Design of Permanent Magnetic Yoke for Subsurface Defect Detection

with Magnetic Particle Inspection Methode

Mohammad Anas Fikri, Auliana Diah Wilujeng

and Muhammad Faizal Eka Prasetya Putra

Politeknik Negeri Madura, Jl. Raya Camplong Km. 4, Taddan, Sampang, Indonesia

Keywords

:

Magnet, NDT, Permanent Magnetic Yoke, Subsurface Defect.

Abstract

:

The development of magnetic particle inspection testing is not only focused on testing materials placed

indoors, where the need for electrical resources is the main thing. The increasing number of requests to carry

out Non-Destructive Test (NDT) testing with the magnetic particle inspection method makes inspectors

unable to speculate whether in open areas such as mining areas there is a power source available. To reduce

the speculation of inspectors about the limited electrical resources in the open area, a permanent magnetic

yoke was designed. Permanent magnetic yoke is an NDT testing tool with a magnetic particle inspection

method that does not use an electric power source but uses permanent magnets. Yoke material used is Al6061

with a thickness of 50mm. The magnet used is a Neodymium type permanent magnet. The working principle

of a permanent magnetic yoke uses the properties of permanent magnetism with the magnetic particle

inspection method in areas where there is no power source Based on the results of the comparison test between

Permanent Magnetic Yoke and DC Yoke through the same treatment, the level of accuracy of reading

subsurface defects on welding joints of steel material with dimensions of 300 x 150 x 10 mm with 3G position

SMAW welding process using permanent magnetic yoke is 96.78%.

1 INTRODUCTION

The development of manufacturing is currently

increasingly advanced, especially in welding

technology or engineering because it has an important

role in metal engineering and repairing. The

manufacturing process for metal in modern times

currently involves many elements of welding,

especially in the fields of design. In the welding

process, not all the results of the metal connection are

good. There must be a defect and discontinuity in the

metal resulting from the connection. Some of these

defects include defects that are on the surface (surface

defect) and defects below the surface (subsurface

defect). When welding doesn’t pay attention to the

guidelines contained in the Welding Procedure

Specification (WPS) and Procedure Qualification

Record (PQR) documents, generally the product will

experience defects in welding.

Defects in the welding process will affect the

material strength of a product. This is very vulnerable

and it is the responsibility of a WI (Welding

Inspector) to maintain in order to minimize and even

eliminate defects, namely starting from

theemergence of porosity clusters which result in

repairs

in the welding process (Warman, 2017).

In the process of welding work equipment from

excavators, such as parts of the excavator boom,

which use thick steel plate material, it is necessary to

use special welding techniques. This technique is

used to avoid defects that often occur in the boom

joint welding process of excavators. Defects can be

detected and identified using non-destructive testing

with one of the methods, namely magnetic particle

inspection (Pardede and Hendroprasetyo, 2015).

Several research have begun to use magnets as a

defect identification with NDT (Non Destructive

Test) using the Magnetic Particle Inspection method.

In the research that has been done, it can be concluded

that the effectiveness of reading using Magnetic

Particle Inspection will decrease along with the

increase in the thickness of the nonconductive coating

from the actual crack size. while in particle magnetic

examination, magnetization can use an electromagnet

yoke (AC current) and permanent magnet. Permanent

magnet yoke has different sensitivity with AC yoke

in detecting surface defects. AC yoke is good at

detecting surface cracks while permanent magnet

806

Fikri, M., Wilujeng, A. and Putra, M.

Design of Permanent Magnetic Yoke for Subsurface Defect Detection with Magnetic Particle Inspection Methode.

DOI: 10.5220/0010954000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 806-813

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

yoke is better at detecting cracks on the subsurface

(Dyatmika and Akbar Putra, 2012)

1.1 Magnet

µ

r

= µ

material /

µ

o

(1)

with:

µ

r

: Relative permeability of a material

Any

text or material outside the aforementioned

µ

material

:

Material Permeability

margins will not be

printed.

Magnets are metals that can attract iron or

steel and have a magnetic field. The word of

"magnet" is thought to have come from the word

"magnesia" which is the name of an area in minor of

Asia, where magnets were first thought to have been

discovered by humans. In the Magnesia area, rocks

that can attract iron and steel were first found, which

in turn were called magnets (Puspita and Rohima,

2009). Magnets always have two poles, a north pole

and a south pole. The basic concept of magnetic poles

is shown in Figure 1.

Figure 1: Magnetic Poles (Puspita and Rohima, 2009).

The magnetic poles are the ends of the magnet that

have the greatest power to attract iron particles

compared to other parts of the magnet. Every magnet

has two poles, namely a south pole and a north pole.

The straight line connecting these two poles is called

the magnetic axis. If we hang a magnet and hold it

still, the longitudinal direction of the magnet always

points in a north-south direction. For a while, if a

magnet is cut, each piece will still have two poles and

become a new magnet (Puspita and Rohima, 2009).

Magnetic permeability is the degree of

magnetization of a material in responding linearly to

a magnetic field. According to international units, the

permeability of the vacuum has a value of 4π×10-7

TmA-1 or 12.57×10-7 TmA-1 (Serway and Jewett,

2004). The value of the permeability of a magnetic

material is not constant, which largely depends on the

magnitude of the magnetizing force applied to it. The

permeability of a magnetic material is always

compared to the permeability of a vacuum, where this

comparison is called relative permeability (Lusyana,

Toifur, and Rohman, 2014). Relative permeability is

defined by equation 2.3 as follows (Lusyana, Toifur,

and Rohman, 2014). The relative permeability of a

material can be calculated by the equation 1.

µ

o

:

Vacuum Permeability.

1.2 Magnetic Properties

According to their properties, magnets can be

divided into:

1.

Temporary Magnet

Temporary magnets are magnets whose

elementary magnetic arrangement easily returns

to

irregularity after the magnetic material is used

as a

magnet (Puspita and Rohima, 2009).

2.

Permanent Magnet

Permanent magnets are magnets whose

elementary magnetic arrangement is difficult to be

disorganized again so that they have a relatively

long durability to become a magnet (Widodo

et al,

2009). At this time there are many kinds of

permanent magnets that are often used based on

the

material, including Barium ferrite, and

Neodymium

Iron Boron (NdFeB) Magnets

(Irasari and Idayanti,

2009).

a.

Barium Ferrite Magnet (BaFe

12

O

19

)

Barium ferrite magnets began to be

developed in

the early 1960s, as an alternative

to the use of metal

magnets. This magnet

belongs to the classification

of hard magnetic

ceramic materials that have a

hexagonal

structure (BaFe12O19) (Irasari and

Idayanti,

2009).

The advantage is that the price is cheaper

when

compared to other permanent magnets,

causing

barium ferrite magnets to be very

preferred to be

applied as permanent magnets

(Irasari and Idayanti,

2009).

b.

Neodymium Iron Boron (NdFeB)

In 1980, Neodymium Iron Boron (NdFeB)

magnets

were discovered with high strength,

and they have

been commercialized since

November 1984.

NdFeB is a rare earth type

permanent magnetic

material, because it is

formed by 2 atoms of a

rare earth element

neodymium (Nd), 14 atoms of

iron (Fe) and 1

atom of boron (B), so the molecular

formula

formed is Nd2Fe14B (Irasari and

Idayanti,

2009).

The magnetic characteristics of NdFeB are

better

than other permanent magnets. Because it has better

and higher magnetic

characteristics than other

magnets, in its

application NdFeB magnets have

small

dimensions and volume. The application of

NdFeB magnets is quite a lot, such as in

electronic

equipment, electric motors,

generators, sensors,

Design of Permanent Magnetic Yoke for Subsurface Defect Detection with Magnetic Particle Inspection Methode

807

automotive industry,

petrochemical industry and

medical

equipment products (Irasari and Idayanti,

2009).

The drawback is that it cannot be applied

at

high temperatures, which is only a

maximum range

of up to 200

0

C. In addition,

these magnets are

quite expensive and have

low corrosion resistance,

so that in their

application a surface treatment is

required,

such as being coated with nickel, zinc or

gold

(Irasari and Idayanti, 2009).

Non-destructive testing or non-destructive testing

is defined as an inspection, test or evaluation applied

to a material to determine the structure or components

in the material in order to maintain the quality of the

material use process (Ministry of Transportation,

2016). In NDT testing, it can determine the condition

of the material and can detect any defects or damage

to the material.

In the periodic inspection of non-destructive

testing, the Magnetic Particle Inspection method has

standard tests that must be carried out so that a

construction is declared safe. The standard contains

Acceptance Criteria so that a construction is declared

safe to use, it must go through a testing process based

on applicable standards. The recognized standards of

Magnetic Particle Inspection testing and evaluation

are:

▪

Legislation No. 1 of 1970 concerning Work

Safety.

▪

Legislation No. 13 of 2003

concerning

Manpower.

▪

ASME (American Society of

Mechanical

Engineering) Sec.V Article 7

▪

ASTM (American Standart for Testing Material)

E3024,709 8

2

MATERIALS AND METHODS

2.1

Materials

Making this research requires several tools and

materials as a support in the process of making these

tools. The tools and materials used are as follows:

2.1.1

CNC Milling/Milling Machine

In the research, the CNC Milling machine used

type

Brother S500XI for making magnetic grip

frames on

Permanent Magnetic Yoke.

2.1.2

Aluminium Al6061

In the research, the material used for the

manufacture of the design / frame of the handle

is

mild steel type Al6061

Figure 2: Materials Al6061.

2.1.3

Neodymium Magnets

Neodymium magnets are used for the

magnetization

process of the workpiece to be

inspected so that

it can find out the existing

defects.

Figure 3: Neodymium Magnet.

2.1.4

Calibration Metal (18.2 Kg)

Calibration metal weighing 18.2 kg (40 lb) was

used

for the calibration of the Permanent

Magnetic

Yoke before being applied for the

inspection

stage to the workpiece.

2.1.5

Magnetic Yoke AC/DC

The AC/DC magnetic yoke in Figure 3 is used

as a

comparison of the test results of the

permanent

magnet yoke.

Figure 4: Magnetic Yoke AC/DC.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

808

2.2

Methods

In the manufacturing process, the workpiece

design process goes through the CAD (Computer

Aided Design) process. CAD (Computer Aided

Design) is a computer program for designing a

product. The CAD process is very necessary as an

initial design before making a product using the

manufacturing process. Basically, CAD can be in the

form of 2-dimensional or 3-dimensional technical

drawings with detailed drawing descriptions to make

it easier for the next processing. In the process of

making this research design using Solidworks.

This permanent magnetic yoke design is based on

3 main parts, Handle Yoke, Link Yoke, and Housing

Magnet Yoke, where all manufacturing processes are

carried out with 3 axis CNC Milling. The geometric

shape of each part of the permanent magnetic yoke is

as follows. Figure 5 has shown handle yoke and link

yoke design.

Figure 5: Handle Yoke and Link Yoke.

Yoke handle serves as the holder of the permanent

magnetic yoke test equipment. The design of the

handle yoke design follows the morphology of the

inspector's fingers so that it does not cause work

accidents on the fingers during the testing process.

The link Yoke functions to adjust the length and

shortness of the test area so that the effectiveness of

the performance of the magnet during testing

becomes better. Magnet housing has shown on Figure

6.

Figure 6: Housing Magnet.

The housing magnet serves as a place for the

Neodymium permanent magnet to be implanted. The

size of the housing magnet hole is made using a fitting

adjustment tolerance, so that the magnet insertion is

carried out with the help of heating on the housing.

Permanent Magnetic Yoke design has shown on

Figure 7.

Figure 7: Permanent Magnetic Yoke Design.

Furthermore, the CAD softcopy of the three-part

design will be imported into the CAM software for

CAM programming to be made before being

executed on the CNC Milling machine. CAM

programming has shown on Figure 8.

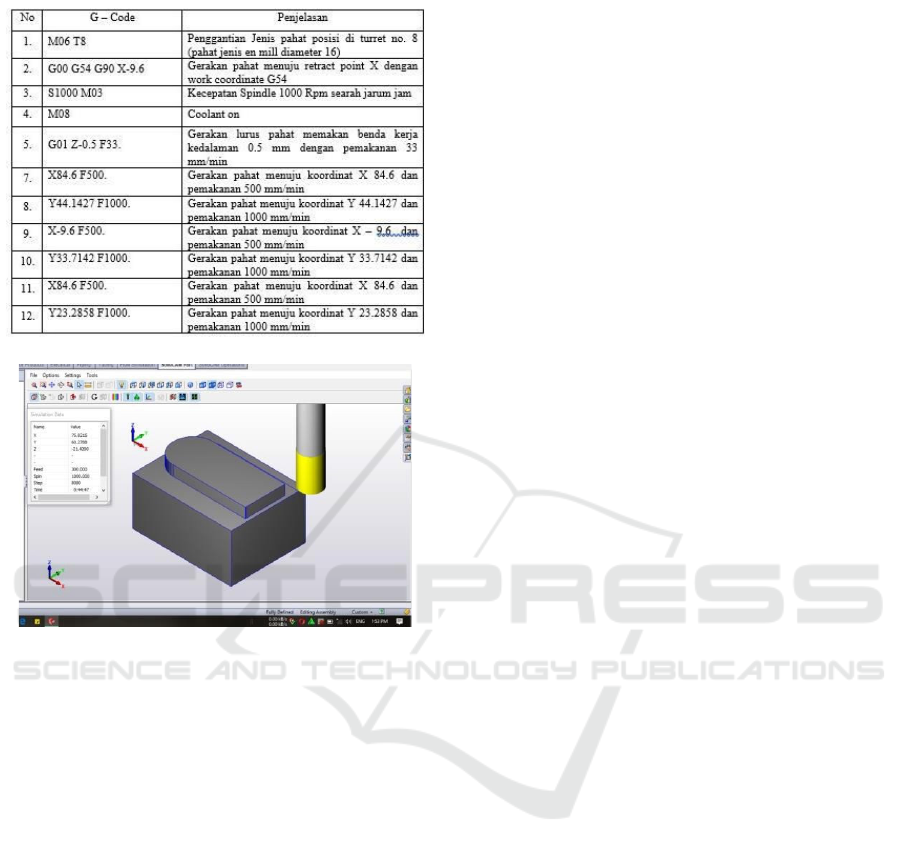

Figure 8: CAM Programming.

Making the CAM program still refers to the

appropriate parameters for machining raw materials.

The examples of G-Code simulation programs above

and their explanations has shown on Table 1.

Before being executed on a CNC machine, it is

necessary to verify in the form of a toolpath

simulation from the CAM program that has been

created. One form of the simulation has shown on

Figure 9.

Design of Permanent Magnetic Yoke for Subsurface Defect Detection with Magnetic Particle Inspection Methode

809

Table 1: G-Code program for Housing.

Figure 9: Toolpath CAM simulation.

3

RESULTS

Testing of the permanent magnetic yoke is carried

out by referring to the ASME Sec standard code. VIII

Mandatory Appendix 6 of 2009 with criteria for

acceptance of defects in the Magnetic Particle

Examination testing method. An indication of a

defect is evidence of the imperfection of a material

caused by certain things. Only indications having

dimensions (dimensions) greater than 1/16 inch

(1.5mm) will be considered. Evaluation of indications

according to ASME Sec.VIII Mandatory Appendix 6:

a.

A linear indication is one having a length greater

than three times the width

b.

A rounded indication is one of circular or elliptical

shape with a length equal to or less than three

times its width.

c.

Any questionable or doubtful indications shall be

reexamined to determine whether or not they are

relevant.

These acceptance standards shall apply unless

other more restrictive standards are specified for

specific materials or applications within this Division.

All surfaces to be examined shall be free of:

a.

relevant linear indications;

b.

relevant rounded indications greater than 3 ∕ 16 in.

(4.8 mm);

c.

four or more relevant rounded indications in a line

separated by 1 ∕ 16 in. (1.6 mm) or less, edge to

edge.

Based on SEC ASME standards. 5 article 7

regarding Magnetic Particle Inspection, the AC Yoke

testing procedure is different from the Permanent

magnet yoke. However, for the evaluation and

analysis of defects that occur in the material, it still

refers to the ASME Sec. VIII Mandatory appendix 6.

3.1

Equipment and Material Used

Equipment Used:

a.

duster

b.

AC Yoke

c.

Lighting

d.

Iron Brush

e.

Light Meter (Lux Meter)

f.

Ruler

Material Used:

a.

Cleaner

b.

White Contrast (WCP-2)

c.

Wet Pacticle (7HF)

3.2

Procedure Test

a.

Prepare tools and electrical resources, then test the

strength of the AC yoke first (Power Lifting of

Yoke) based on ASME section V Article 6 (T-

773, 2), namely for AC current the yoke must be

able to lift a load of 4.5 kg (10 lbs). If the yoke can

still lift the required load, then the yoke is still

suitable for use. This lifting power test is usually

carried out once a year.

b.

Clean the surface of the test specimen from oil,

and other impurities in the form of rust, grease,

paint, and other impurities with a cleaner

c.

Spray the test specimen with White Contrast Paint

(WCP 2) evenly.

d.

Wait for the white contrast paint to dry (dwell

time).

e.

Arrange the yoke in such a way that it can

magnetize the test specimen properly and during

the process of magnetizing the test specimen the

yoke is placed in different positions so that all

discontinuities in the test material are visible, both

cracks on the surface and subsurface.

f.

When the yoke is magnetized, the test specimen is

sprayed with wet particle so that the defects in the

test material appear.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

810

g.

Observing discontinuities and defects.

h.

Demagnetization or removal of magnetic residue

on the specimen after evaluation.

i.

Post Cleaning

4 DISCUSSION

The level of accuracy in the process of reading

and measuring defects is very necessary in

determining whether the workpiece is suitable for use

or not. Basically, precise measurement and

calibration of precision measuring instruments can

support the success rate in data analysis.

To determine the performance of the permanent

magnetic yoke test equipment, a welding defect

detection test was carried out on the test specimen in

the form of steel with a 3G connection type SMAW

welding process. The test also uses a DC yoke as a

comparison. The following are the results of welding

specimen testing, has shown on Figure 10 and Figure

11.

Figure 10: Permanent Magnetic Yoke testing.

Figure 11: Comparison with Yoke AC/DC.

Identification of defects in the weld metal of the

test specimen can be seen in the following Figure 12.

Figure 12: Specimen Test Results with Permanent

Magnetic Yoke.

Figure 13: Test Specimen Defect Measurement.

Measurement of defect readings on test specimens

can be seen in the following Figure 13:

Table 2 is the test result data and analysis of the

accuracy of Permanent Magnetic Yoke and DC Yoke

readings.

Table 2: Comparison of Yoke DC and Permanent

Magnetic Yoke readings

Based on the results of the permanent magnetic

yoke test with a DC yoke comparison, the following

results were obtained, has shown on Figure 14.

Design of Permanent Magnetic Yoke for Subsurface Defect Detection with Magnetic Particle Inspection Methode

811

Figure 14: Defect Reading Comparison.

Based on the data in Figure 13, the Yoke DC

reading is always 100% because the reference for

comparison in this study is the "Magnaflux" brand

DC Yoke which has been tested and calibrated with

reference to the ASME BPVC, ASTM E1444, ASTM

E709 standards.

For Permanent Magnetic Yoke readings, the

average reading accuracy is 96.78% because at the

time of making the permanent Yoke it was not

calibrated to the standard applicable to the NDT test

classification.

In the 4th defect indication, it was found that there

was a significant decrease in the percentage due to

several factors, one of which was an error in

measurement due to the concave position of the

defect and the irregular shape of the defect, so the

measurement could not be precise with the original

size of the defect (Nurachmandani, 2009).

5 CONCLUSION

After analyzing and collecting data using the

Permanent Magnetic Yoke, it can be concluded as

follows:

a.

The percentage of accuracy in reading Permanent

Magnetic Yoke defects is 96.78%. These results

are obtained by reference to readings from Yoke

DC Magnaflux which have been calibrated to

international standards.

b.

The increasing trend in the graph of the Permanent

Magnetic Yoke test results shows that the

effectiveness of the test equipment with the base

material of Neodymium permanent magnets is

reliable enough to be used in open areas such as

mining and shipyards.

The suggestions that can be given for further

development and research are as follows:

a.

The results of several tests and data analysis,

should be for accuracy in reading defects using a

special specimen (test object) in the form of a

measurable artificial defect.

b.

Substitution in the selection of Permanent

Magnetic Yoke material does not only pay

attention to the light weight and ergonomics

aspects, but the material characteristics also need

to be considered. The basic nature of aluminum

material turns out to be able to weaken the

magnetic properties.

REFERENCES

ASME INTERNATIONAL. (n.d.). ASME (American

Society of Mechanical Engineering) Sec. V Article 7.

Dyatmika, I. G., & Akbar Putra, W. H. (2012). Analisis

Perbandingan Metode MPI Menggunakan Yoke AC

dan Permanen Magnet Untuk Pendeteksian Panjang

Retak Permukaan yang Dilapisi Cat Pada

Sambungan

Las di Kapal. JURNAL TEKNIK POMITS, 1(1), 1-4.

Irasari, P., & Idayanti, N. (2009, Oktober). APLIKASI

MAGNET PERMANEN

BaFe

12

O

19

DAN NdFeB

PADA

GENERATOR MAGNET

PERMANEN

KECEPATAN RENDAH SKALA

KECIL. Jurnal Sains Materi Indonesia, 11, 38 - 41.

Kementerian perhubungan. (2016). Administration and

control of aircraft welding and non destructive test.

Peraturan direktur jenderal perhubungan udara no.

Kpp 122 tahun 2016.

Lusyana, A., Toifur, M., & Rohman, F. (2014, Nopember).

UJI SIFAT MAGNETIK PASIR PANTAI MELALUI

PENENTUAN PERMEABILITAS RELATIF

MENGGUNAKAN LOGGER PRO. Jurnal Fisika, 4

No.2.

Ministry of Transportation. (2016). 5 Year Plan for

Transportation Infrastructure Development.

Nurachmandani, S. (2009). Fisika 1 Untuk SMA/MA

Kelas X. Jakarta: Grahadi.

Pardede, L, & Hendroprasetyo, W. A. (2015). Analisa

Perbandingan Sensitivitas Metode Magnetic

Particle

Inspection (MPI) Menggunakan Metode

Visible Dry,

Visible Wet, dan Wet Fluorescent

Terhadap

Pendeteksian Panjang Retak pada

Permukaan dan

Toe Sambungan Las di Kapal yang Dilapisi

Nonconductive Coat. JURNAL SAINS DAN

SENI

ITS, 4(1), 2337-3520.

Puspita, D., & Rohima, I. (2009). Alam Sekitar, IPA

Terpadu Untuk SMP/MTs Kelas VIII. Jakarta: Leuser

Cita Pustaka.

Serway, R. A., & Jewett, J. W. (2004). Physyc for Scientist

and Engineers (6th ed.). California: Thomsoon

Brooks/Cole.

Widodo, A., Kim, E. Y., Son, J. D., Yang, B. S., Tan, A.

C., Gu, D. S., ... & Mathew, J. (2009). Fault diagnosis

of low speed bearing based on relevance vector

machine and support vector machine. Expert systems

with applications, 36(3), 7252-7261.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

812

Warman , S. P. (2017, Jul). ANALISIS FAKTOR

PENYEBAB CACAT PENGELASAN PADA PIPA

(Study Kasus Pada Pipa Distribusi PDAM Kabupaten

Kutai Barat). Jurnal Mekanikal, 8(2), 730-736.

Serway, R. A., & Jewett, J. W. (2004). Physyc for Scientist

and Engineers (6th ed.). California: Thomsoon

Brooks/Cole.

Design of Permanent Magnetic Yoke for Subsurface Defect Detection with Magnetic Particle Inspection Methode

813