %. The average error is less than 1% or 0.81%,

which makes this measurement device has a good

performance.

Table 1: Voltage measuring instrument testing.

Voltage (V) Error

Standard Measurement Value %

1.000 1.012 0.012 1.20%

2.000 2.001 0.001 0.05%

3.000 3.030 0.030 1.00%

4.000 4.020 0.020 0.50%

5.000 5.010 0.010 0.20%

6.000 6.013 0.013 0.22%

7.000 7.050 0.050 0.71%

8.000 8.037 0.037 0.46%

9.000 9.015 0.015 0.17%

10.000 10.012 0.012 0.12%

11.000 11.030 0.030 0.27%

12.000 12.011 0.011 0.09%

Average 0.020 0.42%

Minimum 0.001 0.05%

Maximum 0.050 1.20%

Table 2: Current measuring instrument testing.

Current (A) Error

Standard Measurement Value %

0.100 0.100 0.000 0.00%

0.200 0.200 0.000 0.00%

0.300 0.300 0.000 0.00%

0.400 0.401 0.001 0.25%

0.500 0.508 0.008 1.60%

0.600 0.600 0.000 0.00%

0.700 0.702 0.002 0.29%

0.800 0.801 0.001 0.13%

0.900 0.902 0.002 0.22%

1.000 1.010 0.010 1.00%

Average 0.002 0.35%

Minimum 0.000 0.00%

Maximum 0.010 1.60%

In general, the measuring instruments that have been

built for current and voltage measurements are under

the standard. This also applies to the speed and torque

measurements device that meet the standard.

Table 3: Speed measuring instrument testing.

S

p

eed (r

p

m) Error

Standard Measurement Value %

10 10.01 0.01 0.10%

50 50.01 0.01 0.02%

100 100.03 0.03 0.03%

200 200.11 0.11 0.06%

300 300.05 0.05 0.02%

400 400.87 0.87 0.22%

500 500.76 0.76 0.15%

750 751.20 1.2 0.16%

1000 1002.10 2.1 0.21%

1250 1251.55 1.55 0.12%

1500 1500.98 0.98 0.07%

2000 2002.31 2.31 0.12%

3000 3003.22 3.22 0.11%

4000 4003.97 3.97 0.10%

5000 5005.01 5.01 0.10%

5500 5506.85 6.85 0.12%

Average 1.81 0.11%

Minimum 0.01 0.02%

Maximum 6.85 0.22%

Furthermore, the error value is not significant for

the current measurement, which is an average of

0.35% with a maximum of 1.6% and still below 2%,

as shown in Table 4.

Table 4: Torque measuring instrument testing.

Torque (Nm) Error

Standard Measurement Value %

1.00 1.001 0.001 0.10%

1.50 1.502 0.002 0.13%

2.00 2.018 0.018 0.90%

2.50 2.502 0.002 0.08%

3.00 3.021 0.021 0.70%

3.50 3.526 0.026 0.74%

4.00 4.017 0.017 0.43%

4.50 4.552 0.052 1.16%

5.00 5.046 0.046 0.92%

5.50 5.523 0.023 0.42%

6.00 6.107 0.107 1.78%

6.50 6.581 0.081 1.25%

7.00 6.825 0.125 1.87%

Average 0.040 0.81%

Minimum 0.001 0.08%

Maximum 0.125 1.87%

Testing speed and torque measuring instruments

have been carried out with adding the calibration to

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

714

ensure both meterings meet the standard. The result

found that these devices only have a maximum error

of 0.22% and 1.87% for the speed meter and torque

meter, respectively.

4 CONCLUSIONS

The speed and the torque meter are built using

Arduino Uno to make them inexpensive. These

measuring instruments have been tested for current

and voltage measurements. Both devices are under

the standard, with the maximum error at less than 2

%. The speed and torque meter are also shown a good

performance under the test with maximum error for

both instruments is 0.22% and 1.87%, respectively.

So, all the instruments meet the standard.

ACKNOWLEDGEMENTS

The Authors thank The Center of Research and

Community Service, Politeknik Negeri Bali, for

funding this research.

REFERENCES

Alger, P.L.; et al. (1949). 'Induction Machines' sub-ection

of Sec. 7 - Alternating-Current Generators and Motors.

Knowlton, A.E. (ed.). Standard Handbook for Electrical

Engineers(8th ed.). McGraw-Hill. p. 705.

Alsofyani, IM and Idris, NRN. (2016). Torque ripple

reduction and fast torque control in DTC of induction

machine using overlapping triangular-based constant

frequency torque controller. 2016 IEEE International

Conference on Power and Energy (PECon), Melaka,

Malaysia, 2016, pp. 194-198, doi: 10.1109/P

ECON.2016.7951558.

Avinash, S., Ravi, K.. (2013). Torque Slip Characteristics

of Induction Motor. Course Notes. Malnad College Of

Engineering

Elec-toolbox.com. (1999). Motor Formulas. Archived from

the original on 8 May 1999. Retrieved 1 January 2013.

Leitner, S., Krenn, G., Gruebler, H and Muetze, A. (2019).

Rheometer-based Cogging Torque Measurement for

Sub-Fractional HP Permanent Magnet Motors, 2019

IEEE Transportation Electrification Conference and

Expo (ITEC), Detroit, MI, USA, pp. 1-7, doi:

10.1109/ITEC.2019.8790471.

Liu, X., Liang, D., Du, J., Yu,Y and Yang, X. (2014). A

torque measuring method based on encoder for

permanent magnet synchronous machine. 2014 17th

International Conference on Electrical Machines and

Systems (ICEMS), Hangzhou, China, pp. 1510-1514,

doi: 10.1109/ICEMS.2014.7013730

Ma, P., Wang, Q., Li, Y., Jiang, S., and Zhao, M. (2021).

Research on Torque Ripple Suppression of the Slotted

Limited Angle Torque Motor. IEEE Transactions on

Magnetics, vol. 57, no. 2, pp. 1-6, Feb. 2021, Art no.

8200106, doi: 10.1109/TMAG.2020.3006018.

NEMA MG-1 2007 Condensed. (2008). Information Guide

for General Purpose Industrial AC Small and Medium

Squirrel-Cage Induction Motor Standards. Rosslyn,

Virginia US: NEMA. p. 29 (Table 11). Retrieved 2

December 2012.

NEMA Standards Publication (2007). Application Guide

for AC Adjustable Speed Drive Systems. Rosslyn,

Virginia US: NEMA. p. 6. Archived from the original

on 28 April 2008. Retrieved 2 December 2012.

NSW HSC Online. (2012). AC Motors. Charles Sturt

University. Archived from the original on 30 October

2012. Retrieved 2 December 2012.

Penton Media, Inc. (2007). Induction Motors.

electricmotors.machinedesign. com.. Archived from

the original on 2007-11-16. Retrieved 2016-04-12.

Sarwar, I., (2018). 3 Phase Smart Energy Meter using

Arduino. Engineer Experiences, 2018. [Online].

Available: http://engineerexperiences.com/3-phase-

smart-energy-meter-using-arduino.html. [Accessed 9

March 2019].

Sharma, T.R., and Y. Pal, Y. (2019). Direct Torque Control

of BLDC Drives with Reduced Torque Pulsations. 2019

3rd International conference on Electronics,

Communication and Aerospace Technology (ICECA),

Coimbatore, India, 2019, pp. 1242-1247, doi:

10.1109/ICECA.2019.8822141.

Simón-Sempere, V., Burgos-Payán, M. and Cerquides-

Bueno, J. (2015). Cogging Torque Measurement Using

the Electromotive Force in Surface-Mounted

Permanent-Magnet Motors. IEEE Transactions on

Magnetics, vol. 51, no. 7, pp. 1-10, July 2015, Art no.

8105910, doi: 10.1109/TMAG.2015.2394477

Steinmetz, .P., Berg, E.J. (1997). Theory and Calculation of

Alternating Current Phenomena. McGraw Publishing

Company. OL 7218906M.

Wang, X., Wang, Z., Xu, Z., Cheng, M. and Hu, Y. (2020).

Optimization of Torque Tracking Performance for

Direct-Torque-Controlled PMSM Drives with

Composite Torque Regulator. IEEE Transactions on

Industrial Electronics, vol. 67, no. 12, pp. 10095-10108,

Dec. 2020, doi: 10.1109/TIE.2019.2962451.

A Simple Speed and Torque Meter using Arduino

715