Design and Development of SHIPS-ROV

Budianto

1a

, M. Basuki R.

2

, Imam Sutrisno

2

, Zindhu Maulana

2

, Eko Julianto

3

and Arie Indartono

3

1

Shipbuilding Engineering, Politeknik Perkapalan Negeri Surabaya, Surabaya, Indonesia

2

Electrical Engineering, Politeknik Perkapalan Negeri Surabaya, Surabaya, Indonesia

3

Marine Engineering, Politeknik Perkapalan Negeri Surabaya, Surabaya, Indonesia

Keywords: Remotely Operated Vehicle, Underwater, Bio- fouling, Performance, Corrosion, Design, Development.

Abstract: Ships that are operating can experience damage to the hull during operation, including: damage to

deformation, fatigue, corrosion etc. The presence of bio-fouling attached to the hull makes the hull plates thin

due to the formation of deposits or deposits on the hull caused by marine life. This will cause the condition

of the ship’s structural strength to decrease due to the decreasing moment of inertia of the structure due to

thinning plates. Therefore, it is necessary to inspect the condition of the ship’s hull after a period of operation.

The amount of the bio-fouling component will affect the speed of the ship as well because the condition of

increasing ship resistance increases if the bio-fouling is not cleaned from the hull. This paper describes a

development of SHIPS-ROV (Ships building Institute of Polytechnic Surabaya-ROV) as a device that help to

monitor the condition off ship’s hull.

1 INTRODUCTION

Some of the damage to the hull in operations include

deformation, cracks, fatigue, fouling, corrosion, thus

requiring an earlier hull investigation process so that

more hull damage does not occur. The number of

marine transportation accidents, such as ship

collisions can result in some parts of the ship being

deformed or the condition of the hull breaking which

causes a hull leak that causes the ship to sink. The

condition of bio-fouling in the hull, a condition where

the thickness of the hull plate is reduced due to the

presence of marine life attached to the hull, these

conditions can be in the form of deposit formation,

encrustation, curding, deposition, scaling, scale

formation, slagging, and mud formation. Therefore,

the Bureau of Classification will always check the

thickness of the hull plate every year in terms of

issuing the feasibility of the ship in sea operations, but

the docking process must be carried out and this

requires no small cost. Therefore, SHIPS-ROV

technology is urgently needed to directly investigate

the condition of the hull submerged in water, both due

to fouling and even deformation or crack conditions

in the hull. ship hull for low- cost investigation

processes with simpler size and function capacity

a

https://orcid.org/0000-0002-4155-5008

settings but using reliable technology and materials.

In the process of designing SHIPS-ROV, a design

method with the latest technology is needed so that

optimum product results are obtained with a few rows

of wasted material. The latest product design

technology can control material requirements,

structural strength, and product optimization forms

and can more easily carry out the inspection process

for the product design process. Some of the SHIPS-

ROV product design processes with product design

methods can be grouped into three parts, including:

• Computer Aided Design (CAD) is a computer

software program for the process of drawing a

product or part of a product component. Products that

are designed can be represented with lines or symbols

that have certain meanings according to applicable

standards. In CAD it can be a 2D or 3D drawing.

• Computer Aided Engineering (CAE) which is

the use of computer software in product design that

assists technical propulsion system, controlled and

piloted by an on board analysis tasks. Such as finite

element methods (FEA), fluid dynamics (CFD), and

optimization.

• Computer Aided Manufacturing (CAM) which

is a design process in the form of working drawings

and G-code results that can be directly used in the

756

Budianto, ., Basuki R., M., Sutrisno, I., Maulana, Z., Julianto, E. and Indartono, A.

Design and Development of SHIPS-ROV.

DOI: 10.5220/0010953000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineer ing Science (iCAST-ES 2021), pages 756-760

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

production process. In CAM includes the needs of

row material, G-code, working drawings, assembly

drawings and others.

2 SHIPS-ROV DESIGN

Figure 1 shows the step by step process of the

design and development of SHIPS-ROV. The first

step is to identify the system requirements.

Specifications will be owned by SHIP-ROV. This

step will determine the design and equipment

Figure 1: Overall Flow of design of HIP ROV.

requirements of the SHIPS-ROV. The later step,

determine the mechanical design and electrical

design. To develop the mechanical design, Fusion

360 software is used to draw and animate the SHIPS-

ROV that are proposed and expected and AutoCAD

software is used to electrical design for internal and

external. The last step is to test and evaluate the

imperfections of the SHIPS-ROV system and the

weaknesses of the mechanical design and electrical

design of the SHIPS-ROV

3 GENERAL DESIGN OF AN

SHIPS-ROV

In the development of regulation in Ship-RUV

construction some applicable regulations are such as

BKI, ABS, GL, NK, BV and others. Each

classification of the regulation has a critical content

in performing standard in accordance with the results

of research and design.

There are several aspects that need to be considered

in mechanical design and electrical design in order to

success- fully obtain a suitable circuit for SHIP-ROV.

In ship design where in determining the main size and

line plan includes several designs, including:

determining the main size of the ship, determining the

design of comparison ships, making CSA and shape

control body plans. (Budianto, 2018). Some floating

object designs have a fairly high level of difficulty.

The amount of weight placed in light weight and

death weight should not be more than the planned ship

displacement. CAD technology Computer Aided

Design (CAD) is a computer software program for the

process of drawing a product or part of a product

component. Products that are designed can be

represented with lines or symbols that have certain

meanings according to applicable standards. In CAD

it can be a 2D or 3D drawing. Computer Aided

Engineering (CAE) which is the use of computer

software in product design that assists engineering

analysis tasks. Includes for finite element methods

(FEA), fluid dynamics (CFD), and optimization.

Computer. Aided Manufacturing (CAM) it is a

design process in the form of working drawings and

G-code results that can be directly used in the

production process. In CAM can covers the needs of

row material, G-code, working drawings, assembly

drawings and others. In designing a SHIP-ROV that

operates in water, it is very necessary to have

knowledge of ship design, marine use materials and

the laws of physics that support the concept of

underwater vehicles and their environment.

Therefore, the major design aspects that need to be

considered are body design, material selection,

electric power. Figure 2 shows the SHIP-ROV design

using Fusion 360 software.

Figure 2 : The Ships-Rov Design.

Design and Development of SHIPS-ROV

757

3.1 SHIPS-ROV Structure Design

The SHIPS-ROV is designed to operate at a maximum

depth of 200 m. Therefore, it is very important to

calculate the strength of the SHIPS-ROV structure.

The important thing to note is,

1)

Cover strength in operation

2)

Effective Body of Ship-ROV Structure for

effective thickness and design applied

3)

Reduce Resistance

4)

Reduce Power Consumption

5)

Low-Cost

SHIPS-ROV must have a hull (enclosure) that is used

to place components so that it is always dry and

watertight. Components placed in the hull/enclosure

are used for hull investigations. The SHIPS-ROV

hull/enclosure should allow easy access and

maintenance of components, and allow for

modularity in the event of future changes or additions

[1]. In addition to being light and strong, the hull must

also be corrosion resistant because it will experience

a harsh saltwater environment. The tubular spherical

hull offers the best structural integrity; however, its

shape precludes efficient use of the available space as

most components and systems are rectangular. The

cylindrical hull provides the best alternative,

consisting of: high structural integrity and a form

conducive to housing electronic components. The

enclosure or main body or hull is the main component

in the MSB component in the SHIPS-ROV, which is

very protected from water entering the enclosure.

Some of the equipment placed in the enclosure

include: thruster, color camera, monochrome camera,

light- ing, multi beam sonar, Oil Compensated dome.

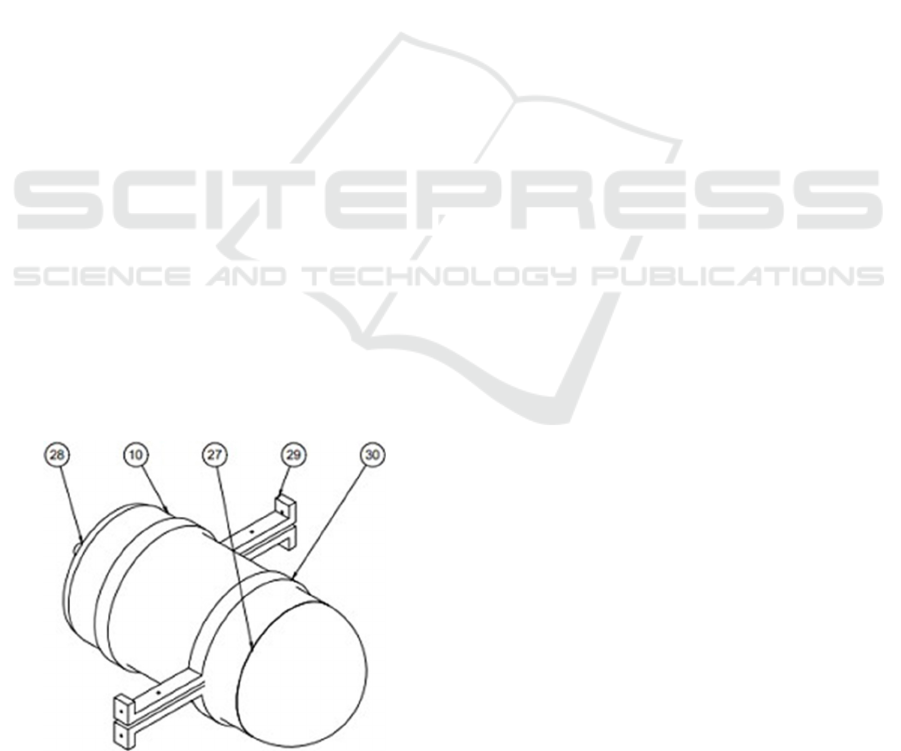

Dual imager and battery. Figure 3 shows the shape of

the SHIPS-ROV hull/enclosure.

Figure 3: Design of SHIPS-ROV Hull/enclosure.

Legend:

(10) Body shell

(27)

Body Head

(28)

Body AFT

(29)

Main support

(30)

Main support

3.2 Submerging

Because the SHIPS-ROV works underwater, for

diving the SHIPS-ROV must be able to increase the

downward force acting on it to counter the buoyant

force. This can be achieved using either an external

thruster i.e. a thruster and a propulsion motor for

forward, reverse, up and down of the SHIPS-ROV.

Details of the SHIPS-RUV enclosure components can

be given in the picture above which contains

component components including cameras, main

circuit boards, capacitors, and others. It is used in the

main function in the process of taking data and setting

the control of the motor and propeller which is

connected to the joystick of the control system. This

is a much simpler system, but quite inefficient in

terms of power consumption and not very suitable for

deeper depths. For the diving process, the SHIPS-

ROV is designed in such a way that it has residual

buoyancy. That is, the weight of the vehicle is made

approximately equal to the buoyant force.

3.3 Propulsion

Propulsion is required SHIP-ROV and is one of the

main sources of power consumption. SHIPS-ROV

uses a motor for propulsion. The location of the

motor will affect which degrees of freedom can be

controlled. Motor placement can affect noise

interference with onboard electronic components, as

well as propeller-to-hull and propeller-to-propeller

interac- tions. Propeller-to-hull and propeller-to-

propeller interactions can have unintended effects on

the dynamics of the SHIP- ROV maneuver. When

traveling at a constant speed, the thrust generated by

the motor is equal to the friction or resistance of the

vehicle, namely:

Thrust = Drag = 0.5s

2

A

CD

(1)

where is the water density, s is the speed, A is the

effective surface area and CD is the drag coefficient.

Power consumption for the propulsion system

increases dramatically as the vehicle speed

increases. This is because the thrust is equal to the

product of the thrust and the speed, meaning that the

thrust is a function of the cube of the speed,

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

758

Thrust

Power

=

Thrust x s

= 0

.

5

s

3

A

CD

...

(2)

Therefore, due to the limited energy supply of the

SHIPS- ROV. the one is functioned according to its

task, namely to investigate the hull of the ship. And

try not to travel at a speed that doesn’t draw too much

power, and in completing the task it doesn’t take too

long

3.4 Electric System

Electrical power is usually provided via a sealed

battery. The ideal battery arrangement is to connect

them in parallel with diodes between each battery to

allow for even discharge and to prevent current flow

between the batteries. Fuses or other protective

devices must also be used to prevent excessive current

flow in the event of a short circuit or component

malfunction. The limited power properties of the

SHIP-ROV affect the types of components and

equipment that can be used. Components and

equipment must be selected to draw as little power as

possible so that the battery can provide more than

enough time for the vehicle to complete its mission.

the arrangement of the electrical diagram is shown

in Figure 4

Figure 4: Design of SHIPS-ROV Hull/enclosure.

4 RESULT

SHIPS-ROV was designed in 3D using Fusion 360

software. This software allows users to easily design

and analyze the strength of the design. The steps in

the design process are as follows:

1.

CAD and Material Definition

At the beginning of the analysis can be done by

making CAD with existing components. Then do the

material definition using 5083 marine used aluminum

alloy material.

2.

Meshing

The meshing process is carried out to discuss the

object into the Ships-ROV constituent elements

which are conditioned in fine mesh conditions.

3.

Load and constraint

The loading process is placed in the loading area of

the structure which is then entered for the value of the

force acting. It’s as placement is applied at the bottom

of the structure.

Buckling Analysis of buckling load is an value -

passable condition in maintaining the strength of the

structure on the SHIPS-ROV. The buckling load is

very risky to the structure which can cause the

structure to break or deform. the results of the

buckling analysis are shown in Figure 5.

Figure 5: Buckling Analysis.

Mechanical and electrical structures have been

developed as described in the previous chapter.

SHIPS-ROV is an auxiliary equipment as a substitute

for divers to see the condition of the ship’s hull. Next

will be developed as a test bed platform for various

underwater researches, where the prototype

developed has a fixed mechanical system, has a

modular electronic system for the development of

various controllers, recording devices and sensor

modules.

Performance test was conducted to determine the

perfor- mance of SHIPS-ROV. Test l refers to the

specified technical specifications. Performance

testing can be carried out in sev- eral ways under

complete conditions, including: Progressive speed,

Circle rotation, Zigzag, Inertia Stop testing, Crash

Stop Ahead and Crash Stop Astern. Progressive speed

is a test to determine the speed of the test object,

because speed is very important in the characteristics

Design and Development of SHIPS-ROV

759

of the test object and this is one of the bargaining

abilities in its operation. Zigzag is a motion condition

of the test object in the form of maneuvering this

condition in real operation to determine the

characteristics of the test object in avoiding other

objects. Inertia stop test is a test to find out how far

the test object stops after the driving force is turned

off. It can also be used to find out how far the test

object is to avoid colliding with other objects. Crash

Stop forward and stern are test conditions to position

the test object to move forward and backward

simultaneously. Due to the limited size of the test

object, the performance test is carried out at least into

2 (two) main capabilities of the test object, namely:

Progressive Speed and Turning Circle Maneuvering.

ACKNOWLEDGEMENTS

Many thank s to lecture PPNS to support and sharing

knowladge.

REFERENCES

Budianto, M. T Wahyudi, U Dinata, Ruddianto & M.M.

Eko P. (2018). Strength Analysis on Ship Ladder Using

Finite Element Method. Journal of Physics: Conference

Series, 953, 012043, 1-8.

M. Abdul Hamid Koli, E. D, “Rancang Bangun Robot

Bawah Air Mini ROV (Remotely Operated Vehicles).”,

Jurnal Teknik Elektro Universitas Tanjungpura,(015,hal

1-10.

M Shahrieel M Aras, H A Kasdirin, M Herman Jamaluddin,

M Farriz Basar, “Design and Development of an

Autonomous Underwater Ve- hicle (AUV-FKEUTeM)

,” Proceedings of MUCEET2009 1 Malaysian

Technical Universities Conference on Engineering and

Technology June 20-22, 2009, MS Garden, Kuantan,

Pahang, Malaysia MUCEET2009

Surface ships: Principles of stability. [online], 2004.

Available:http://wrc.chinalake.navy.mil/warfighter

enc/SHIPS/shipeng/stability/basics/basics.htm/.

Imam Sutrisno, Mohammad Abu Jami’in and Jinglu Hu.

(2014). Modified fuzzy adaptive controller applied to

nonlinear systems modeled under quasi-ARX neural

network., Artificial Life Robotics, 19, 1, 22-26.

Marine structures. (1991). U.S. Patent No. 5,018,471.

Mhatt, Gouri, Emmanuel LefranÃ, and Gilbert Touzot.

(2012). Finite element method. John Wiley & Sons.

M. Abdul Hamid Koli, E. D. (2015). Rancang Bangun

Robot Bawah Air Mini ROV (Remotely Operated

Vehicles). Jurnal Teknik Elektro Universitas

Tanjungpura, 1-10.

Machine, W. (2009). Autonomous Vehicles, (2nd Ed).

Institute of Marine Technology, Bangladesh.

Tutu, S. (2017). Penyebab kerusakan kapal. (Edisi 1).

Surabaya.

Wahyudi. (2018). Dua Kapal Tabrakan di Perairan Kendari,

KM Bunga Melati 79 Tenggelam. Kendari: Basarnas.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

760